The standard ABEC1 bearings I originally found have questionable tolerances:

I bought the mr52zz Not all bearings have the same internal measurement, I noticed that some are very loose when inserted into a shaft 2mm, being inserted with the hand without problems, others are very tight, and others simply do not pass on the 2mm axis, probably these have to hit with hammer. Please be aware that it may not work on your project.

--- 2-star reviewer on AliExpress

At the same time, I wanted to confirm my suspicions that standard bearings could corrode when submerged in water.

Looking to see what options I had for water resistance in regards to robotics, I watched the following:

Bearings indeed were listed as something that could corrode.

I soon found out about hybrid ceramic bearings, and it's probably not a coincidence why they're advertised for things such as RC cars and fishing reels.

From what I understand, there are 3 options for bearings used in water: stainless steel, ceramic, and a hybrid of the two. Hybrids and ceramics seem to be 3x and 6x the price of stainless respectively.

On my search, one listing essentially said the following for ABEC ratings:

- ABEC1: Low speed, low requirements

- ABEC3: Sub-6kRPM, suitable for motors

- ABEC5: Over-6kRPM, suitable for high-speed motors and precision equipment

Thus, it seems that I require ABEC3 at the minimum. I found some, but I later found some ABEC5's for £1 more (at 50pcs) (see further below).

Ceramic and hybrids are preferable since they use dry/no lubrication. This is useful for both longevity, reducing the "sticktion" and rotational friction. The drawback is that they would add £8/ea to the BOM, compared to £2/ea for stainless steel.

I looked at a rollerskate stress test and the ceramic hybrid was the only one that didn't seize up:

There's also this free-spin test with miniature bearings very similar to the size I'm looking for. They're MR63 bearings, meaning that the only difference is that the inner diameter is 3mm not 2mm. The ceramic bearings were the only ones that needed a 10x timelapse, and the bearings were so low-friction that it was noticeable that the wheel wasn't balanced.

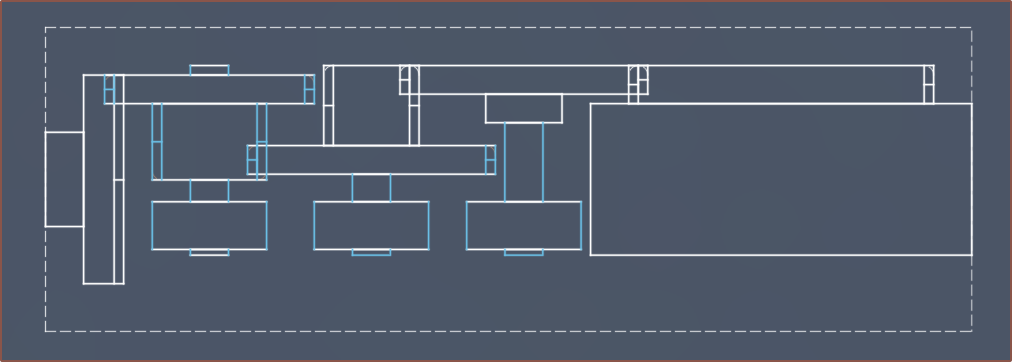

Considering that downtime is problematic, a frictionless sliding experience is highly desired and expected usage is "daily for years", hybrids seem to be the leading choice. To reduce the quantity of bearings needed, I've tweaked the gearing plan so that the moments are reduced:

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.