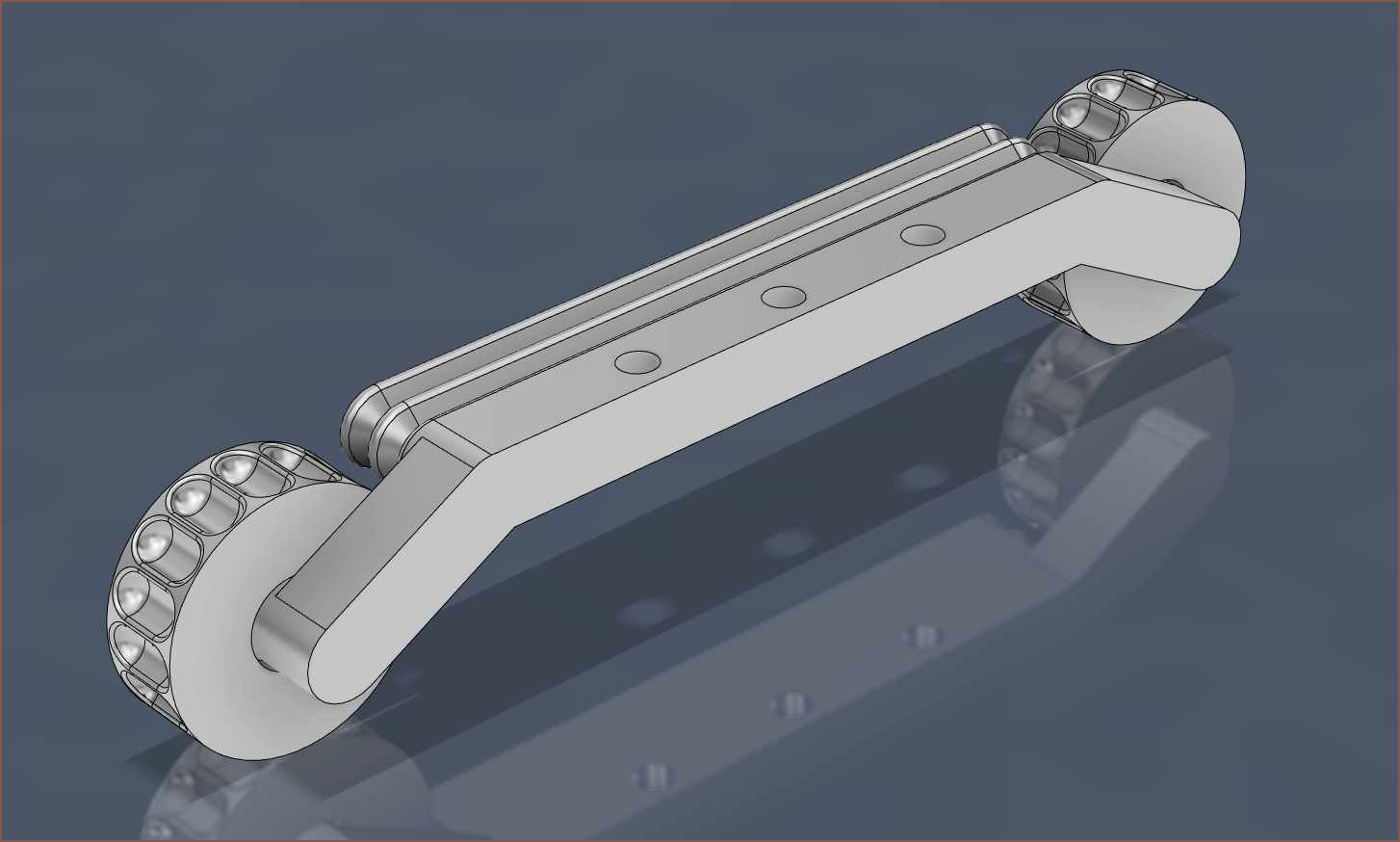

[15:45] I've designed this print-in-place test part to obtain the correct chan fit before I start redesigning the main file all over agian. I'm also going to design for a less ambitious 4mm internal tube bend instead of 3mm as in the main file.

The hope is that I can subsequently print multiple of these and then test ergonomics of possible Tetent designs.

[17:00]

The first print is welded together, but it does seem that the first try tension equation of:

SprocketDistance = 20 * BallSpacing

has worked out ok. For a ball spacing of 20, there are a total of 21 balls between the tooth of the first and second sprocket (a.k.a 19 balls floating in air and 2 balls in contact with the sprockets). In the next print, I'm thinking of trying

SprocketDistance = 20 * BallSpacing - 0.2 mm

in an effort to aleviate any excessive stresses, as right now it's as tight as a tensioned GT2 belt. Not sure if that's good or if it'll mean I have issues with friction yet. This model has a length of 116.2mm, so I'd imagine that the final would be 116mm or less.

When I attempted to create the chain loop, I actually had one too many balls in the chain so I respliced it. Even though there are 2 reformed balls in the chain, it still seems sturdy enough. I'm not sure if this is just a limitation of the tool or another "Used, Like New" problem, but the ball dies on the Maun 5066 don't acutally meet and so the ball isn't completely closed.

[7 Aug: Edit 1] It has been identified by the seller as having a manufacturing fault.

[/Edit 1]

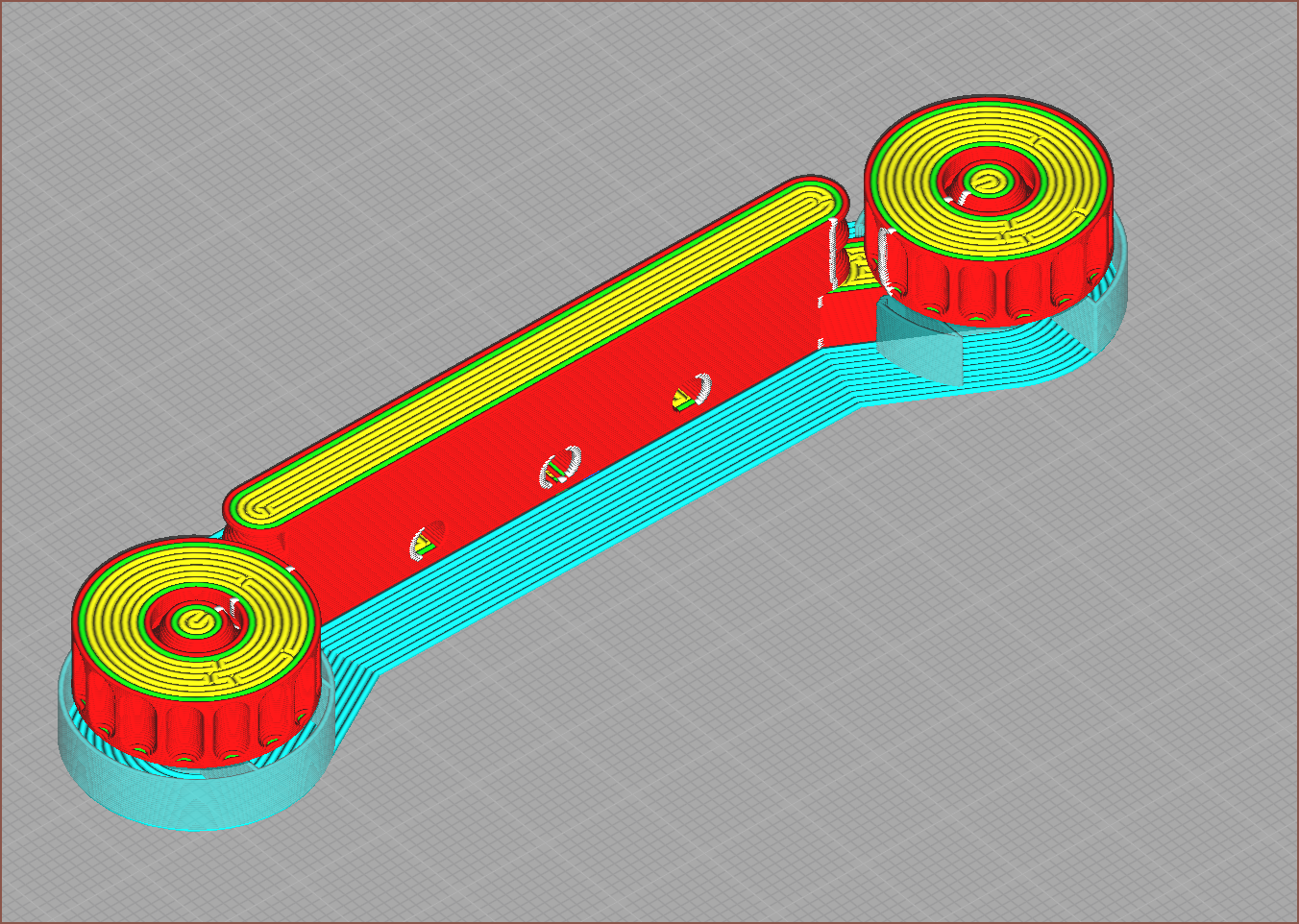

This time, I'm going to print this upside down to see if I can avoid first layer squish issues:

If anything, it'll give me a chance to improve my support settings.

[18:20]

As expected, the undersides of the sprockets are rough, but it actually spins now, albeit with quite some resistance. The full length is now 115.7mm. Now to figure out how much of an offset I can get away with.

- The sprocket with the ball chain is 26.2mm, the sprocket by itself is 22.0mm (it was modelled as 22.2mm).

- The full length without the chain at all is 111.8mm, though it's supposed to be 113.0mm.

- This can be explained to the looser tolerance, as the first attempt was 113.4 modelled, 112.8mm on calipers.

- The above 2 bullet points imply that the chain sticks out of the sprocket by approximately 2mm.

- Not sure how relevant that number is to this calculation, but it's nice to know.

- The chain is still taught on the second print even though it's 1mm shorter than the first one, so perhaps I don't need a super critical tolerance and can just design a fixed length solution.

- It does feel slacker though.

- I guess a refined equation is probably the equation below:

SprocketDistance = (Ball_Amount - 1) * BallSpacing - TensionOffset - 0.6 mm

- JLCPCB is likely to make the parts much closer to the CAD model than my Linear Plus FFF 3D printer, so that's what the "- 0.6mm" part of the equation is.

- Since the first print was probably the max achievable tension and the second print is closer to the minimum, I'll assume that the range of TensionOffset is from 0 to 1.2mm. Thus, if I use an offset of 0.6mm, I'd have ±0.6mm of tolerance to work with. However, it's likely to be in my best interest to have a TensionOffset closer to 0 than 1.2mm.

Ok. Noted.

Another thing to note is that this design uses 56 balls a chain, but I have to cut 57 balls off the 5m length. Thus, the length required is as follows:

1 Chain: 4.55mm * 57 = 259.35mm 1 Tetrinsic: 259.35mm * 2 = 518.70mm 8 Tetrinsics: 518.7mm * 8 = 4.1496m (appx. 4.15m) 10 Tetrinsics: 518.7mm * 8 = 5.1870m (appx. 5.19m)

It's a good thing that stainless steel ball chain is relatively cheap. Shame it gets negated by the price of the splicing tool though. Hopefully there's some AliExpress seller that sells varying closed loop lengths of ball-chain similar to the many that sell closed GT2 belt lengths.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.