Everything about the printer except the application, collection and washing of resin is more-or-less standard stuff. The exclusions are things that could only really be fully tested when inside a system (imagine trying to find a good FDM 3D printer bed material by using a 3D pen). With only 8 cartridges, 1-bit colour is the only thing I can think of presently that I won't be able to try out.

Everything about the printer except the application, collection and washing of resin is more-or-less standard stuff. The exclusions are things that could only really be fully tested when inside a system (imagine trying to find a good FDM 3D printer bed material by using a 3D pen). With only 8 cartridges, 1-bit colour is the only thing I can think of presently that I won't be able to try out.I'd like to attempt 10 cartridges over 8 so that full 1-bit colour could theoretically be supported. It also allows me the option to leave a 2 or 3 high cartridge installed for print jobs that use a frequently used colour, such as white.

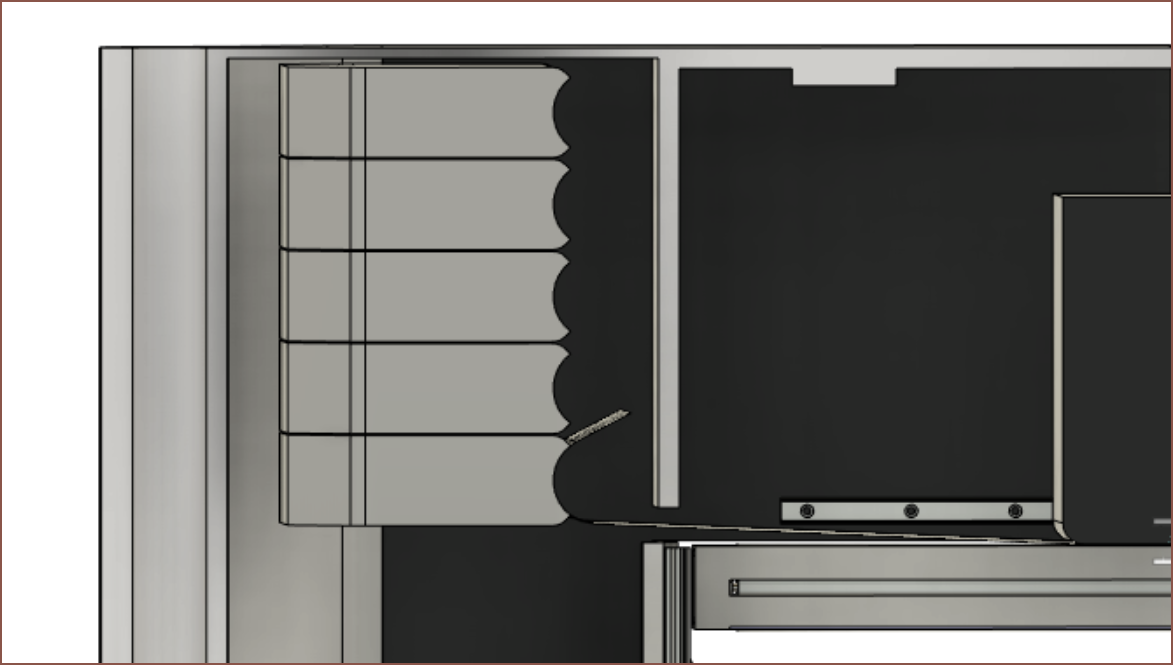

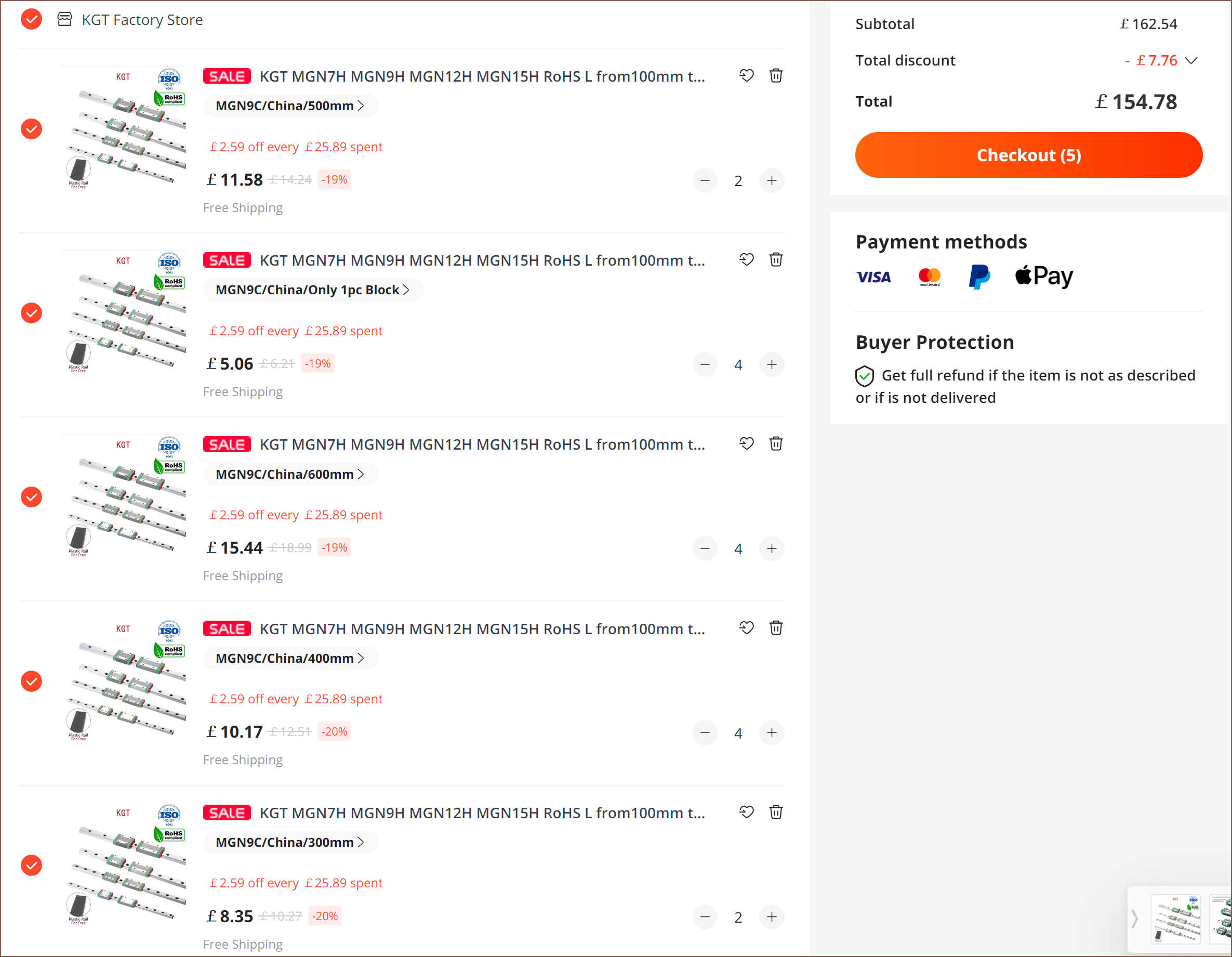

Now knowing this, I plan to use MGN9C for all linear motion. I'd imagine it'll make the BOM slightly less daunting to tackle.

2x300 for the rollers, 4x400 for the Z, 2x500 for the X axis and 4x600 for each set side of cartridges. The cartridges also get 4 additional MGN9C carriages. The roller linear rail length is the only one I've confirmed in CAD for now.

2x300 for the rollers, 4x400 for the Z, 2x500 for the X axis and 4x600 for each set side of cartridges. The cartridges also get 4 additional MGN9C carriages. The roller linear rail length is the only one I've confirmed in CAD for now. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.