"Vintage" as applied to sewing machines has a somewhat specific meaning. Antique sewing machines are ones made before 1900. Vintage machines were made between 1900 and about 1970. Modern machines are anything after about 1980.

Vintage machines were made after all the early wrinkles were worked out and before the manufacturers switched from all metal construction to using plastic in the housings and mechanisms.

The all metal machines are nearly indestructable. About all that can kill a vintage sewing machine is rust or being dropped on a hard floor - cast iron tends to be brittle.

Supplies (needles, bobbin cases, replacement parts, etc.) are often still available for popular vintage machines. Sometimes because there's a lot of new-old-stock still around, sometimes because modern machines still use parts originally designed for older machines, and sometimes because there's enough of a market that somebody, somewhere, fired up a production line to make new parts for the old machines.

Joseph Eoff

Joseph Eoff

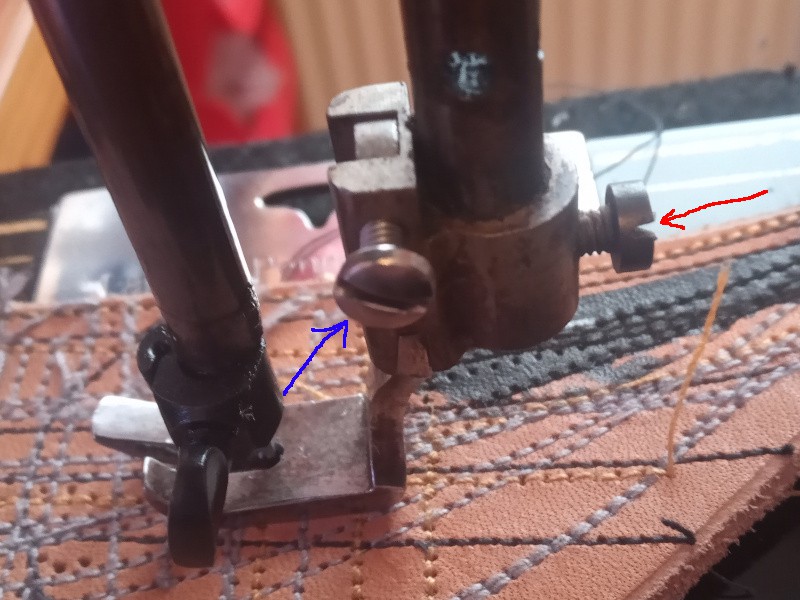

Despite the generally good condition of the Pfaff 30, it did need a few things done.

Despite the generally good condition of the Pfaff 30, it did need a few things done.

If you've been following my sewing machine adventures, you may have seen the

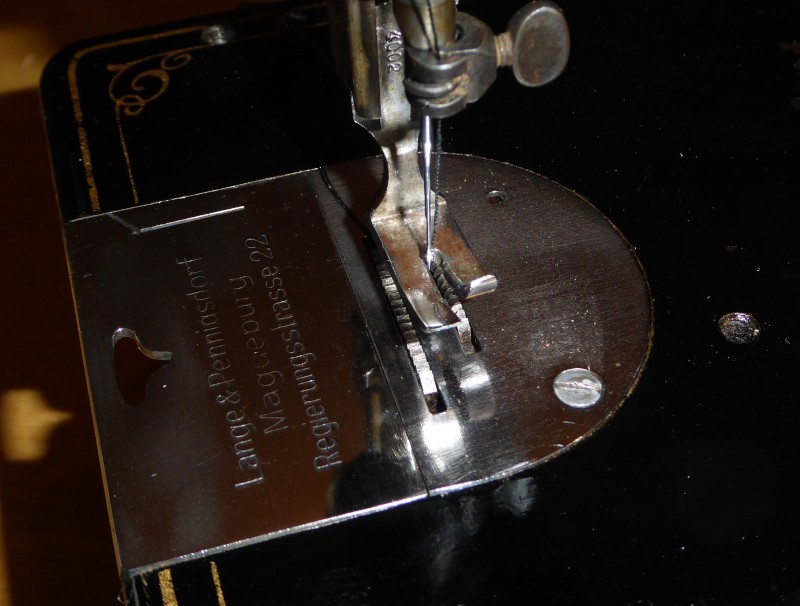

If you've been following my sewing machine adventures, you may have seen the  The Pfaff 30 has a lot of parts that are black rather than chromed.

The Pfaff 30 has a lot of parts that are black rather than chromed. That's not a general thing - many if not most Pfaff 30 machines are chromed as well.

That's not a general thing - many if not most Pfaff 30 machines are chromed as well.

I used that bottle of "Fernol" on the walnut veneer. Fernol is an oil based furniture polish made to clean up and restore old finishes. It took care of the scratches and the house paint drips on the front of the cabinet.

I used that bottle of "Fernol" on the walnut veneer. Fernol is an oil based furniture polish made to clean up and restore old finishes. It took care of the scratches and the house paint drips on the front of the cabinet.

Sewing machines are traditionally cleaned with sewing machine oil. Wipe on, wipe off. It leaves a thin film that shines and prevents rust. You do have to wipe off, though. My Adler 8 appears to have only ever had oil applied to it without the excess being removed.

Sewing machines are traditionally cleaned with sewing machine oil. Wipe on, wipe off. It leaves a thin film that shines and prevents rust. You do have to wipe off, though. My Adler 8 appears to have only ever had oil applied to it without the excess being removed.

kristina panos

kristina panos

Tim Wilkinson

Tim Wilkinson

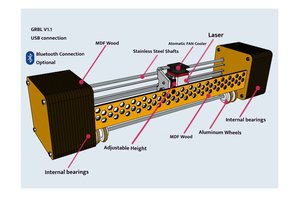

Remember it's not a sewing machine, it's a power thread injector. 8 )