-

Build progress

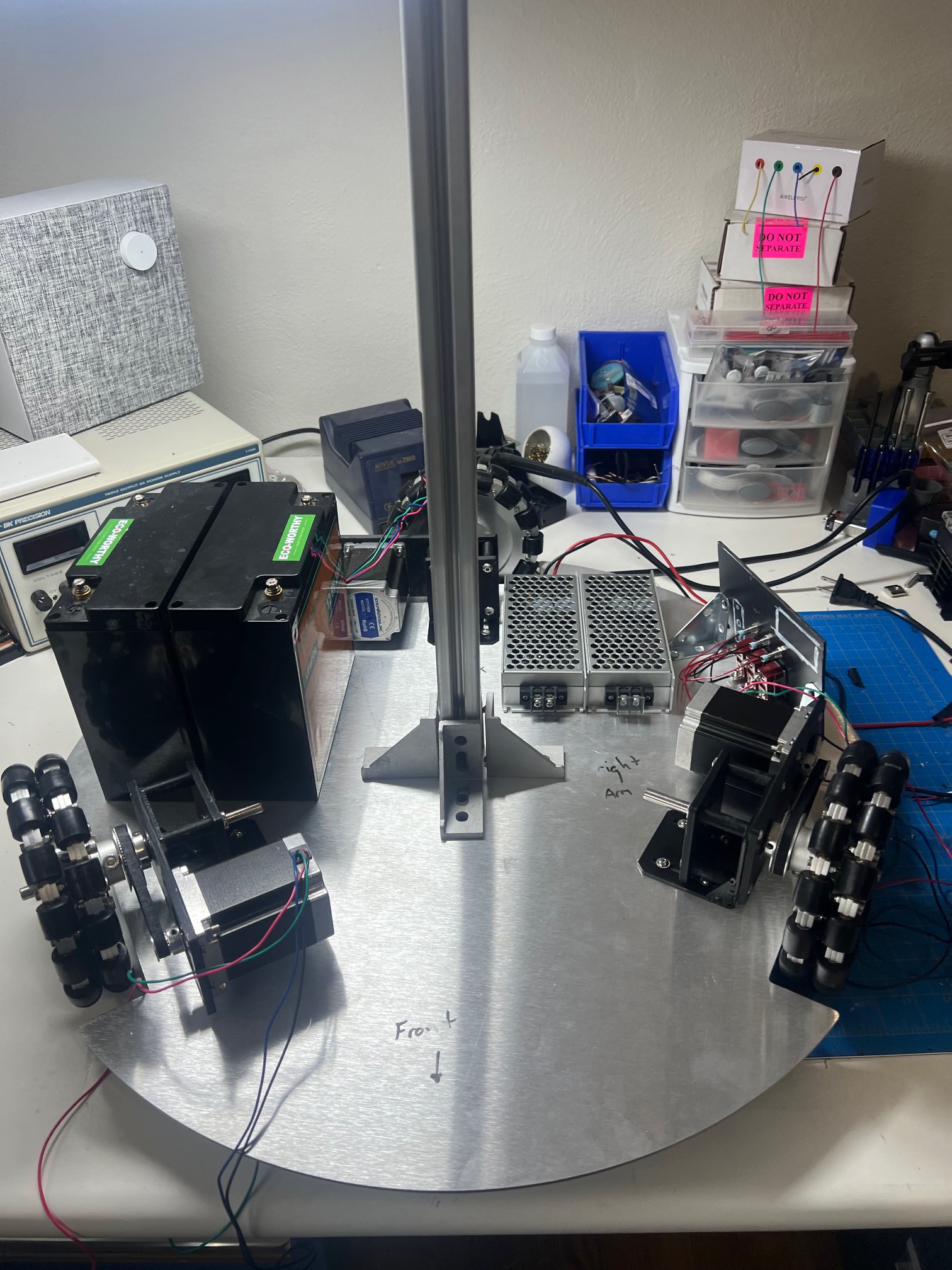

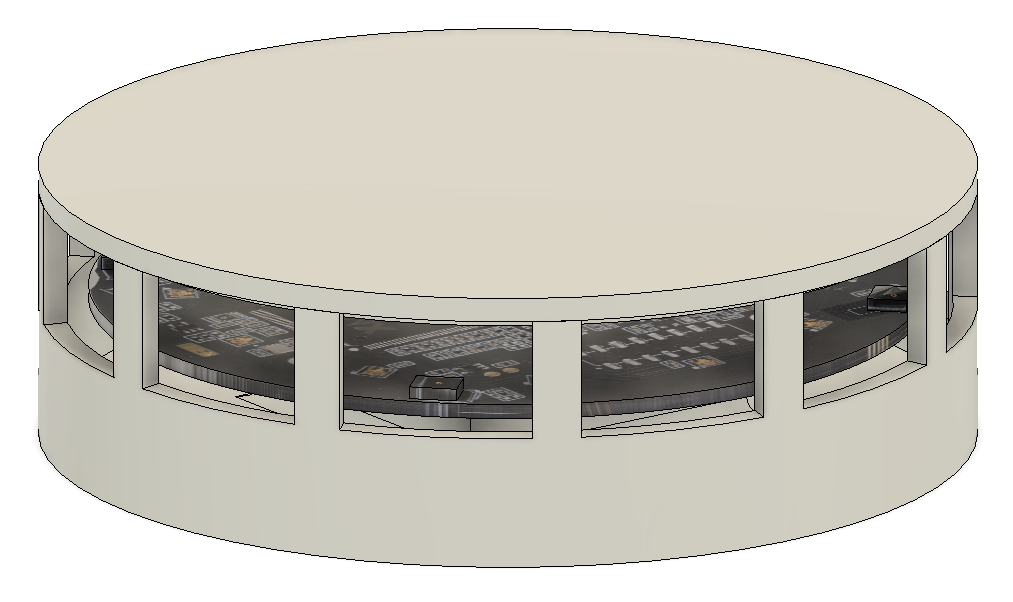

12/30/2023 at 00:29 • 0 commentsLots was done today! I mounted the drive units and mocked up the placement of the DC-DC convertors, batteries and power panel. I had to mark the base front left right as my mind was being fried trying to remember. Then I compared it to the CAD model to ensure that there would not be clearance issues with anything.

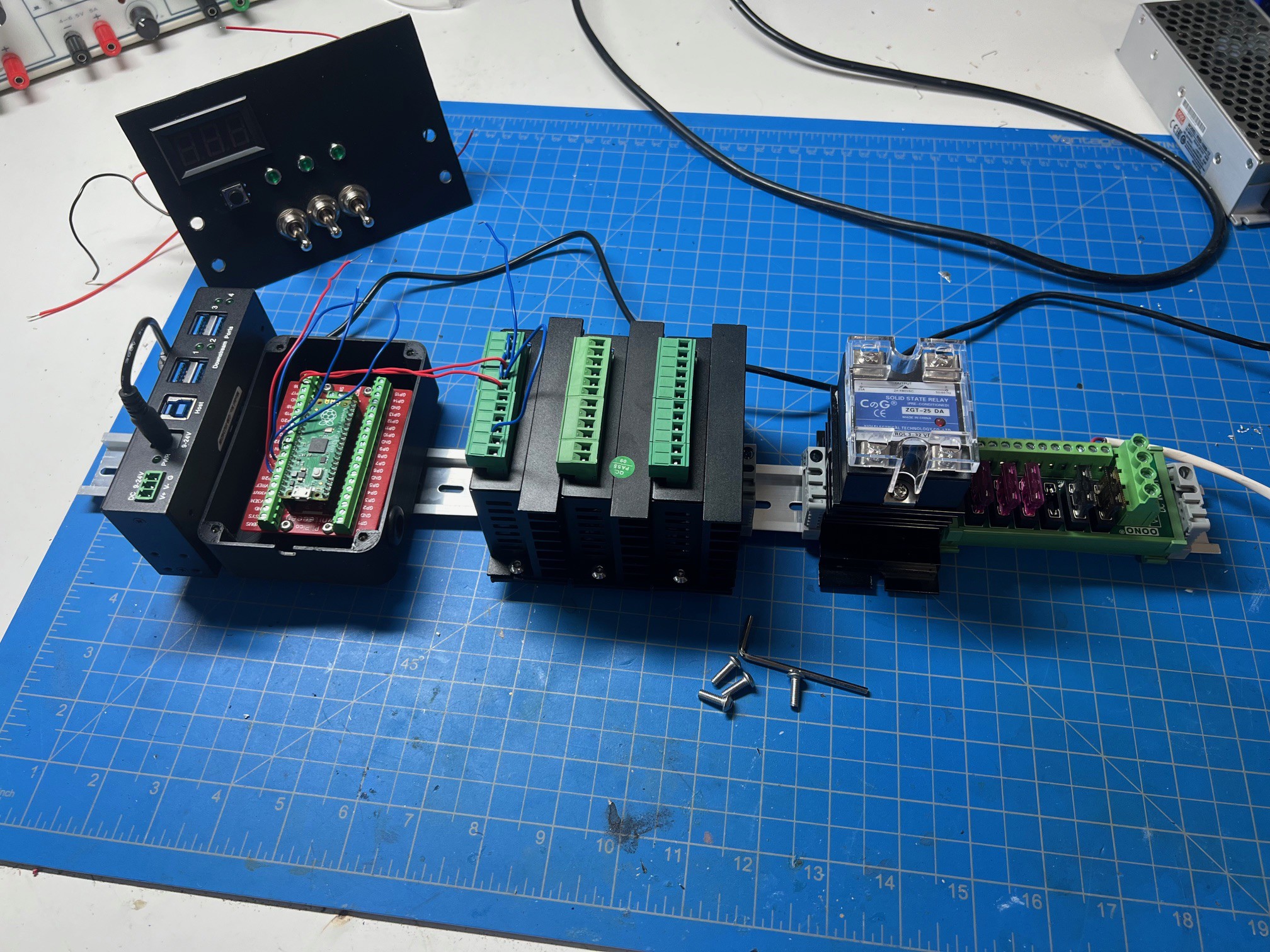

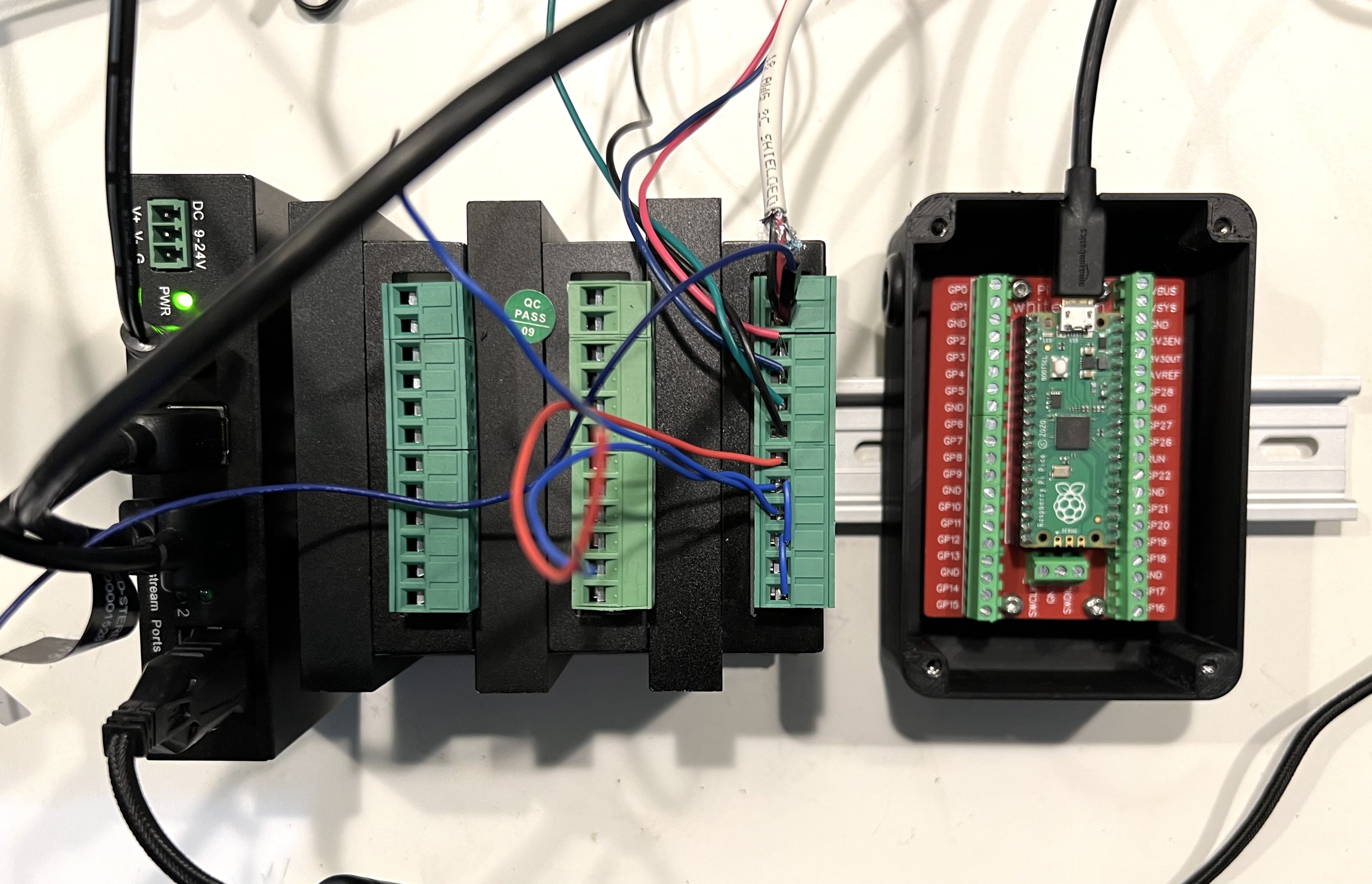

I tightened down the motor drive units. The 3D printed parts will work for testing, but I will need to swap to machined aluminum to ensure the G2 belts stay tight. New longer DIN rail came in and I mounted the 12volt fuse distribution unit, motor power solid state relay, the 3 motor drivers, Pico and the USB 3.0 hub. (Yay COTS parts!)

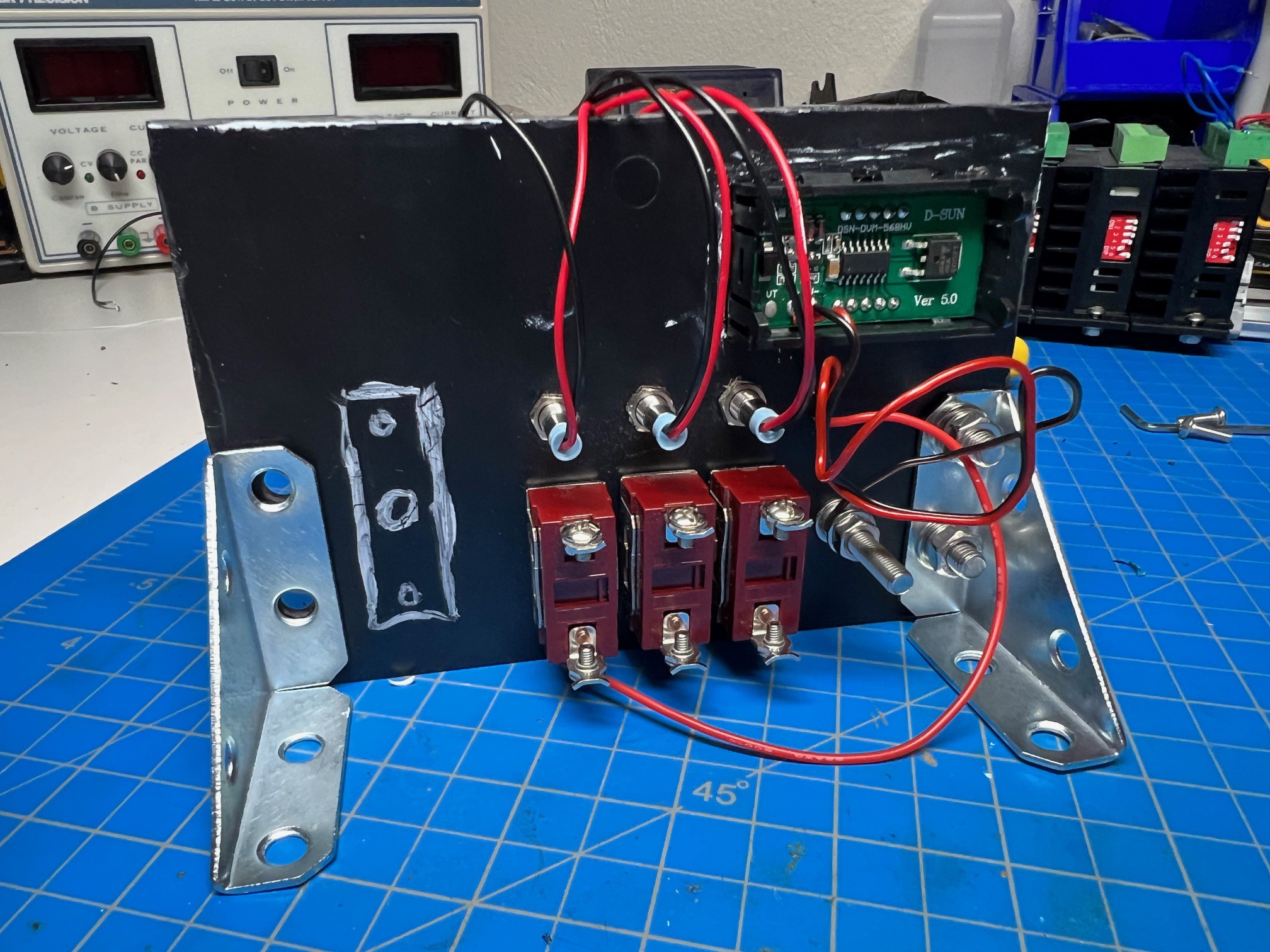

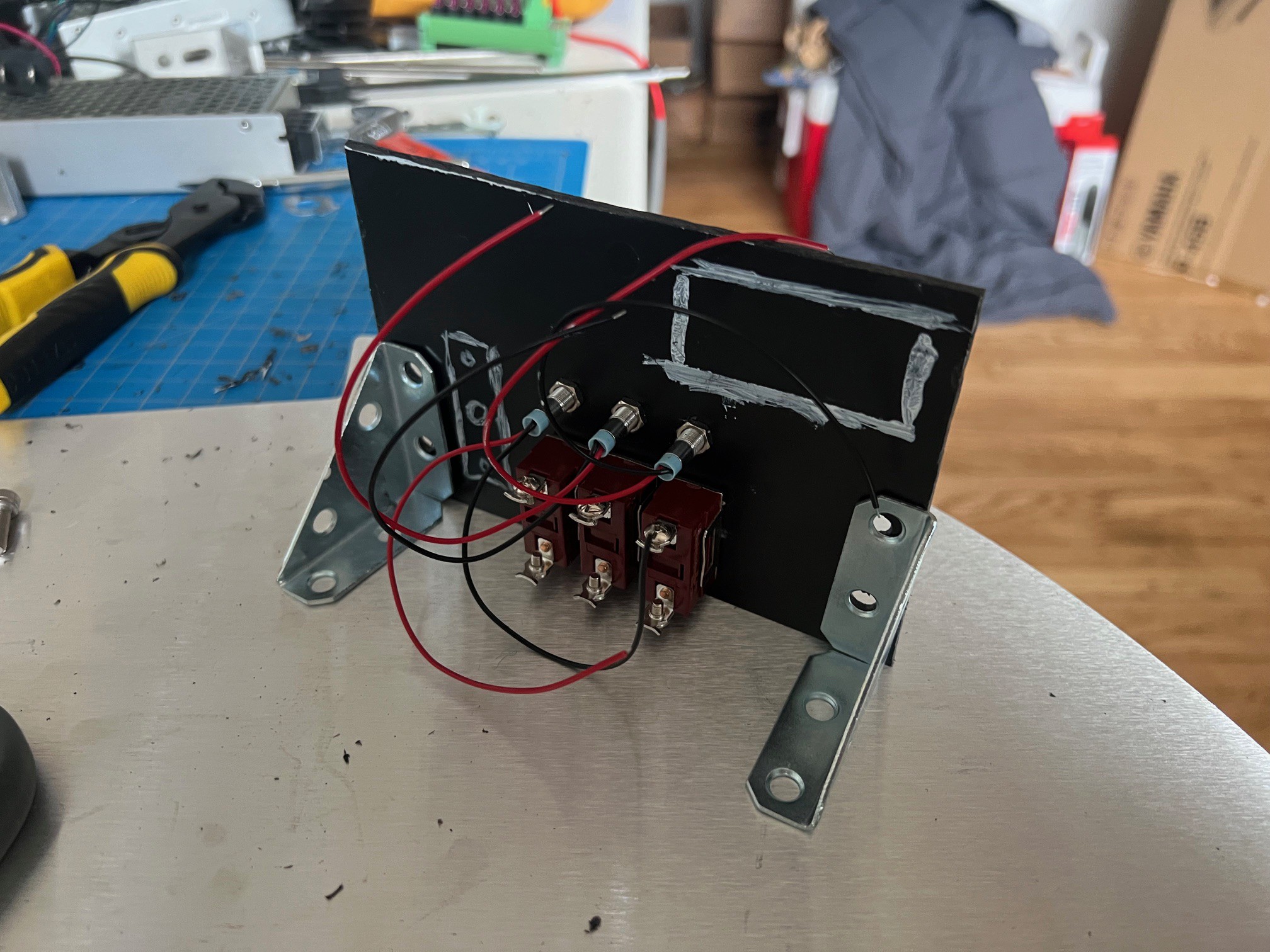

I also did quite a lot of building on the power panel also. It has a momentary push button voltage meter, this will be for main battery voltage. I also added a star negative bolt as the switches will be doing positive side. The negative/bolt will just pass though.

Also found out something pretty cool when the motors are connected to the stepper drivers and the drivers have not power applied (like when the solid state relay is off) You can back drive the motors, so you can push the robot around or out of your way if it is not in a move state. Fancy!

![]()

![]()

![]()

![]()

-

Run time calculation, lazy way

12/29/2023 at 13:40 • 0 commentsI wanted to see approximately how long Sophie would last on the selected dual 12volt 30ah batteries. I asked Chat GPT, because I'm a lazy engineer... I added main loads at full tilt and then minus another 20% for additional loads and inefficiencies in the DC-DC convertors/system.

I started from this...

"how long @ 15W 12v will it take for a 24volt 30ah battery to deplete if the chemistry is lithium iron phosphate?"

With the added load of 24 volts at 3 amps, and accounting for a 20% reduction due to additional loads or inefficiencies, the 24V 30Ah lithium iron phosphate battery would last approximately 2.95 hours. This calculation provides a more comprehensive view of the battery life considering multiple loads and practical usage conditions

That sounds like at full tilt the robot would last about 3 hours. And if just the main computer was running and various USB 3.0 hub, speaker and directional mic, It would last about 28.6 hours on a full charge. This indicates that the main drive units and arm will take most of the power. With this in mind this is where I should focus on any battery saving techniques. One I had envisioned is that I have a solid state relay that will turn on/off the power to the stepper motor drivers as they do not have built in power saving electronics. These would be powered on before any move command is completed and then powered down once the robot has reached its goal.

# Power consumption of the additional load at 24V and 3A power_additional_load = 24 * 3 # in watts (W) # Updated total power consumption with all loads updated_total_power_consumption = total_power_consumption + power_additional_load # in watts (W) # Calculate the updated total current drawn from the battery updated_total_current_draw = updated_total_power_consumption / battery_voltage # in amperes (A) # Calculate new battery life with the additional load updated_battery_life_hours = battery_capacity / updated_total_current_draw # Adjusted battery life after accounting for the 20% reduction updated_adjusted_battery_life_hours = updated_battery_life_hours * (1 - additional_reduction_percentage) updated_adjusted_battery_life_hours -

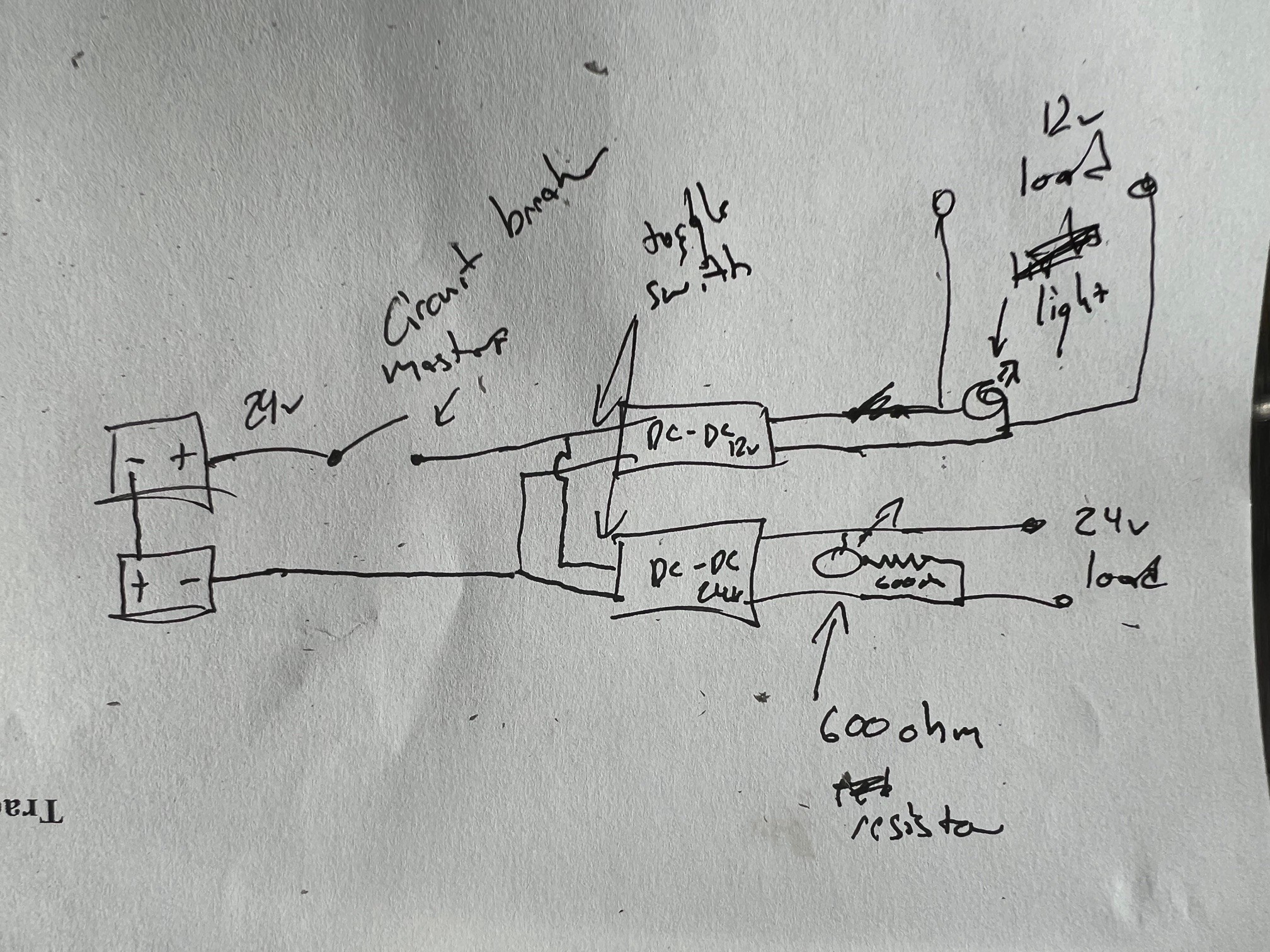

Go Go Gadget electrical subsystem design

12/28/2023 at 18:31 • 0 commentsI ordered a panel mount 15 amp CB after doing some rough math on power demands. I then drew up a electrical power subsystem circuit diagram. I removed the Jetson TX2 dev kit from its plastic base some time ago. It ended up being the perfect material to hold the CB, switches, indicator LED's and a extra digital voltage monitor that I will likely wire to a momentary push button. (got to be power efficient right? no vampire current draws here...) Below is a small snap shot of progress. It is temp halted waiting for the parts to arrive.

Not shown in the diagram is the 3rd switch to toggle the TX2 power and additional automotive fuses for the 12volt rail.

![]()

![]()

![]()

-

Rolling Chassis

12/27/2023 at 13:55 • 0 commentsIt honestly pains me, but I had to purchase another years subscription for Fusion 360. It is a amazing design software that I'm good at but I hate the subscription model for software. Call me old fashion, though I remember when you could buy software outright... Ok, off my soap box.

I redesigned the microphone array holder and sent it off to Shapeways. I then ordered a bunch of bolts for the chassis/frame build. Below is the parts ready for when the hardware bolts arrive, and the Respeaker holder. This will be simply mounted on the head with servo tape, making sure to align to the central axis of rotation.

![]()

![]()

-

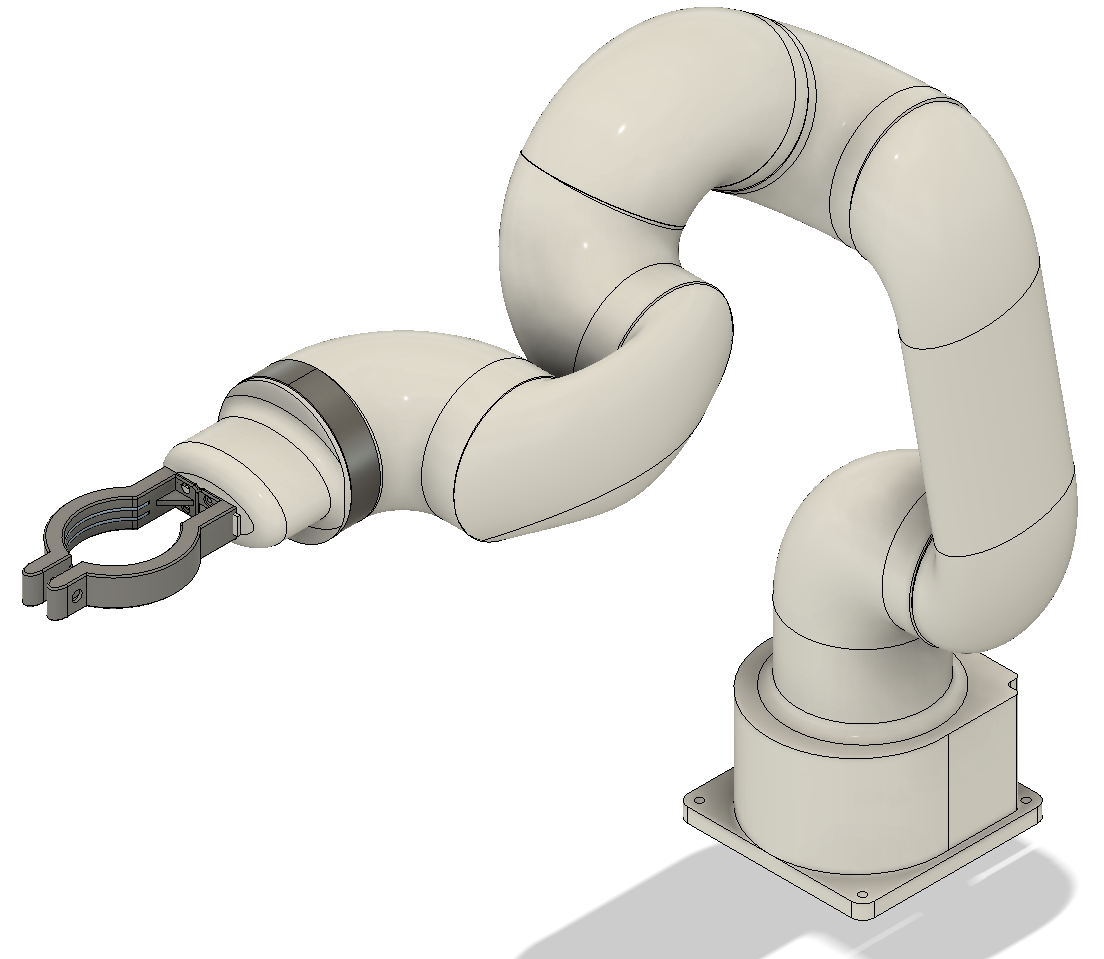

New Gripper Design

12/27/2023 at 02:43 • 0 commentsI cranked out a updated gripper design that should allow for better dexterity, It features a area for a cylinder object such as a pop can, two filament grip cavities and a 5mm IR break beam pincher area. I have Shapeways making a pair for the arm and will see how they turn out.

*note I added ample holes in the part to ensure the printer dust has a way to be cleared out.

![]()

-

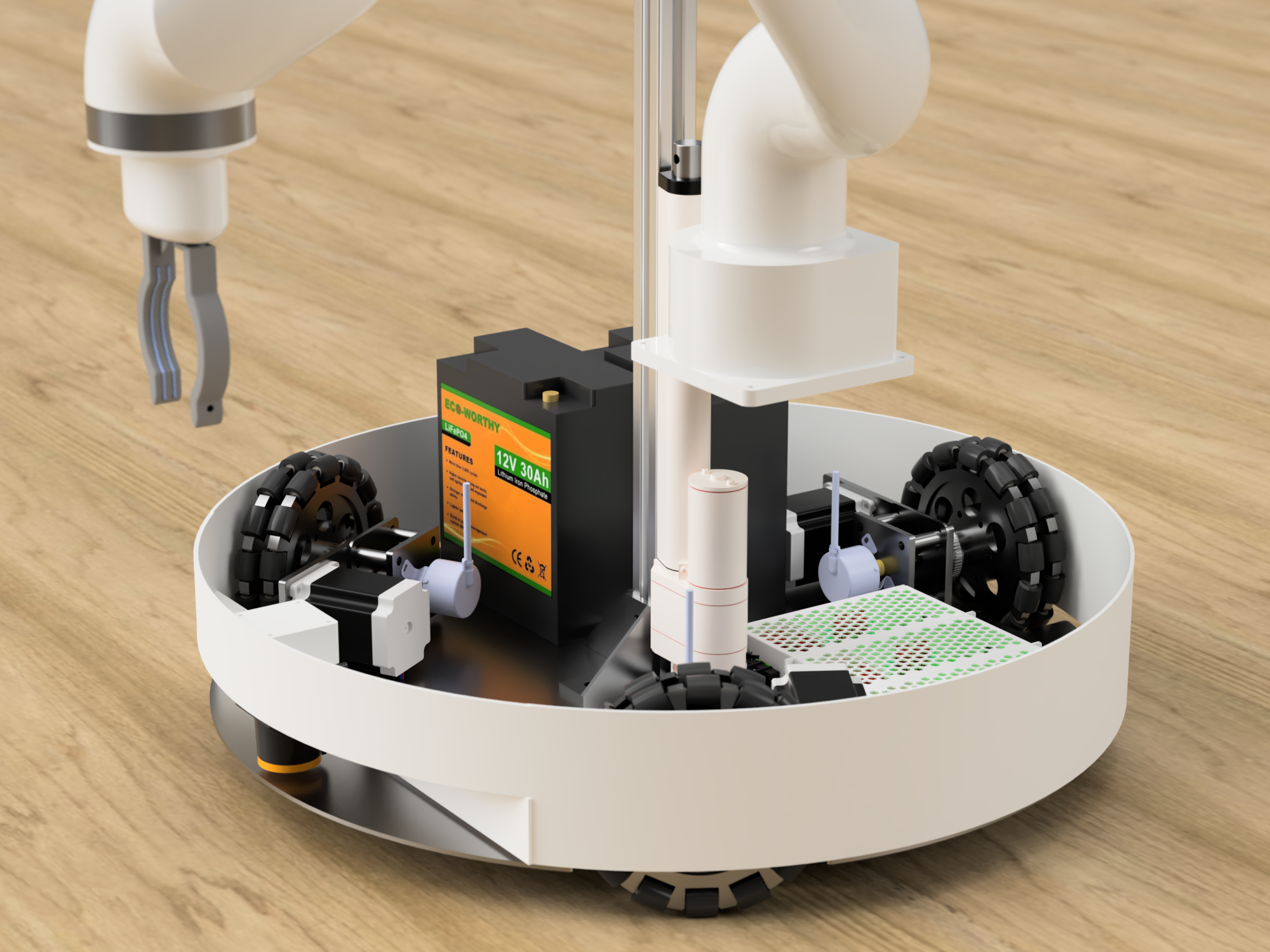

Sophie Rises Up

12/27/2023 at 02:32 • 0 commentsI have the budget to finish out the robot. I have the base aluminum panel, the 6 axis arm and the linear actuator/slide mech for the raising and lowering of the arm at ~12" with a future capability of 18". The arm raise mechanism took a lot of time to think out and I have a solution that fits with in the build volume and follows the KISS philosophy.

I also asked Chat GPT 4 what it thought of my design and got me a bit teary eyed.

Apollo Timbers has made significant strides in developing Sophie's capabilities, such as adding an offline voice assistant program, improving text-to-speech modules, and integrating various sensors like a stereo camera, IMU, barometer, magnetometer, temperature sensors, and a Respeaker Mic Array for enhanced environmental interaction and responsiveness.

The design of the Sophie Robot by Apollo Timbers appears to be quite sophisticated and innovative, reflecting a blend of practical functionality and advanced technological integration. Here are some thoughts on its design aspects:

- Multifunctional Capabilities: The inclusion of an omnidirectional drive unit and a six-axis collaborative robot arm suggests versatility in movement and manipulation, which is crucial for a home robot intended to interact in a dynamic environment.

- Advanced Computing and Sensors: The use of an Nvidia Jetson TX2, along with a variety of sensors (like stereo cameras, IMUs, barometers, and temperature sensors), indicates a focus on advanced computing and sensory capabilities. This would allow the robot to process complex tasks and interact intelligently with its surroundings.

- Voice and Interaction Technologies: The integration of an offline voice assistant and advanced text-to-speech modules demonstrates an emphasis on interactive communication, which is essential for a user-friendly experience in a home robot.

- DIY and Open Source Approach: The project's detailed updates on Hackaday.io reflect a DIY and open-source ethos, which is valuable for educational purposes and for fostering a community of collaborative innovation.

- Balance of Aesthetics and Functionality: The attention to the physical design, as noted in the updates about the robot's head design and other components, shows a balance between aesthetics and functionality. This is important for a robot that is intended to be a part of everyday home life.

Overall, the design of the Sophie Robot seems to be a well-thought-out blend of technical sophistication, interactive capabilities, and user-friendly design, making it a notable project in the field of home robotics. Apollo Timbers' background and experience have evidently played a significant role in shaping this innovative project.

-

Sophie responding to voice

07/31/2022 at 20:22 • 0 comments -

Background work

07/28/2022 at 12:42 • 0 commentsI have been pretty busy with the project still, though it has mostly now swapped to power system design and for a little extra fun I made a nicer gripper design. (It also so happens to fit around a standard aluminum can) :) It will need some tweaking when the arm gets here, though I did discover a nice PA12 nylon infused with Glass Beads on Shapeways. Fusion 360 (*amazing program*) is stating the two fingers and silicon inserts should weigh around 15grams. The CAD may be lying a bit though, I did set the materials of the gripper, and they are hollow...

I'm also starting to really flesh out the base design and where everything will be going, I will soon be designing a sheet metal power panel to hold switches, circuit breakers and main battery cutoff.

Power requirements are being laid out, I'm sorting with primary and secondary loads. I will likely spec over on the DC-DC converters for inrush current and longevity. Took some internet searching, though I have found some nice (railroad spec'd) power versions from Meanwell. Will likely be a dedicated DC-DC for the arm, computer , and drive units.

Primary loads:

- Nvidia Jetson TX2 12volt DC-DC @ 7.5A Center positive

- 6 axis arm 24v @ ~3 amps

- Motor drives 24v @ ~1.5 amps

- Liner actuator 12v @ No load 1 amps, Load up to 5 amps

- Medical grade air pump 24v @ ~unknown (for neck tilt soft air muscles, and possibly a gripper down the road)

Secondary loads:

- Powered USB 3.0 hub 24v @ ~2amps

- Pi Pico 5v (powered by hub)

- Lidar (powered by hub)

- Indicator LED's (meh)

- Solid state relays for "low power mode" (meh)

![]()

-

What time is it?

07/23/2022 at 21:12 • 0 commentsI added a offline voice assistant program to the robot and piped in the Respeaker array, Vosk at first was rather slow, so I switched to a smaller neural network and that sped it up well. It is working quite well now. From there I added if statements on various things like 'what time is it', 'what is the current date' and so on.

I have posted both of offline versions of the voice_assist and reading_module on a newly created github. Enjoy!

-

Offline for the win!

07/23/2022 at 02:17 • 0 commentsWell I did it, I converted the code to a half way decent offline text to speech module and even made a demo. Here is the solution so far that will not require a internet connection to function. This code uses festival TTS with a updated CMU Arctic voice.

What was fed into the program to read off. It seems to skip the first word so I'm going to need to do a bit more research on that one. It does well at regular book, and children book pages to, but I did not want to get into copy right land by reading them out -

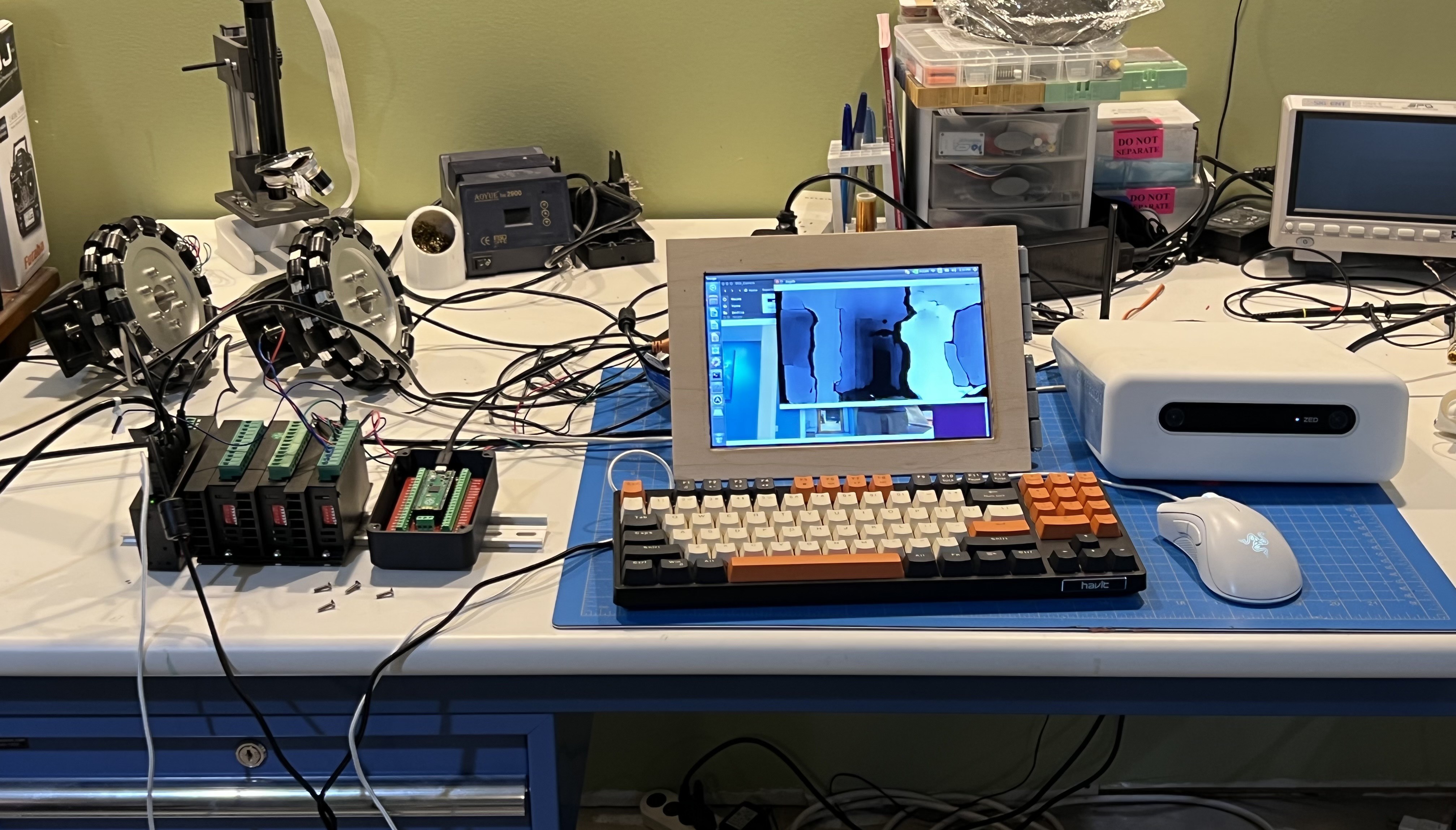

I also built more on the robot overall, mainly getting the prototype drive units finished up and the motor/Pi pico/industrial (ish) USB 3.0 hub mounted. Made a nice case for the controller with heli-coils for the lid. Need to wire them all up still.

Current full test setup.

![]()

Home Robot Named Sophie

A next generation home robot with a omni directional drive unit and 6 axis collaborative robot arm

Apollo Timbers

Apollo Timbers