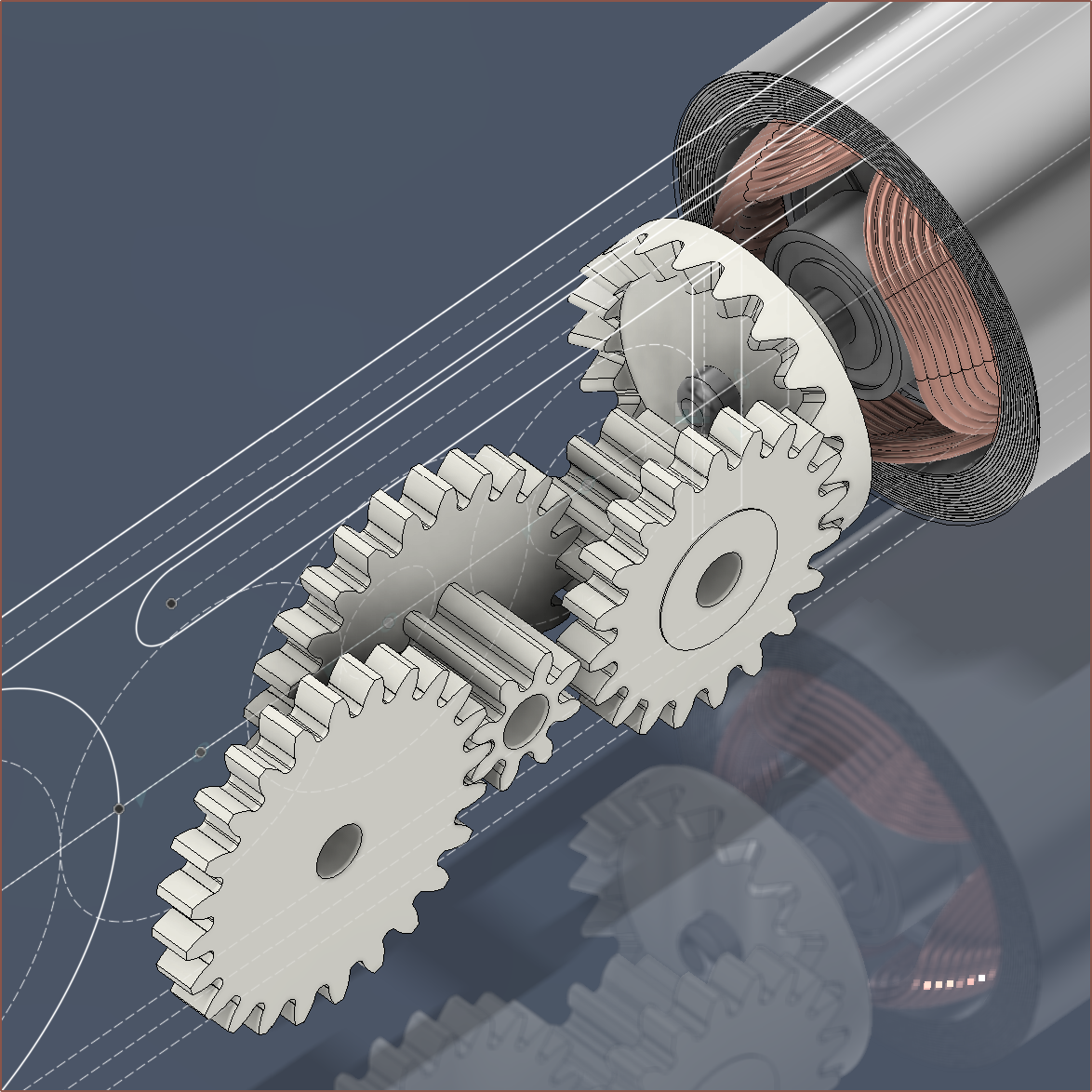

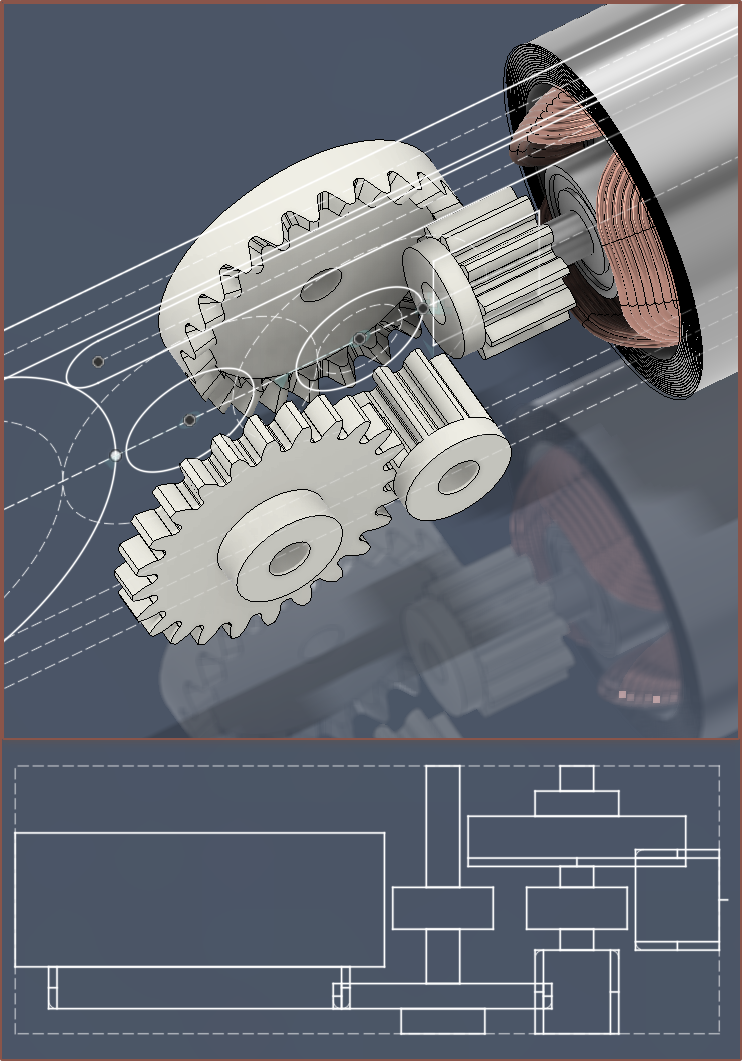

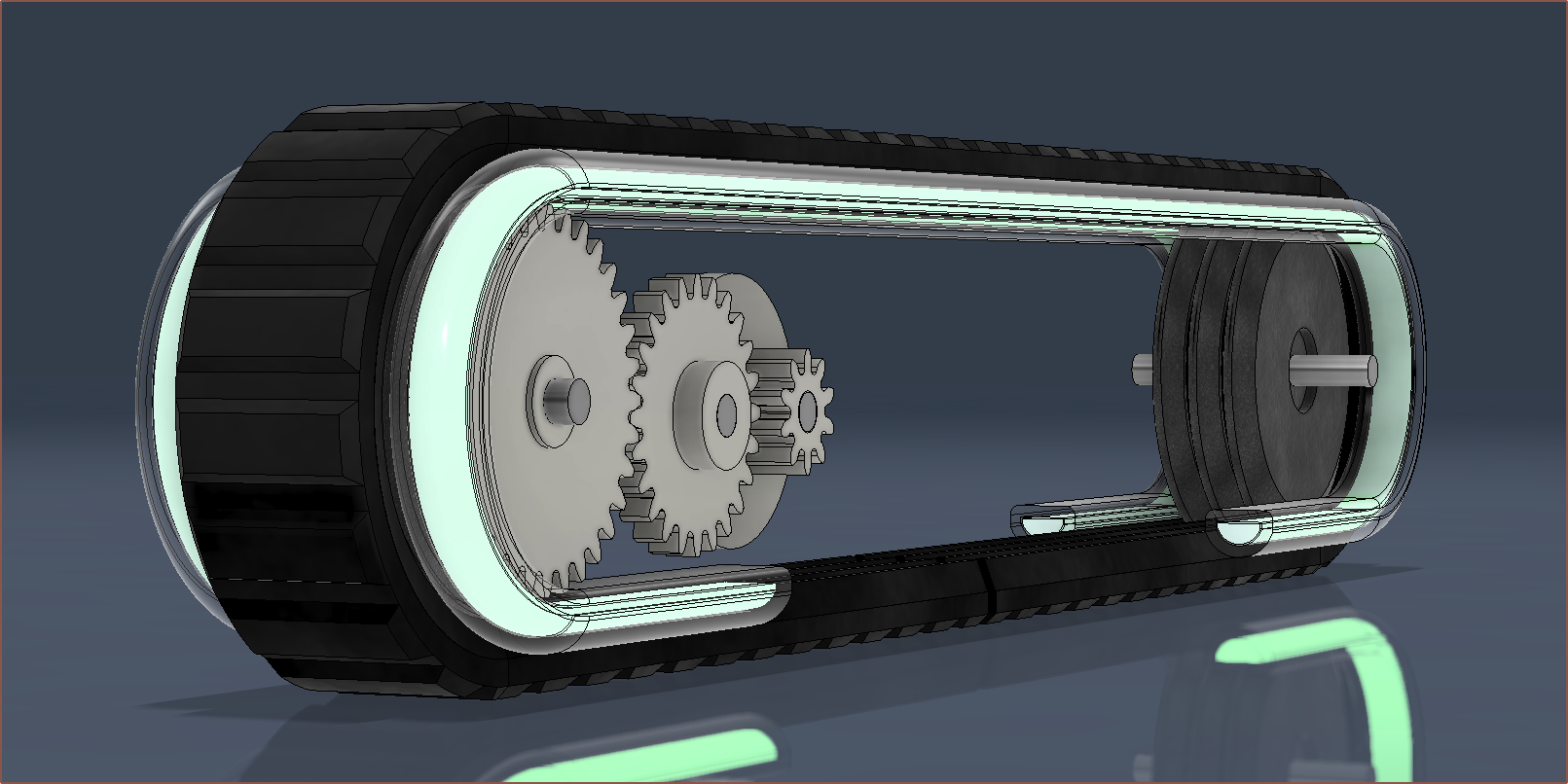

Except for the pulley itself, I've modelled the gears and overall geartrain assembly.

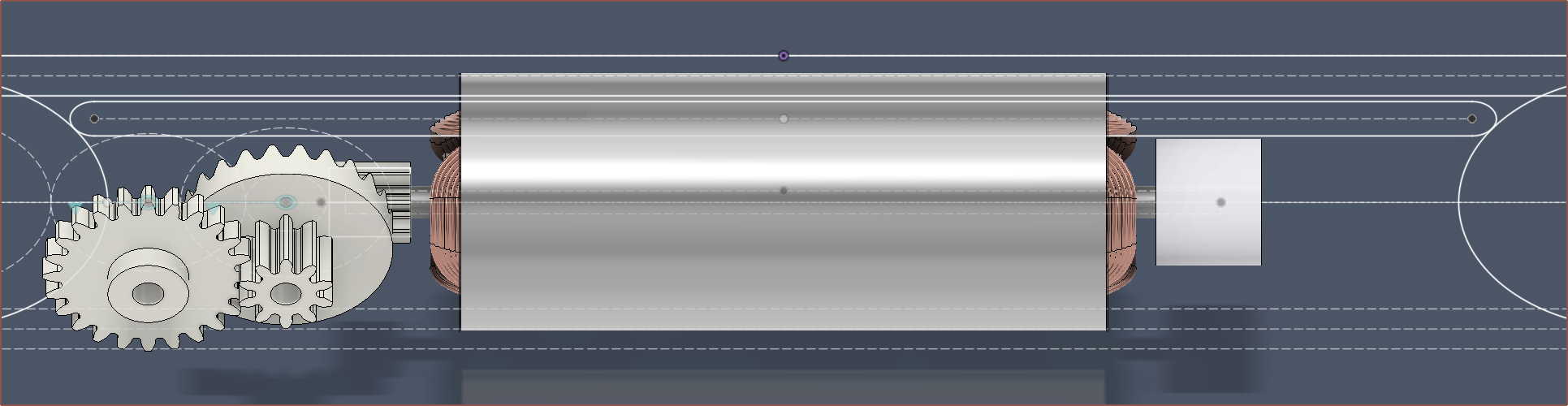

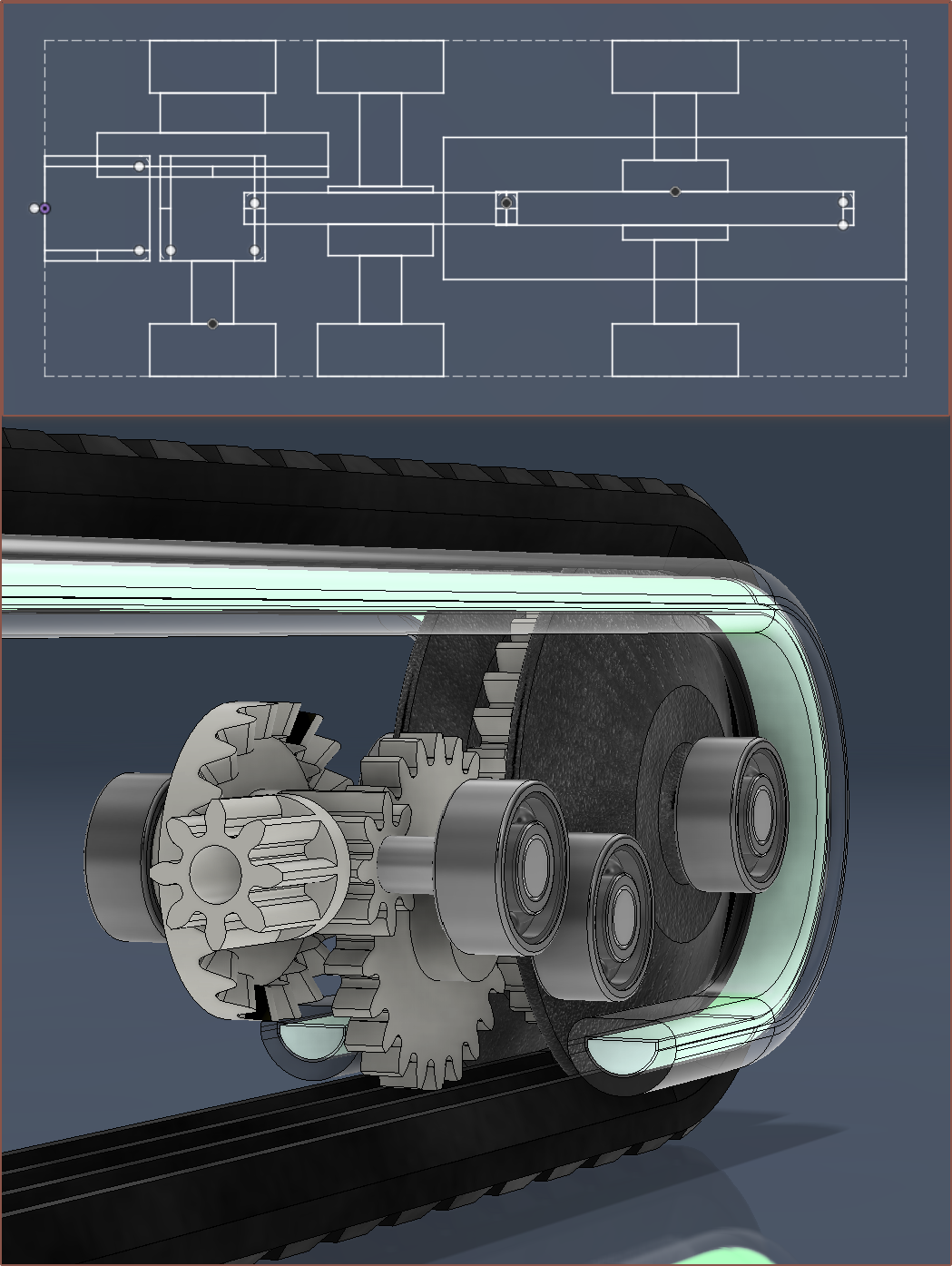

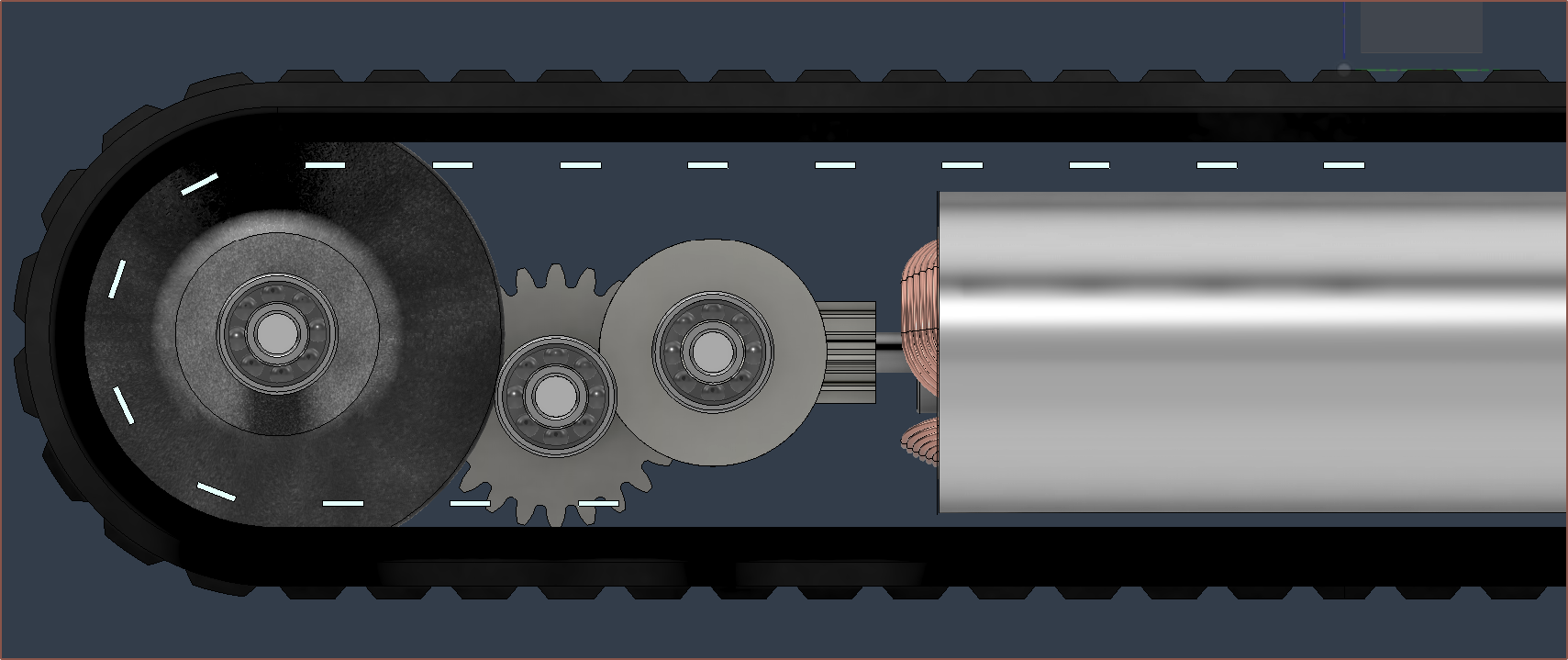

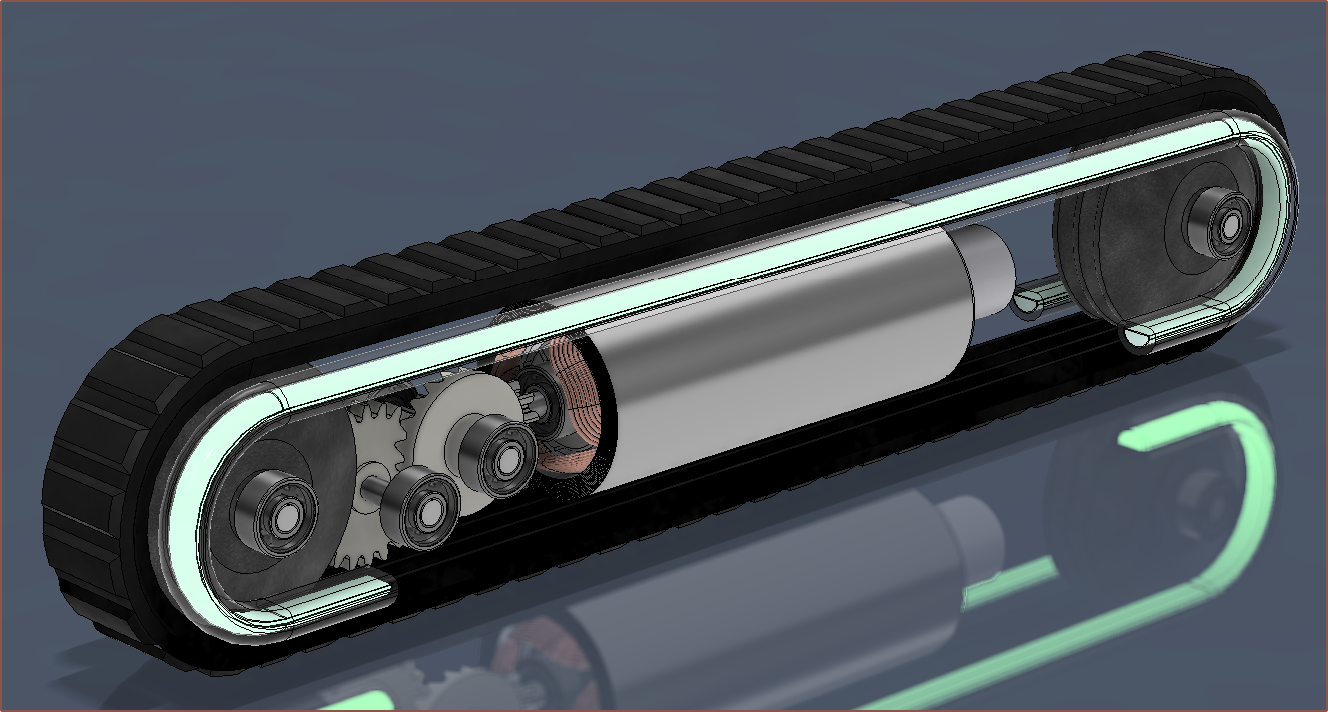

Except for the pulley itself, I've modelled the gears and overall geartrain assembly.[Jul 09] - I've figured out a more compact solution. This reduces the length by up to 9mm, the specific gears are cheaper (79p savings) and means one less bearing is needed. Due to this, I can now use the more popular and cheaper 4PJ280 v-ribbed belt.

The theoretical top travel speed and power consumption are slightly reduced.

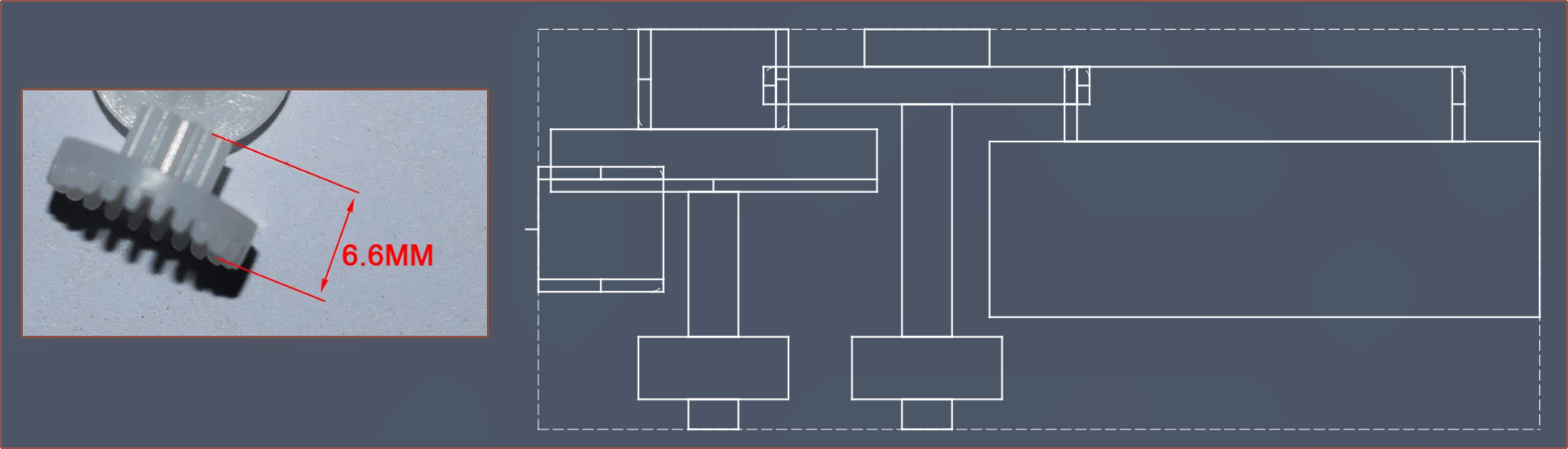

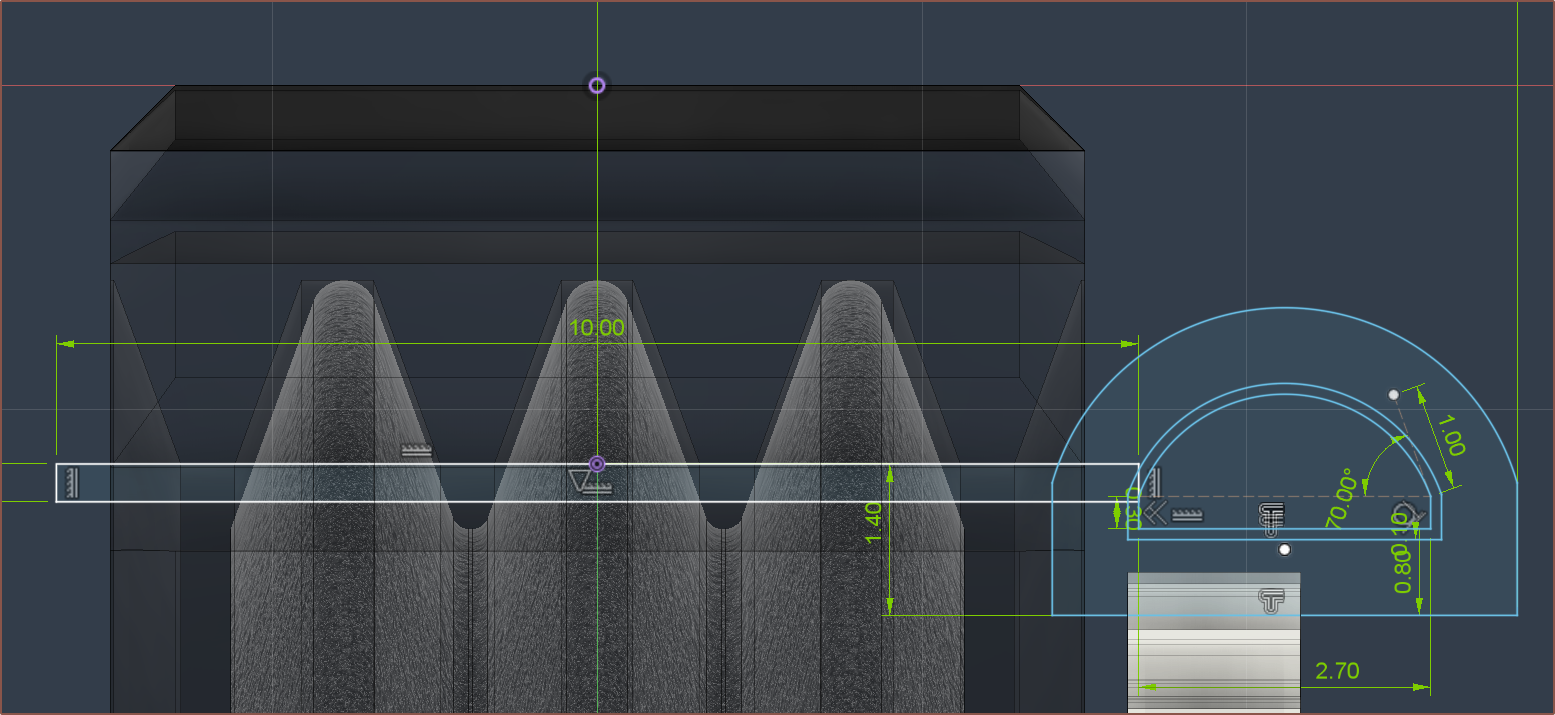

[Jul 10] Against the odds, there just happens to be a dual layer crown gear that has the right number of teeth and fits in the space available:

It's the C24102A and it's only 0.1mm longer than the space I have. If needed, I likely can file down the tiny excess. This both saves a bit more money, reduces the manufacturing complexity and allows enough space to actually centre the main body portion of #Tetoroidiv [gd0152]!

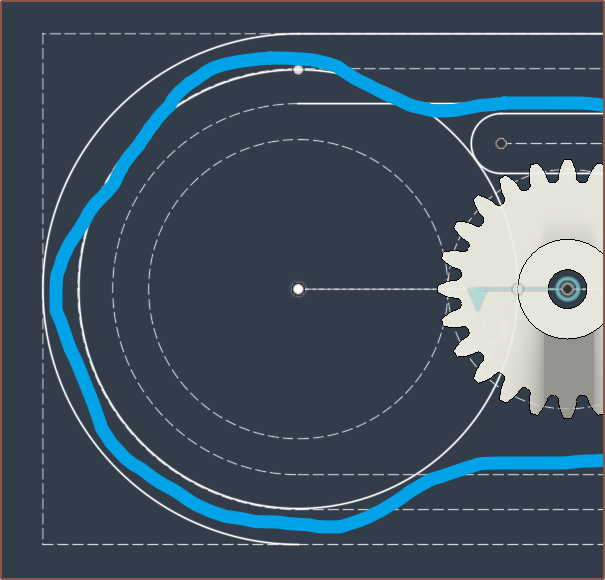

Since a 30T on the end pulley still means that the theoretical max power consumption is under 0.2W, I'm going to use it instead of a larger gear to reduce any dogbone-shaped curve of the LED strip around it. A rough drawing of what I mean is below:

[Jul 11] I've hit some issues that are at odds with each other.

For aesthetic compliance, ideally the LED strip would look like this:

For the total width to be limited to 17mm whilst still protecting the LED strip from the elements, the strip has to actually be slightly under the belt. Unfortunately, this would intersect both the 322A gear and the FSR:

Why is there a 322A gear instead of the printed 30T as planned yesterday? Well, the teeth are so small that it's unlikely going to print with any adequacy, and 32 teeth was more power efficient.

I'd much rather not have to resort to things like 1 strip per Tetrinsic because then the belt won't be centered and it could be visually ambiguous which LED corresponds to which belt. It also notably reduces the future-science vibe.

Another issue is that the wall thickness specified in the product listing is for when it's not heat-shrunk. It looks like the waterproofing heat-shrink actually thickens quite a bit after:

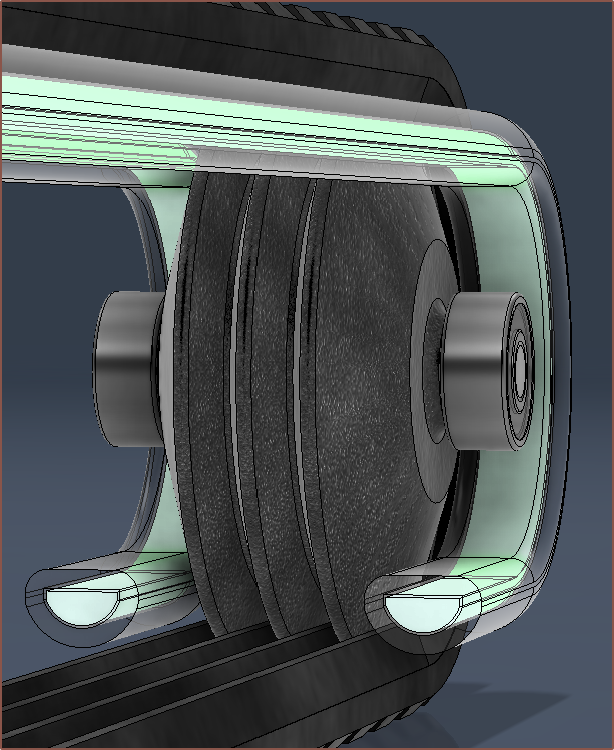

[Jul 12] So I was able to compute a new solution, and there also happens to be enough space (a handful of microns worth) that I can "bend" the geartrain so that the center of the motor stays aligned with the center of Tetrinsic:

The driving pulley is split in two, where the 322A fits inside. The 242A gear is where the tooth gap of the belt is, so hopefully this strategy should be fine. I've decided to use 2pcs J082A so that I don't have to spend time ensuring I haven't accidentally picked up a J102A or vise versa. Lastly, I've gone back to the C202A which allows the geartrain to be a crip 10 : 1 reduction.

I also didn't have confidence that one bearing per M2 pin would suffice, so that's why they're all double bearings now.

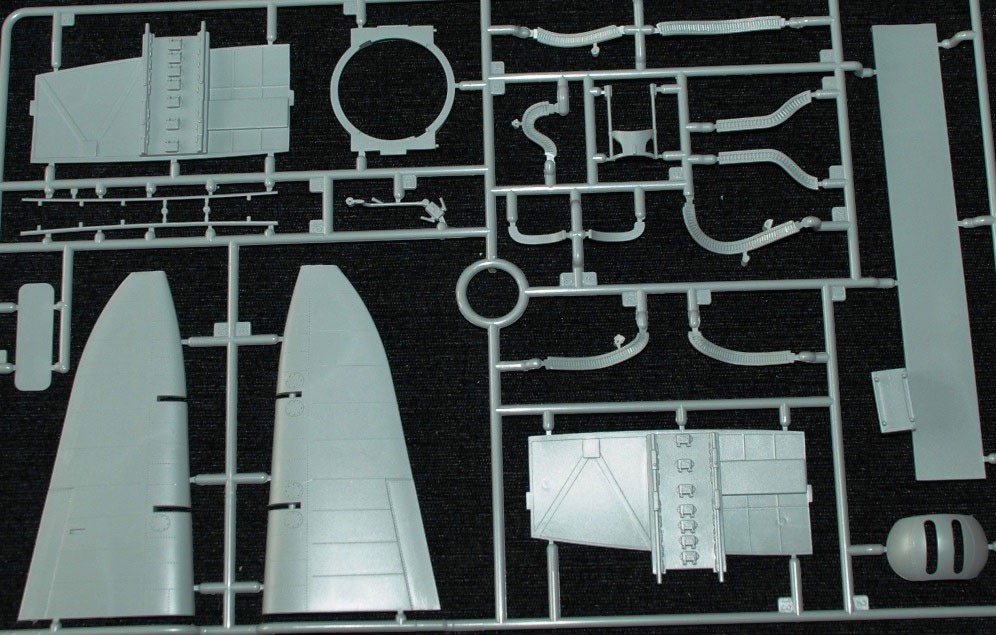

I'm hoping that I can connect all the pulley SLS/MJF prints similar to a hobby kit (see below) so that I can avoid having to spend $1 for each individual part. The other pulley is one solid part:

I've also tried aligning the individual LEDs in the strip. I do hope that a 320LED/m option comes out eventually, because the coverage is rather sparse:

Taking a step back, I'm not sure if designing something that currently looks sci-fi (without it ever being the goal) means I'm on the right track or not, but the coolness is coursing through my veins so I'll just keep calm and carry on.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.