A compute that has failed has been the desire to have a resin cartridge that can be sealed-like-a-bottle. This is because it wouldn't be possible to pump in collected resin into the cartridge tank without a way for the air to escape. I think I have a solution which would also eliminate the application pump--

My mental compute as I'm writing this log:

The compute... fails, due to the following confliction: - The X axis will not move a sufficient amount (>3mm) to be able to change the state of the proposed spring loaded seal A new compute is being processed... A compute... succeeds.

Ok, as I was saying. I have a solution which eliminates the application pump, resulting in the reclaimation pump doing everything. This reduces the moving parts on the cartridges and the amount of motors needed. I'll explain again once I have a concept modelled, but for now I'm going to have to describe it via text.

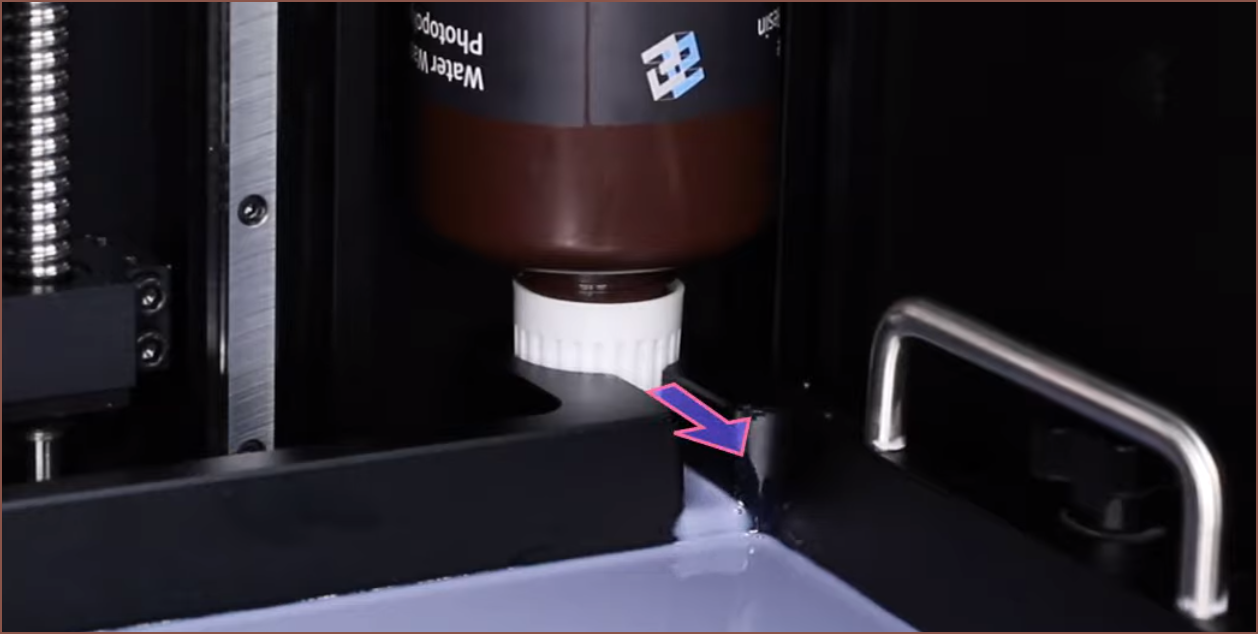

Instead of my original idea to have both the reclaimation -> tank and tank -> application ports on the bottom of the tank, the reclaimation -> tank silicone tube port will be at the top of the tank and trickle in as seen on the self filling vats that are appearing on printers these days. This is to prevent noise and bubbles.

The silicone tube length between the application silicone tube port and the new application minivat (explained further below) will be long enough that the volume in the tube exceeds the volume pumped into the tank when the layer is reclaimed from the film. This is so that the resin can be retracted to milimetres before the application port before reclaimation (the air would exit through the reclaimation port) and by the time all the resin has been reclaimed, the resin in the application tube would be pushed to the application minivat.

There are two "minivat's" in the design. The first one serves as a buffer for the reclaimed resin to reduce the amount of air that is pumped into the cartridge tank. The second one I've thought of now is the application minivat, which is something more like a waterfall tap.

These changes reduce the amount of steppers to 9, but since that's just 1 more than the M8P and the X axis strategy I'm doing prevents me from applying from one side while reclaiming from the other, I'm replacing the £10 EXP MOT + cables with a £2.70 2 channel relay that connects to the 2 pump motors. These motors are actually the only ones that won't need constant power, so is the most fit for this purpose.

These changes reduce the amount of steppers to 9, but since that's just 1 more than the M8P and the X axis strategy I'm doing prevents me from applying from one side while reclaiming from the other, I'm replacing the £10 EXP MOT + cables with a £2.70 2 channel relay that connects to the 2 pump motors. These motors are actually the only ones that won't need constant power, so is the most fit for this purpose. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.