So I went around researching other attempts of reusable supports and the comments of internet users.

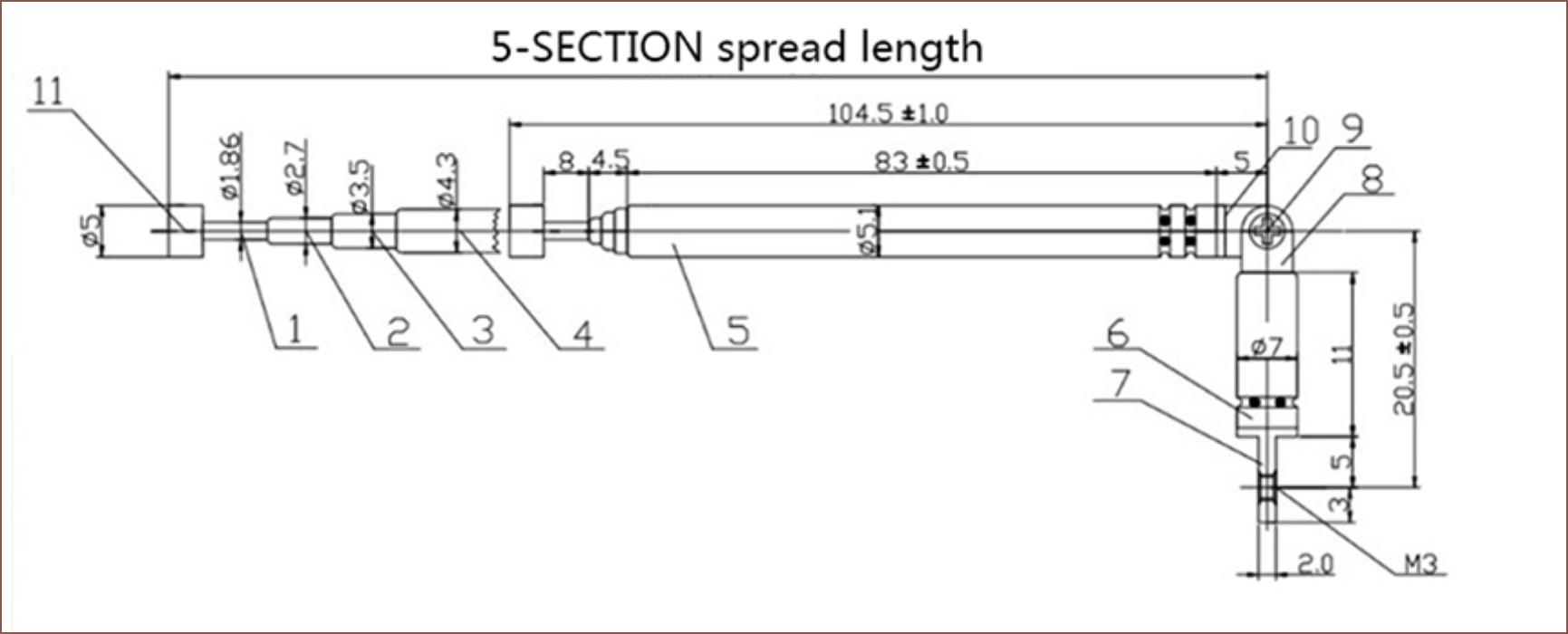

One of the comments in here talked about using telescopic antennas. Looking at build plates for SLA, especially top-down designs, it seems that resin prints can tolerate gaps, so I looked into a full-bed solution. Telescopic antennas would allow a finer height adjustment than stacking magnets (and magnetic cylinders of the same size and thickness in an alternating pattern so that the stacks don't push each other apart).

I found some 27p/each antennas that extend up to 37cm, though in practice with many antennas, I expect the safe height to be 36cm. The end cap looks similar to the face of a magnet and flat enough to print on.

I found some 27p/each antennas that extend up to 37cm, though in practice with many antennas, I expect the safe height to be 36cm. The end cap looks similar to the face of a magnet and flat enough to print on.

5mm sounds like an ok size.

165mm / 5 = 33 515mm / 5 = 103 33 * 103 = 3,399 3400 * 0.27 = £918

However, that's not an OK price. Apparently, the system in the hackaday article was or is estimated to be $10K, so that's a 10x reduction, but it would need another 10-20x reduction to be financially feasible. If I assume that I can go with a 10mm distance, the price drops to £239.

For this concept to work, I think it would have to be 3D printed in order to get that kind of precision but cut out labour and shipping costs. In terms of material usage, it's a fair assumption to assume that almost all the volume needed for this bed would use resin. Thus, for 10mm square size and print dimensions of 520x170x100, 8.84 litres of resin would be needed. For a reasonable price, that would require £4/L resin. In my opinion, that would be a nice price for the stuff anyway since I've lived the lifestyle of £5/kg PLA filament. The factory delivered 11kg of the 20kg I ordered for £55. 1kg of filament is 1.3kg of weight including the spool and box, so a shipping charge for a 14.3kg delivery was also built into that price.

If conductive traces could ever be printed cheaply, it could even mean that each telescopic pole can become a linear actuator like this.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.