I'm looking at my thickness options for the cast tooling plate and want to balance cost and weight reduction. For a 540x168mm bed, 5mm is £25, 6mm is £30, 8mm is £40 and 10mm is £50.

I went scanning on the internet for some calculator, but I have access to Fusion 360 so I used that instead to get a more accurate simulation. The plate is fixed up to 20mm away from the edges.

Simulating the bed with and without a part on it

The 6mm plate is 1469g and the 5mm is 1224g.

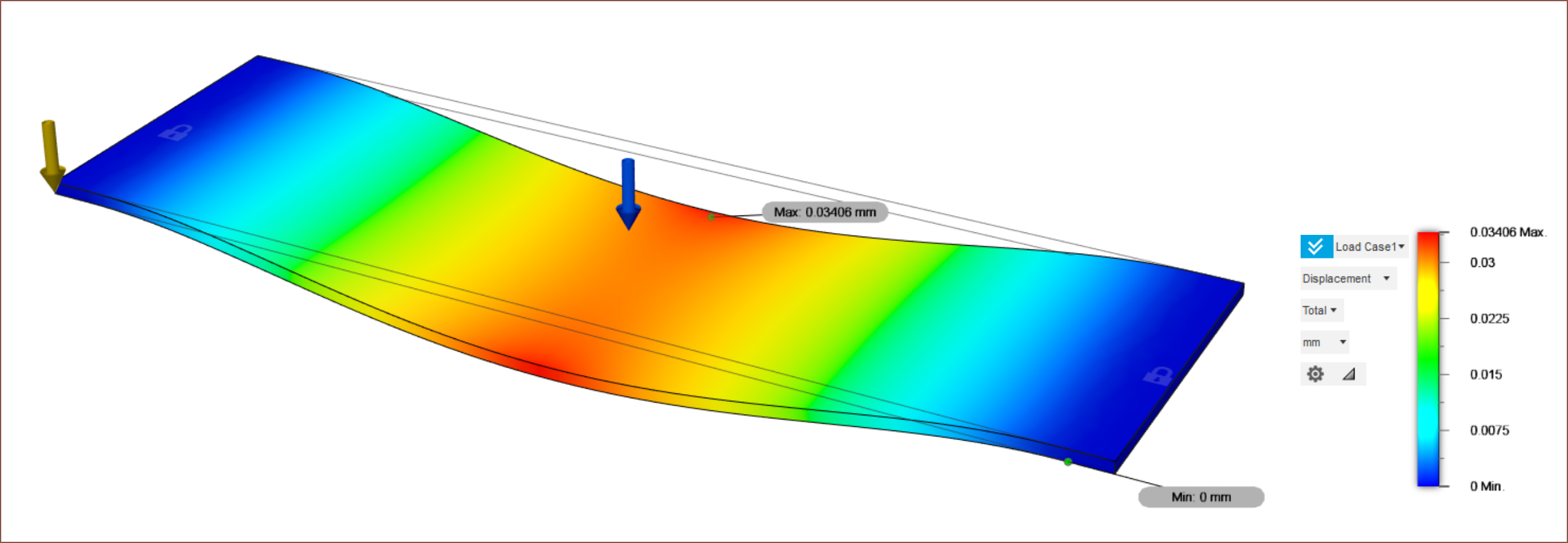

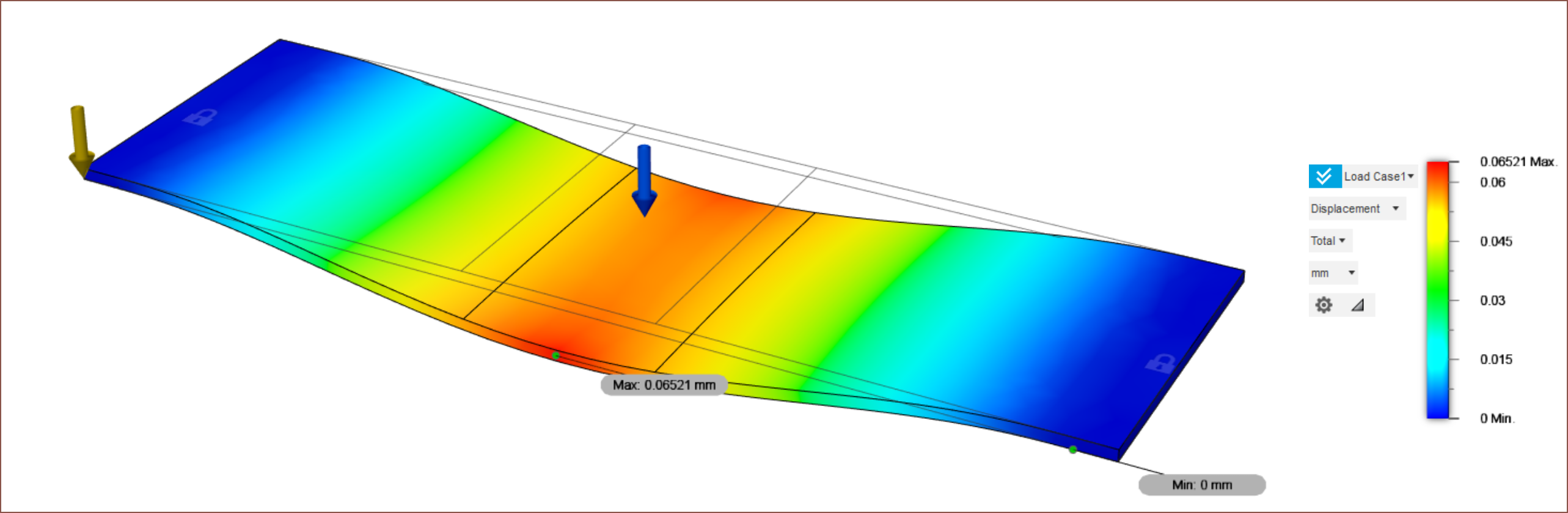

This is the 6mm bed with a 10N (approx 1kg) uniform load on the top. The max deflection is 34um which sounded pretty good so I went to 5mm.

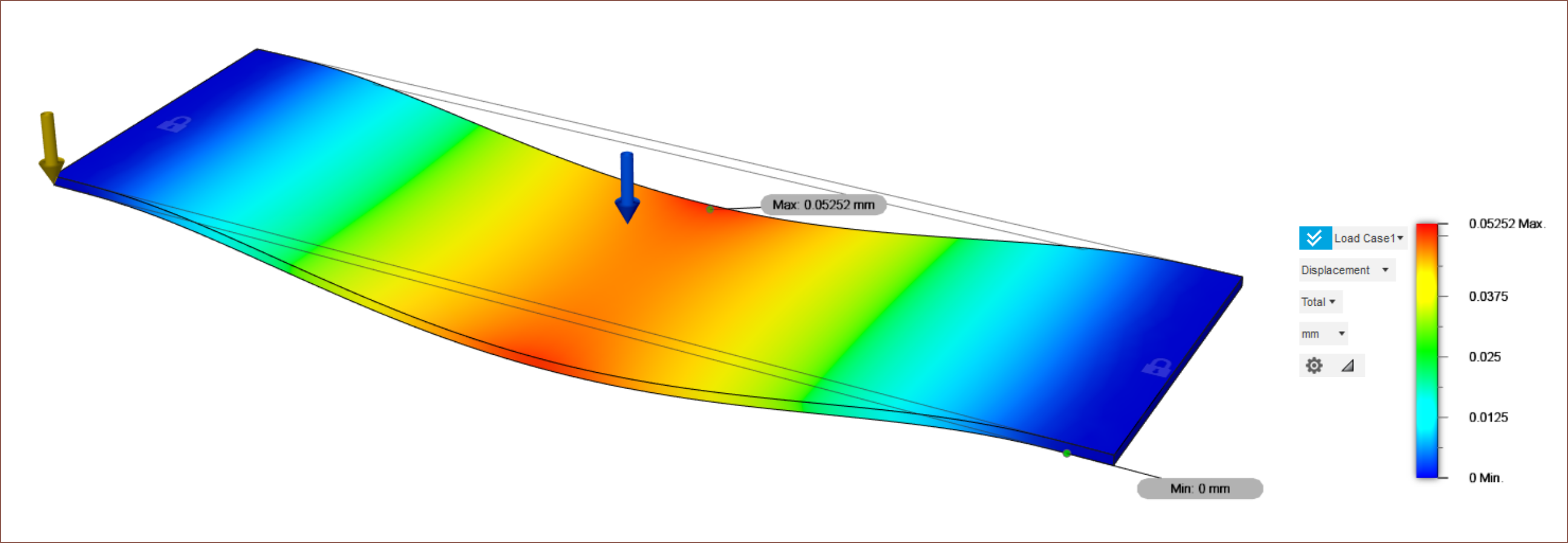

The deflection is now 52.5um. Considering that deflection is over an entire print job, it likely wouldn't affect printing anything.

The deflection is now 52.5um. Considering that deflection is over an entire print job, it likely wouldn't affect printing anything.I wanted to do a more localised force test, but first I wanted to see deflection of an empty bed.

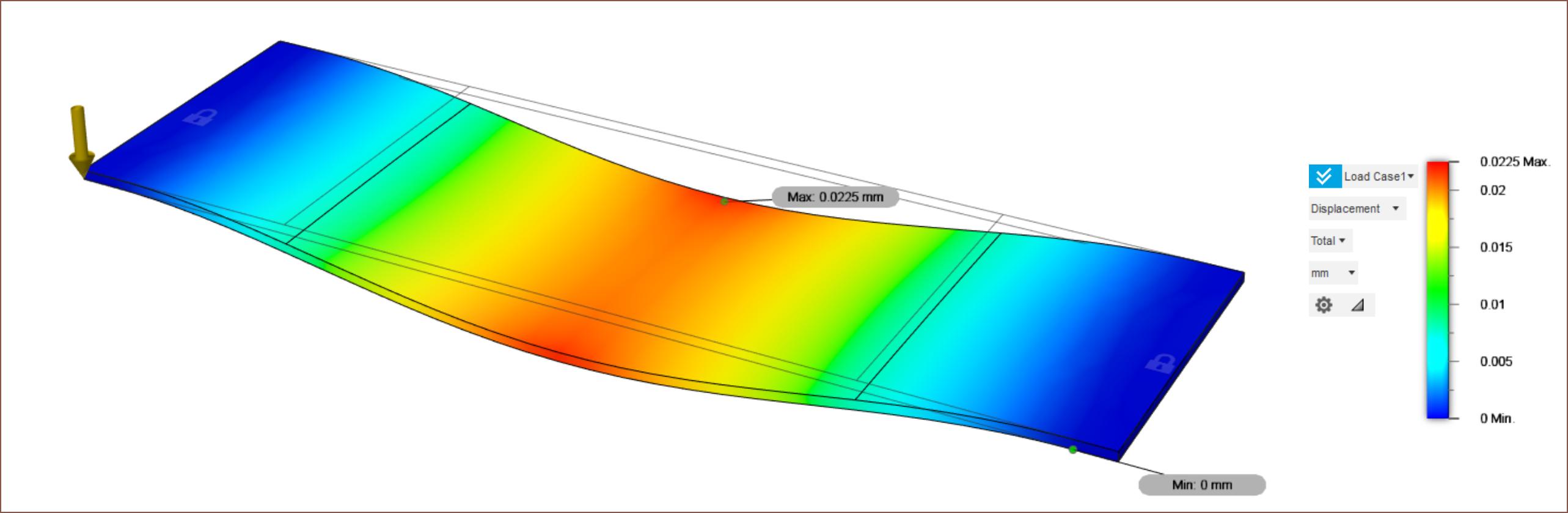

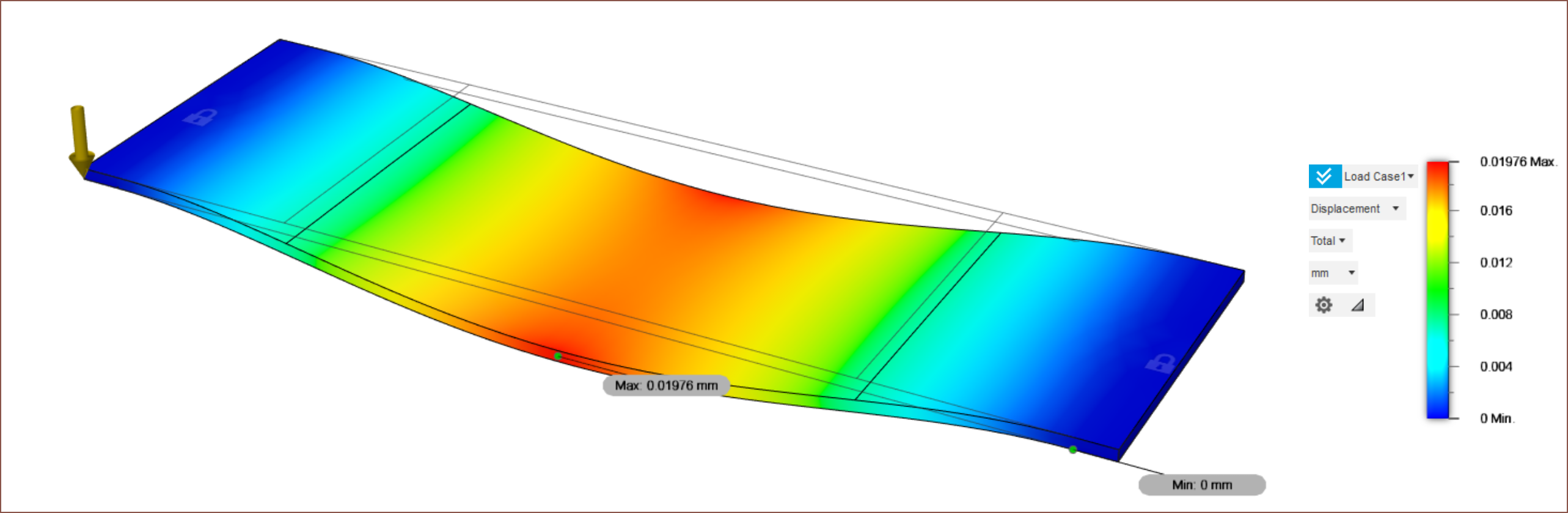

Without any load applied and only gravity acting, the max displacement of the plate is 23um on the 5mm plate. I do wonder if that could cause some first layer complications. 6mm isn't much better at all, reducing deflection by only 3ish microns.

Without any load applied and only gravity acting, the max displacement of the plate is 23um on the 5mm plate. I do wonder if that could cause some first layer complications. 6mm isn't much better at all, reducing deflection by only 3ish microns.![]() Simulating pressing against the screen

Simulating pressing against the screen

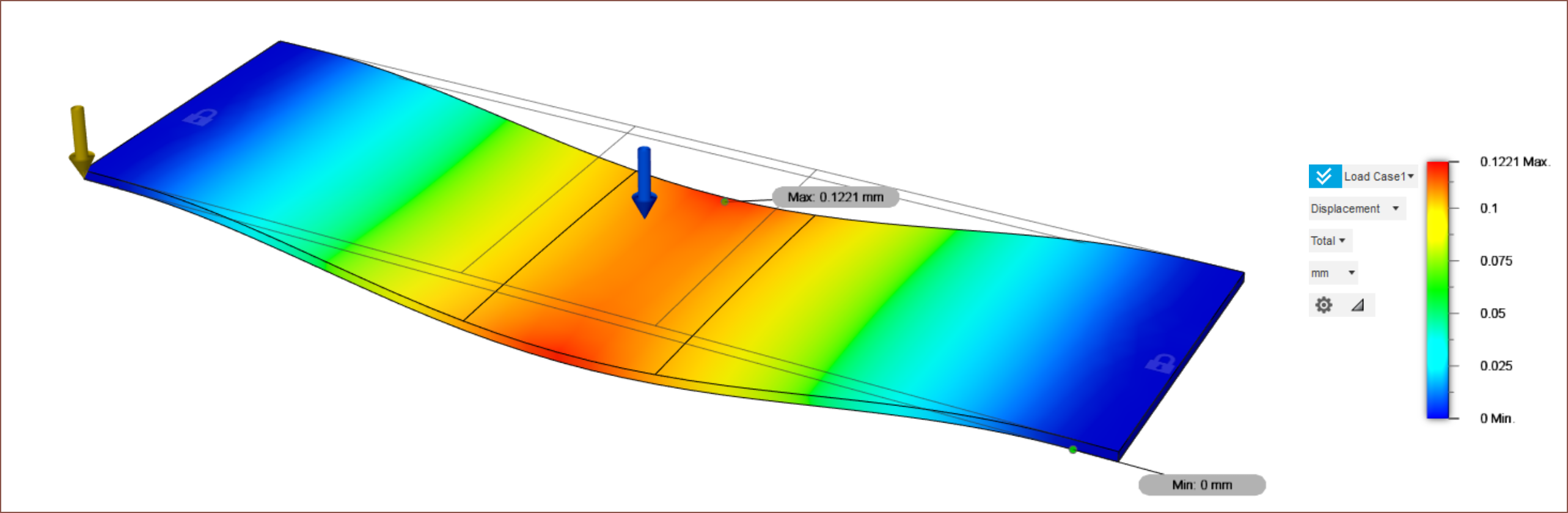

I'm just going to assume a 2kg force is applied to the screen.

5mm isn't looking too good.

There's a displacement of over 100um from no force applied. In practice, the distance between the screen and the part would likely be similar across the length of the bed if compensated in software and would likely not be seen in the part. The force against the screen may also reduce as resin gets pushed out of the way.

There's a displacement of over 100um from no force applied. In practice, the distance between the screen and the part would likely be similar across the length of the bed if compensated in software and would likely not be seen in the part. The force against the screen may also reduce as resin gets pushed out of the way. 6mm halves the deflection to about 1 pixel length (40um).

6mm halves the deflection to about 1 pixel length (40um). Conclusion

Considering the 250g difference in weight, £5 difference in price and better performance, I'll use the 6mm thickness. Before this simulation, I was thinking that I'd have to use 8, 10 or even 12mm. Considering I don't know all the factors just yet, I think 6mm is the safer decision. It's also closer to 1/4", which is likely a common cast tooling plate thickness.

kelvinA

kelvinA Simulating pressing against the screen

Simulating pressing against the screen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I only have one local supplier here, so very limited data set. And cheap is relative ;) But they do offer 2.25" OD aluminum tube, in either .125" or .375" wall thickness, cut to size. I doubt the prices will be competitive with ebay, but I tend toward buying local when I can rather than chasing prices. I was mostly just trying to confirm that they were "standard" sizes.

Are you sure? yes | no

I can confirm in America, 1/4 inch is readily available, and is the thinnest such size at my local metal supplier. 1/4, 3/8, 1/2, 5/8, 3/4, 1, 1-1/4, 1-1/2, 1-3/4, 2, 2-1/2, 3, and 4 inches. Just for your reference in case it matters later.

Are you sure? yes | no

Is there cheap 2 1/4 inch (57mm) aluminium tube (cut to length) over there? The surface looks good enough to at least try it, it's seamless and it's £10 delivered from ebay.co.uk for 500mm or £11 for 600mm with free cutting service. I'm wondering if I should spring for the full 510mm X axis (5 screen areas) or stay under a X axis length imposed by a probably-common max roller length of 500mm.

Are you sure? yes | no

Gah, I did the old person thing and replied to the OP rather than this. I'll be even more old person and put my edit here rather than adding onto the other one. The "standard" length if you don't pay slightly extra for cutting, seems to be 24" or 2 feet.

Are you sure? yes | no

As long as there's a cutting service, that's good enough for my science. I've already moved to a 510mm design since there'd probably be more situations that call for a 500mm print instead of a 490mm one. I just want to avoid a Positron scenario (special order parts) where possible.

Are you sure? yes | no