Trailer

Technical Overview

Assembly Tutorial

Important Notice

-

This is not a beginner friendly enclosure! If this is your first enclosure, we highly do not recommend tackling this project. For more beginner friendly enclosures check them out at: https://github.com/meshtastic/enclosures This project requires a intermediate knowledge in electronics, intermediate skill level in soldering, 3D printing, and CNC machining

-

Do not proceed with this project until you have gotten Meshtastic working on the t-beam first! This enclosure requires a lot of semi-permanent modifications that will make debugging very tricky.

-

The water resistance should be treated as a “Safety” feature! Although the enclosure performed flawlessly in our testing in extremely wet environments, the effectiveness of the seal is dependent on how the enclosure is assembled and the assembler's experience. If you do not have experience waterproofing enclosures, do not attempt to submerge or wet this enclosure. If you are confident in the seal, operate at your own ris

-

THIS CAN CAUSE PERMANENT DAMAGE TO YOUR T-BEAM! Steps such as the rewiring of the USB or desoldering the battery tray can damage your T-Beam if done improperly. It is highly recommended to gain experience with other projects first before proceeding with this one

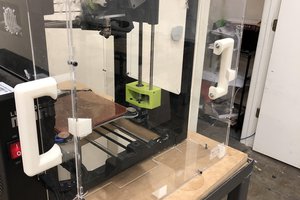

3D Printing Info

Included are 2 versions, one for FDM and one for SLA. The only difference is how the screws mount, for the FDM version the holes are larger to accommodate threaded heat set inserts, whereas the SLA version has 3 mm holes intended to be tapped straight into the resin print itself. For the SLA version all the files are identical except the center frame. Ensure you are printing the correct center frame file! For full rugged performance, FDM printing is favored over resin printing, however for more moderate usage resin prints should also work (Indoor, casual hiking, urban environment, ect.).

- FDM Recommended Settings:

- 100% infill

- 0.2 mm layer height minimum

- PETG, Polycarbonate, or ABS

Canine Defense Technologi

Canine Defense Technologi

sjm4306

sjm4306

Nick Rehm

Nick Rehm

Marius Taciuc

Marius Taciuc

Any chance you can share links to the parts you used? or at least what site?