In the previous log, I mentioned that I found some 16% glass fibre ABS pellets. They came on Thurs and I tried them on Friday with the 3Devo my university just happened to have, wearing a gas mask. I couldn't smell the odour unless a quick slip of air got past the face seal.

It has a very similar extrusion issue to the GF PBT. It seems that if the extrusion is left to its own devices, it looks kind of nice, wheras if I attempt to pull it so that it approaches 1.75mm, it all thins out. It's like the extrusion is "dry" and not fluid.

A slow RPM like 2 seemed to be more susceptible to the line breaking than high RPMs like 10. 5RPM was the one I did the most testing at. My temps were 230 - 240 - 240 - 240 =>, and bumping the last to to 250 didn't seem to have any improvement. I also tried between 34 and 85% fan speeds.

A slow RPM like 2 seemed to be more susceptible to the line breaking than high RPMs like 10. 5RPM was the one I did the most testing at. My temps were 230 - 240 - 240 - 240 =>, and bumping the last to to 250 didn't seem to have any improvement. I also tried between 34 and 85% fan speeds.Cleaning also took a while, with this marble-like extrusion:

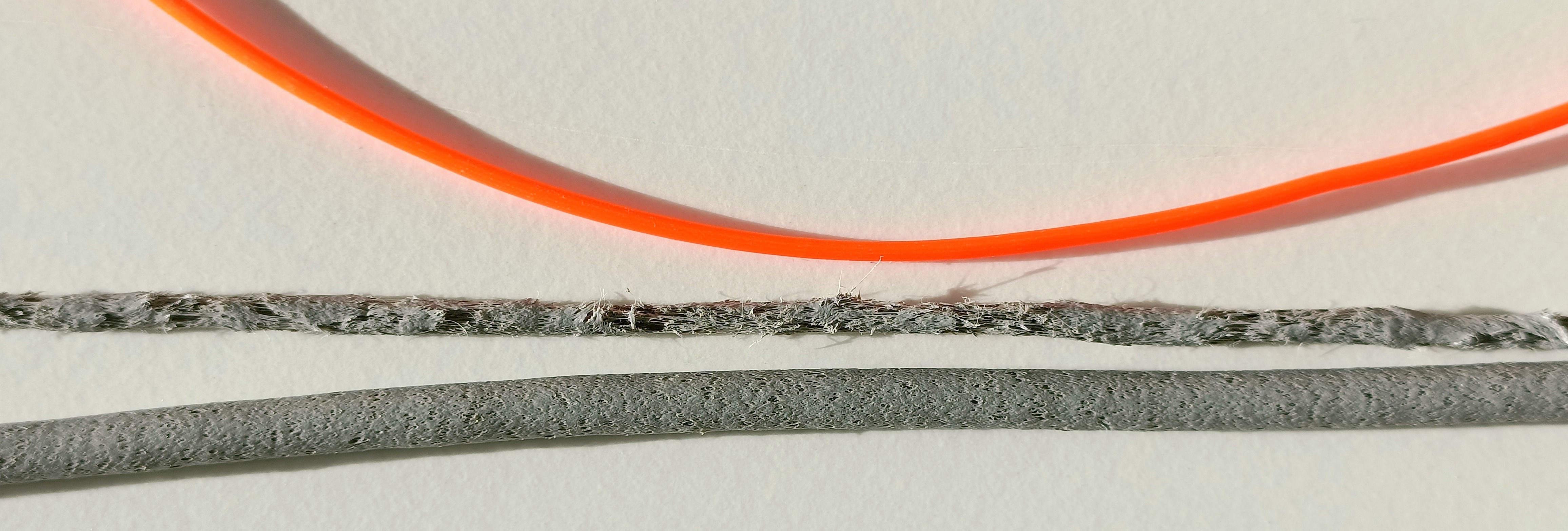

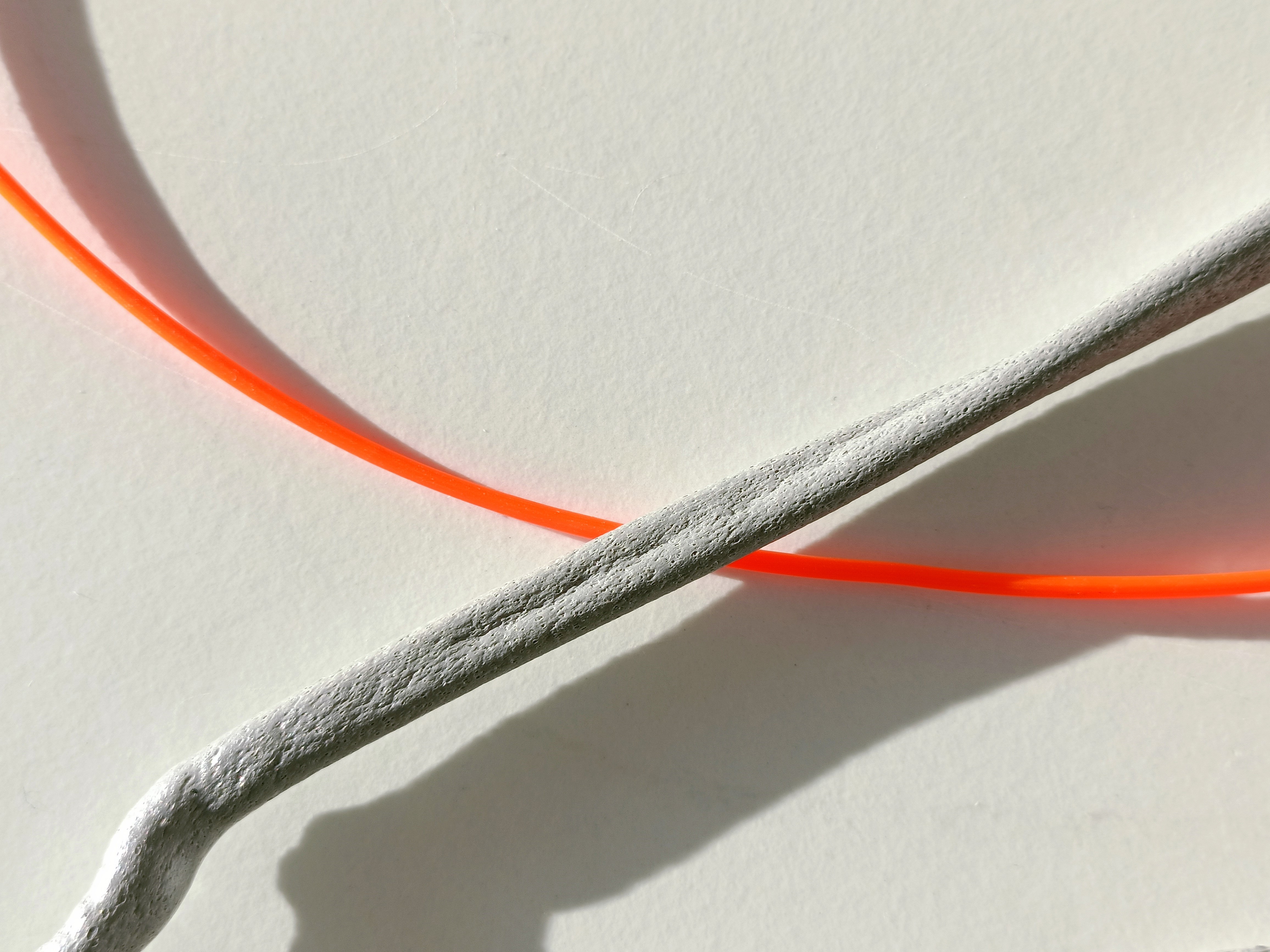

These is what I was able to get. The orange is 1.75mm filament, the middle is the longest approach I got, which looks like it's about to fall apart, and the bottom is the good looking but uselessly thicker extrusion:

These is what I was able to get. The orange is 1.75mm filament, the middle is the longest approach I got, which looks like it's about to fall apart, and the bottom is the good looking but uselessly thicker extrusion:

That thicker extrusion was also notably stiff, making redirect-from-the-floor attempts challenging. It's a very nice looking colour though.

Oh right I want to mention that I was worried about flow rate when I saw 3cm^3 / 10min in the datasheet, but this stuff extrudes fast! If it could cool fast enough and be stretched to 1.75mm, I think 1m under 10s is doable when at 10RPM.

Anyway, my current takeaways is that filled pellets may not play nice with the extrusion method of starting with a wide diameter orifice and tensioning the material to reduce its diameter. It looks like there needs to be some amount of compression or the fibers move at a different rate to the material. Like the GFPBT, it looks like this material would've had excellent anti-ooze properties.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.