The concept print: https://hackaday.io/project/184181-tetent-gd0090/log/221171-p-concept-half-print

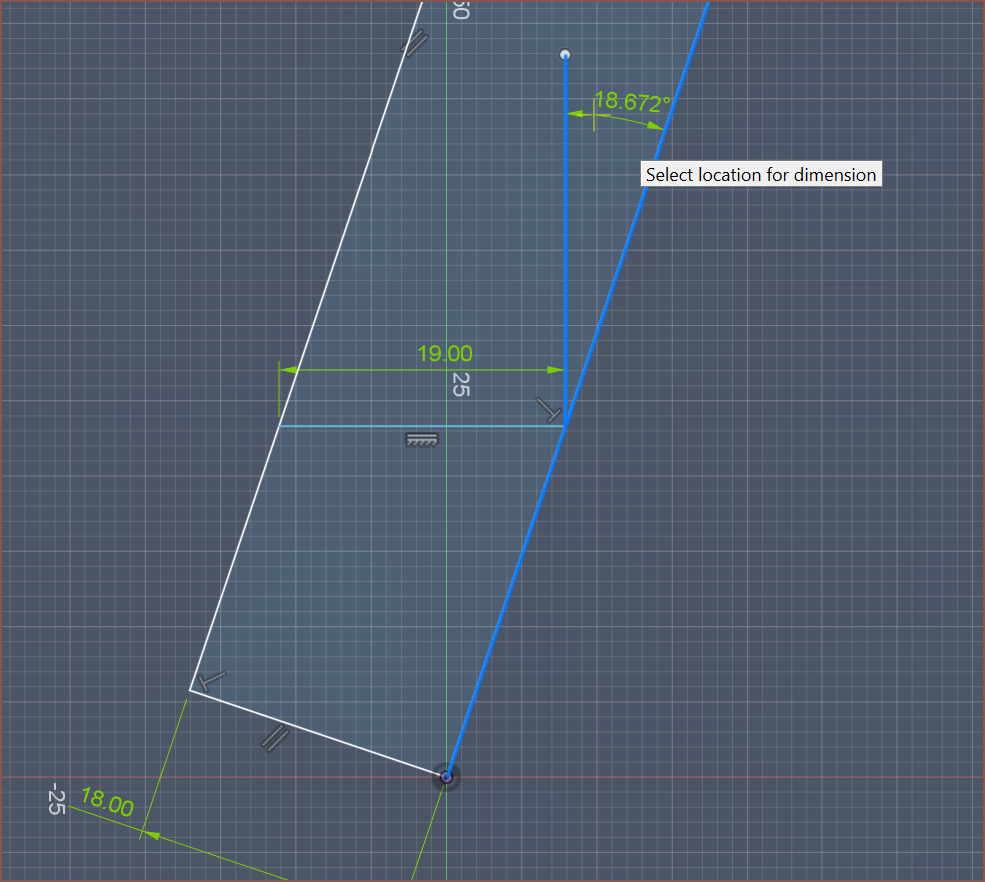

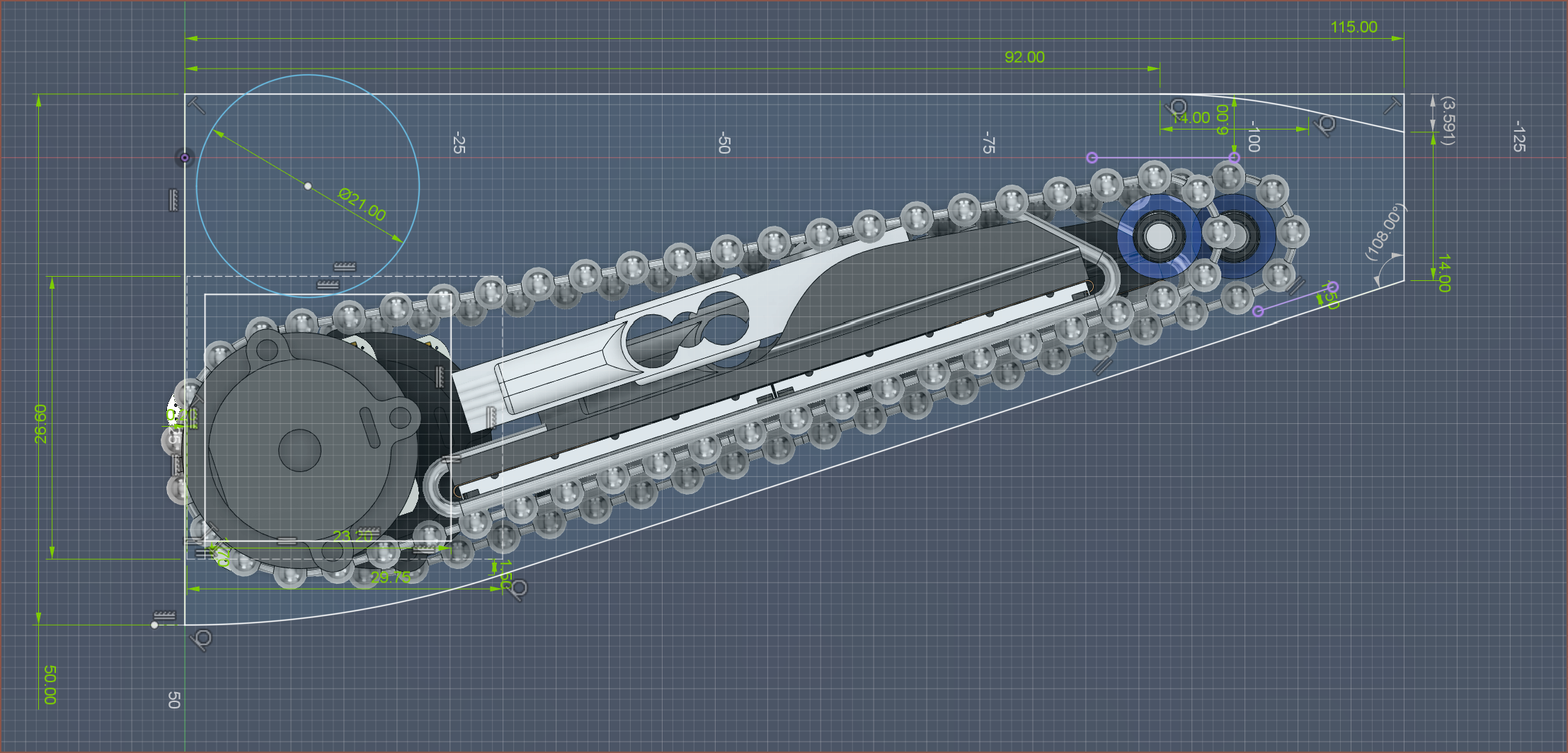

Essentially, I'm going to have to mandate that 18mm thickness I just so happened to acheive when switching to this 3.2mm ball chain solution. I've also got to aim for a slope angle of 18 degrees.

Solar Cell

First, I wanted to research on my off-the-shelf solar panel options. I have a feeling that I could always cut down a larger panel if I get the process right, but off-the-shelf reduces manufacturing requirements on an already multi-fabrication design (wire bending, 3D printing, PCBA, aluminium milling).

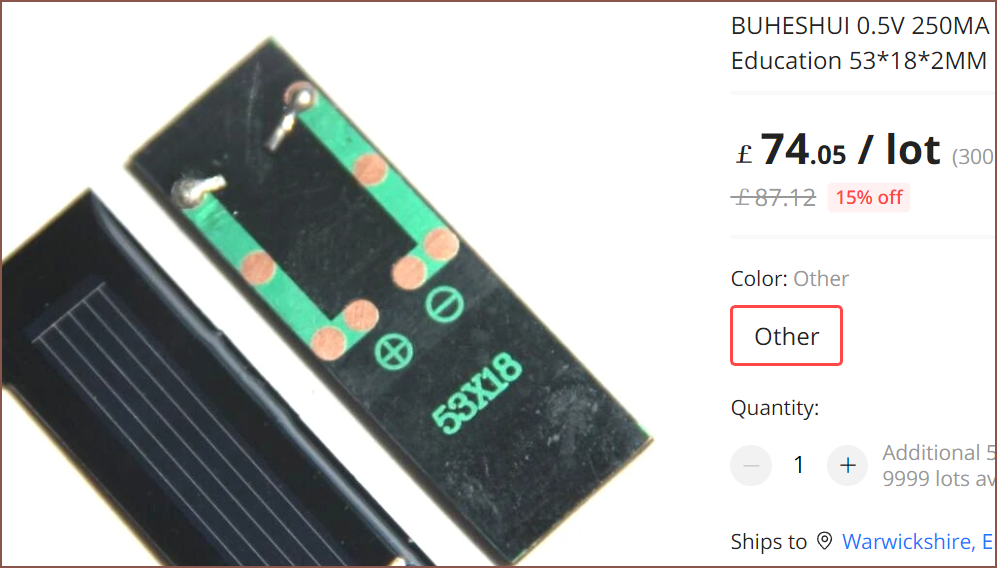

First thing I saw was this:

Something felt kind of... off, since I probably would've been fine with this already if I got 0.25A from one. It turns out that most of them are understandably only 0.1A:

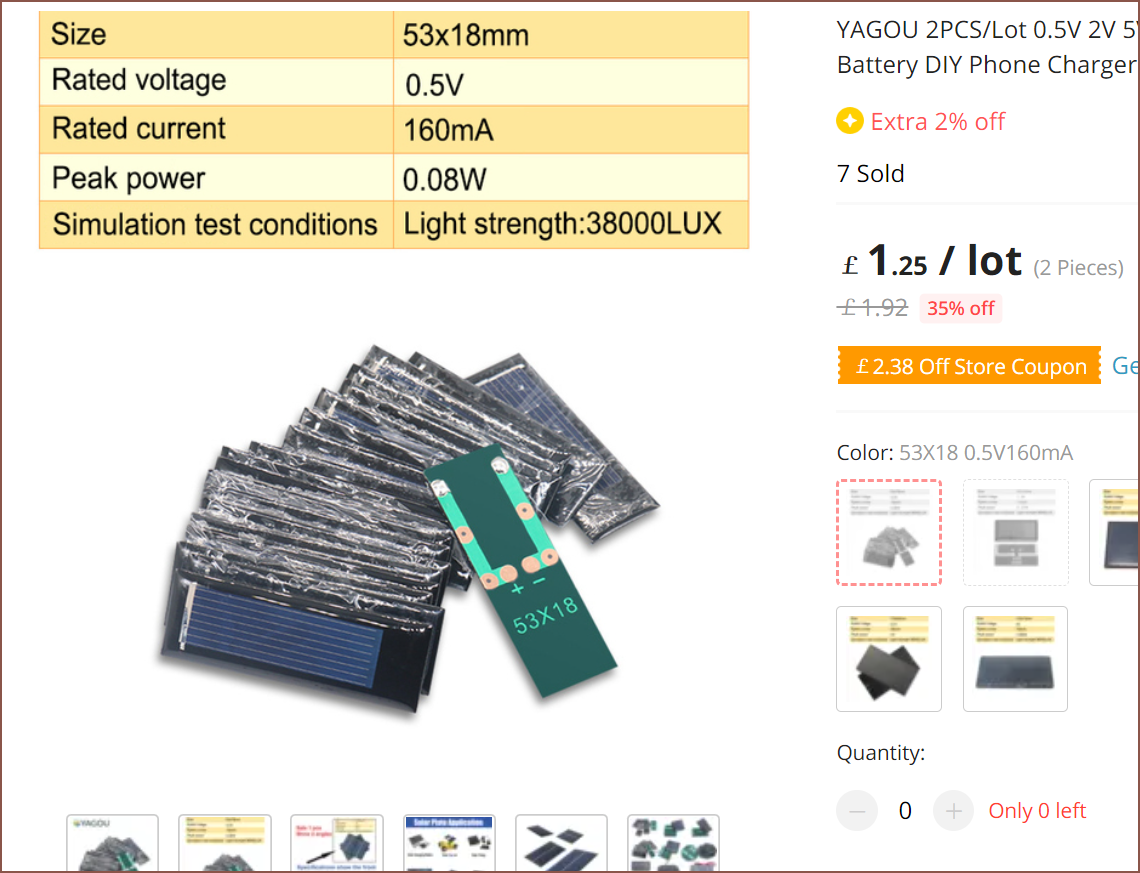

I was able to find one that produced 0.16A, and it visibly has more solar panel area inside:

Oh wait. I just found the below video. It's super easy -- barely an inconvinience -- to cut a cell:

That means "reality can be whatever I want". The cheapest, highest efficiency cell that I can cut to size would be the 78x19mm cell I found earlier on, but it's more efficient from a cost and manufacturing standpoint to cut 2 panels at once from a 78x39mm cell:

There's also a seller that has a 15mm wide kit:

Modelling

Sometihng interesting to know is that, if spaced precisely 18mm apart, I'd achieve a 18-ish degree "stagger" with a horizontal spacing of 19mm:

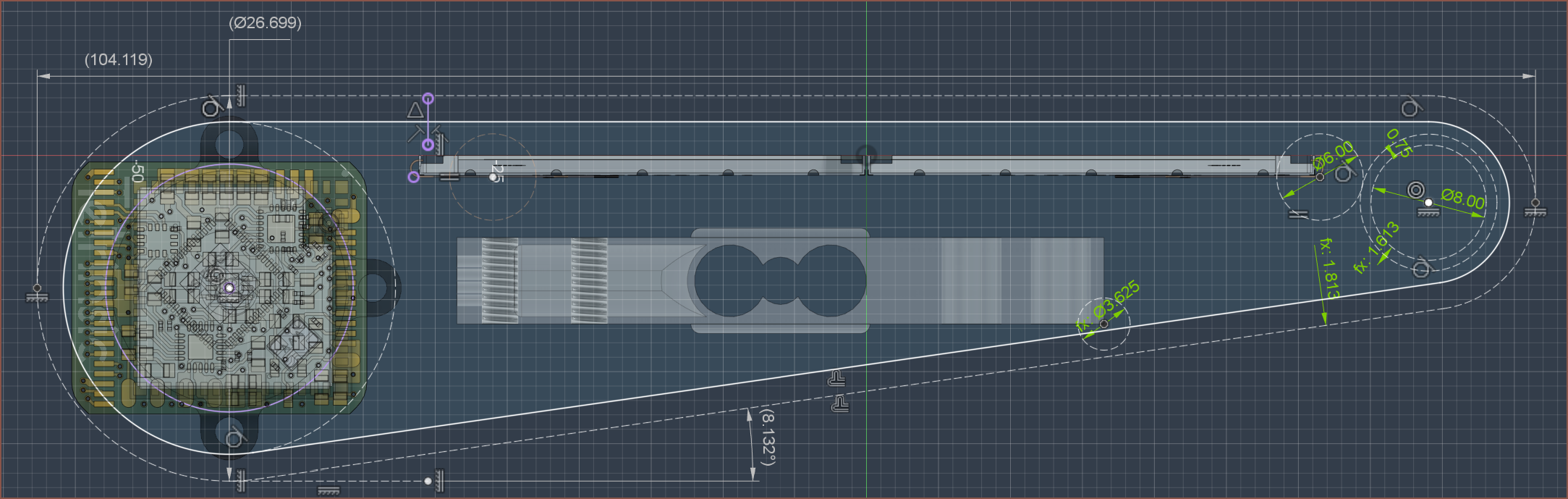

Anyway, the new design is a rather long 104mm:

That, along with the steeper angle, makes for some issues downstream:

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.