[09:30, 28 Aug]

It first helps to define what Tetrinsic needs to be at this point in time. It needs to:

- Be no wider than 18mm.

- Use a 45mm load cell or some other precision force sensing technology.

- Precisely detect finger position.

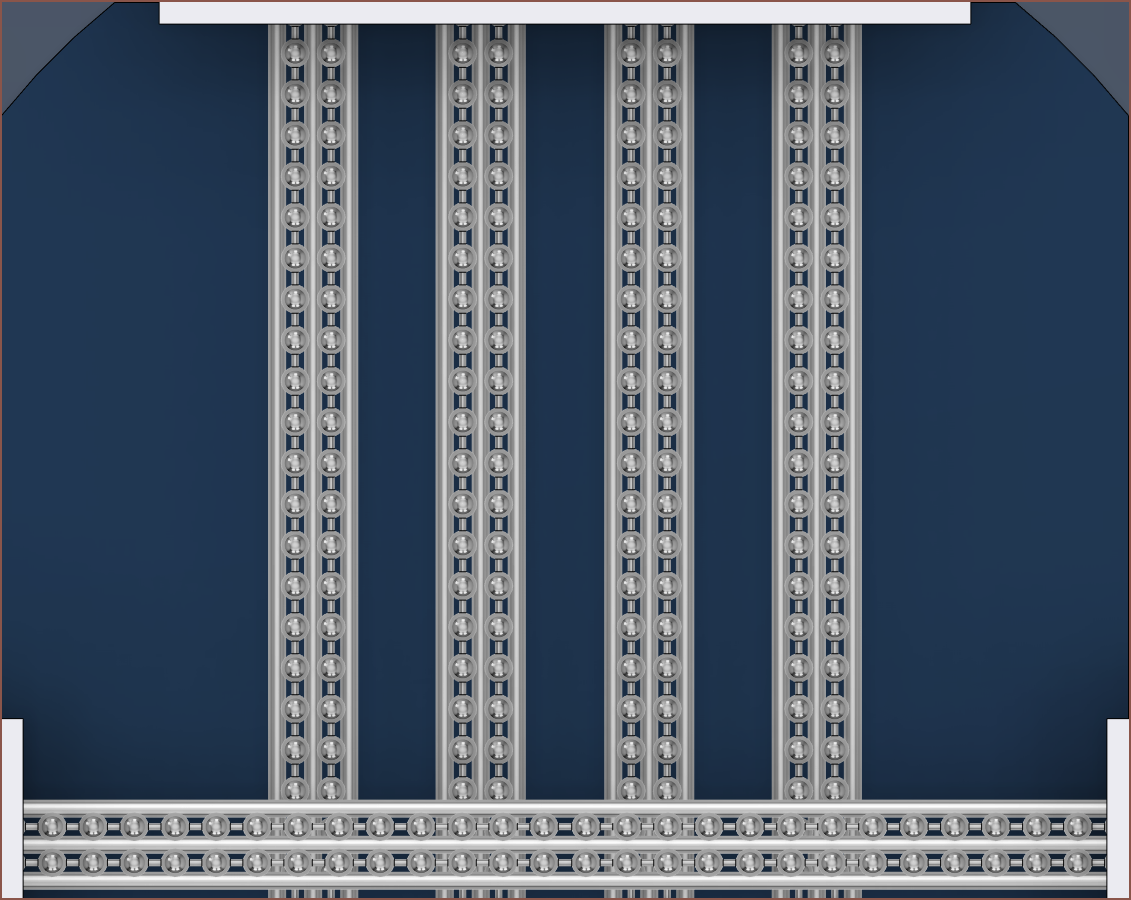

- Provide a grippable, low resistance, linear sliding medium for the fingers and thumb, ensuring fingernail compatibility.

- Have a brushless motor that exerts at least 300gf at point of finger contact.

- Allow for the below sliding medium configuration, unless another suitable ergonomic solution is found.

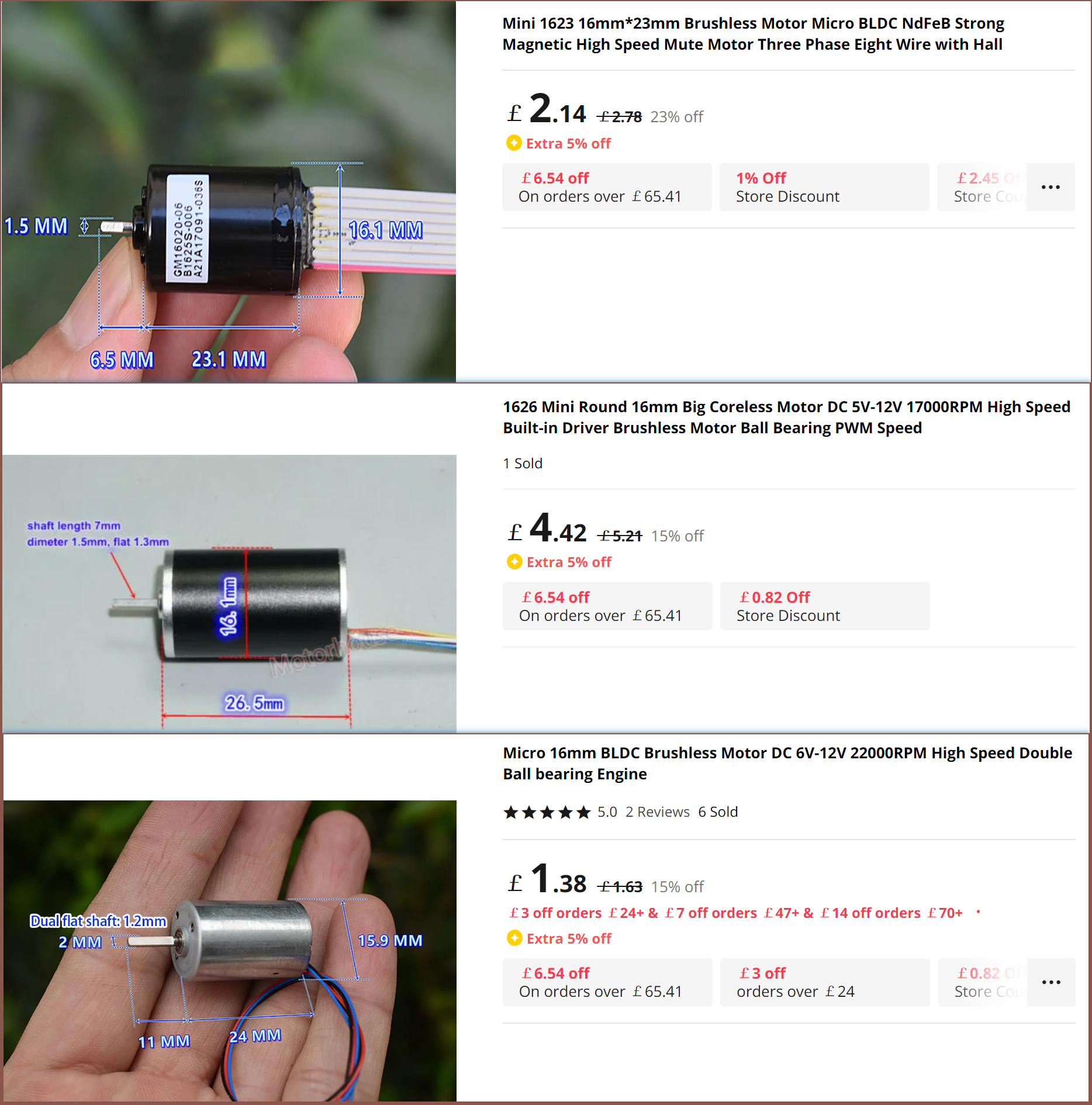

I've looked around AliExpress and there are a few motors that have a diameter of 16mm and lengths of 23mm and over.

Of which, the one with the best KV is this 1632 motor:

Specification:

Voltage range: DC 8V-18V.

Speed: 5600RPM-12000RPM.

Motor length: 32mm.

Motor diameter: 16mm.

Shaft diameter: 2mm.

Shaft length: 7mm.

Weight: 23g

Precision 16mm brushless motor with inner rotor, body length 32mm, the appearance of the bulk motor is somewhat scratched by transportation, the motor is relatively good quality, all aluminum alloy shell CNC processing, motor front and rear ball bearings, built-in Hall-type brushless motor.

The rotor is composed of 4 rare earth neodymium magnets. The magnetic force is very strong. It is obvious that the reluctance of the motor shaft is rotated manually. This motor does not have a drive, so it needs an external brushless drive to run.

The motor should be nominally used at 12V, and the measured voltage can also be used between DC 8V-18V.

Test data:

Voltage: 8V No-load current: 0.08A No-load speed: 5600RPM.

Voltage: 12V No-load current: 0.13A No-load speed: 8200RPM.

Voltage: 18V No-load current: 0.16A No-load speed:12000RPM.

The RPM at 12V is 17% higher than the 580KV motor. The KV range of this inrunner motor is 700 - 667KV. It also sounds like the cogging torque of this motor is notable.

I then watched the following:

The summary:

- Matching KV to the application is the most important

- Generally, inrunners have a higher KV than outrunners

- Inrunners can be more efficient as the windings can conduct heat through the case

- Cogging happens in a slotted but not slotless motor [relevant video]

- Cogging is stronger on a 6 pole motor.

Looking in the SmartKnob discord, it seems that for a device which is supposed to dynamically create it's own dedents, cogging is understandably not toleratable. This is what the creator means when he says that a motor has no cogging:

Even if that 1632 motor didn't sound like it had cogging so strong that the seller thought to mention it, I currently can't imagine a geometric configuration that I find acceptable.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.