It feels like a while since I've actually done some grind modelling. It's likely because there are so many moving parts to gd0036 that I never really dove deep into a computation since things could change, so most designing has been pseudo conceptual. Modelling this reminds me of the days spent modelling the #SecSavr Skyrise [gd0092].

It feels like a while since I've actually done some grind modelling. It's likely because there are so many moving parts to gd0036 that I never really dove deep into a computation since things could change, so most designing has been pseudo conceptual. Modelling this reminds me of the days spent modelling the #SecSavr Skyrise [gd0092].

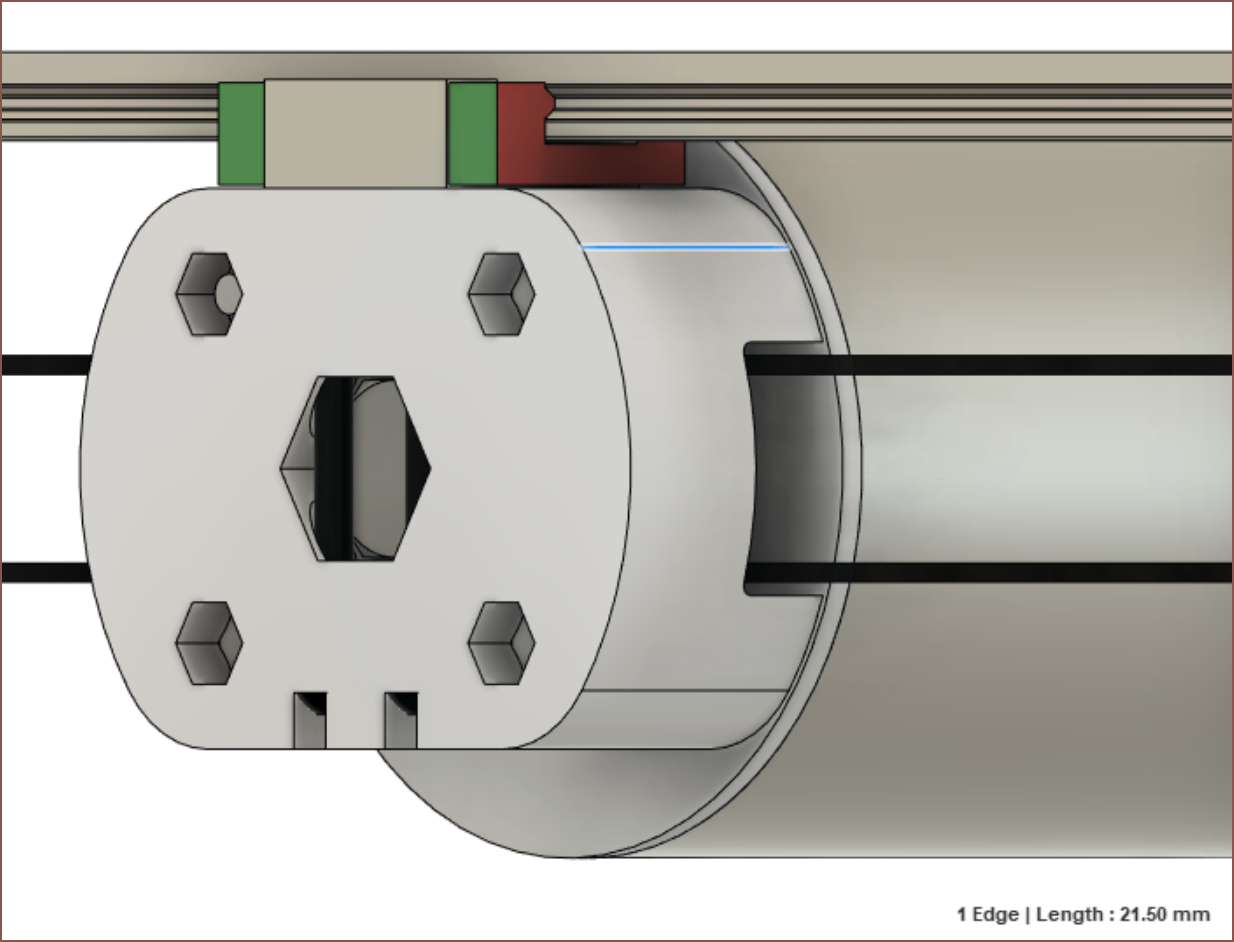

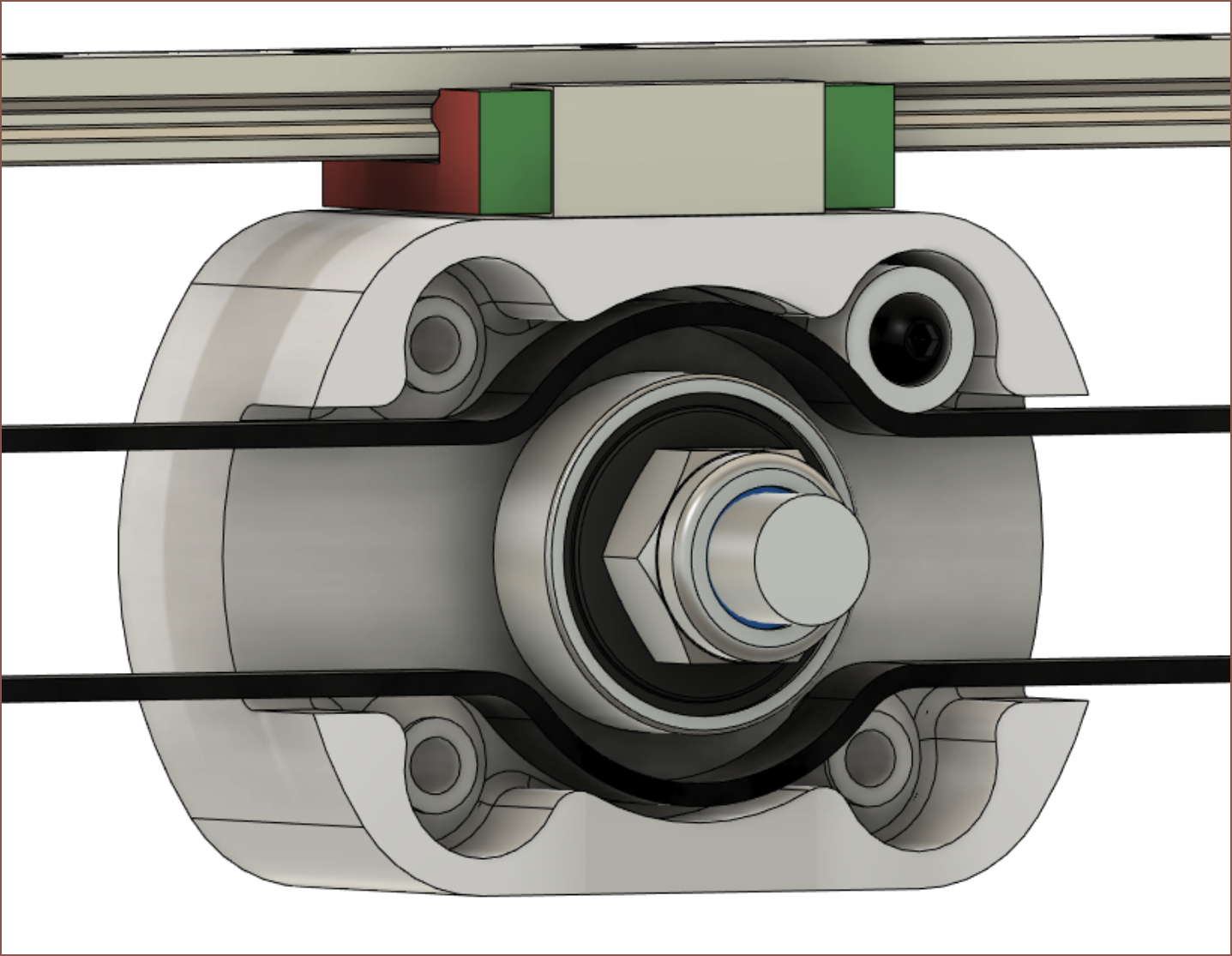

Anyway, I was hoping that my belt system idea would reduce the roller sides from the estimated 25mm in the concept, but that isn't the case since I needed to be able to mount to the outter carriage holes (the black bolts).

Part of the reason is the rail, for which I first mentally computed a solution that probably woudln't intersect the bed assembly. At least it looks more sleek and actually has a linear rail, unlike the concept model. I'm also trying a new way to do bolts in Fusion. Instead of having a file for each bolt length, have a file for the bolt head and, before importing it into the model, making a "Bolt" component. Then the head can be jointed to a part and a cylinder can be extruded to a specific length. Lastly, the body and the head component are asbuilt jointed.

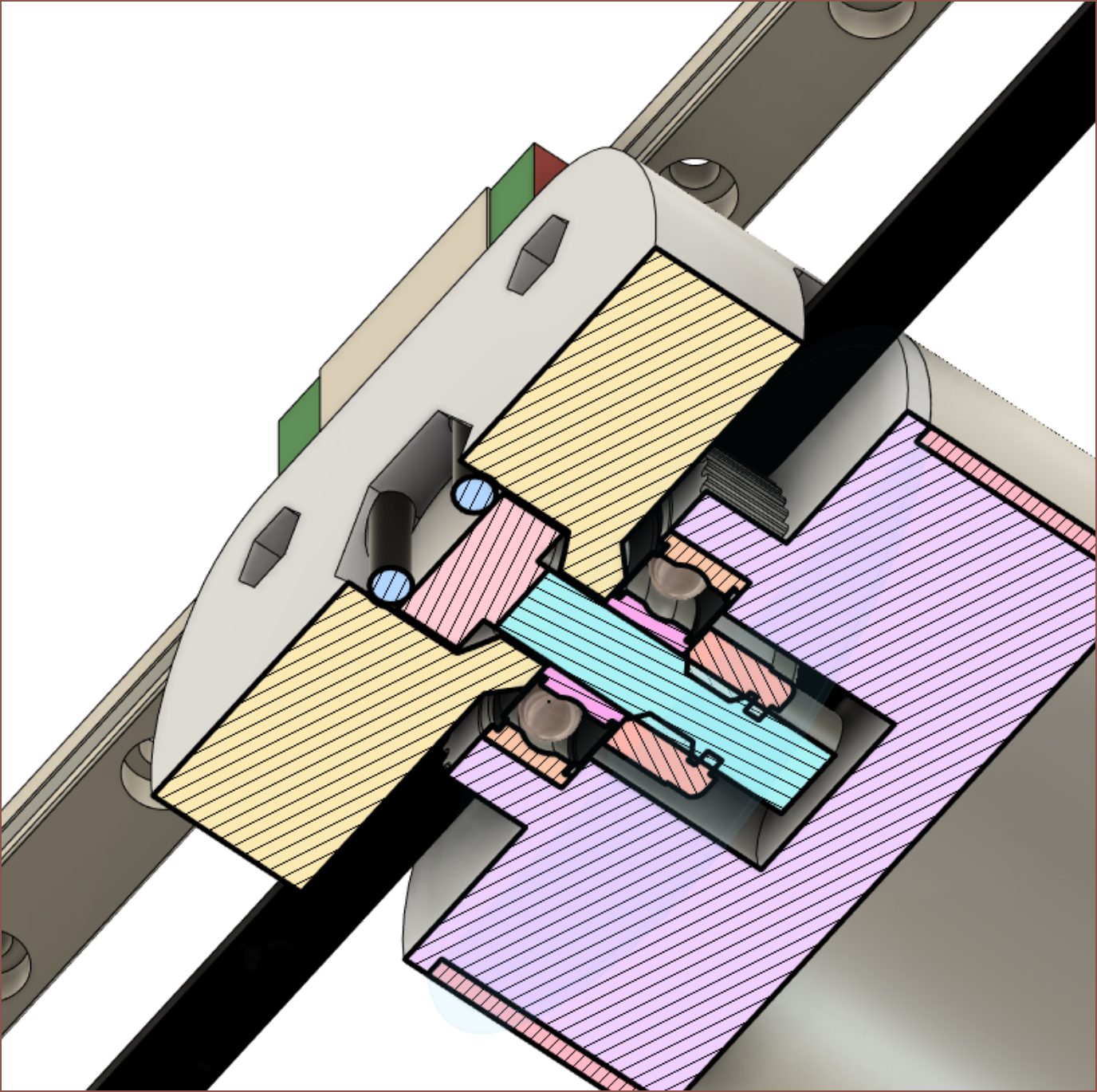

Whilst computing the solution, I've established that the current order of dependencies is as follows:

- Desired X Axis length

- Roller length

- R Axis kinematics

- Y Axis kinematics

- Bed length

- Cartridge length

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.