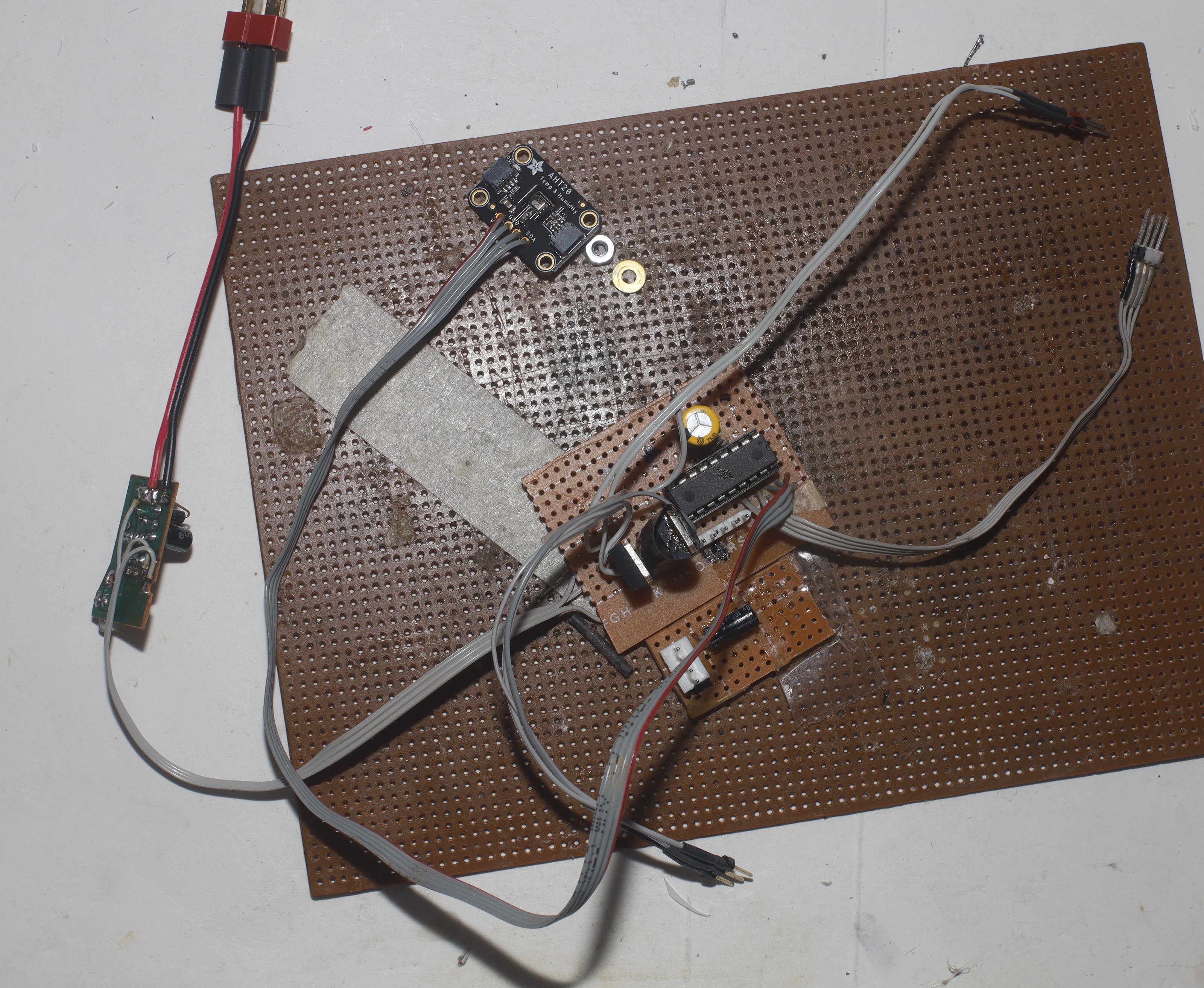

The decision was made to replace the pump, after a very noisy final TPU drying. Lions have lived in a very noisy environment for 25 years, with confusers, atomizers & fans, but the inkjet printer pump was a uniquely difficult noise.

After taking out the fuse connection & the stall LED, it became quite clear that the 3/4" ID tube was never going to have an airtight connection on top & it was never going to navigate the tight corners. The angle connectors might have hope with narrower tube, but narrower tube requires a noisier pump.

The easiest fix with this design is going back to 1/4" tubing, using store bought barbed farsteners, & just enclosing the inkjet pump in something soundproof. The inkjet pump turns out to fit 1/4" tubing better than 3mm tubing.

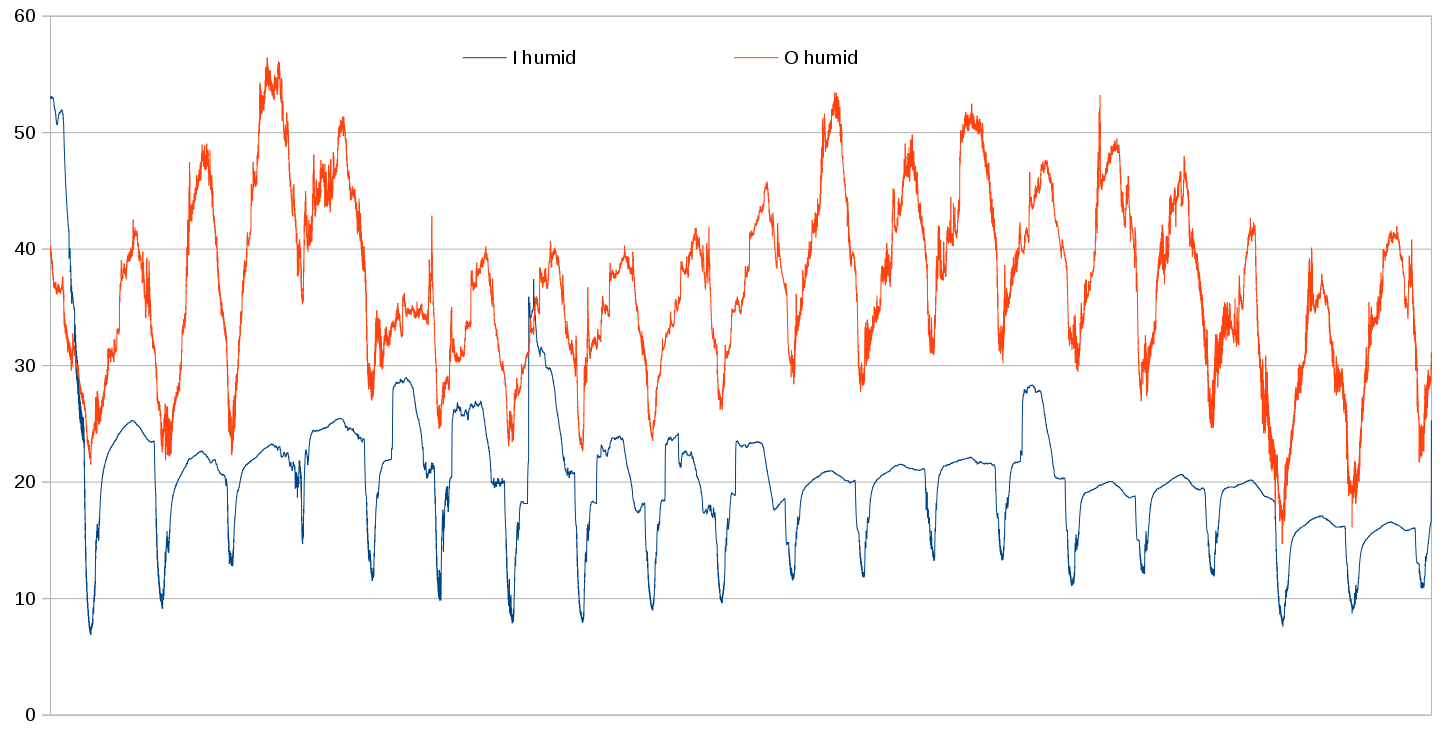

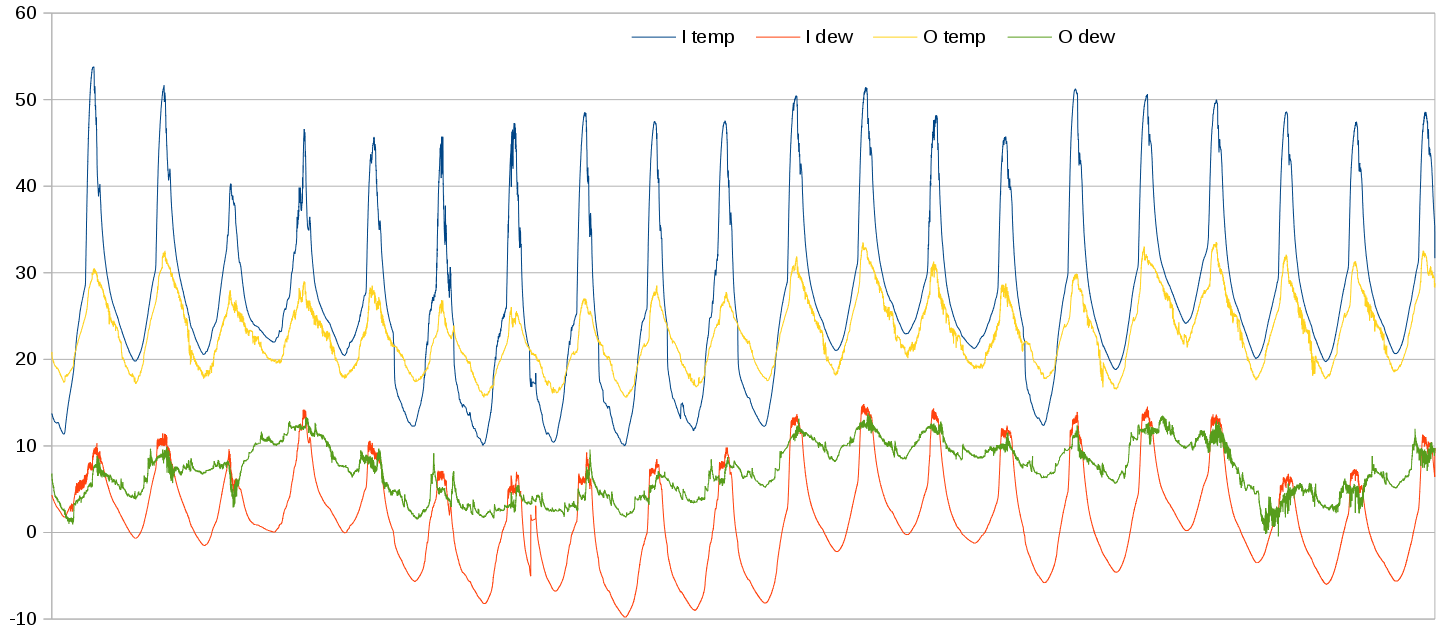

Another idea is an air tight barn door on the side with no tubing or pump. Position the circulation fan near the barn door. When the inside dew point gets high enough, open the barn door & rely on the circulation fan to replace all the air.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.