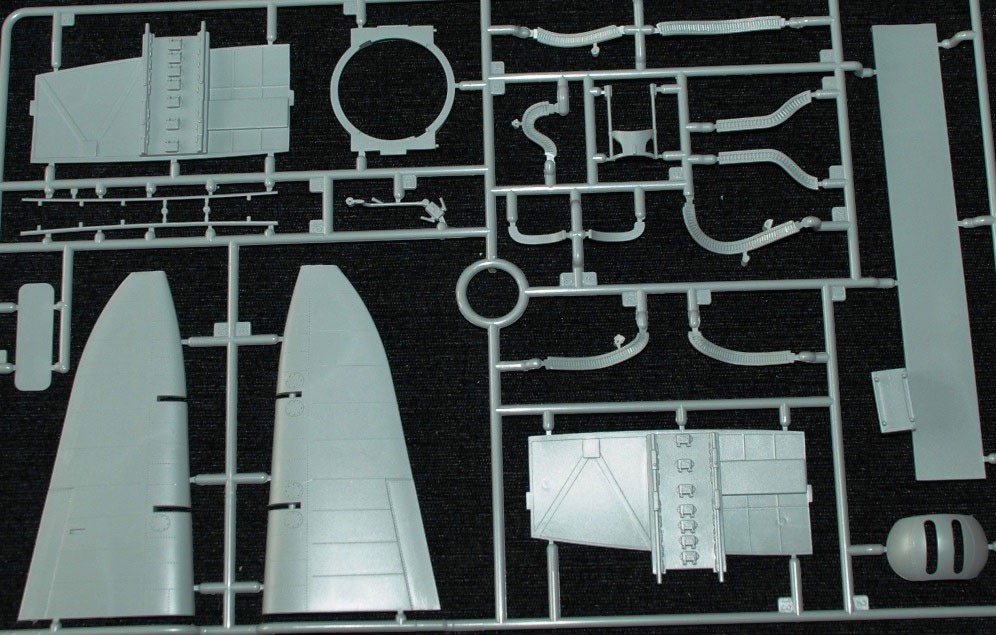

Inspiration and/or examples of working principle

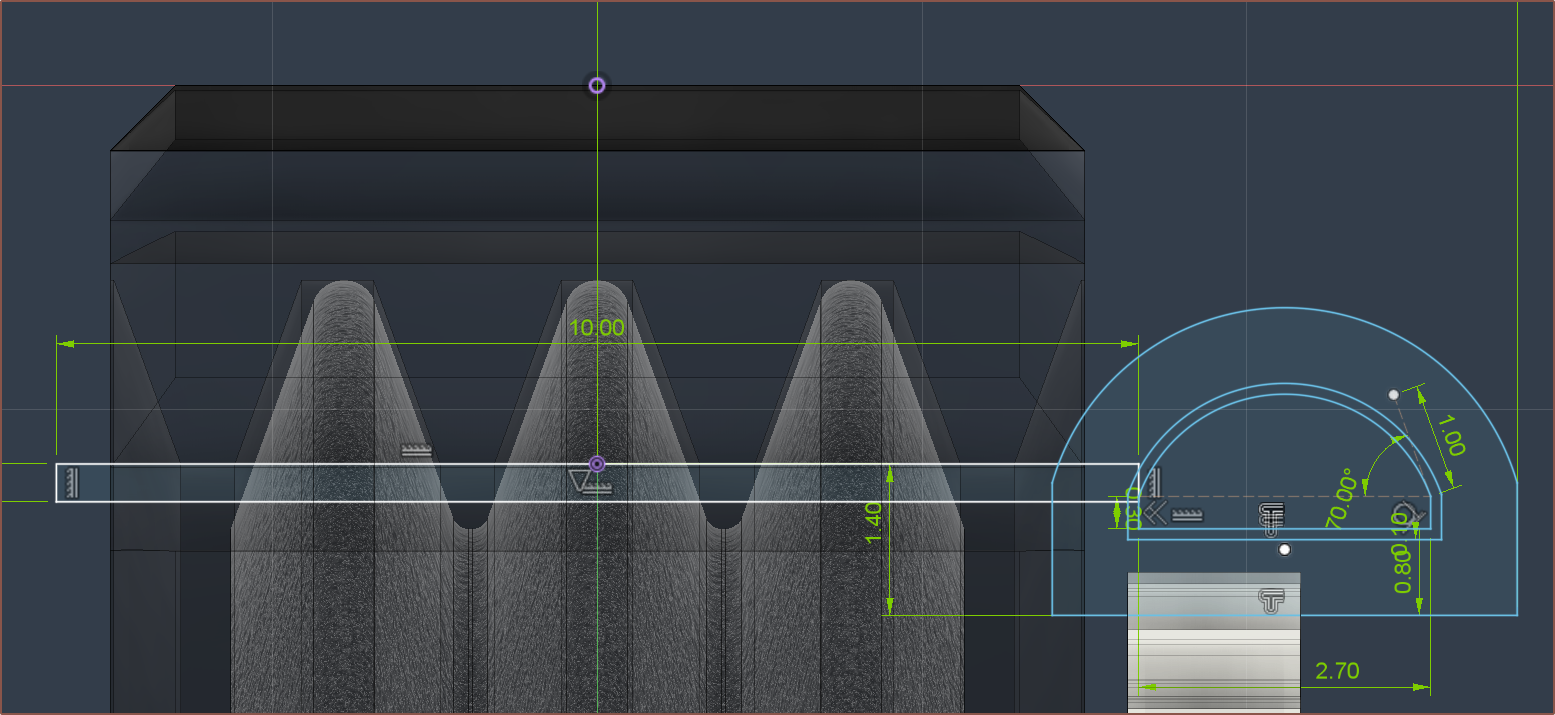

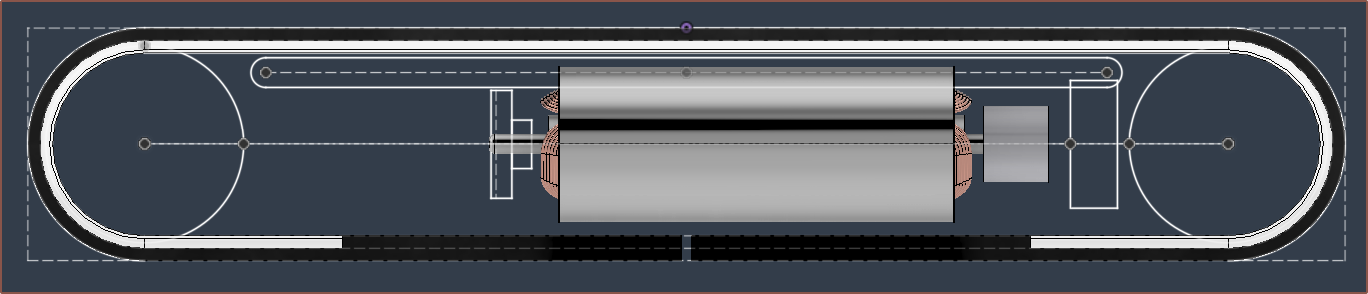

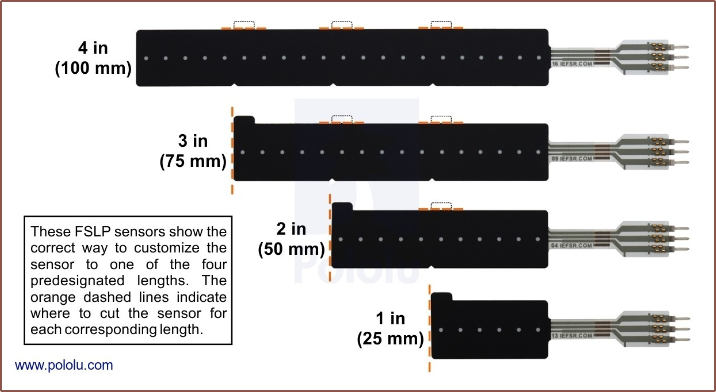

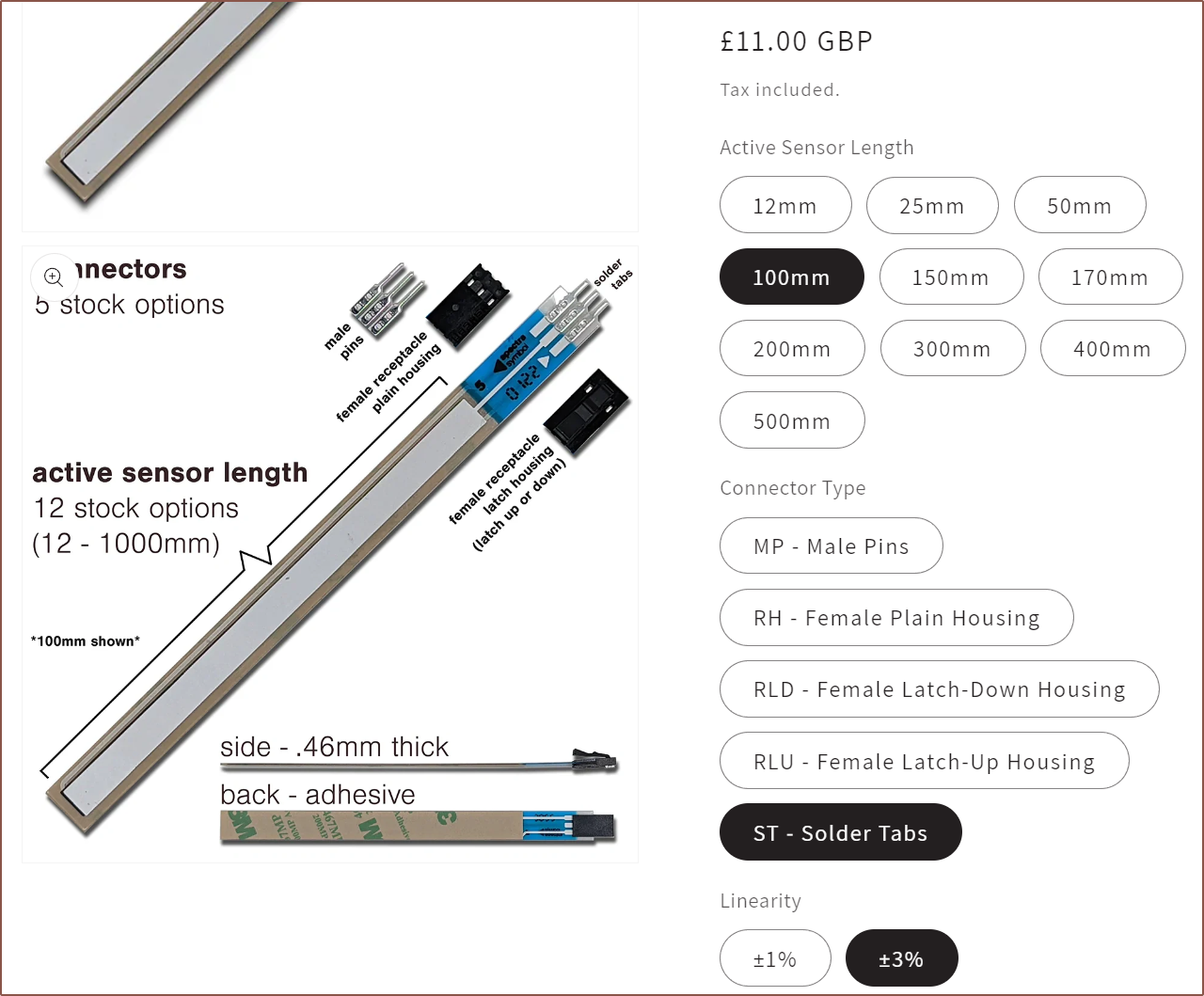

Tetrinsic can be thought of as a merge between the form factor of a motorised fader, the infinite movement and adjustable configurations of the SmartKnob View and the force/position sensing like a Force Sensitive Linear Resistor (FSLR).

Instead of a single Force Sensing Linear Resistor (FSLR), the above video use a Force Sensing Resistor (FSR) and soft membrane potentiometer (trade name SoftPot / ThinPot) to get the same thing. Tetrinsic obtains position via a magnetic angle sensor like SmartKnob View.

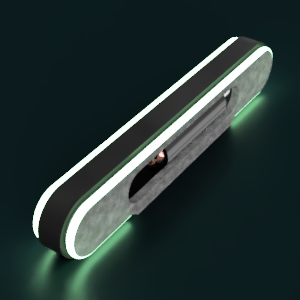

Another goal was to look as minimalist as possible, so that things like an LCD backlight may be used for designs:

Unlike the Flux Keyboard, tactility and actuation force can be tuned to ones precise tastes in software.

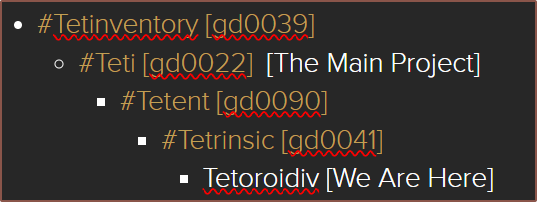

Navigation

The title tag system is explained here, and the table is updated when a change occurs. Notable logs have bold L# text.

Read more » kelvinA

kelvinA

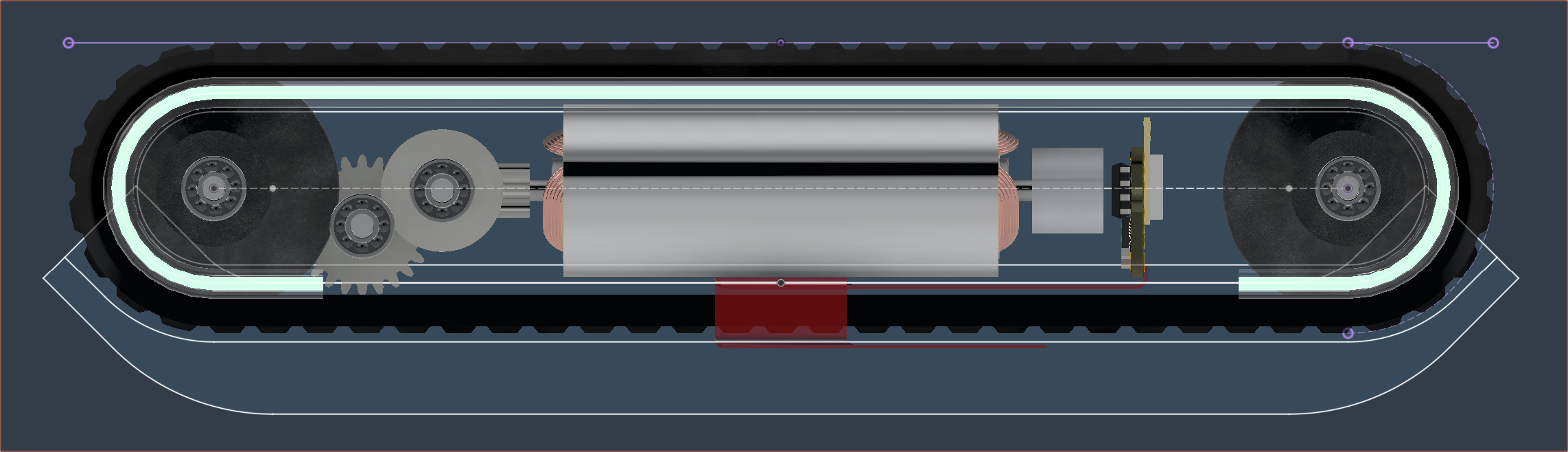

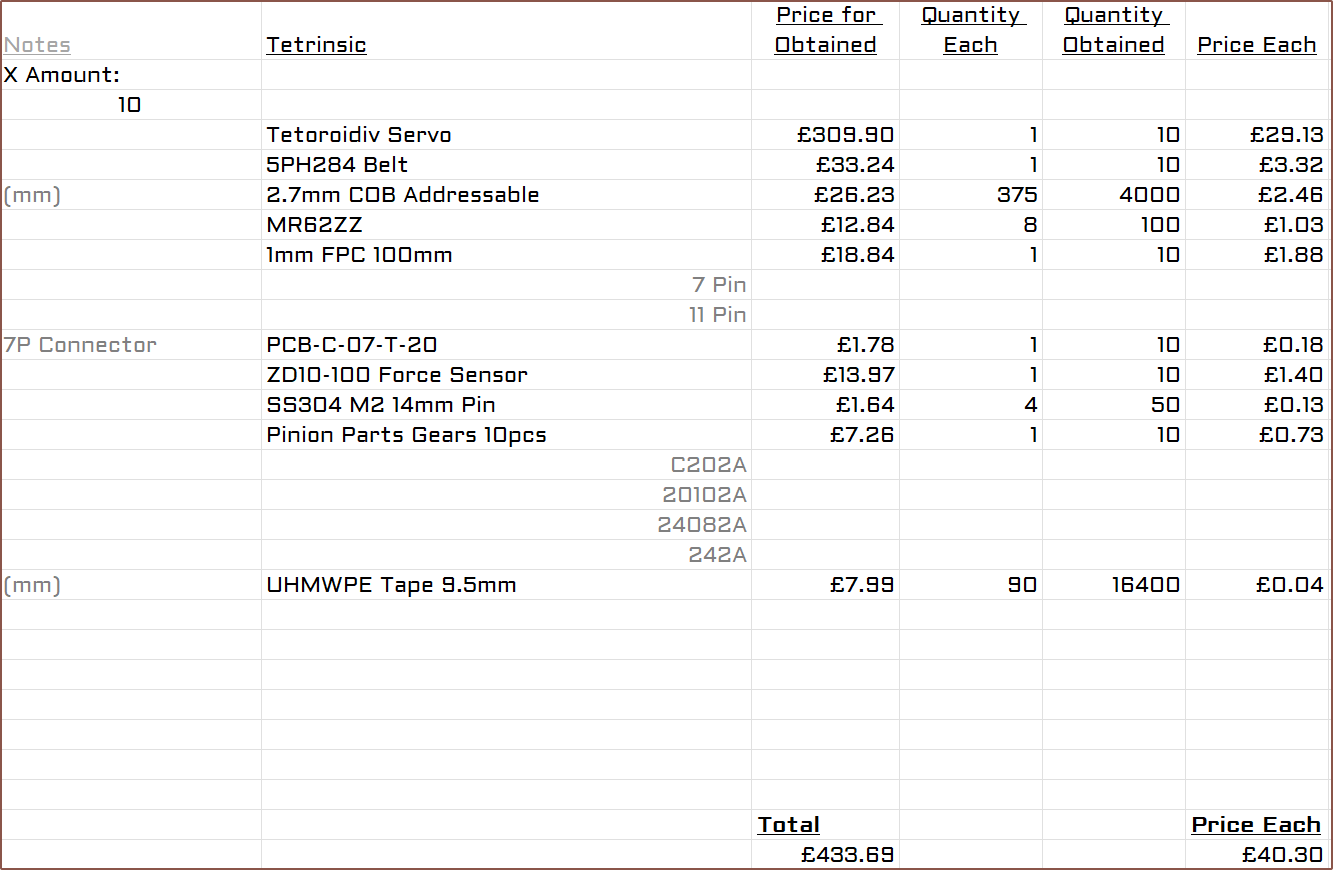

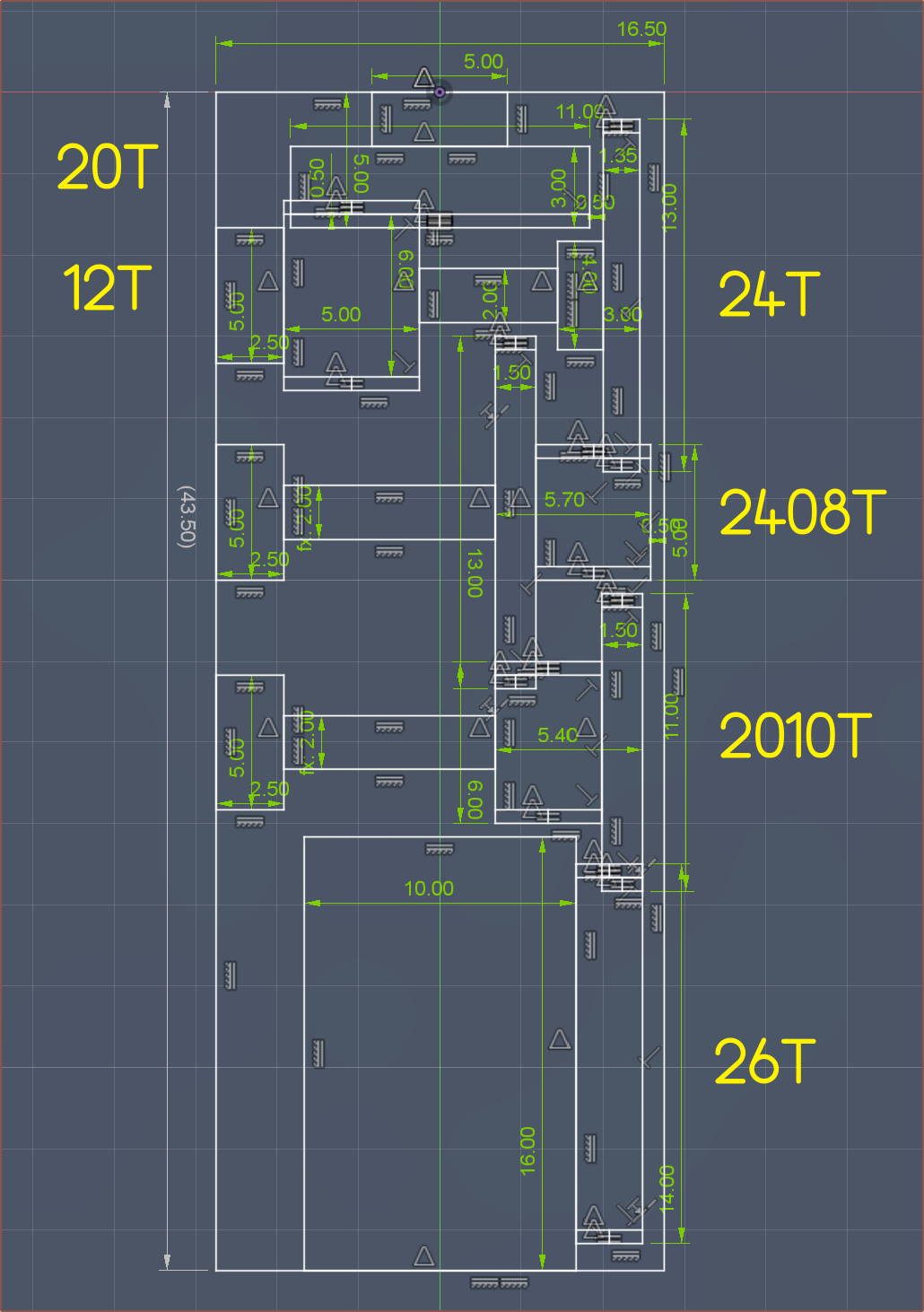

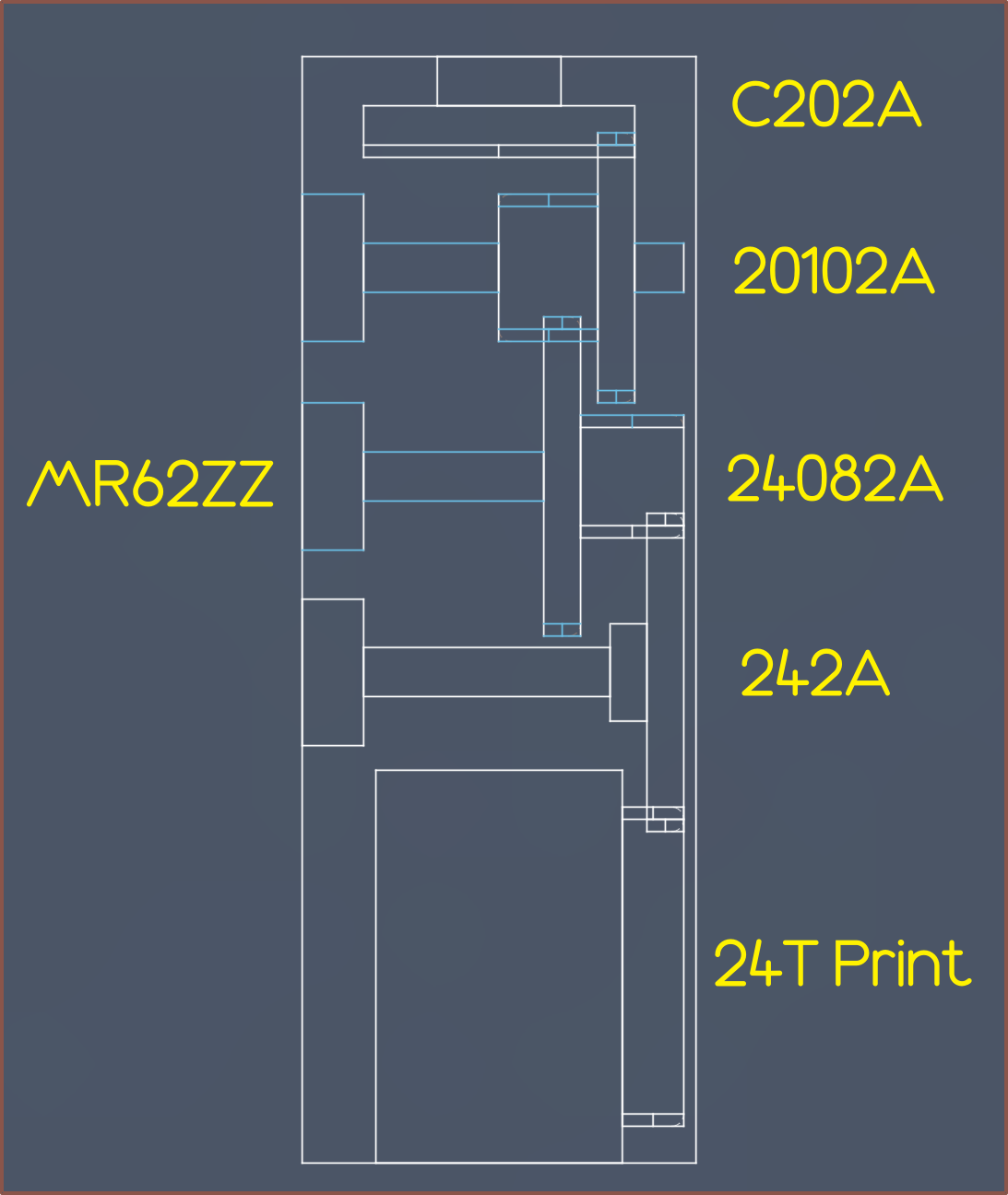

So I've recently designed the

So I've recently designed the

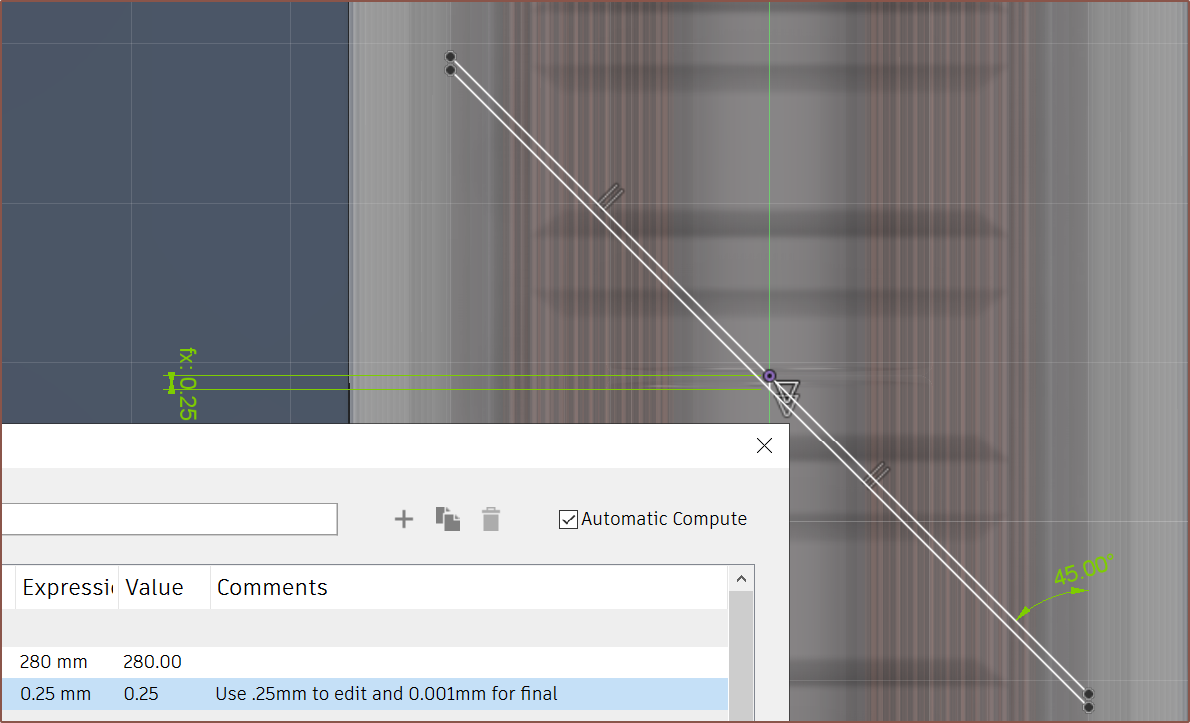

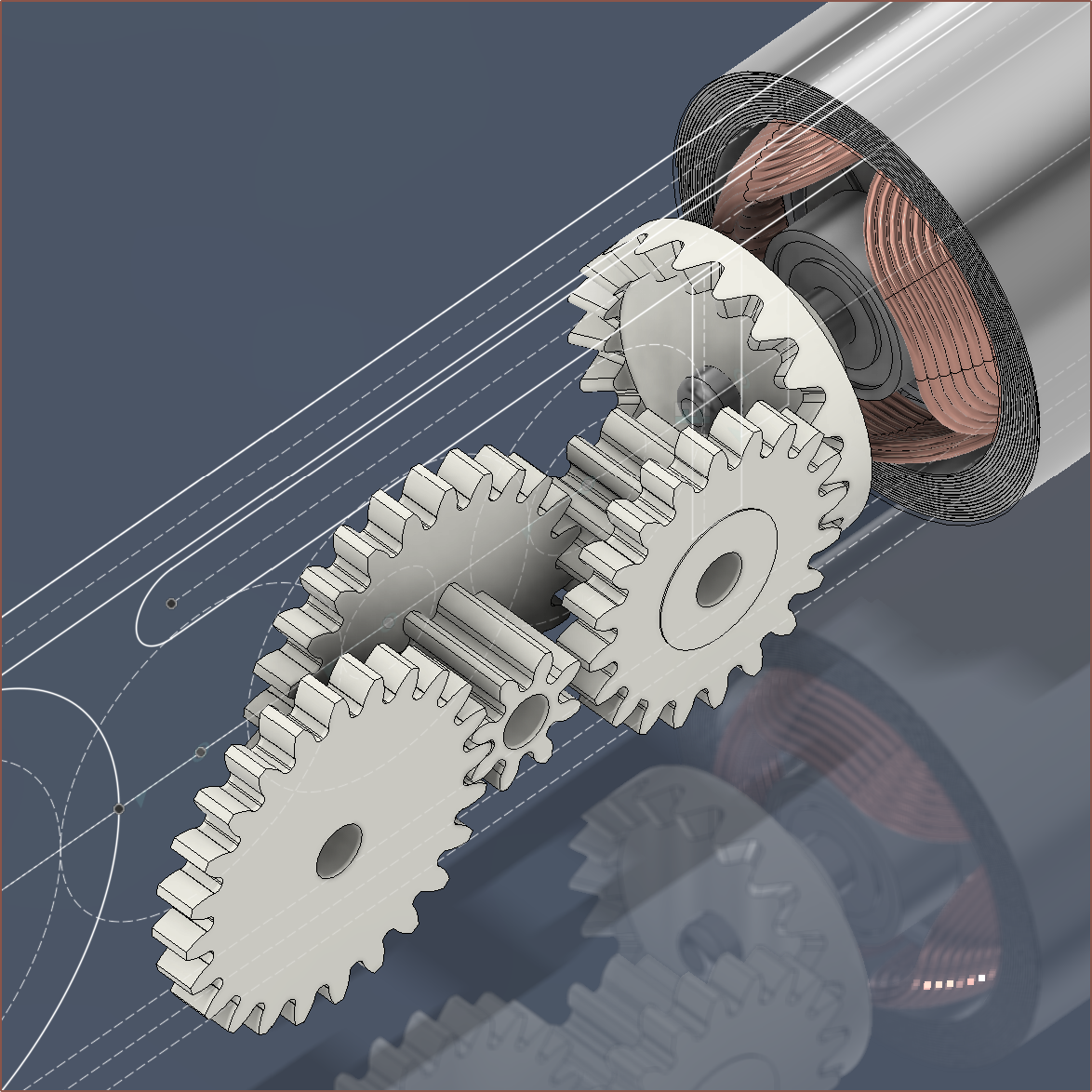

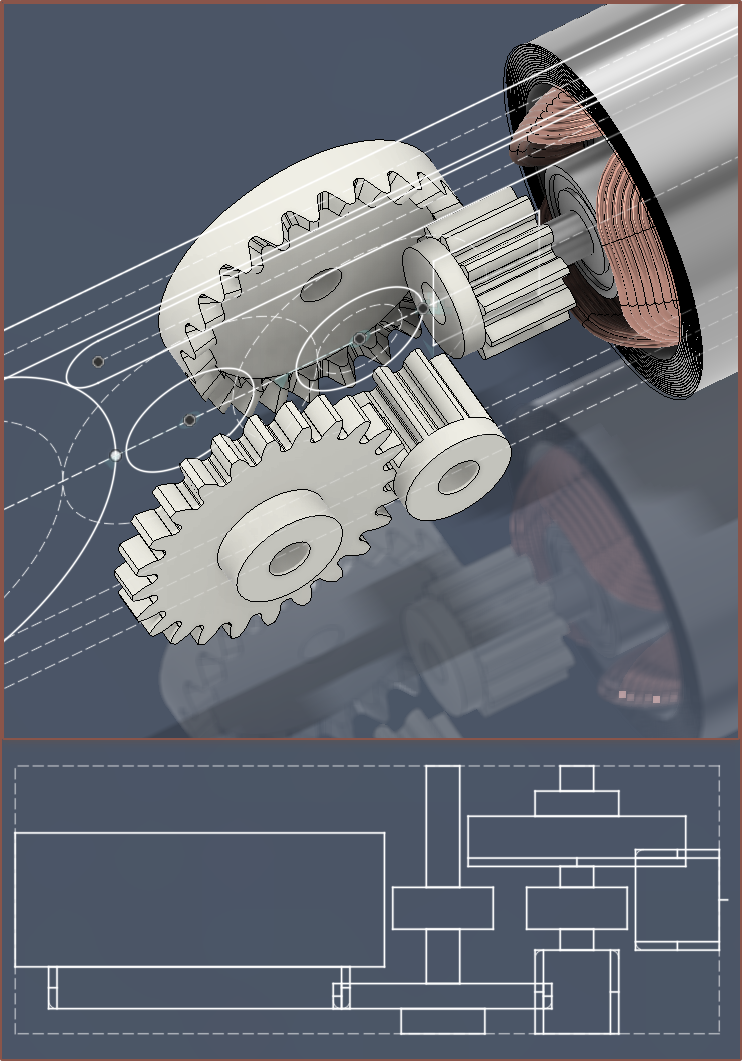

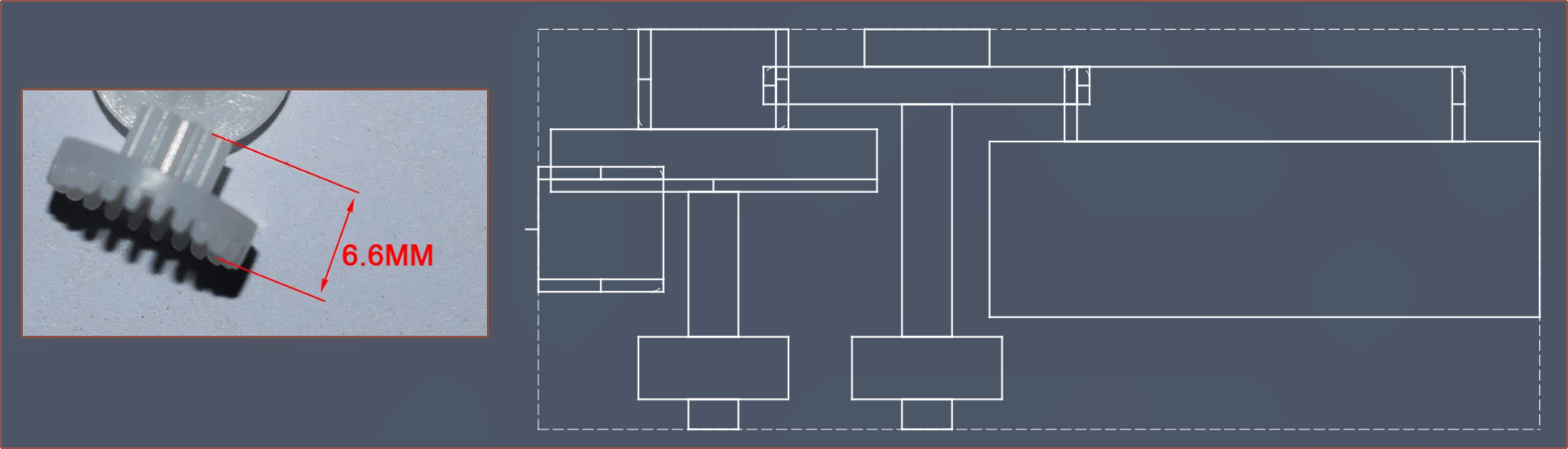

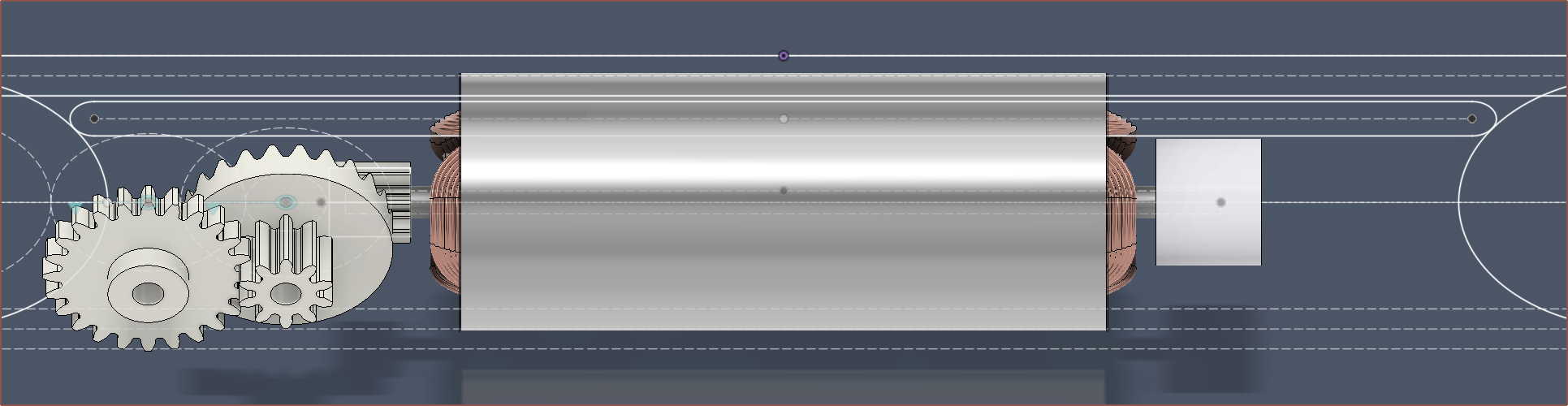

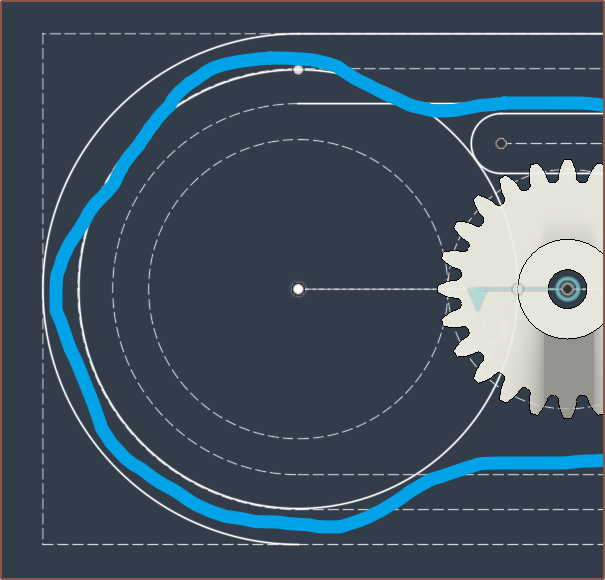

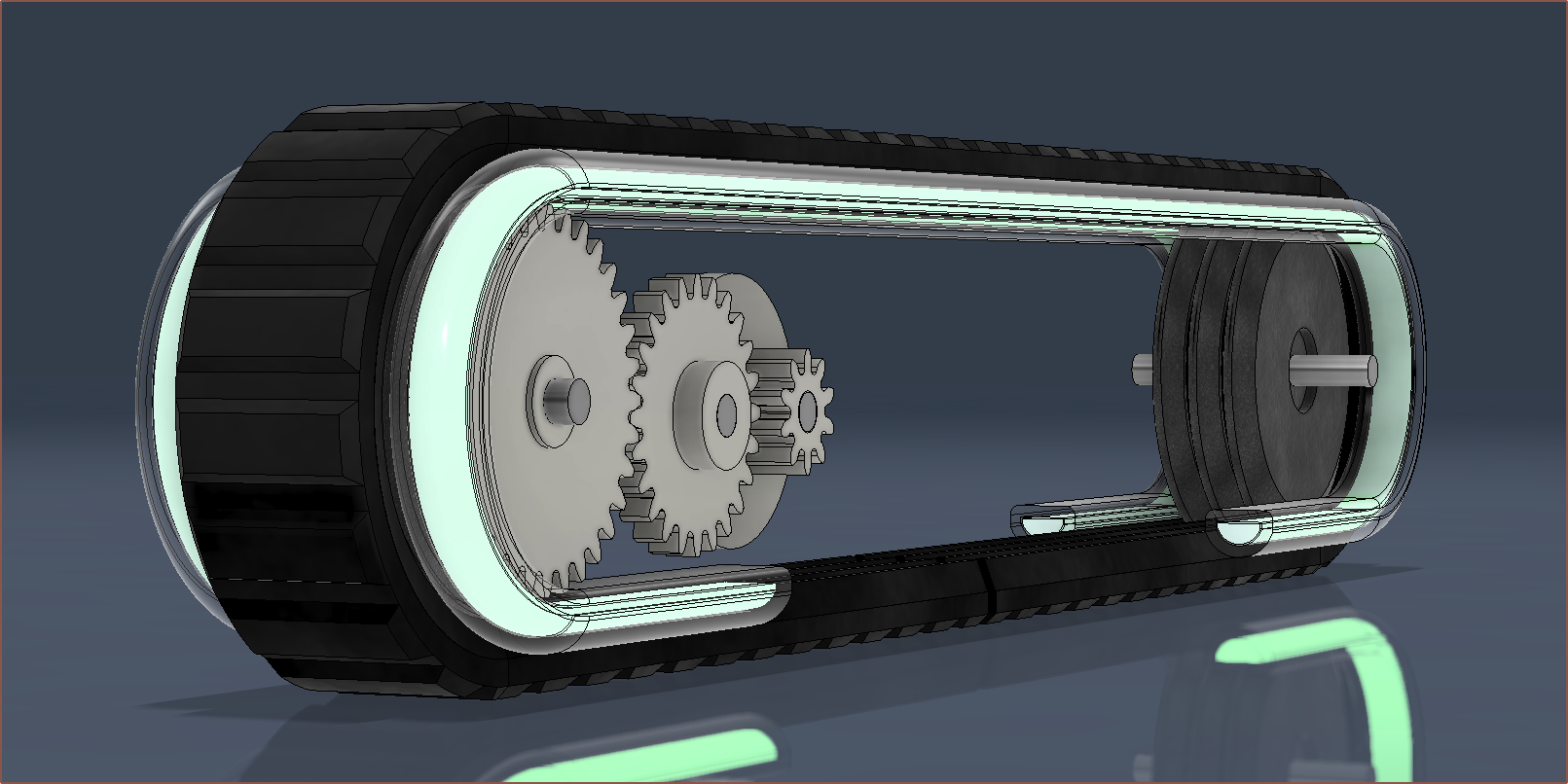

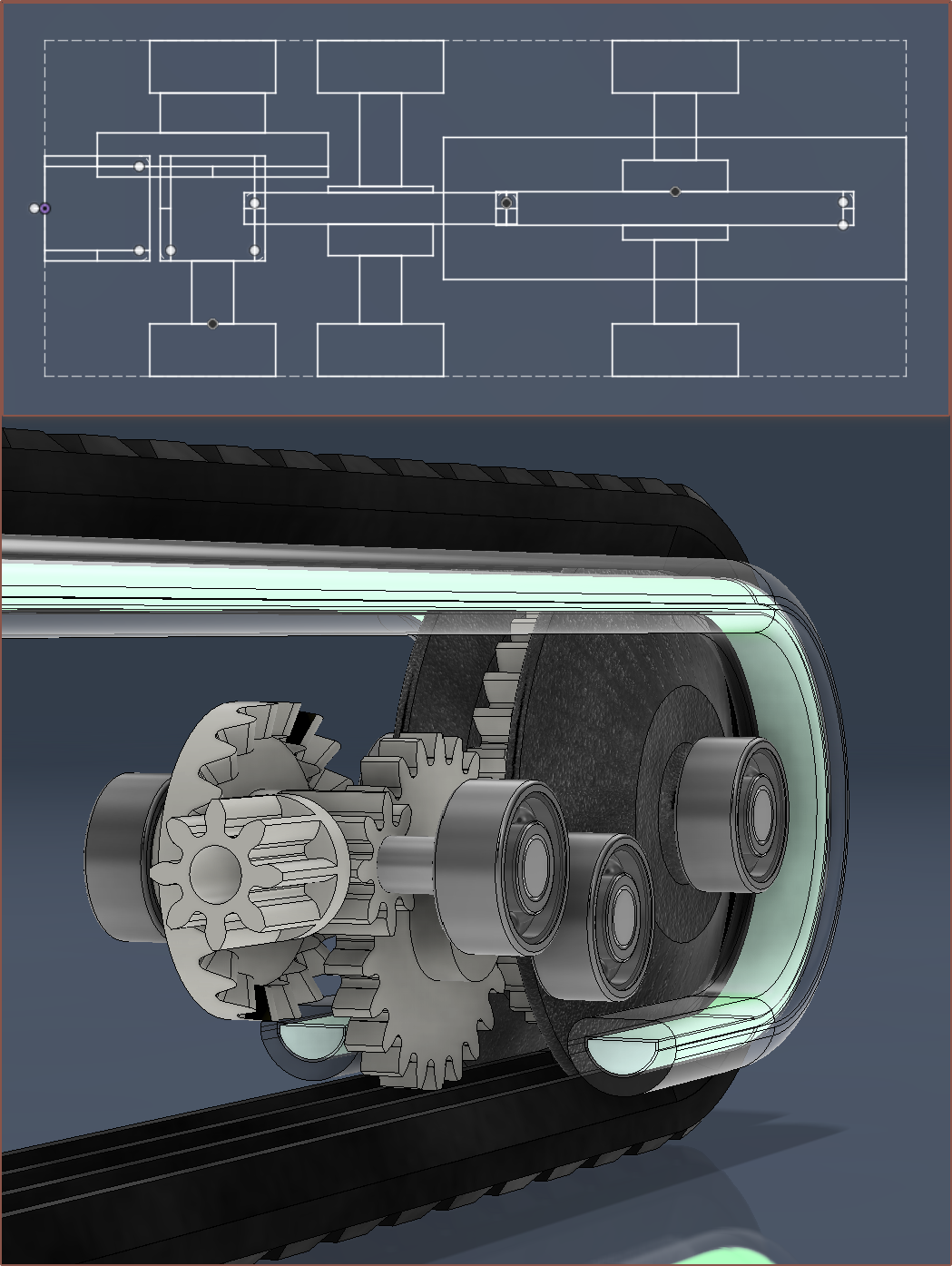

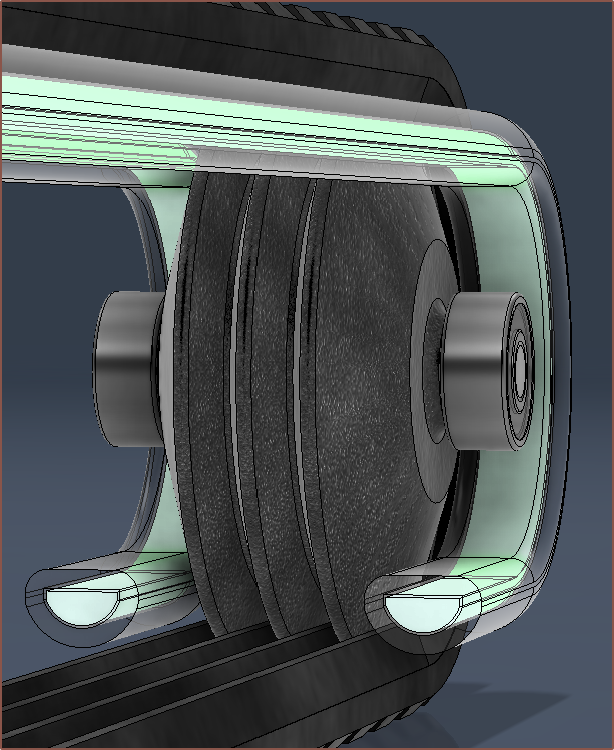

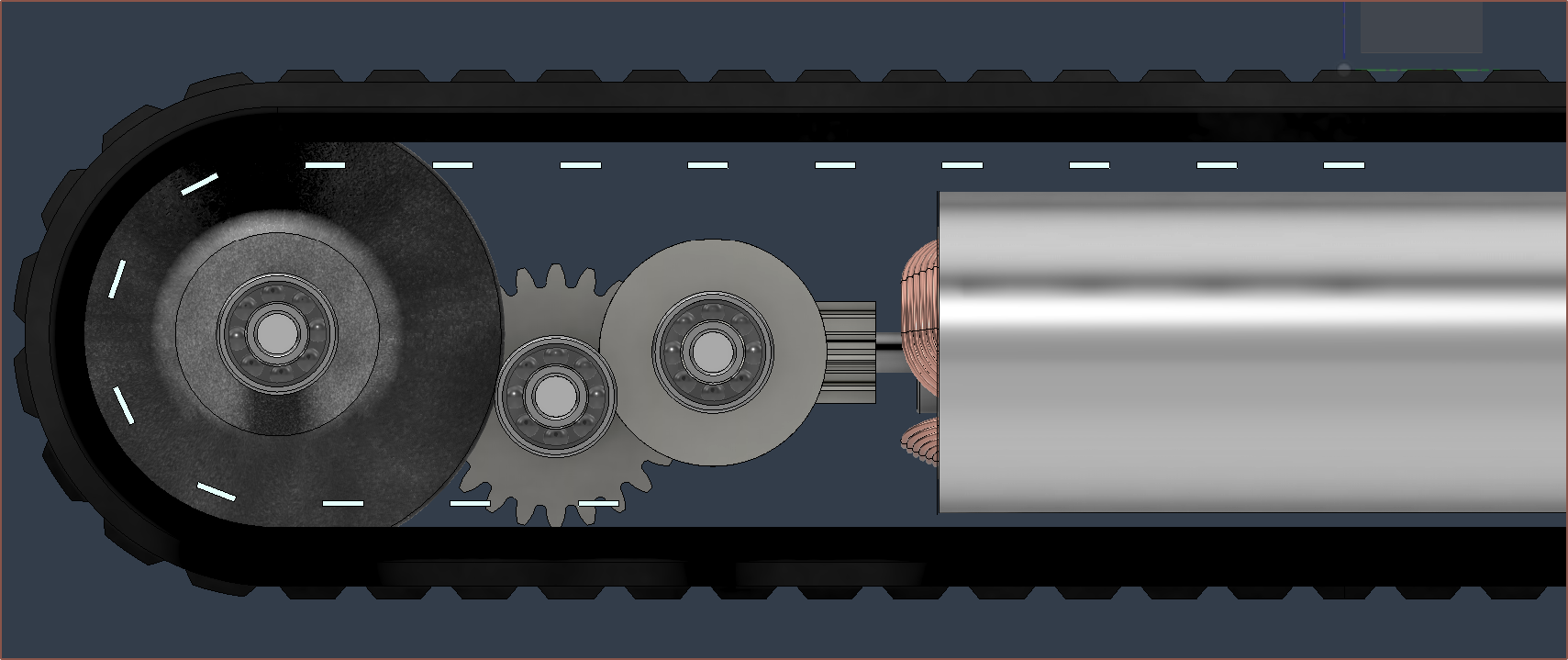

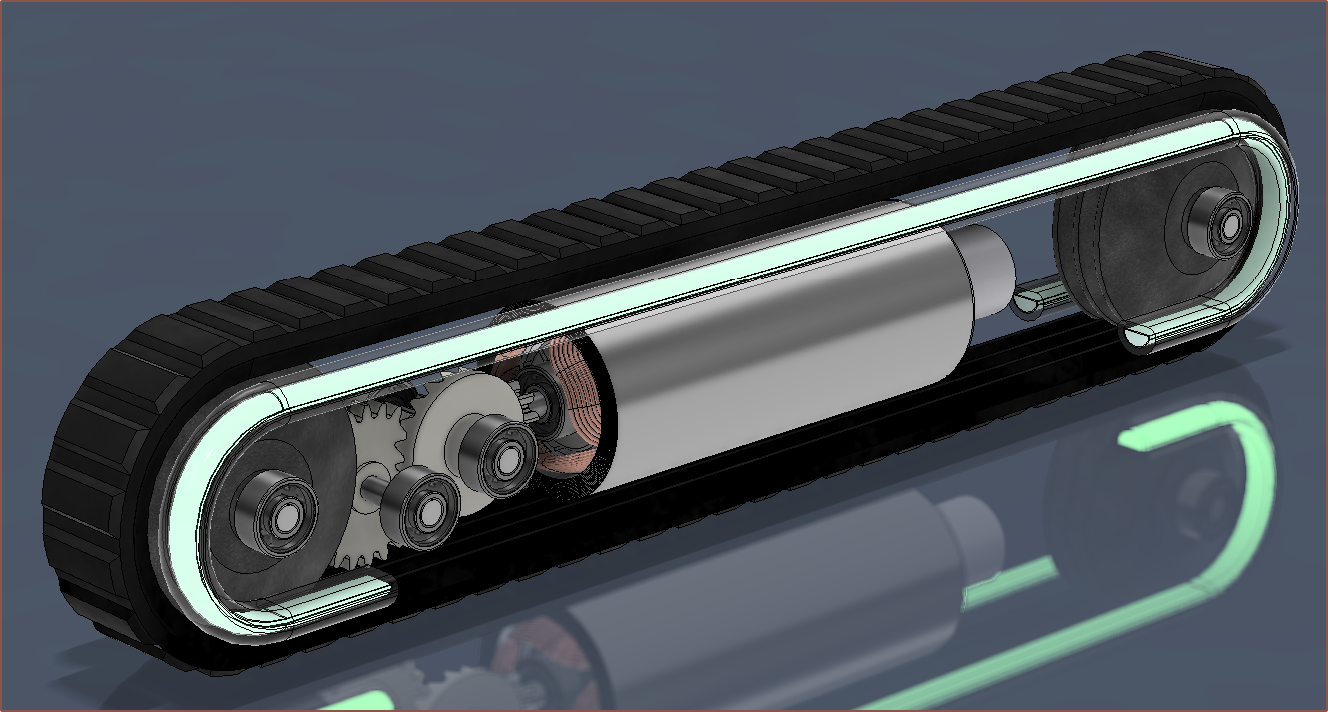

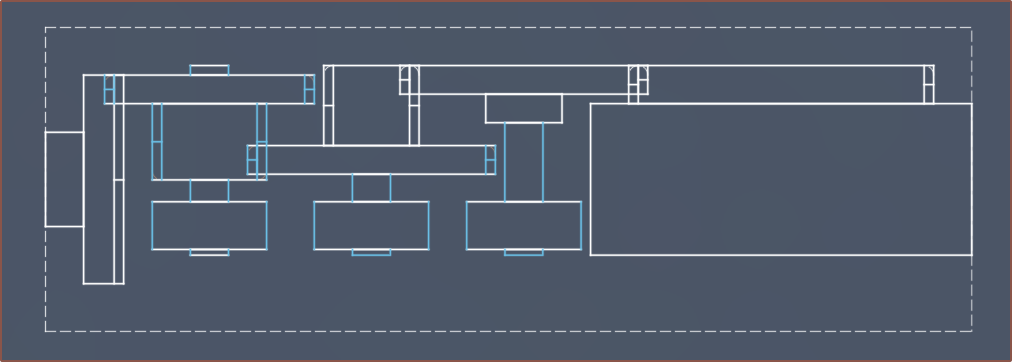

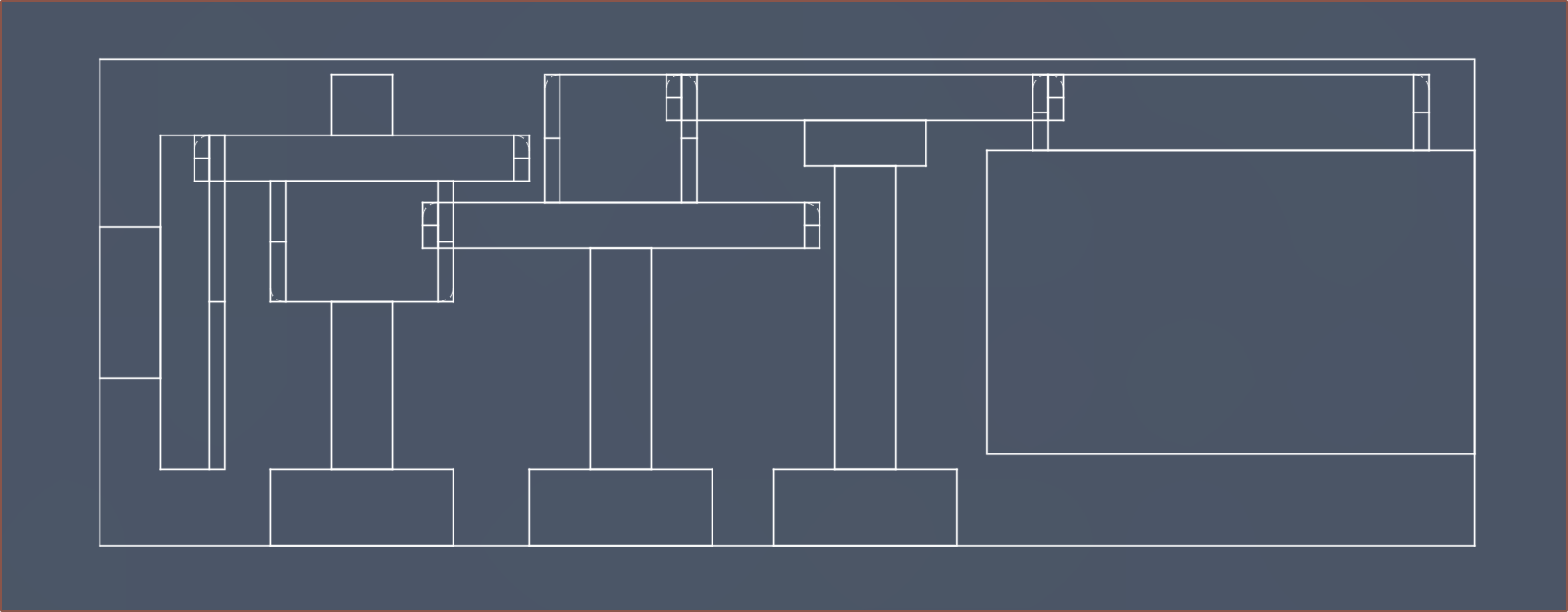

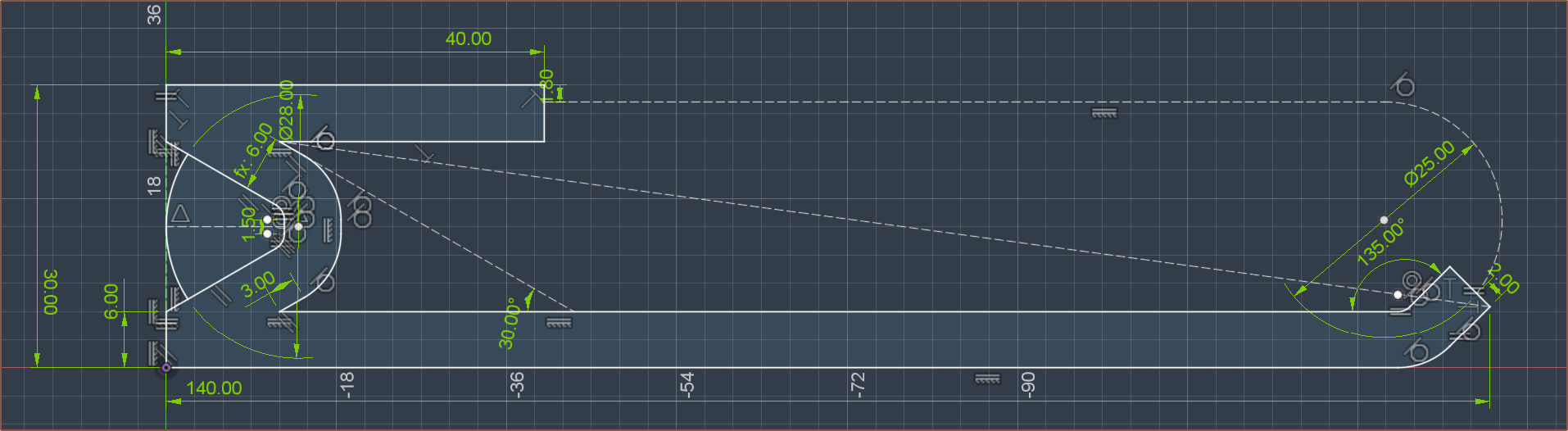

Except for the pulley itself, I've modelled the gears and overall geartrain assembly.

Except for the pulley itself, I've modelled the gears and overall geartrain assembly.

(EDIT: This was supposed to be a reply to the other thread; I don't know what happened)

Well, I love blinkenlichten as much as the next guy, but if I ever made any of these, that would likely be omitted entirely or perhaps replaced by a single WS2812 LED. My ideal input device is something I never have to look at, anyway.

I didn't use the term "voice coils" but that's what a PCB motor (or, really, any electromagnetic motor) boils down to. The whole point of the magnets and (PCB) coils is to eliminate the BLDC motor for haptic/tactile feedback. As I stated, I think the hall-effect sensors would offer good enough position sensing for both motor feedback and reporting motion to the host device.

Absolute position would be easy enough to keep track of in software, and I don't see why you would need absolute positioning across power cycles in this application (although I admit I only vaguely understand the concept beyond "one slider per finger that are also analog buttons" at this point). As the "belt motor" would be coreless, I don't think cogging would be an issue.

"Are there any specific optimisations you're trying to achieve with your idea, such as footprint / price / ease of manufacturability?"

It's just a gut feeling, but I think eliminating the rotary motor & mechanics would positively affect all of these, and maybe even improve user experience. (Although I've never tried it, I'm not enthusiastic about trying to drag bead chains across an OLED with my fingertips for any length of time, with or without a 240g opposing force).

Anyway, I was just brainstorming possible alternative ways of achieving the basic idea, not trying to upend the entire project.