The story so far...

I have been engineering my system for months, trying to learn as much as I can from YouTube about good sources for panels, inverters, batteries, battery management, etc. Big thanks to Andy at the Off-Grid Garage and the DIY Solar Power with Will Prowse channels, among others.

After buying a house in rural San Diego county in 2019, we immediately expanded our solar power, knowing the meager 4 kW array it had would never be enough for our needs. We beat the rush to get Tesla PowerWalls and that has turned out to be a wise choice, as recent wildfires have scared the utilities into emergency cutoff plans when fire danger is high and high winds are predicted. We added 12kW of microinverter solar panels and two Tesla PowerWalls, which provide 28 kWh of storage and 10 kW combined off-grid power capacity.

Unfortunately, 10 kW capacity from battery did not allow for the PowerWalls to have enough capacity left for running a Level 2 EV charger, but that project set us back $52000. We probably goofed in several areas on that design as well. We upgraded the old DC string from dual 1800W grid-tie inverters to a single 3800W inverter with monitoring capability. It probably would have been wiser to remove the old panels and use the newer SunPower microinverter panels. This would have allowed a bigger capacity, uniform appearance, and a single point to monitor. It probably would have cost a bit more, though, exceeding our solar loan amount we qualified for. Meh.

After studying the DIY channels and researching sources, I was inspired to do a system myself, and also avoid tying to the grid for the sake of simplicity. Brand-new bifacial 410W panels by the pallet load (30 panels) were only $185 each + freight. 12kW off-grid inverter, $2049. Freight $570 from Signature Solar in Texas to SoCal was $570.... plus a U-Haul truck rental when it turned out the lift gate truck could not get to our house. Add another $335 for renting a U-Haul + fuel costs to DIY the delivery.

Words for the wise: the pallet weighed about 1800 pounds, plus about 200 for the crated inverter. This requires a heavy lift gate truck, which has poor ground clearance and bottomed out on the highway when hitting the slope of the driveway. Light lift gates have delivered to my house successfully, so I wasn't expecting this. U-Haul trucks are easy to find in the Western US states, but Penske trucks have been hard to find since the pandemic. Penske is more expensive to rent, but you want their trucks because they have standard loading dock deck heights, which allows a forklift to drive right in and deposit the pallet. Since I could only get a low-deck U-Haul, the very helpful delivery guy was able to back his liftgate truck up to my truck, lower the gate to the U-Haul height, and use a pallet jack to transfer the 2000 pounds of equipment over. Sounds simple, right? This was dangerous AF in terms of personal safety and risk of damage to trucks and cargo. Solar pallets are huge, like 40" x 85". Since we had to use a pallet jack (with 48" forks), the pallet had to be loaded wide-ways, which barely fit in the U-Haul, and we had to remove the "helpful" rental hand truck to get the pallet to fit. This cost me a $30 rental fee they wouldn't take off my bill. Sigh.

Finally got the panels and inverter home, where it took a bit of brainstorming to figure out how to get the 200 pound inverter out of the truck, not an easy task since the crate was full of splinters and razor-sharp metal trim holding it together. It is intended to be lifted by forklifts, not soft fleshy bits. Once done, we dismantled the 30-pack crate of panels and carried them by hand into storage.

Bryan Williams

Bryan Williams

tiefpunkt

tiefpunkt

Dylan Bleier

Dylan Bleier

Guido

Guido

Drew Pilcher

Drew Pilcher

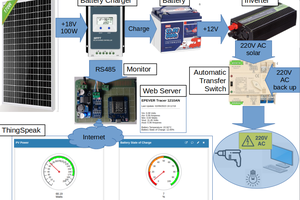

Expanding your fleet of EVs in California, considering the high power prices, sounds like a smart move. It's unfortunate that your current setup with Tesla PowerWalls is limiting due to its combined output and the need to exclude high-amperage devices. To address the peak-time charging costs and the short-range of your EVs, it seems like you have a comprehensive plan in place. Building a 28kWh expandable LFP (LiFePO4) 48V battery array, adding ground-mount solar panels, off-grid inverter/chargers, dual Level 2 chargers, and a rainwater collection system for the array and solar shed shows a proactive approach towards sustainability and cost efficiency.

You can read more about Tesla cars at https://nerdycar.com