2024 - Apr 05: New render with Soapavr handle

I do imagine that I'd have to add a middle section that forms into something more comfortable to grab with a hand.

2024 - Jan 09: Sub £200 20W laser?!

I noticed this a few days back when it was already a suprisingly low £204, but I was expecting the price to go up, not down. It's quite a bit larger in dimensions than the ZBAITU module, but it would be notably cheaper if the time comes to actually get a laser.

2024 - Jan 04: Powder filled photopolymer for expanded material options

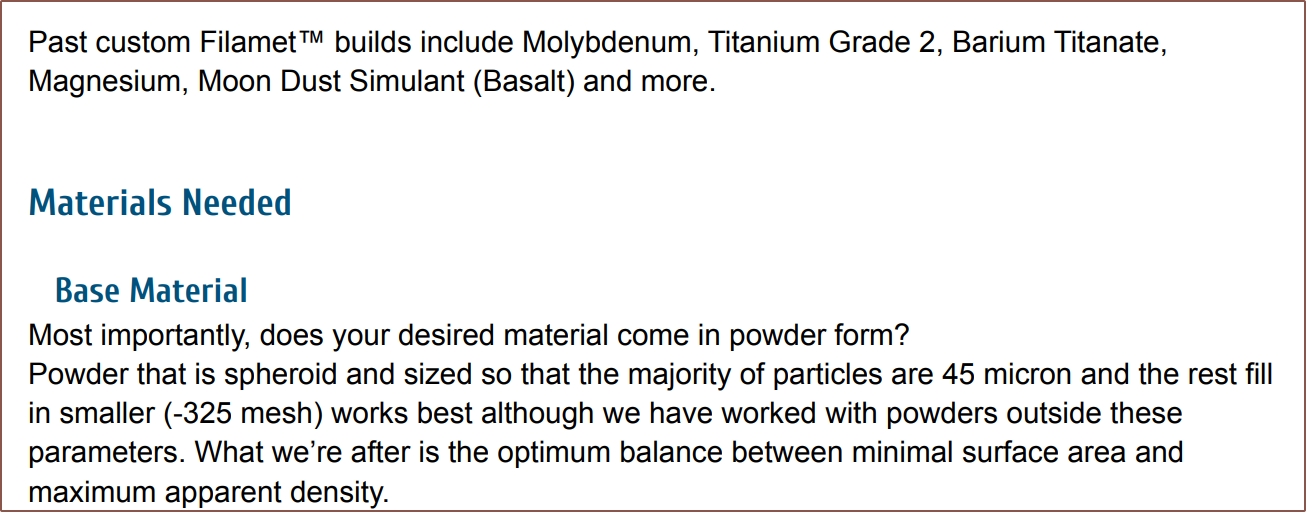

I've always thought that if the copper material worked, other materials that were in powder form could work too as long as the photopolymer sufficiently absorbed the laser power. I've just found out about The Virtual Foundry that sounds like they're doing that with PLA for FFF 3D printing, looking at this pdf about custom Filamet filament. The most notable part is that they recommend 45 micron particles:

I'm hoping that, during the printing process for L^3, shrinking predominantly happens vertically. To put another way, a 100um layer of photopolymer shrinks to 80um after being iradiated by the diode laser.

I'm hoping that, during the printing process for L^3, shrinking predominantly happens vertically. To put another way, a 100um layer of photopolymer shrinks to 80um after being iradiated by the diode laser.2023 - Dec 18: Orient omniwheels to long axis

This is so that the larger-diameter main wheel can go over bumps like the floor dividers in doorframes instead of the smaller wheel array on the omniwheel.

2023 - Nov 11: Send new print whilst current job is printing

The idea is to use the magnetic supports to build a scaffold for a designated amount of print area that is used if a user decides they want to print something whilst a multi-hour / multi-day print is already in progress.

Like, say you've got PartA that'll take 10 hours to print because it's multi-material, but you also think that you might finish designing a smaller/shorter/single-material PartB in 2 - 3 hours from now. The goal is to be able to start PartA, specifying to also stack scaffolds for a 50 x 50mm area. Then, when PartB is ready to be sent over, the Suspense starts printing it at its earliest possibility. Taking advantage that the area covered by the LCD will take the same amount of time to cure regardless, the hope is that the additional print would be negligible and it'll almost be like having multiple printers on demand.

2023 - Nov 11: Bed that only moves in Z

As a project targetted towards consumers, the amount of print space compared to the amount it takes up is an important metric. I looked at UK door widths, and the smallest was 27" / 686mm. I then looked at desk heights and the lowest was 28". Assuming that the thickness of the table is 1", it'll mean that there's 27" of space underneath it. From that, I'm thinking of going with a 52" x 26" x 26" (1320.8mm x 660.4mm x 660.4mm) maximum footprint area.

To maximise the print area, the plan is to have the LCD and material cartridges on a heavy duty gantry. Conveniently, this shouldn't be a printer that needs high accelerations to perform at a decent speed.

The hope is to get about 650mm x 490mm x 330mm of XYZ build volume (1cm more than the round sounding 64cm x 48cm x 32cm, like how the CR10 is advertised for 300mm but can usually do 310mm). Part of this large size is so that it meets / exceeds the XY bed area of the #SecSavr Sublime [gd0036], and part of it is because I beleive it's a very nice size to have for the expected price, but a part is so I can do reliability testing.

2023 - Nov 08: Enclosure pressure test for added safety

I'm thinking that, to test that the printer is airtight, the pressure is changed so that it's not 1 ATM and this pressure is electronically monitored. It doesn't need to be that much different, but enough to detect if there is a leak before or during the print. I'd imagine negative pressure is safer, as leaks will cause fresh air to move into the enclosure instead of pushing contaminated air out into the environment.

2023 - Sep 20: Moved from comment area

I've moved all the ideas from the comment section (called "Discussions") into the log itself so that it can be picked up by search engines. Think of these as nano-logs. The main header includes the general gist of the comment. Replies to the main coment will be shown under a smaller header.

I've also renamed this log from "Seemingly solid specification and quick comments".

2023 - Sep 19: Load cells

Considering using load cells on the bed to be able to detect pressure. Theoretically, this would allow the printer to make sure that the pressure against the LCD is constant across the printing area as well as detect if there's an unexpected amount of force being applied, stopping before LCD damage.

2023 - Aug 05: Shelving SecSavr

Currently shelving all SecSavr projects due to Tetent [gd0090] delays. This is due to manufacturing issues with Tetrinsic (https://hackaday.io/project/184180/log/221847), and I haven't even gotten to the programming stage yet.

I'm just going to have to hope that BCN3D and I are not the only ones designing a lower cost, higher viscosity compatible alternative to Polymer Jetting.

2023 - Aug 08: Never mind

nvm: https://hackaday.io/project/184896-secsavr-suspense-gd0105/log/222049

2023 - May 01: Triangulation

Might be useful for fast + accurate bed probing using laser triangulation: https://www.micro-epsilon-shop.com/de/wegsensoren/laser-wegsensoren/

2023 - March 20: 4-bit not 3-bit full colour

Just read https://hackaday.io/project/85463-color-open-source-smartwatch/details and realised that I'm aiming for 4-bit full colour, which is 1-bit per channel. 4 bits is for RGBA, where A stands for "alpha". It's the transparency channel.

2023 - March 04: Target under 1.2m long

Because things like X * 1.2 * Zm grow tents and cheap 1.2 * Ym heavy duty shelving exists, I'm thinking of trying to get the footprint of the printer under 1.2m long so that it can fit in such store-bought solutions.

2023 - March 20

This seems not possible whilst still keeping the 652mm X axis. I'm only 10cm out though, so perhaps I can find a way when I start modelling.

2023 - Feb 15: Increase Placement Block X acceleration

I'm going to put a sping / damper between the PnP motors and everything else in the Placement Block to increase X axis acceleration.

[PnP][Damper][Polishing Spindle + Laser + Syringes/Fibre Applicator]

I'm planning to use a self supported HGR15 rail (due to the 700mm+ span required now), so the Placement Block makes up less of a mass percentage when accelerating in the Y axis (the total mass = HGR rail + carriage + Placement Block). On the other hand, X mass = Placement Block + HGR cariage.

The syringe stuff is light so that can stay alongside the spindle (which needs the stiffness as a load will be applied against it) and laser (which is sensitive to ringing/ghosting oscillations, and high acceleration movement is a bigger factor of print time). The PnP shouldn't have any X axis loads applied to it and the 2 stepper motors likely have a significant enough mass % of the entire Placement Block such that mounting them like flying extruders in the FDM world will show noticable improvement in acceleration.

2023 - Jan 13: Meshed bed instead of solid

I'm thinking of initially trying to print on a mesh (similar to the print beds used in top-down SLA printers). I need the mesh anyway because of the laser cutter, and I can already see it now where I'm having difficulty cleaning off the first layer if I used a solid bed. Plus, I'd then have the option to fill the bottom of the build area with bolt heads for auto part eject similar to the SLAminator. I can imagine that now, and it looks sweet!

2023 - Jan 05: Another multi-material resin method found

https://www.nature.com/articles/s41467-022-35622-6

2023 - Jan 05: Magnet support adhesion concern

I just realised that if I fully cure the first layer or layers under magnet stacks, won't the part the part be bonded too securely? Would the slicer need to print some kind of surface area reducing pattern?

2022 - Dec 10: Q5D 3D printer found

I saw this video and it's possible to laser sinter copper inks (with what looks to be a red (likely infrared) laser. Their machine can also lay copper wire or continuous fibres.

2022 - Dec 10

https://duplex3d.com/duplex-s2/

I'm trying to understand how they're doing it, but this company has been able to print from both the top and bottom of a build plane at the same time, essentially cutting the print speed in half and reducing the amount of supports required. They call it MAP(tm).

2022 - Oct 16: Tiles for enclosure

I'm likely going to use tiles for the outer enclousure. I've got maybe £60 of 50x60 and 55x60 tiles I bought for the SecSavr Soap that are now not doing much. Additionally, I'm looking for a rigid, cheap, opaque, non flamable, good looking sheet material, and tiles sure tick all those boxes. I'm somewhat concerned about weight, but I'm also going to be using galvanised steel tubes where I can for the frame, so it's probably not a metric I should use to consider usability.

This could merge 2 printer ideas I've wanted to do. First, the "original SecSavr" (which I renamed to the SecSavr Cylinder) was going to be a cube CoreXY printer that used tiles as an enclosure. The second was a printer built into a coffee table. At over 70cm tall and with no foot space, the Suspense would probably be more like a cupboard.

2022 - Oct 10: Increase X to 652mm

I'm tempted to increase the Suspense X from 614 to 652mm because 326x2 = 652 and the MGN9H is 40mm long. I'd like to stick to off-the-shelf rail lengths, and so a 650mm rail won't be long enough and I'd have to go to 700mm.

Additonally, I'm likely not going to build the SuspenseSmall mainly because the Suspense hypothetically CanDoTheTaskApp and an additional SuspenseSmall would only CanDoTheTaskBetter. If any component had to be (re)bought because expectations differed from reality, it'll cost 2x with 2 printers. To further add, the money would be better spent towards the materials R+D budget. I'd still have the SuspenseSmall in the BOM to confirm that a solution can cost under the arbritrary £999 with the Placement Block, but the real value meal deal in this lineup is the Suspense.

2022 - Oct 08: Laser edge smoothing

I just realised that, since I most likely would have to formulate the materials anyway, and the whole system blocks visible light getting in or out, I could have a photoinitiator for both 405nm and 450nm wavelengths. Then, the 450nm laser could be used to obtain SLA like surfaces. This would primarily be used on block-colour or transparent-coated surfaces to add a smoother or glossy surface.

The order would be: Coat film -> expose layer -> peel part -> laser edges -> clean excess -> cure all -> recoat film.

2022 - Sep 06: Increase X to 614mm

Now that the printer is planned to be fully enclosed and sealed (again), the requirements for the SleepCinema / CeilingSingle [gd0099] kinda just fell of a cliff, to the point where it would make much more sense to use a "heavy duty" shelf off ebay for cheap than cobble together the CeilingSingle. Therefore, I'm going to reclaim the 85+mm of space the 42.4mm vertical tubes would've taken up and increase the lengths of the Suspense + Slim to 614mm.

Can I think of a use for a 600mm long X axis? No, not really; there's more 500mm prints I've got in mind than 400mm ones, but the amount of prints drops off after 510mm. However, I expect the cost difference to be like <£30, the footprint to be about the same and FutureMe might have that one-off print and glad I made the decision. Additionally, the largest FDM in the hobbyist space is the TronXY X5SA 600 and I did ask "The best of resin with the best of filament; is such a 3D printer possible?" and this is an easy way to get even closer to "the best of filament" across all metrics.

2022 - Sep 10

Oh it makes the SecSavr Skyrise practically redundant. That printer has a >700mm Z height and I only cared for >600mm long prints.

2022 - Sep 04: Discovered Nevermore

I'm adding filtration back onto the list of features due to this article.

2022 - Sep 01: Silver paste in ceramic tracks

I'm thinking of trying to print the silver paste tracks in ceramic / ceramic-like resin in the hope that a near full sinter of the silver trace is possible with the laser.

2022 - Sep 01: Kickstarter 3D printers

Oh yeah. I forgot I heard about the NexD1 at the start of June. The Kickstarter got suspended because it was a complete scam apparently. I'd really like the Suspense to be the actually-working-version of the concept and have it not cost over 2300 euros (55% off super early bird, shockingly). Actually... I shoud probably keep a low profile until I've got prints because the project's deliverable now sounds like a massive overdeliver in comparison to anything else currently on the market, even though the science seems sound in my eyes. 🥺

There's also this little machine called Rubanmaster that can be turned upside down to switch from SLA mode to Laser cutter.

2022 - Aug 26: Overcuring and curing speeds

I'm currently reading a paper called Slurry Based Stereolithography and found out that "overcuring" refers to resin that would be in the layer under the one being exposed also being cured. I'm assuming that's the reason why UV blockers are added into the resin, and I suspect that these UV blockers are also responsible for clear resins being yellow-tinted. I don't have the information to confirm such a hypothesis, but I can conclude that UV blockers... block UV, the stuff that is supposed to be curing the material in the first place. This slows down the curing speed, so will not be added into DIY resin since I need curing speeds to go up and there *isn't* uncured resin under the exposed layer -- it's air or fully cured resin. This change would also add into the need for opaque doors to prevent premature curing from stray light.

Speaking of curing speeds, I'm reminded of this reddit post [https://www.reddit.com/r/resinprinting/comments/pcbvbv/diy_continuous_resin_printer/] where the vat is rotated to replenish the PDMS layer with oxygen. I don't know if this is going to be a bug or a feature, but the PET film for L^3 is cleaned and exposed to air after every exposure. Does this mean fast peeling of the part or trouble with cleaning up uncured resin?

2022 - Aug 27 (00:13)

I've been reading "Slurry Based Stereolithography" because it sounded like it could actually be a paper that inspired VLM; I still refuse to believe it's never been tried untill BCN3D. By the way BCN3D were talking about it, it sounded like it was one of those technologies that struggled to get out of the lab and they finally perfected the science/engineering.

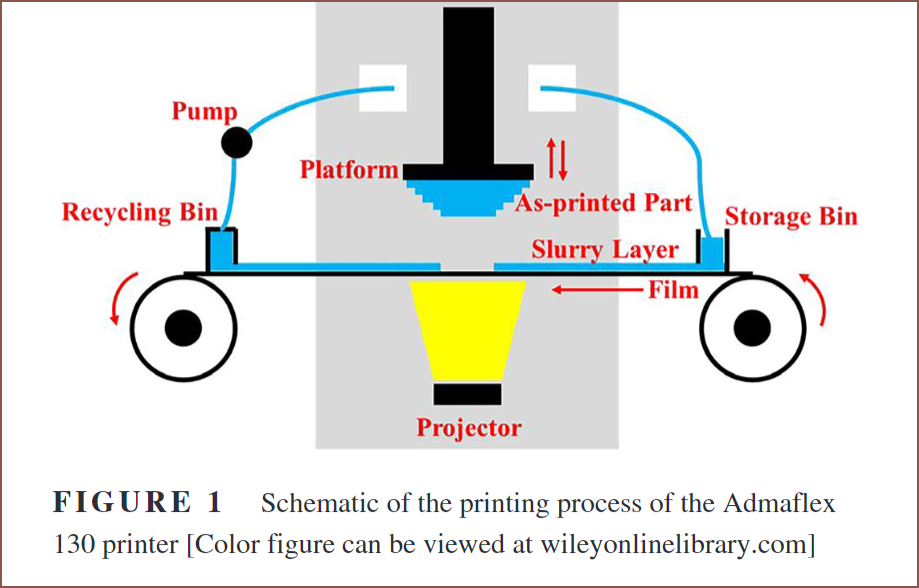

Anyway, they're talking about ceramics and I was like "I've got a laser... could I sinter ceramics with it?", so I google search and see this image:

It's a diagram of a film based printer, where a projection comes in from the bottom, material is deposited onto the film from the right and pumped from the left, and it's a printer designed to print ceramics and metals!

I kinda thought this was possible (and that's one reason why I didn't initally want to use "liquid" in the technology's name), but I valued the rightside up print bed more than the mayyyyyybe that I could print ultra expensive metal powders that I'd still need to sinter. I believe that polymers + continuous fibre would meet the needs of most of the situations I'd want a metal part, which is stiffness without being brittle.

Anyway this is an animation of it printing [timestamp: 39s] and I can finally rest easy knowing that the 3D printing rule still stands: If you think of a cool 3D printing idea, someone else has probably done it already and usually at least 5 years ago. It seems that they are able to pump the liquid up and off the film. I was wondering if there was a solution that could make this kind of process gravity independent and this seems to fufill it.

2022 - Aug 27 (10:05)

I've found another instance of using a film, and this one is closer in line to what I'm doing. The researchers say that the printer is called the Onestage 6500, but Google doesn't find any relevant results.

There's also a study that uses an air jet to clean uncured resin off the part to allow for multi-material printing. It doesn't use a film but a moving glass plate.

2022 - Aug 26: CadQuery

I looked into CadQuery since I wanted to scan over my CAD options again before embarking on implementation modelling in Fusion360 and it was all seeming well until I read in the docs that tangent arcs haven't been implemented yet, which is kind of my "bread 'n' butter" after mutli-profile sketches.

2022 - Aug 28

I'm starting to suspect that Fusion360 is what's preventing me from project progress (in more than just this one) so I tried writing out a concept in Markdown.

2022 - Aug 26: Syringes

Found the syringe needles but it seems that 2x5ml is the max I can fit in the space provided instead of 4 x 10ml due to the lack of screw capped syringes under 100ml. There's a very nice looking steel 10ml on aliexpress, but they're 10x too expensive and I won't be able to use a light-based approach for detecting when the syringe is almost empty. For the latter, I may be able to detect a current difference on the pump.

I might be able to get 2x5ml + a 3ml syringe in there, so that UV curable resin, silver paste and solder paste can be used in a 3DPCB. I'd also be fine with 5ml + 2x3ml or 3x3ml.

2022 - Aug 25: Paste extruding via compressed air

On the search to make sure 400kPa (58psi) was good enough to despense things as viscous as solder paste, I found out about nScrypt's fabulous and fancy printer demonstrations:

Seeing this, it seems that it's possible to do away with the printed tracks, and instead: print PCB surface -> deposit tracks -> laser cure/sinter -> print next layer straight on top, filling in the gaps.

Additionally, I'm thinking of a 6 section rotating cam to use for enabling or disabling 4x10ml syringes + fibre nozzle. Ideally, I'd like to still be able to use pressurised air to extrude the paste, as then I can swap to 5 / 2 / 1ml syringes without much issue.

2022 - Aug 26

It's likely that the paste would spread out if it's not dispensed into a track. It might be something like 0.24mm min track width on substrate vs 0.16mm min into substrate. I'm going to aim for 0.16mm-into since a 30G syringe needle is 0.159mm.

2022 - Aug 25: Piezo probing

I'm thinking of going with piezo sensors instead of 3D Touch so that I can get Z offsets for all nozzles, as well as detecting if the entire head has hit something when the Z axis is raised (eg for laser cutting).

2022 - Aug 25: Curing silver paste with laser

A continuous green laser has been used to cure (and somewhat sinter) silver paste, according to the abstract of this paper: https://www.wlt.de/lim/Proceedings2015/Stick/PDF/Contribution319_final.pdf

The absorption of silver nanoparticles (the stuff in the paste) is closer to 400nm than 532nm green: https://nanocomposix.com/pages/silver-nanoparticles-optical-properties

Thus, it makes sense to have a 5W laser in the Small. I was thinking of no laser since "Do I really need 2 laser cutters?"

2022 - Aug 25: Implementation research

Now I'm in "implementation research", which is the tedious process that can be simplified to something like "Should I use these bolts or those bolts?". I think it makes sense to write such research as comments to this log. The first one is going to be large because of the backlog before this idea.

So far:

- Confirmed that the C80-EAIR + 12V slim PSU is the best option whilst keeping the upgrade price for laser under £200. The 12V has the same outer dimensions as the 24V, so at least I can make the wiring symmetrical.

- Found out that off the shelf pick and place heads are really expensive.

- Found out that silicone tubing is flexible enough to rotate +/- 180 degrees, avoiding a coupler that adds Z height and is apparently leaky.

- Found the SY-020, which looks like the UV-U3 pump but it's rated for 50dB instead of 60dB and has a max pressure of 400kPa instead of 350kPa.

- Found a current sensor (ACS712), which will be used on the pump to detect if a part has been picked up successfully.

- Made a quick sketch in fusion to confirm that everything might be able to fit in 90x90mm XY, though it would be nicer if I could get 80x80mm.

- Confirmed that basalt fibre is the best option currently available to me. I found out about UHMWPE fibres, but then I read a paragraph the basalt fibre seller sent me months ago that said basalt was better. UHMWPE also seems more expensive.

- Decided to scrap the Desktop Metal way of placing continuous tow and will design for a 0.5mm thread. This is because raw carbon fibre and basalt tow doesn't seem to be all that stable at the tip end. I'll have to make a machine that takes the raw fibre and spindles it into nice, managable rolls. Additionally, this change to 0.5mm round thread means that I can get truly continous fibre and fit it in smaller cross sections. Very small and very large parts is what I expect would benefit most from reinforcement.

Currently, I'm:

- Reading about using compressed air to dispense pastes. Apparently, I thought anything that needed "compressed air" needed a massive air compressor. Turns out 20 - 40psi is only 137 - 235kpa, and uh... the SY-020 does 400. I'm looking for solutions different from the classic syringe plunger since Z height is limited. Now I'm wondering if I can actually use this air pressure to move the syringes up and down like a button press pen, as this would further reduce the amount if stuff that needs to be in the Placement Block whilst simultaneously increasing the amount of pastes and the volumes it can carry. I might actually be able to port the chocolate extruder from #SecSavr Sublime [gd0036], though I'd have to look into sub-ambient part cooling for actually decent results.

Things to do:

- Briefly look into sub-ambient cooling.

- Look into cheap + small cameras to use as syringe nozzle and cartridge application cams. Unlike gd0036, the movement would be slow enough to use 30fps cameras without it being a complete blur.

- Look into the pressure required for the button press pen idea.

Things I'm not sure about:

- Inclusion of a vinyl cutter. The blades used are dirt cheap, but that's an additonal tool I need to actuate.

- It might be possible to use the laser to heat the silver and solder paste. Useless for BGAs, but might be required for localised heat curing the traces without having to expose the entire print to temperatures well over its Tg.

Things I might research further:

- Flexures for the LCD screen. I found out whilst watching a video of a DIY scanning laser microscope that those dirt cheap steppers can be used for micron level movement. [see https://openflexure.org] Not sure why this hasn't been done, but if I can get 20 micrometres of movement, I might be able to get edges that even beat current 8K (28um) printers on the market.

- Laser Direct Write. Researchers in 2017 were already making PCBs with it. See Timestamp 210s

2022 - Aug 25

Oh yeah and the rotational axis once used by the fibre tool is now being used for a second PnP nozzle.

2022 - Aug 21: Seemingly Solid Specification

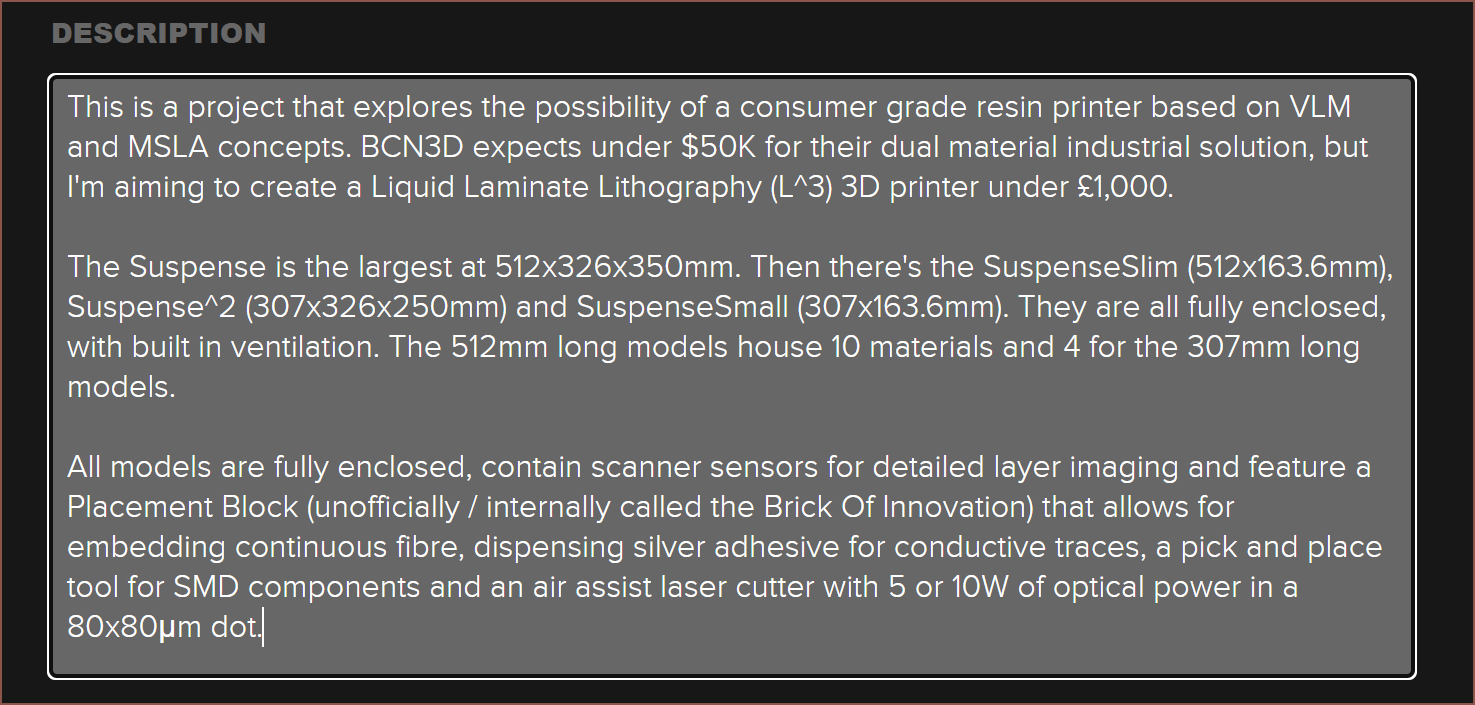

With a description as confident-sounding as this, I think I can assume that I'm out of the bulk research stage and moving into the development stage. I can't think of anything now, but there's a low but not 0 probability of discovering a new innovative feature to implement whilst modelling the printers. Also, the Slim/Small is expected to change from 305mm -> 355mm in Y footprint for the Placement Block.

With a description as confident-sounding as this, I think I can assume that I'm out of the bulk research stage and moving into the development stage. I can't think of anything now, but there's a low but not 0 probability of discovering a new innovative feature to implement whilst modelling the printers. Also, the Slim/Small is expected to change from 305mm -> 355mm in Y footprint for the Placement Block. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I looked into CadQuery since I wanted to scan over my CAD options again before embarking on implementation modelling in Fusion360 and it was all seeming well until I read in the docs that tangent arcs haven't been implemented yet, which is kind of my "bread 'n' butter" after mutli-profile sketches.

Are you sure? yes | no

I'm starting to suspect that Fusion360 is what's preventing me from project progress (in more than just this one) so I tried writing out a concept in Markdown: https://hackaday.io/project/184196-ensweepen-gd0096/log/210254-c-markdown-based-cad

Are you sure? yes | no

Found the syringe needles but it seems that 2x5ml is the max I can fit in the space provided instead of 4 x 10ml due to the lack of screw capped syringes under 100ml. There's a very nice looking steel 10ml on aliexpress [https://www.aliexpress.com/item/1005002498842658.html] but they're 10x too expensive and I won't be able to use a light-based approach for detecting when the syringe is almost empty. For the latter, I may be able to detect a current difference on the pump.

I might be able to get 2x5ml + a 3ml syringe in there, so that UV curable resin, silver paste and solder paste can be used in a 3DPCB. I'd also be fine with 5ml + 2x3ml or 3x3ml.

Are you sure? yes | no

On the search to make sure 400kPa (58psi) was good enough to despense things as viscous as solder paste, I found out about nScrypt's fabulous and fancy printer demonstrations: https://www.youtube.com/watch?v=g6z_n2ulBs4

Seeing this, it seems that it's possible to do away with the printed tracks, and instead: print PCB surface -> deposit tracks -> laser cure/sinter -> print next layer straight on top, filling in the gaps.

Additionally, I'm thinking of a 6 section rotating cam to use for enabling or disabling 4x10ml syringes + fibre nozzle. Ideally, I'd like to still be able to use pressurised air to extrude the paste, as then I can swap to 5 / 2 / 1ml syringes without much issue.

Are you sure? yes | no

It's likely that the paste would spread out if it's not dispensed into a track. It might be something like 0.24mm min track width on substrate vs 0.16mm min into substrate. I'm going to aim for 0.16mm-into since a 30G syringe needle is 0.159mm.

Are you sure? yes | no

I'm thinking of going with piezo sensors instead of 3D Touch so that I can get Z offsets for all nozzles, as well as detecting if the entire head has hit something when the Z axis is raised (eg for laser cutting).

Are you sure? yes | no

A continuous green laser has been used to cure (and somewhat sinter) silver paste, according to the abstract of this paper: https://www.wlt.de/lim/Proceedings2015/Stick/PDF/Contribution319_final.pdf

The absorption of silver nanoparticles (the stuff in the paste) is closer to 400nm than 532nm green: https://nanocomposix.com/pages/silver-nanoparticles-optical-properties

Thus, it makes sense to have a 5W laser in the Small. I was thinking of no laser since "Do I really need 2 laser cutters?"

Are you sure? yes | no

Now I'm in "implementation research", which is the tedious process that can be simplified to something like "Should I use these bolts or those bolts?". I think it makes sense to write such research as comments to this log. The first one is going to be large because of the backlog before this idea.

So far:

- Confirmed that the C80-EAIR + 12V slim PSU is the best option whilst keeping the upgrade price for laser under £200. The 12V has the same outer dimensions as the 24V, so at least I can make the wiring symmetrical.

- Found out that off the shelf pick and place heads are really expensive.

- Found out that silicone tubing is flexible enough to rotate +/- 180 degrees, avoiding a coupler that adds Z height and is apparently leaky [https://youtu.be/6nYbVT_qe1o?t=203]

- Found the SY-020, which looks like the UV-U3 pump but it's rated for 50dB instead of 60dB and has a max pressure of 400kPa instead of 350kPa.

- Found a current sensor (ACS712), which will be used on the pump to detect if a part has been picked up successfully.

- Made a quick sketch in fusion to confirm that everything might be able to fit in 90x90mm XY, though it would be nicer if I could get 80x80mm.

- Confirmed that basalt fibre is the best option currently available to me. I found out about UHMWPE fibres, but then I read a paragraph the basalt fibre seller sent me months ago that said basalt was better. UHMWPE also seems more expensive.

- Decided to scrap the Desktop Metal way of placing continuous tow and will design for a 0.5mm thread. This is because raw carbon fibre and basalt tow doesn't seem to be all that stable at the tip end. I'll have to make a machine that takes the raw fibre and spindles it into nice, managable rolls. Additionally, this change to 0.5mm round thread means that I can get truly continous fibre and fit it in smaller cross sections. Very small and very large parts is what I expect would benefit most from reinforcement.

Currently, I'm:

- Reading about using compressed air to dispense pastes. [https://azcscxpprodcdn.azureedge.net/-/media/Files/Nordson/efd/Products/White-Papers/Solder/Nordson_EFD_Air_Powered_Dispensing_White_Paper.pdf] Apparently, I thought anything that needed "compressed air" needed a massive air compressor. Turns out 20 - 40psi is only 137 - 235kpa, and uh... the SY-020 does 400. I'm looking for solutions different from the classic syringe plunger since Z height is limited. Now I'm wondering if I can actually use this air pressure to move the syringes up and down like a button press pen, as this would further reduce the amount if stuff that needs to be in the Placement Block whilst simultaneously increasing the amount of pastes and the volumes it can carry. I might actually be able to port the chocolate extruder from gd0036, though I'd have to look into sub-ambient part cooling for actually decent results.

Things to do:

- Briefly look into sub-ambient cooling.

- Look into cheap + small cameras to use as syringe nozzle and cartridge application cams. Unlike gd0036, the movement would be slow enough to use 30fps cameras without it being a complete blur.

- Look into the pressure required for the button press pen idea.

Things I'm not sure about:

- Inclusion of a vinyl cutter. The blades used are dirt cheap, but that's an additonal tool I need to actuate.

- It might be possible to use the laser to heat the silver and solder paste. Useless for BGAs, but might be required for localised heat curing the traces without having to expose the entire print to temperatures well over its Tg.

Things I might research further:

- Flexures for the LCD screen. I found out whilst watching a video of a DIY scanning laser microscope that those dirt cheap steppers can be used for micron level movement. [https://openflexure.org] Not sure why this hasn't been done, but if I can get 20 micrometres of movement, I might be able to get edges that even beat current 8K (28um) printers on the market.

- Laser Direct Write. Researchers in 2017 were already making PCBs with it. [https://youtu.be/nc7plvP_hIY?t=210]

Are you sure? yes | no

Oh yeah and the rotational axis once used by the fibre tool is now being used for a second PnP nozzle.

Are you sure? yes | no