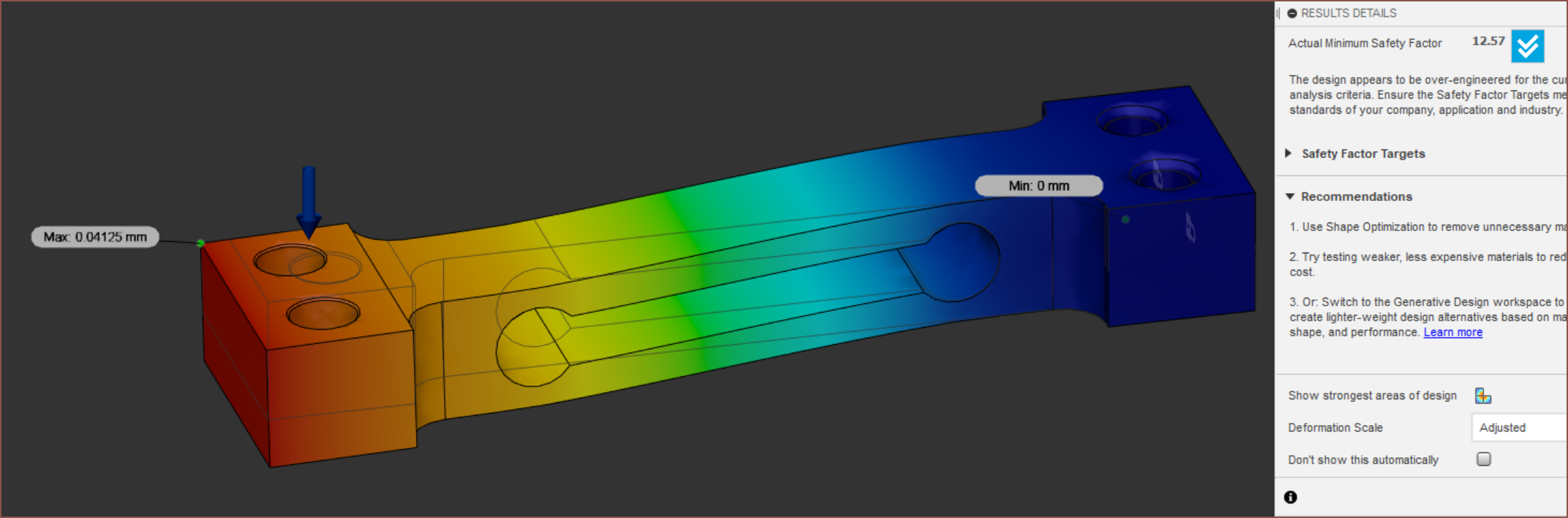

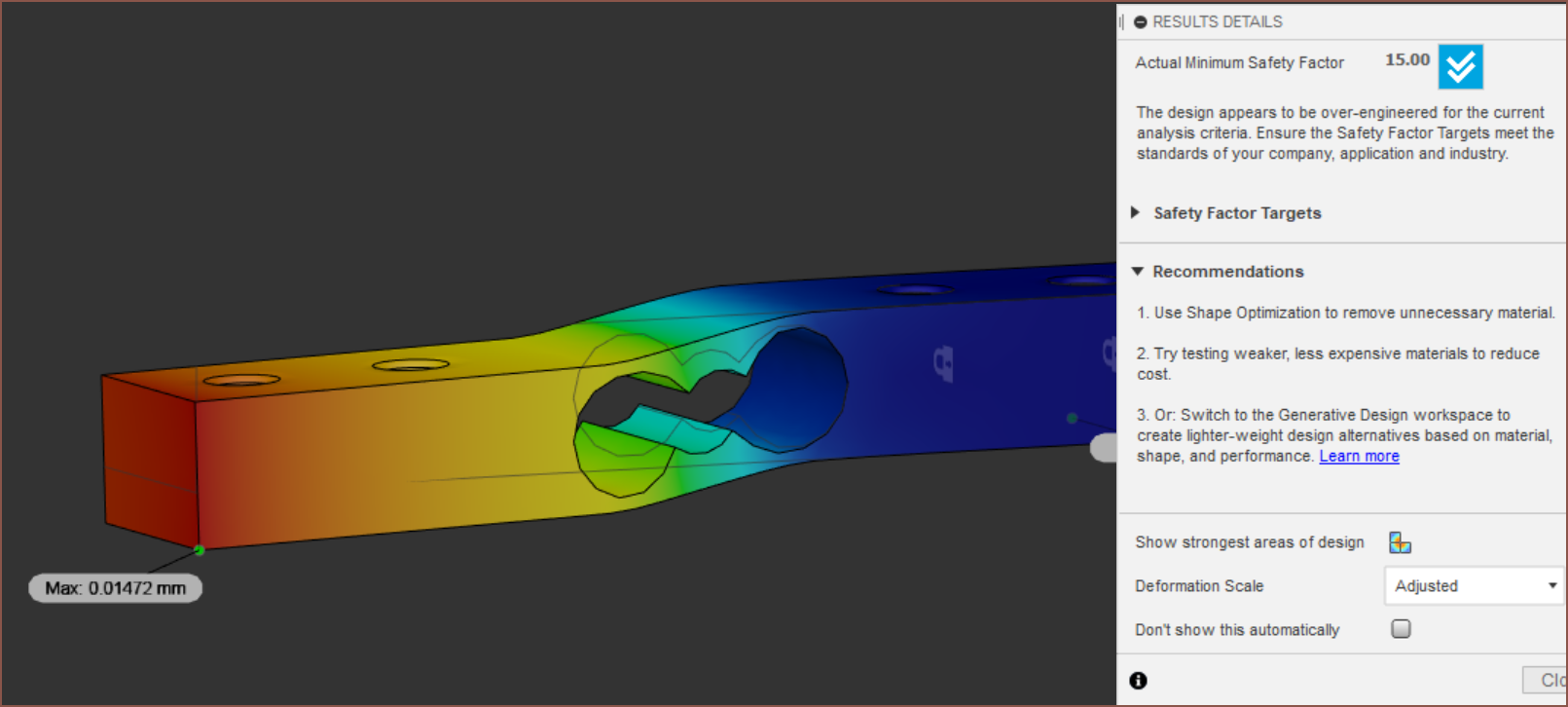

I thought about it overnight and started the day with a simulation:

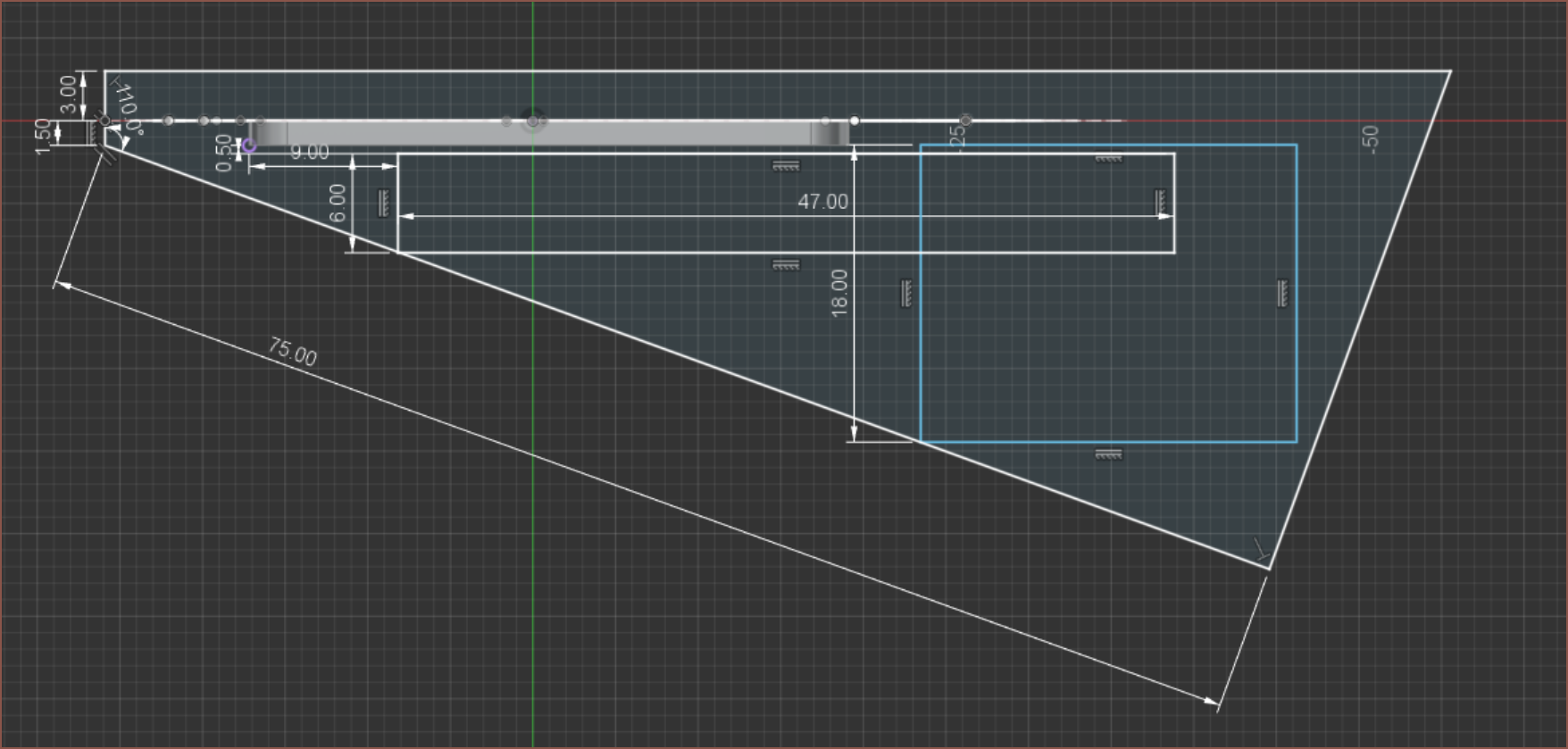

Then I went to plan it, and the solution failed due to instersections between the load cell and the motor block:

If I went with the 750g load cell, I could cut it to get it to fit. Even then, the silicone protection makes the max thickness somewhere around 8mm and things would likely intersect again.

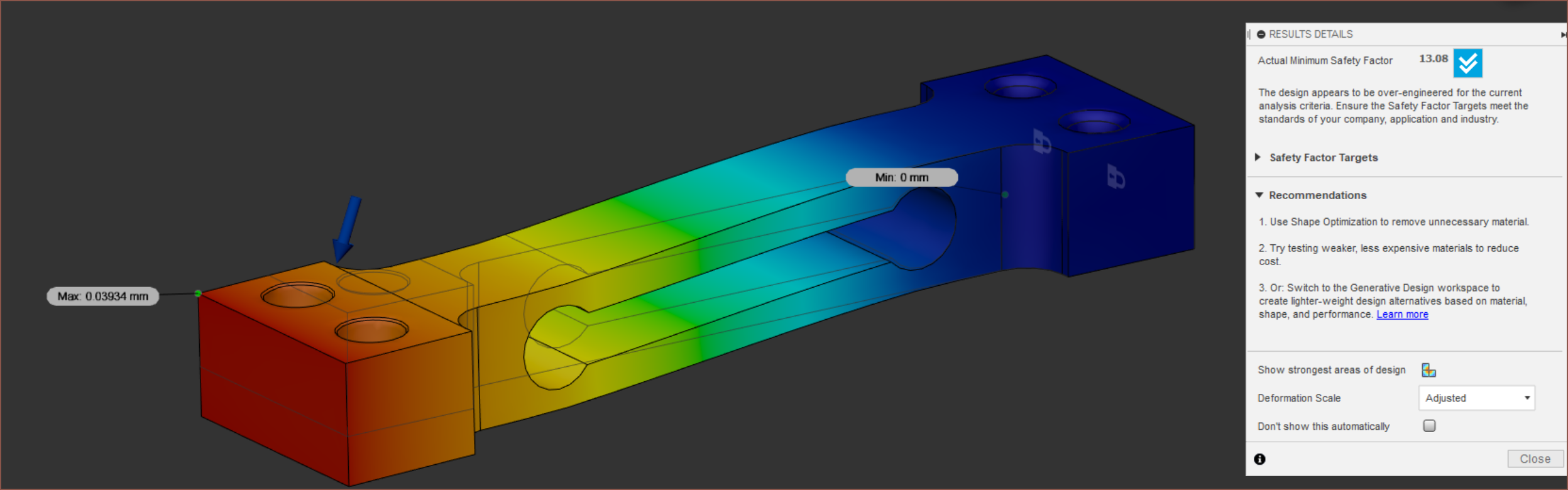

Then, I thought about how much of an impact a small 17.5 degree angle would be to the load cell. 1/cos(17.5) shows that the load cell's rating would only increase by 5% (e.g. a 300g load cell would become a 314g load cell). I did a simulation and the bending shape still looks fine:

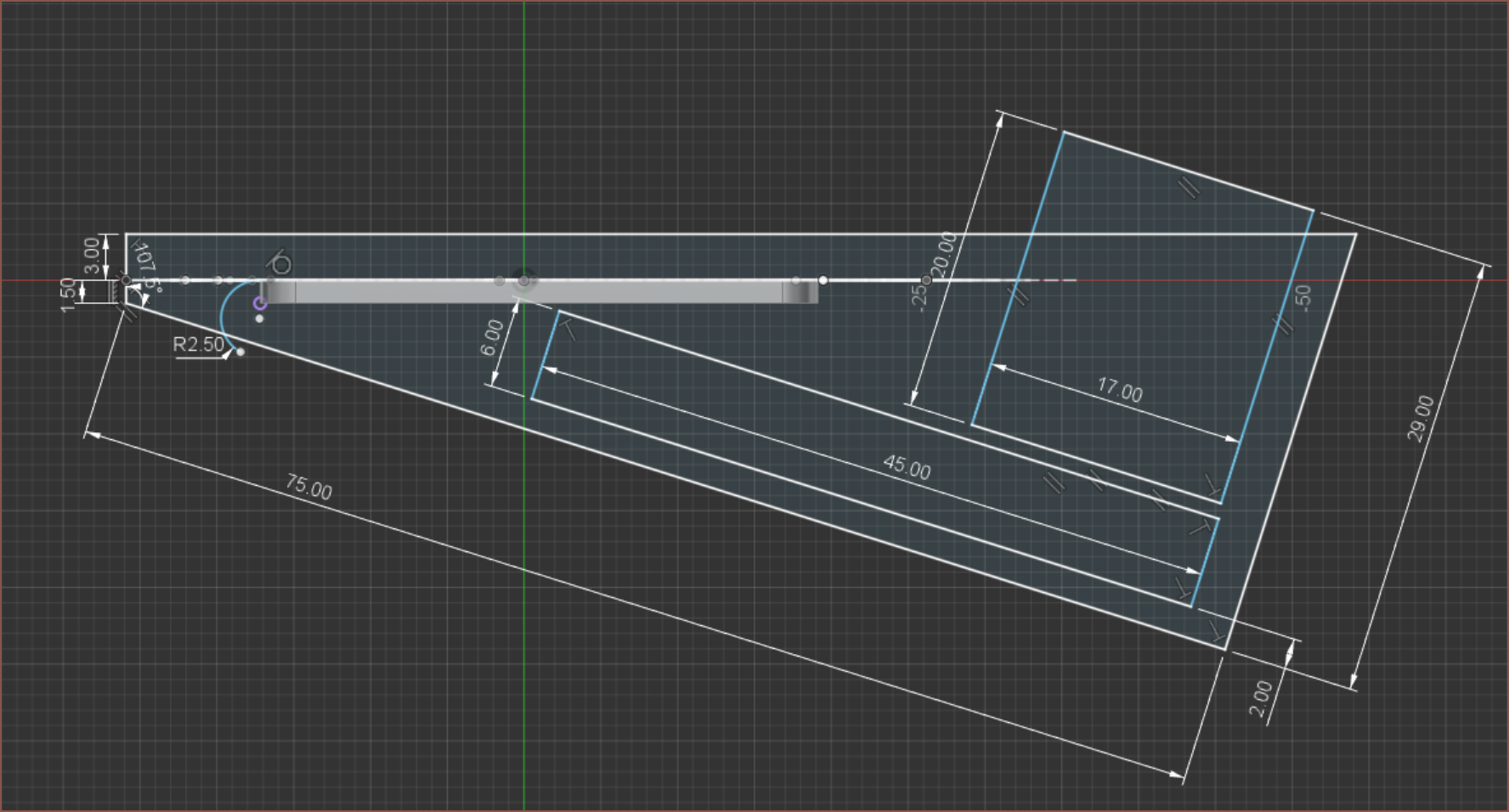

Sketched it in Fusion:

Way overbuilt, but the other version of this cell is rated for 300g, which is not enough. Additionally, I have to consider the forces exerted on the mounting points, and the mounting method on this is much more likely to be rigid. Lastly, all holes are tapped on this cell, which isn't the case for the 500g cell.

Way overbuilt, but the other version of this cell is rated for 300g, which is not enough. Additionally, I have to consider the forces exerted on the mounting points, and the mounting method on this is much more likely to be rigid. Lastly, all holes are tapped on this cell, which isn't the case for the 500g cell.The BOM is now £23.38/each, but now I can use an over-rated, off the shelf, precision load cell instead of having to print and build 10+ mystery-machine load cells.

I think a solution exists for a 19.4mm Tetrinsic (LCD width limited) and I think #Tetent TestCut [gd0139] could work with that slight over-surface protrusion.

Solution mining... ends, in 26 days.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.