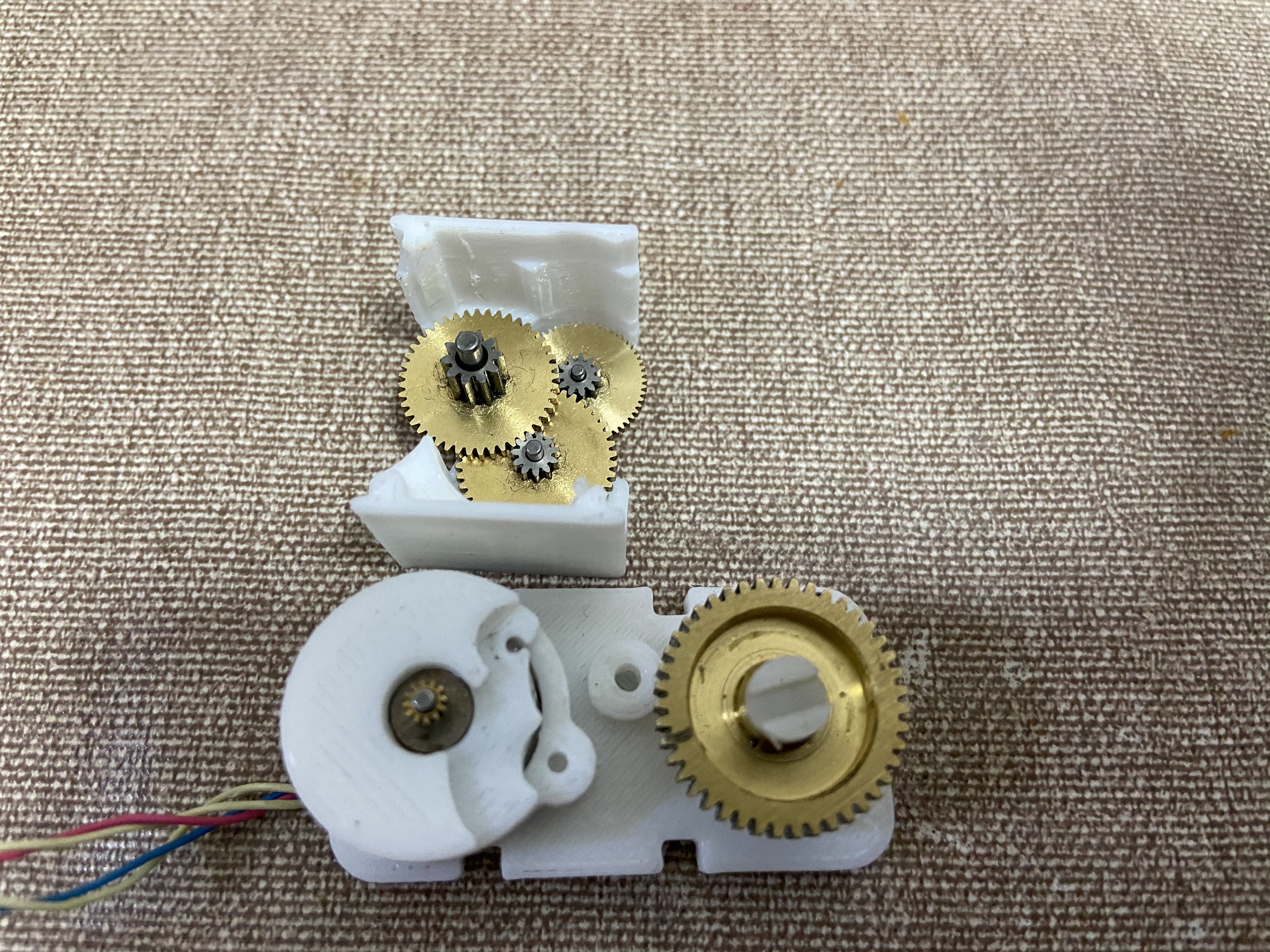

The biggest challenge was to get a small stepper motor with enough torque which could fit in small space. I did not use a hobby servo as those things don't have very accurate position sensors and they cannot do a full 360 turn . Also i experimented with small geared stepper but most couldn't fit into the tight space of the gears where useless after a few high torque runs. So i combined a 15 and 20 mm stepper with a servo gearbox.

ekaggrat singh kalsi

ekaggrat singh kalsi

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.