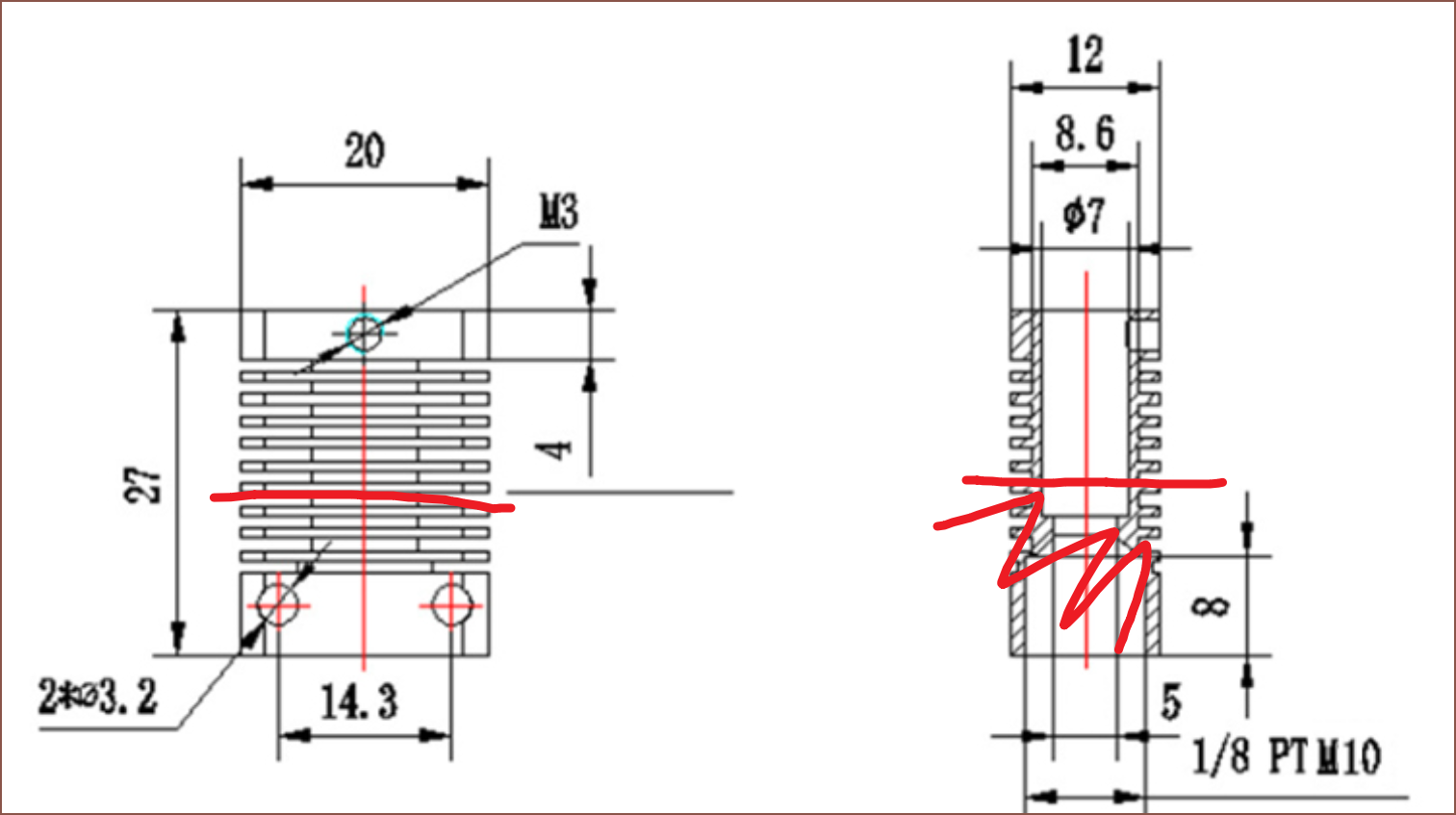

It's going to be another one of those "I don't really have much to say but I should probably write a log about it. Oh wait, there actually is a lot to say." logs. I've been thinking over the past 2 days and somewhat worried about this configuration. The delicate nature of this MQ Mozzle throat means that shaving 1mm from its base would probably be difficult. I also still somewhat doubt this tiny heatsink's cooling ability and would like to test this soon.

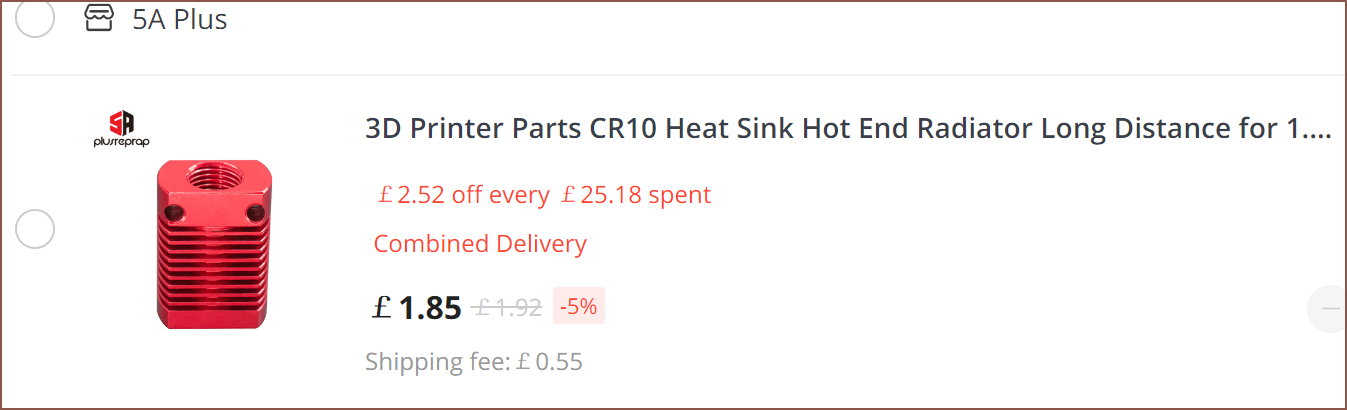

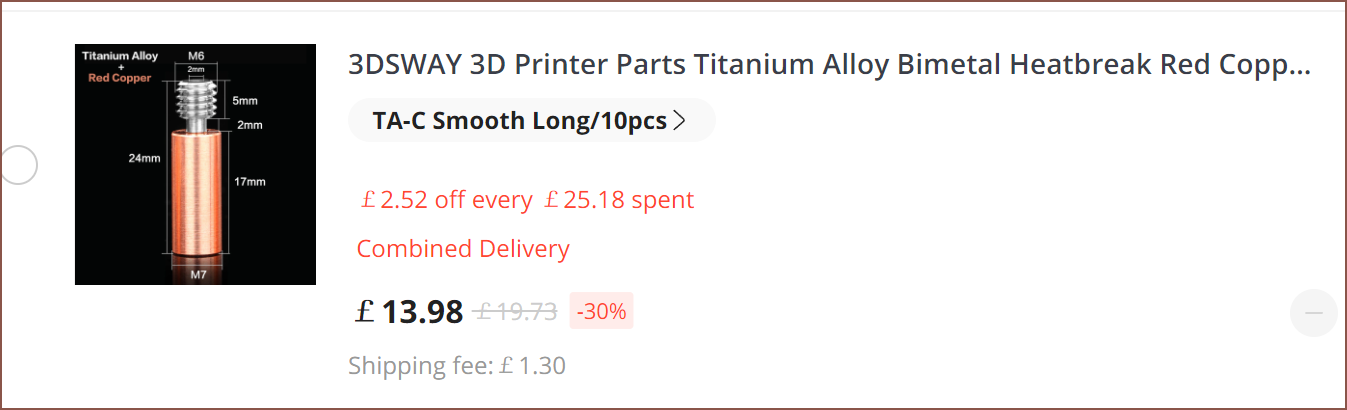

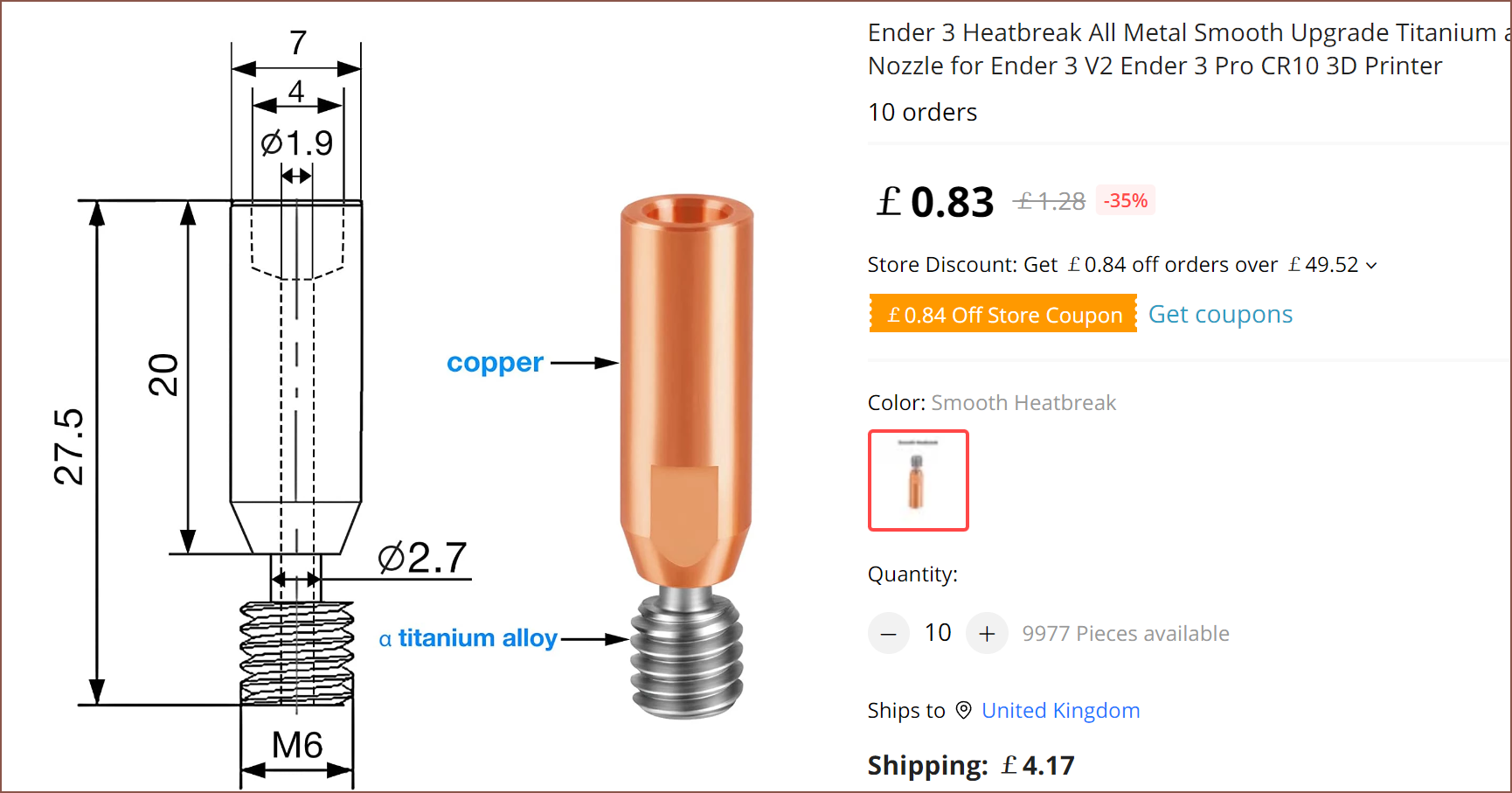

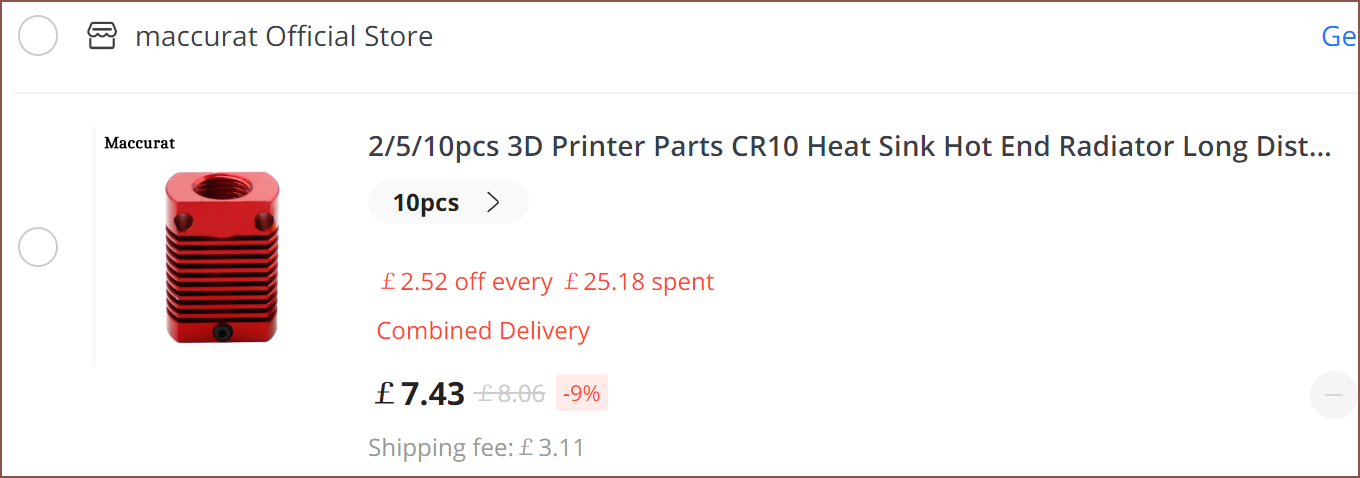

It's going to be another one of those "I don't really have much to say but I should probably write a log about it. Oh wait, there actually is a lot to say." logs. I've been thinking over the past 2 days and somewhat worried about this configuration. The delicate nature of this MQ Mozzle throat means that shaving 1mm from its base would probably be difficult. I also still somewhat doubt this tiny heatsink's cooling ability and would like to test this soon.After some AliExpress searching, I'm thinking that an alternative could be a CR10 heatsink cut so that it's 15mm in height along with a bimetal heatbreak.

This combination would be a comparable to the price of a single MQ Mozzle heatbreak.

Cons

- The filament would be less constrained.

- It could make manufacture more tedious. It looks like there wouldn't be that much material to cut through and the fins should act as a guide for the sawblade, so I have hope that it should be very straightforward to do.

- It's technically would be heavier too, but I'm not one to be chasing grams.

- I've never tried the titanium alloy bimetal heatbreak and only have experience with the copper threads version, and I suspect that clogs could be more likely and lower flow rates.

Pros

- It works and I can have the option for using normal length or volcano nozzles as intended.

- The parts would likely be easier to source, especially considering if the cheap Mozzle heatbreak would still be around in a few years.

- May be easier to securely fix into the Slight due to the larger surface area on the sides.

Other considerations

- Use a more expensive version of the MQ Mozzle throat?

- It doesn't seem like any of the £3 - 10 options would have the 5mm long threads, and I'm still trying to go for a cheaper (and lighter) option to the metal BMG hotend.

- Use an aluminium hex spacer for M7 and stick heatsinks on the flat surfaces.

Oh sweet, a cheaper version

I just found this as I was writing this log. It's even got a flat section for better contact with the grub screw. Copper should be easy to cut like aluminium, right? Perhaps an idea is to cut the throat while inside the heatsink to get rid of that 4mm hole at the top.

I just found this as I was writing this log. It's even got a flat section for better contact with the grub screw. Copper should be easy to cut like aluminium, right? Perhaps an idea is to cut the throat while inside the heatsink to get rid of that 4mm hole at the top. Wait a second. This heatsink is drastically cheaper from this seller and a bunch of others on AliExpress. Nice to know.

Wait a second. This heatsink is drastically cheaper from this seller and a bunch of others on AliExpress. Nice to know. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.