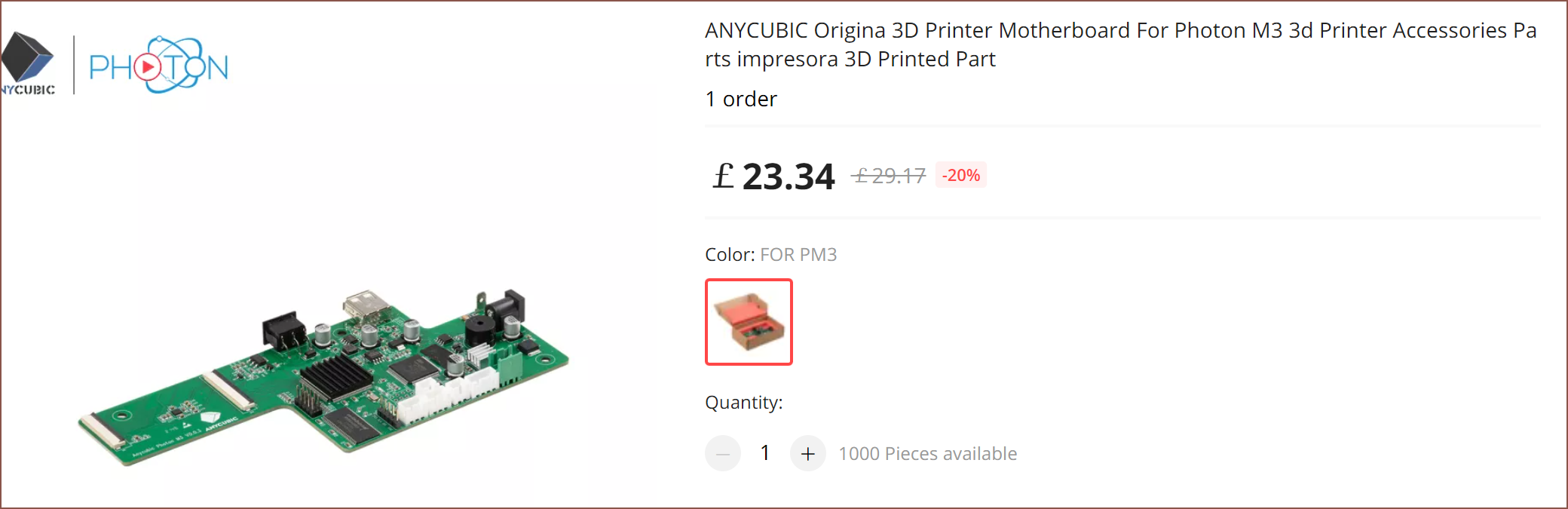

So I'm browsing AliExpress and stumble upon the control board for the Photon M3.

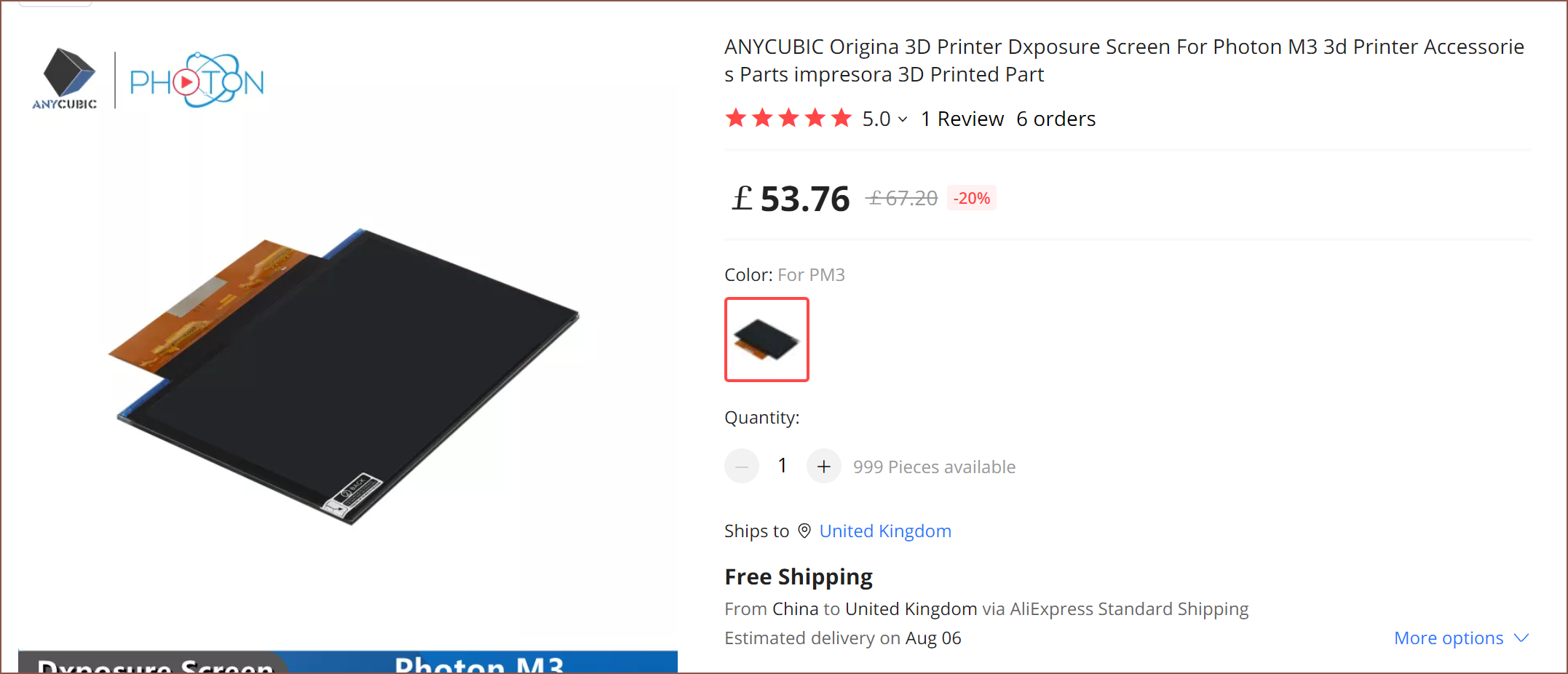

Additionally, the Photon M3 screen was still available for the £54 price, and with more quanitities than 1 or 2.

Additionally, the Photon M3 screen was still available for the £54 price, and with more quanitities than 1 or 2.

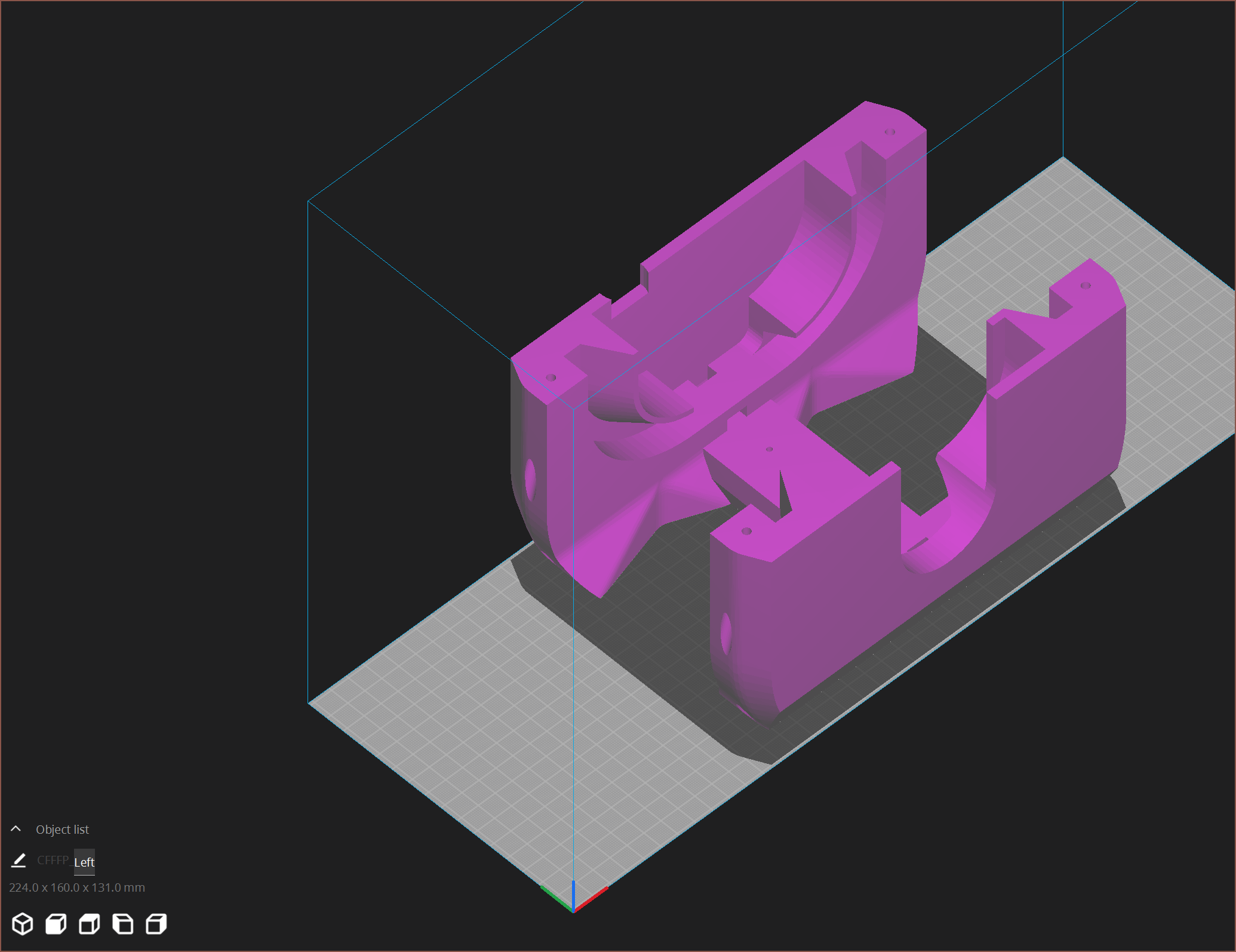

Wait. It... fits?!

Wait. It... fits?!Speed Calculations

But surely, FDM printers like the Sublime will still be faster when it comes to draft prints, so there's a need still.

Assuming 3 * 1.5s exposure for a 120um layer thickness and 3 seconds to change resin whilst cleaning the layer: 160 /(3600/7.5 * 0.12) = 2.7778 .78 * 60 = 46.8 minutes Time: 2h 47m.

*starts slicing with the CR10 0.8mm nozzle + 0.5mm layer height profile*

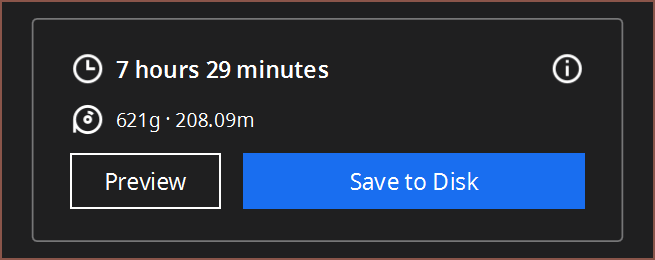

Ok so I just have to beat 2h 47m and the SecSavr Sublime isn't redundan--

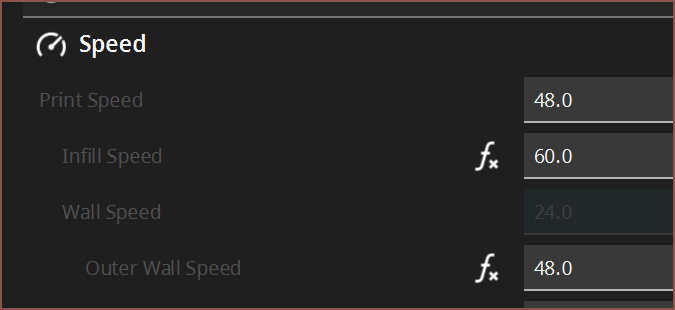

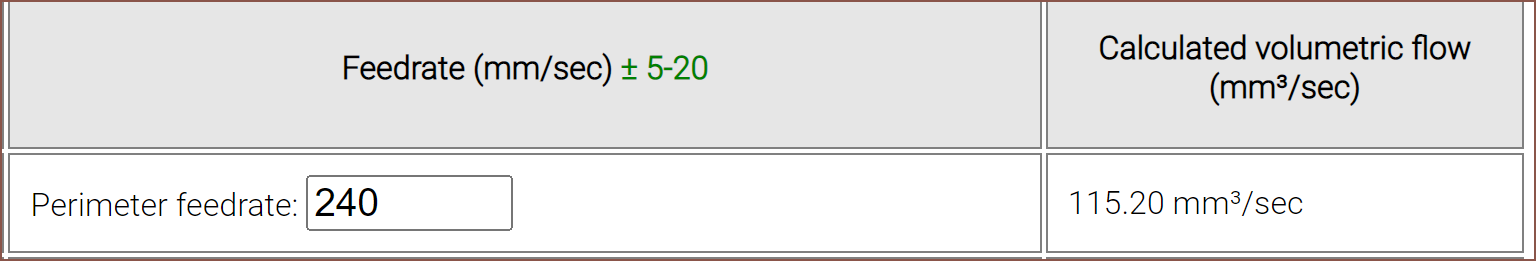

Speeds?

Ok those might be a tad slow, maybe? Ok what if the change takes 6 seconds and not 3?

160 /(3600/10.5 * 0.12) = 3.8889

Still sub 4 hours!!

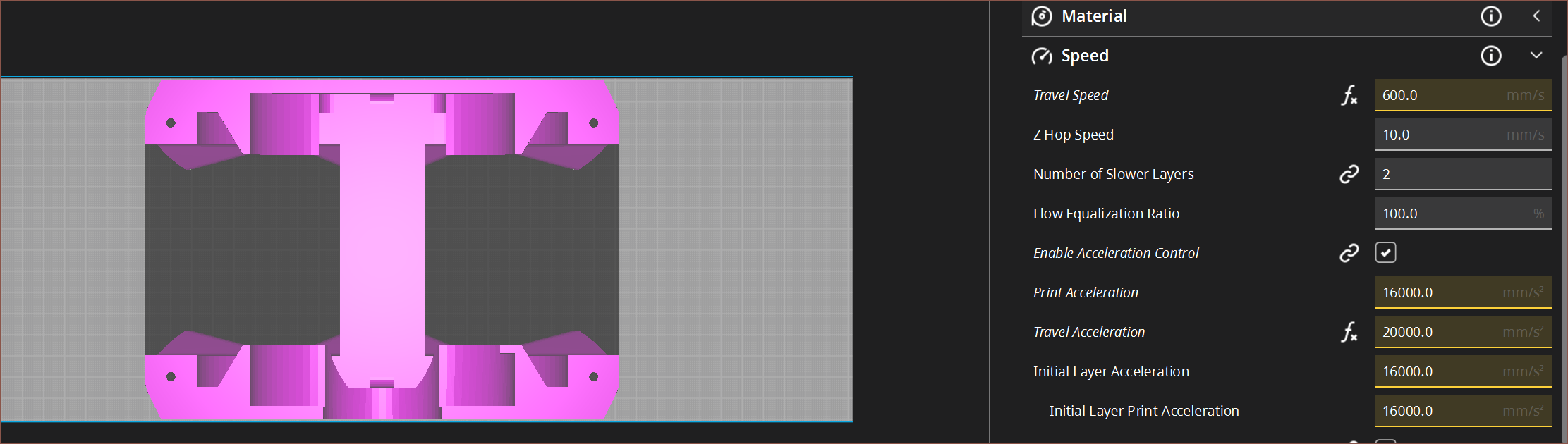

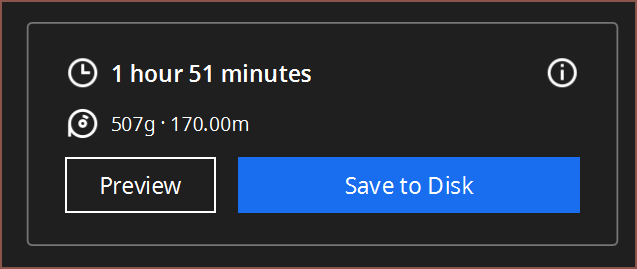

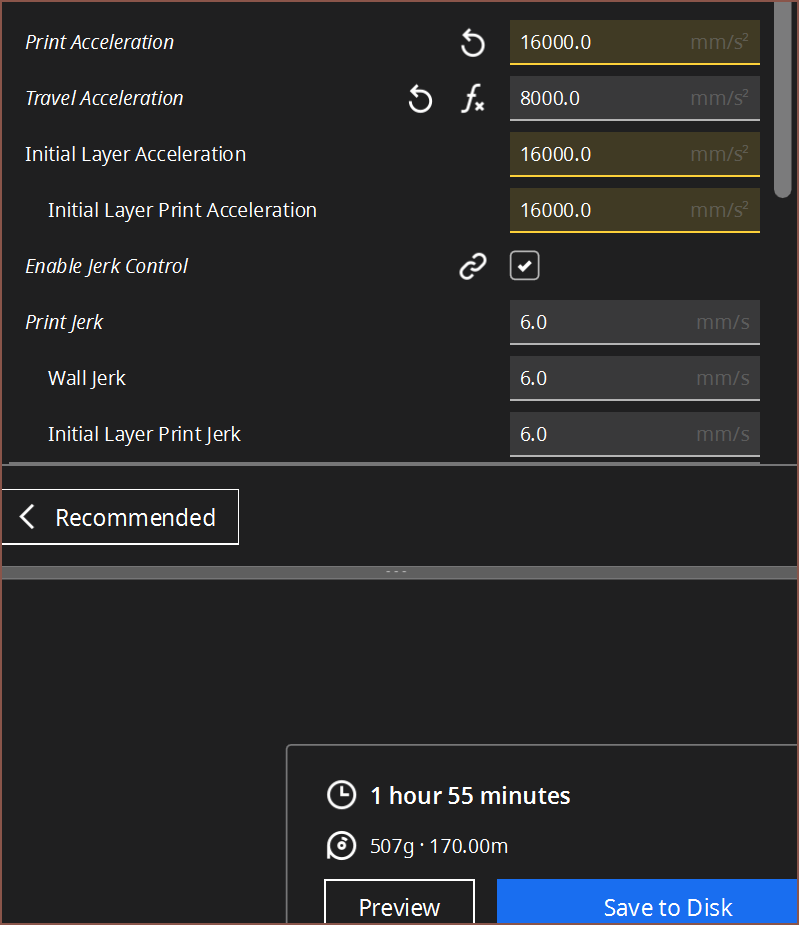

Ok. TestBox Profile Me. 0.8mm nozzle, 0.5mm layer height, 240mm/s everywhere, 16K print acceleration and 20K travel acceleration, 8% double-lined infill.

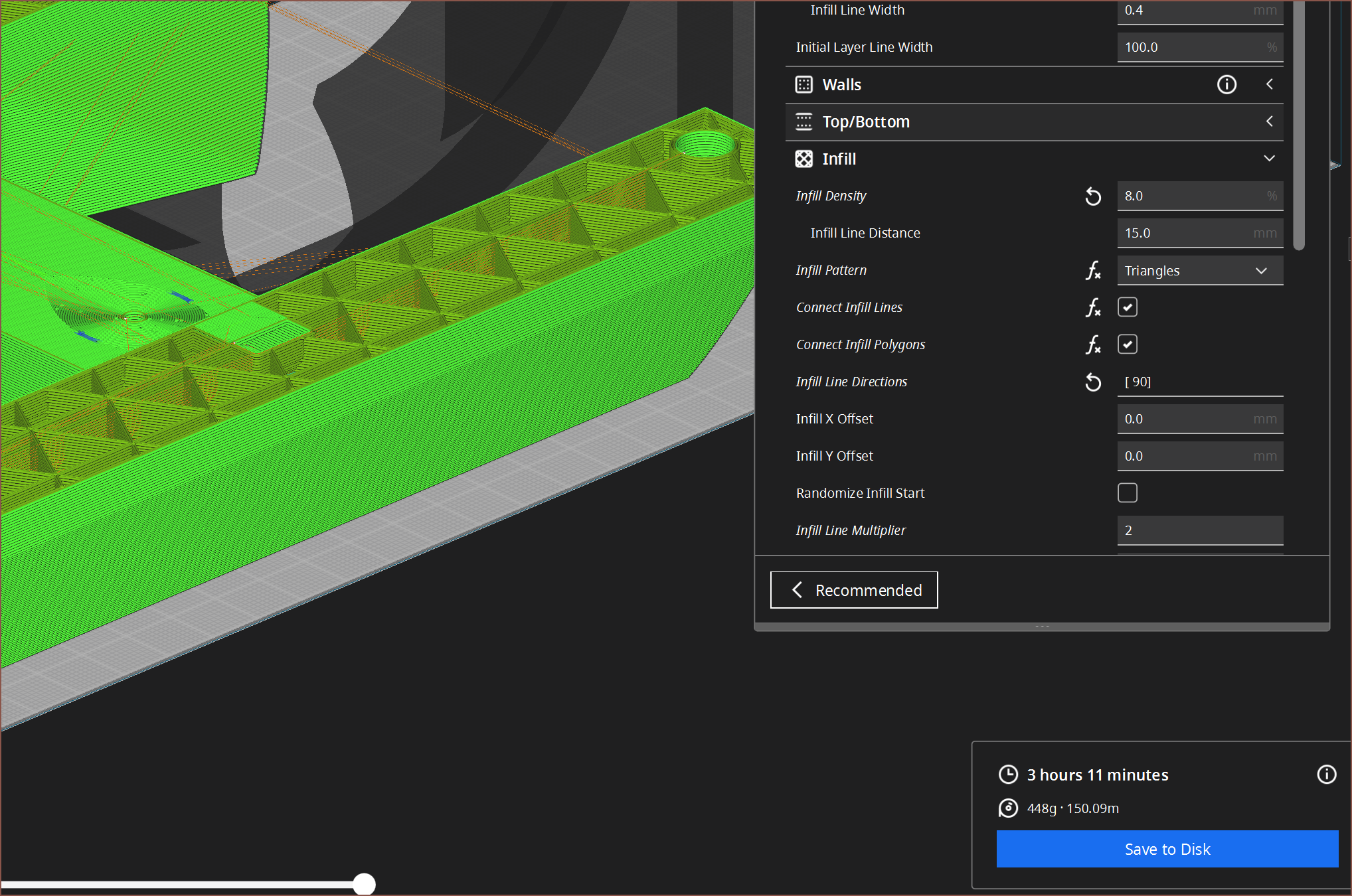

Phew. Wait. The height is 131mm not 160mm.

Phew. Wait. The height is 131mm not 160mm.131/(3600/10.5 * 0.12) = 3.184 .184 * 60 = 11.04 Time: 3h 11m

It's... a tie?

[E1: 18th July] I didn't notice that Cura didn't save the new nozzle size when I changed it in settings.

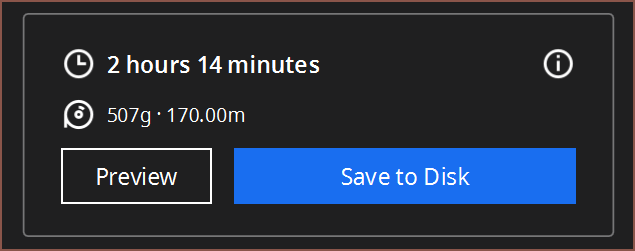

Even with more realistic flow rates of 120mm/s and 9K acceleration isn't that much of a time penalty:

It's still quite a shame that print speeds and accelerations more-or-less cut in half are only a 20ish minute difference apart.

It's still quite a shame that print speeds and accelerations more-or-less cut in half are only a 20ish minute difference apart.  Seems that most of the gains are in acceleration anyway.

Seems that most of the gains are in acceleration anyway.[E1 End]

Doesn't look like the 0.1mm layers would even need the 5 axis ironing step like for a 0.5mm FDM print.

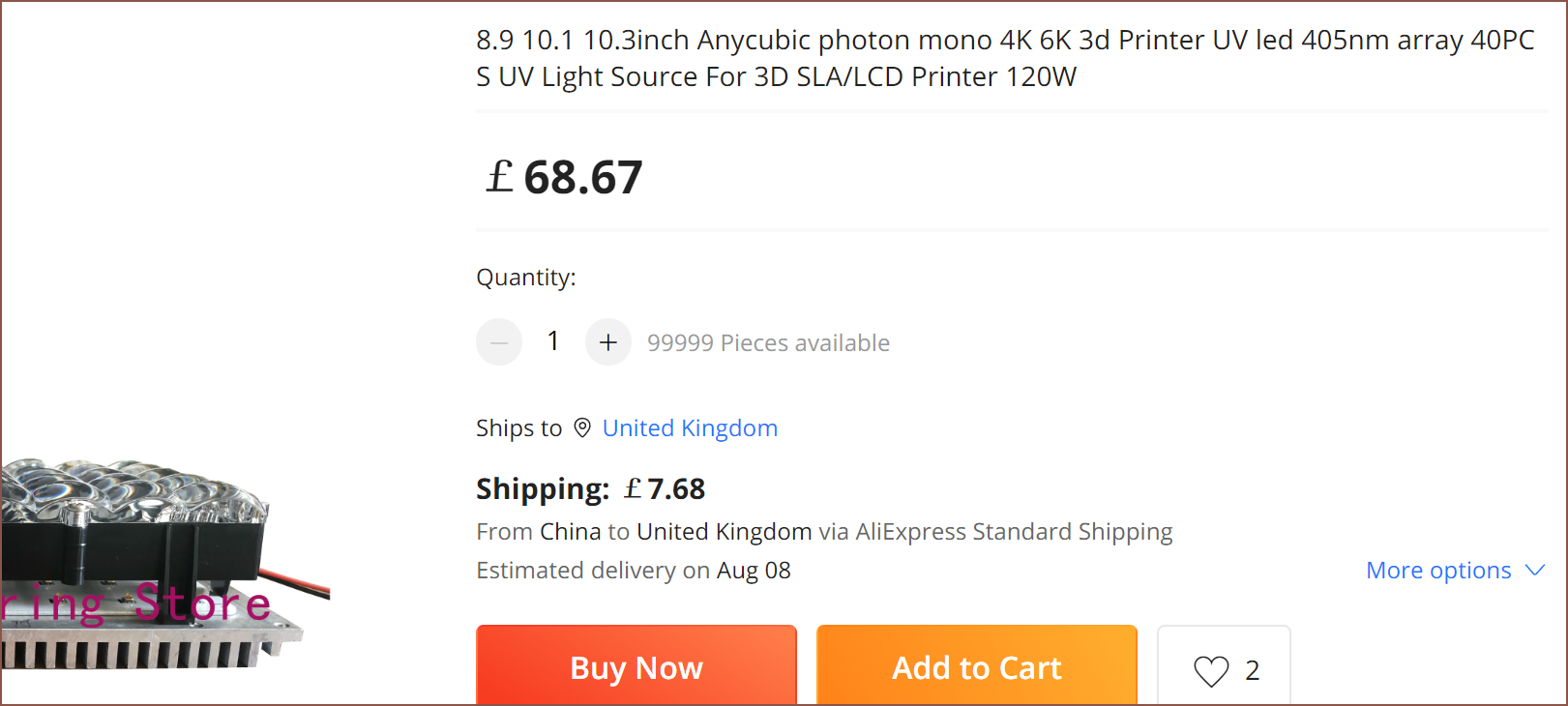

Looking at the 8.9" screen again

8.9^2 / 6.6^2 = 1.8184 108 * 1.8 = 194.4 W source to match 108W COB

Now, writing this log, I realise that the screen sizes aren't square so the area difference is less than this. Anyway, I went off to look for that kind of power since the one at the store was only 120W.

Longgggg story short (like 5+ hours), anything with a power over this one cost a significant amount more, with some over £400.

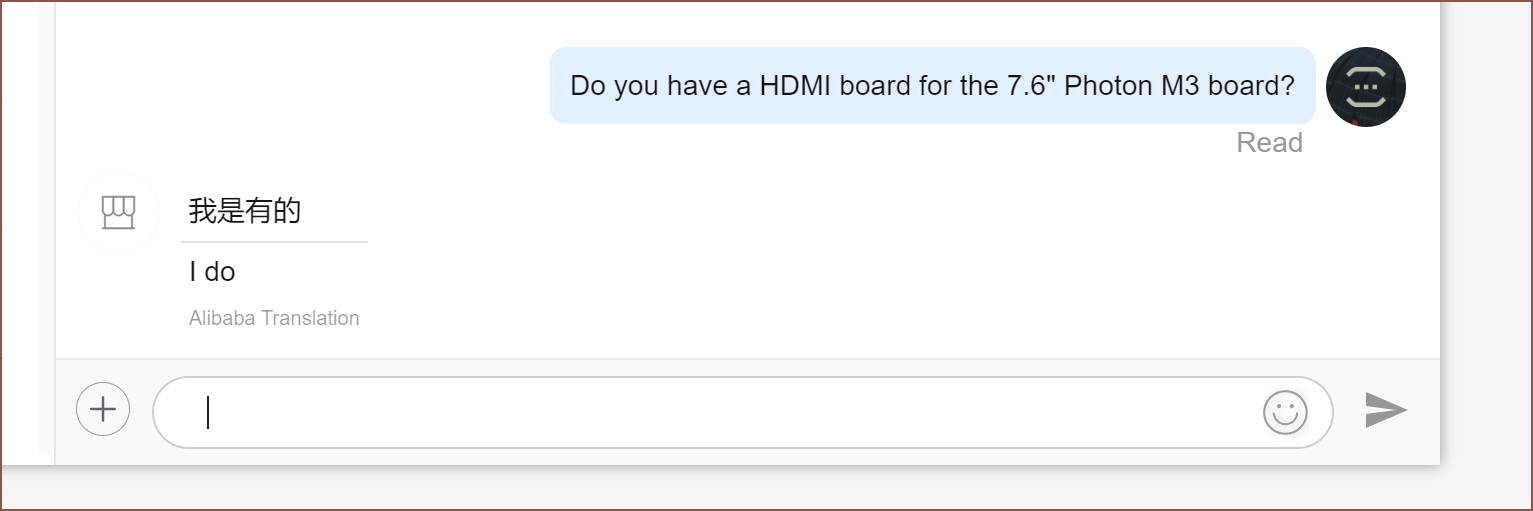

Longgggg story short (like 5+ hours), anything with a power over this one cost a significant amount more, with some over £400.The 7.6" 4K screen

At 4:53 am, I asked this:

The seller said that the 6.6" COB was the best option for what they had. I can confirm, since one of the options was this beast:

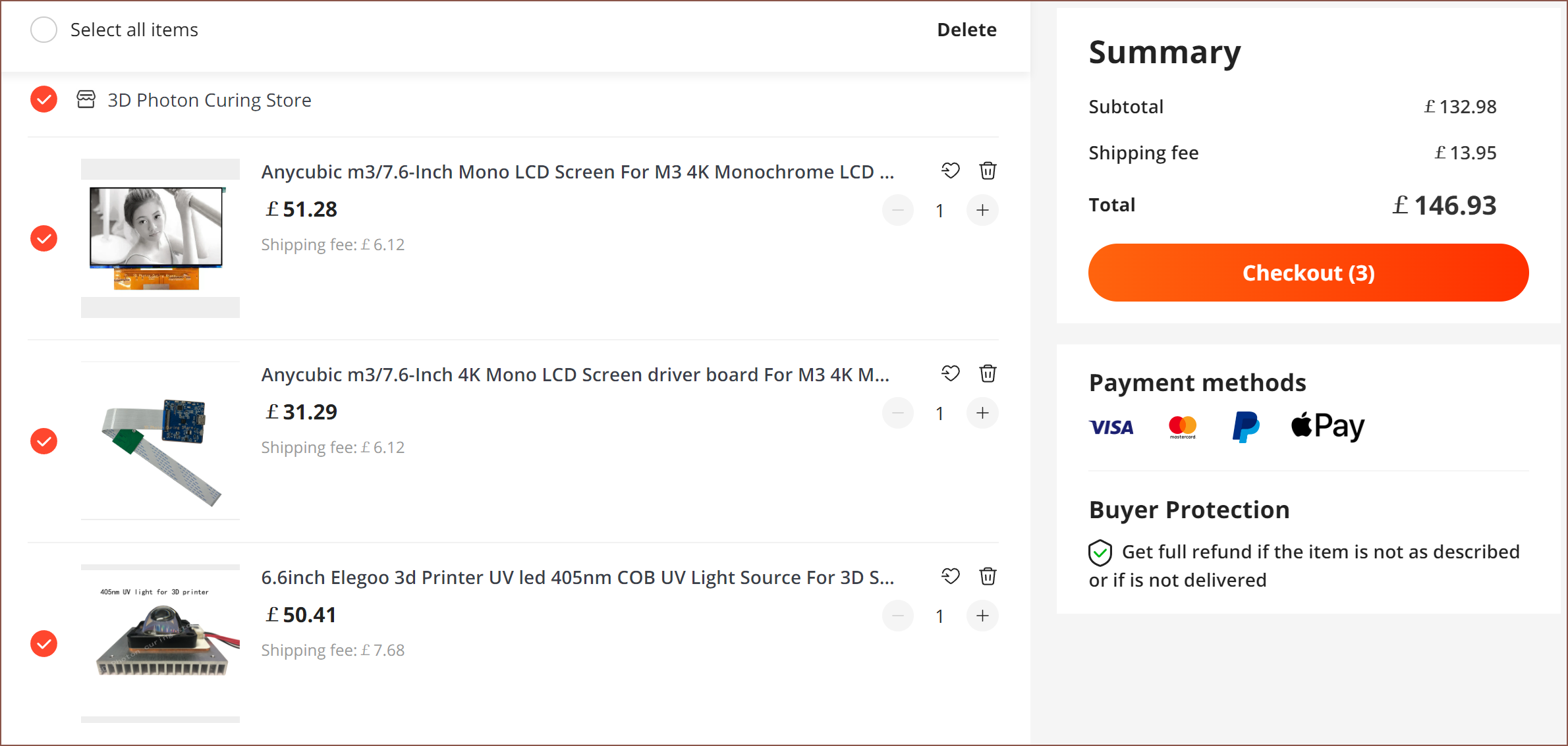

Some time later, the listings were up and the total cost was only £8.60 more than the 6.6" setup.

Some time later, the listings were up and the total cost was only £8.60 more than the 6.6" setup. Truly innovative stuff. Also, the seller sent me an image of the COB height:

Truly innovative stuff. Also, the seller sent me an image of the COB height: Looks to be under 45mm.

Looks to be under 45mm. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.