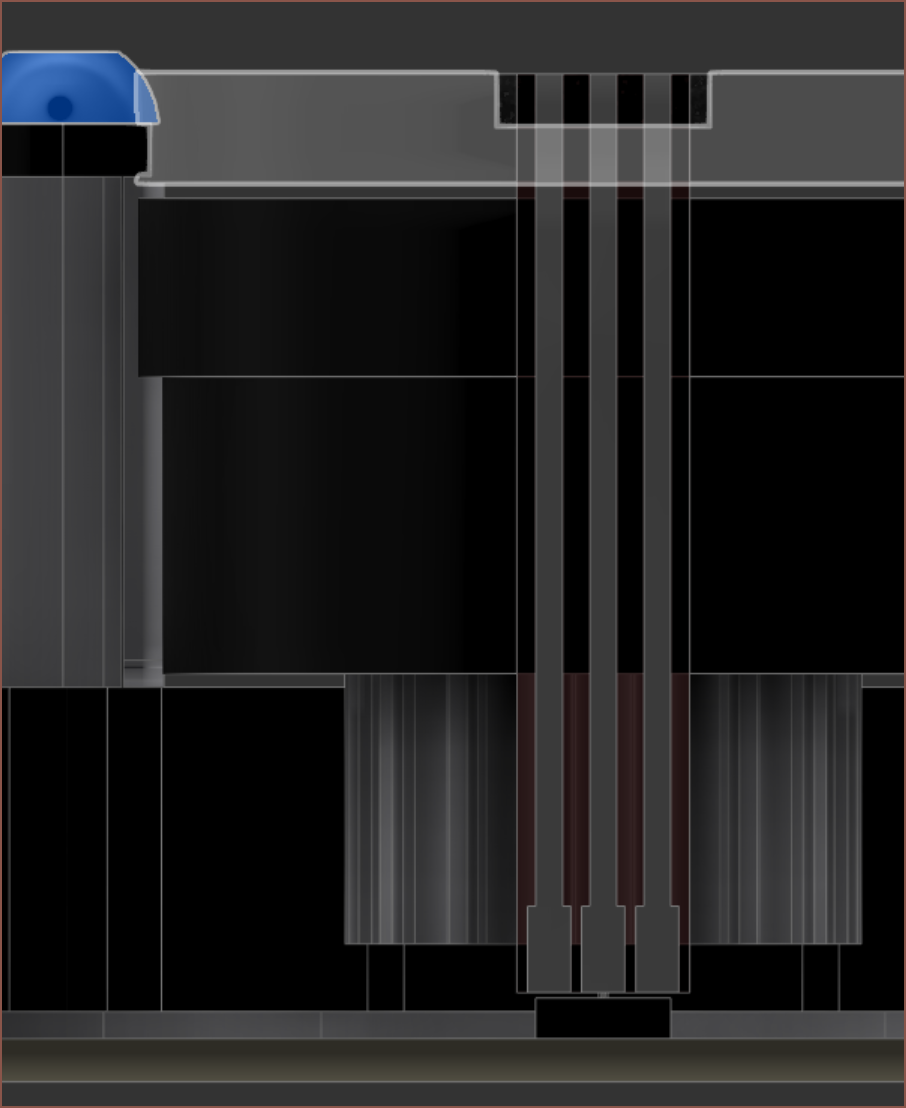

As expected from yesterday's measurements, the built in ribbon cable has no hope of ever reaching the PCB. The bigger issue though is that there's not enough space for an M2 bolt head. I'm unable to understand what these holes are for then. Or perhaps, these motors are cheap because there was an unnoticed design error and a new batch had to be made.

As expected from yesterday's measurements, the built in ribbon cable has no hope of ever reaching the PCB. The bigger issue though is that there's not enough space for an M2 bolt head. I'm unable to understand what these holes are for then. Or perhaps, these motors are cheap because there was an unnoticed design error and a new batch had to be made. It was probably good that I, intentionally or not, waited for this motor to come in.

- Worst case is that I have to recalculate my entire design to make use of that rotor bolt on the other side.

- Perhaps there's enough material that I can just file it down, but it's essentially in a corner so I don't know how close to the surface the file can remove material.

- I could print spacers and try adding holes into the PCB so that the bolt head doesn't interfere with adjacent Tetrinsics.

- This sounds like the most straightforward option.

[E1 - 10:15]

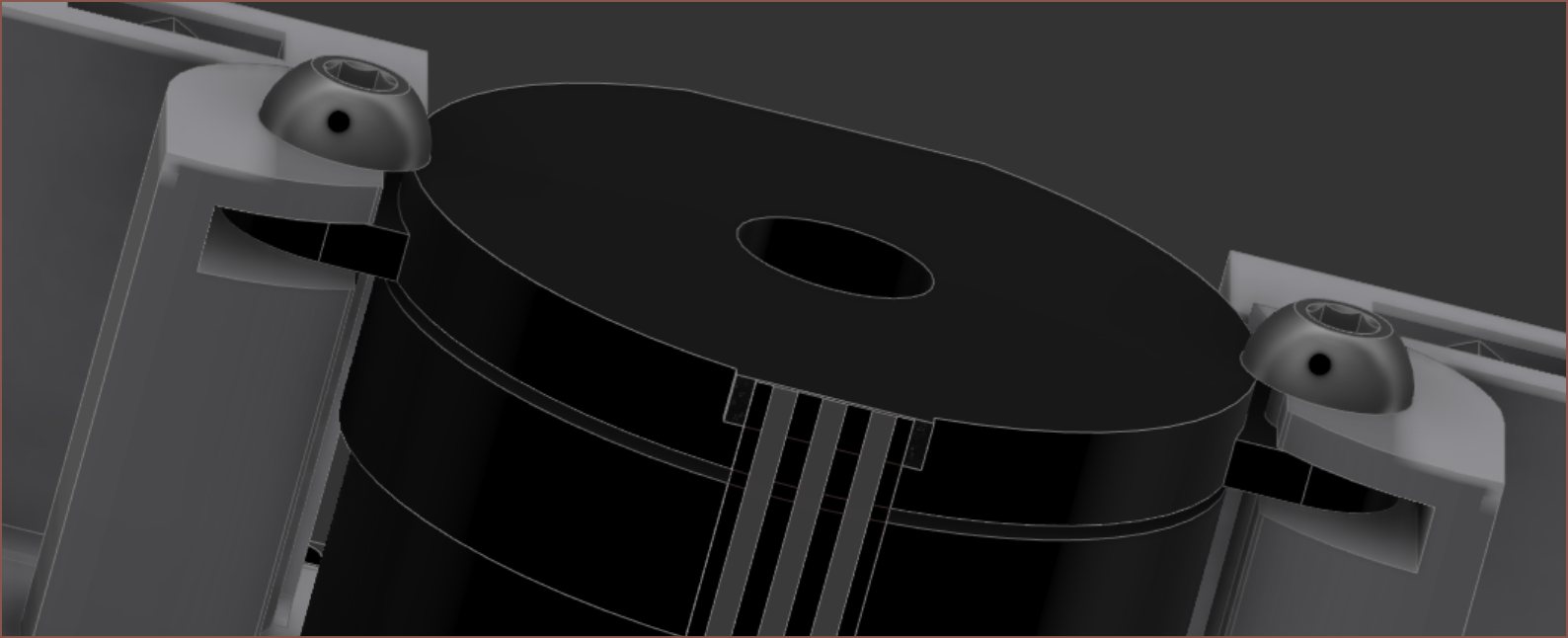

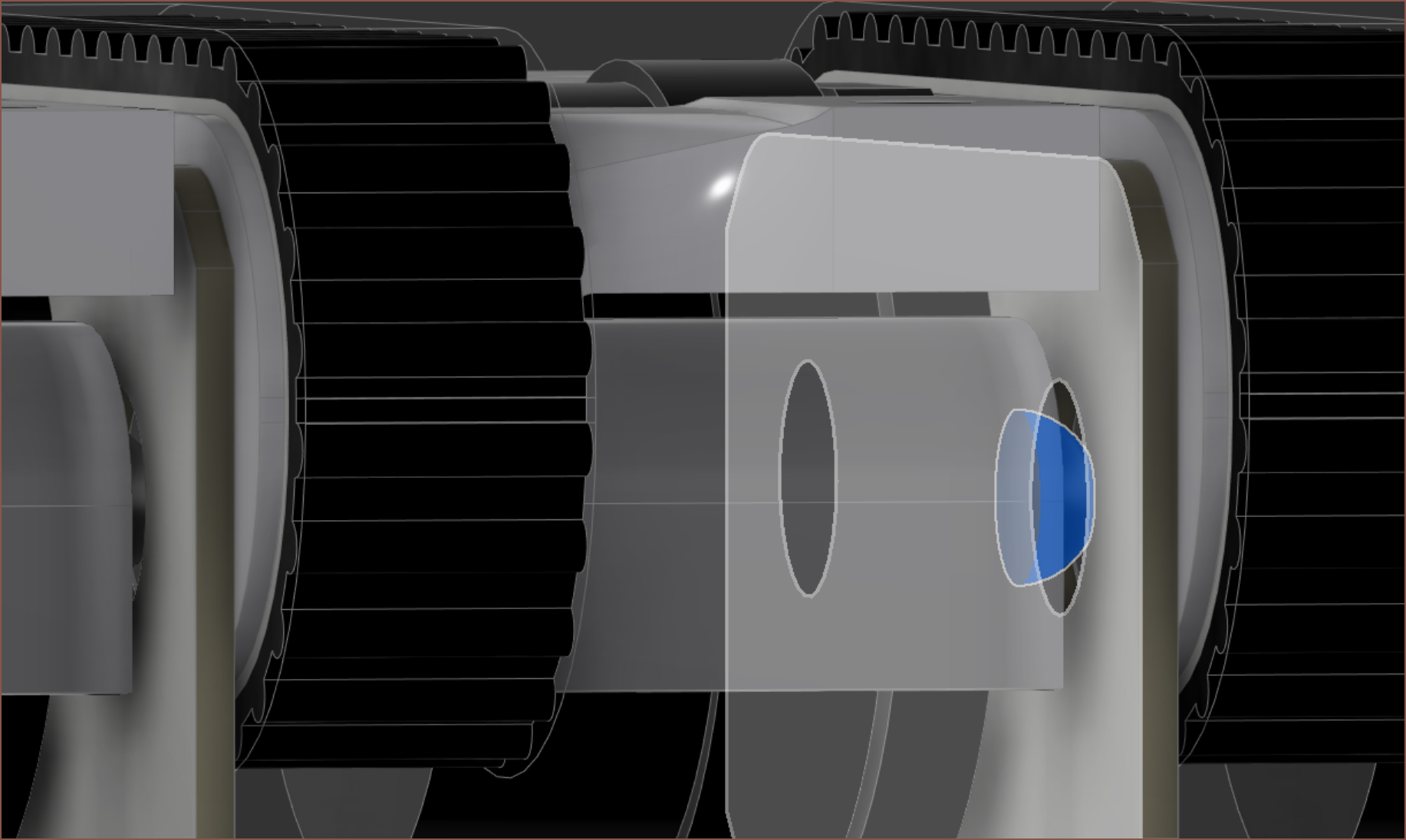

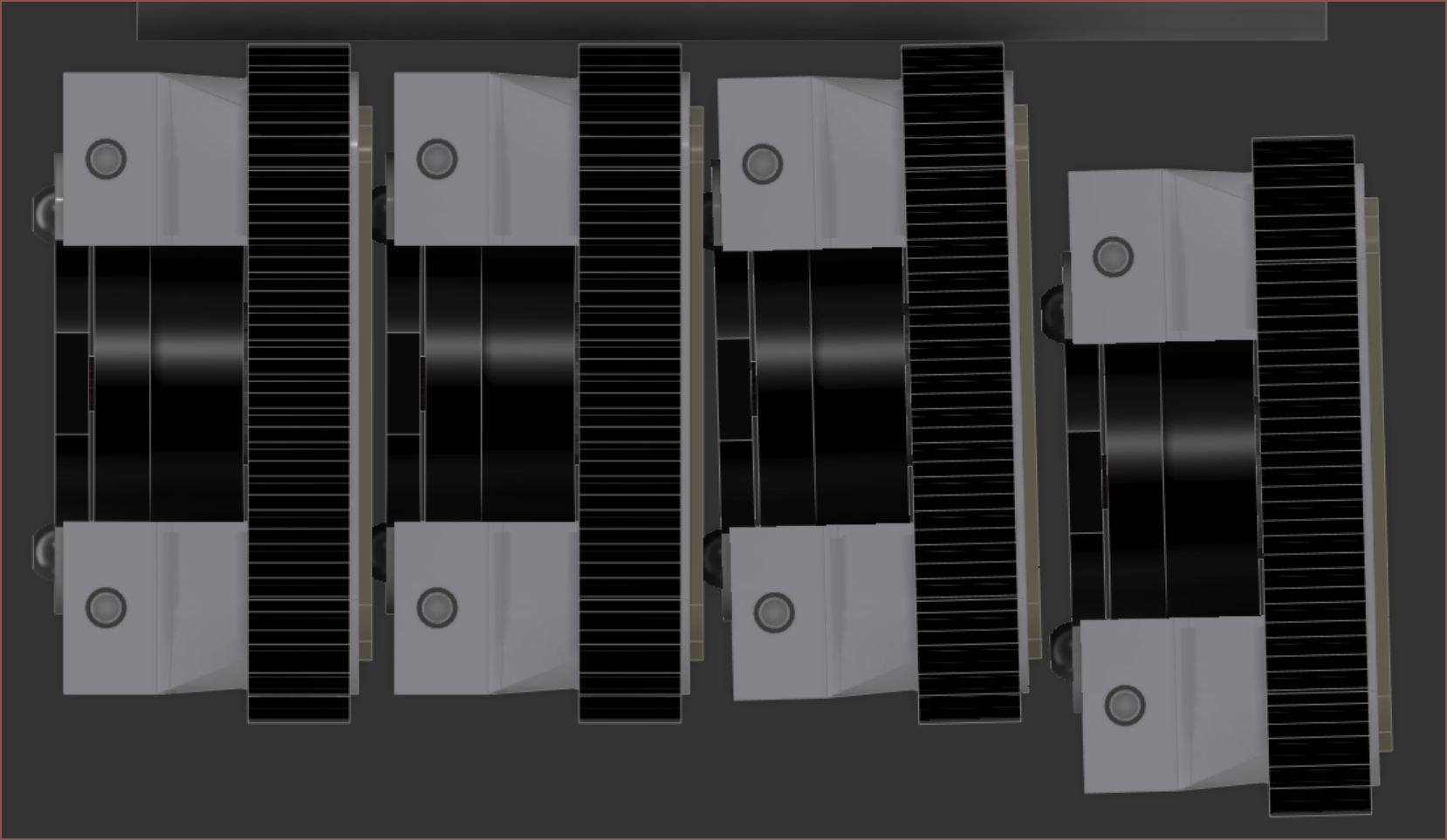

I've modelled the changes and it works in #Tetent Timespy [gd0136] (19.5mm spacing) except for Finger5 which requires 20 - 20.5mm of spacing (I think the bolts in CAD are slightly taller than the physical ones).

I'm wearing the Timespy concept now and I think it would benefit from the move anyway. While I'm on the subject, I'm also going to move Finger5 down for better ergonomics.

I'm wearing the Timespy concept now and I think it would benefit from the move anyway. While I'm on the subject, I'm also going to move Finger5 down for better ergonomics.I've removed the branding for the time being since the PCB keeps changing anyway

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I've been trying to think of a solution that's smaller (15mm high, 17mm wide as opposed to 18.4x18.7) by having the motor rotor face downwards for the past few days, but I am unable to think of a better design than what I currently have, in terms of part count and reliability.

The reason why I'm looking into such an option is because I feel that the thinner Tetrinsic is, the more ergonomic Tetent solutions can be. Size is less of an issue for TestCut, but one of the main requirements of Tetent was that I could use the same layout for both desktop (as in, on a desk/lap) and mobile (smartphones, wearables like Timespy). Mobile is more useful.

I also wanted to increase the amount of available space so that the potential for a cheaper absolute encoder could be used. The current BOM estimate of £20 is not easy to swallow when I can be using up to 10 at once, and have multiple devices. I think 40% of the cost is in the ADC and encoder.

I just want to make sure I've explored other options before I continue converting this concept into reality.

Are you sure? yes | no