Leadscrews to replace ballscrews

About an hour ago, I found out that the 13.6" Prometheus MSLA uses a good old fashioned T8, 8mm-lead leadscrew with a 0.9mm stepper motor. The prints look absolutely fine. Considering that they're cheaper, quieter and have a higher linear stroke : length ratio, I've decided on switching out both sets of ballscrews for T12 leadscrews. I'm using 8mm-lead since that would mean each whole step is 0.04mm, which is the same size as a pixel and I'm only interested in printing in cubic voxels.

T12 was chosen out of concern for the cartridge axes. They're used on the Z axis too to keep the parts consistent (like the linear rails) and because I believe that seeing 12mm diameter leadscrews on the Z axis would make the printer look stronger and more premium.

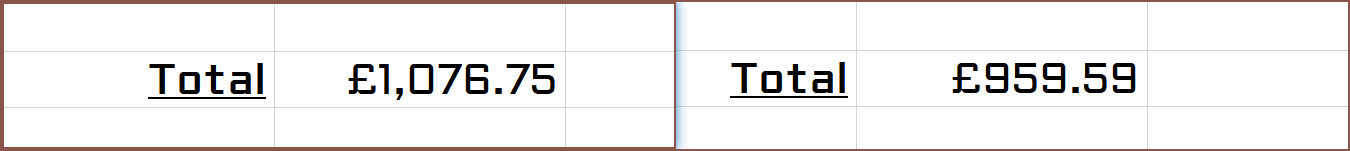

The savings are quite significant, more significant than chasing a couple £ on which Monster8 version to go with. Speaking of which, I just found out that Zonestar made an 8 stepper motherboard. It's smaller than the regulars at 117x95, but unfortunately doesn't seem to come with UART support and costs more than the BTT Octopus.

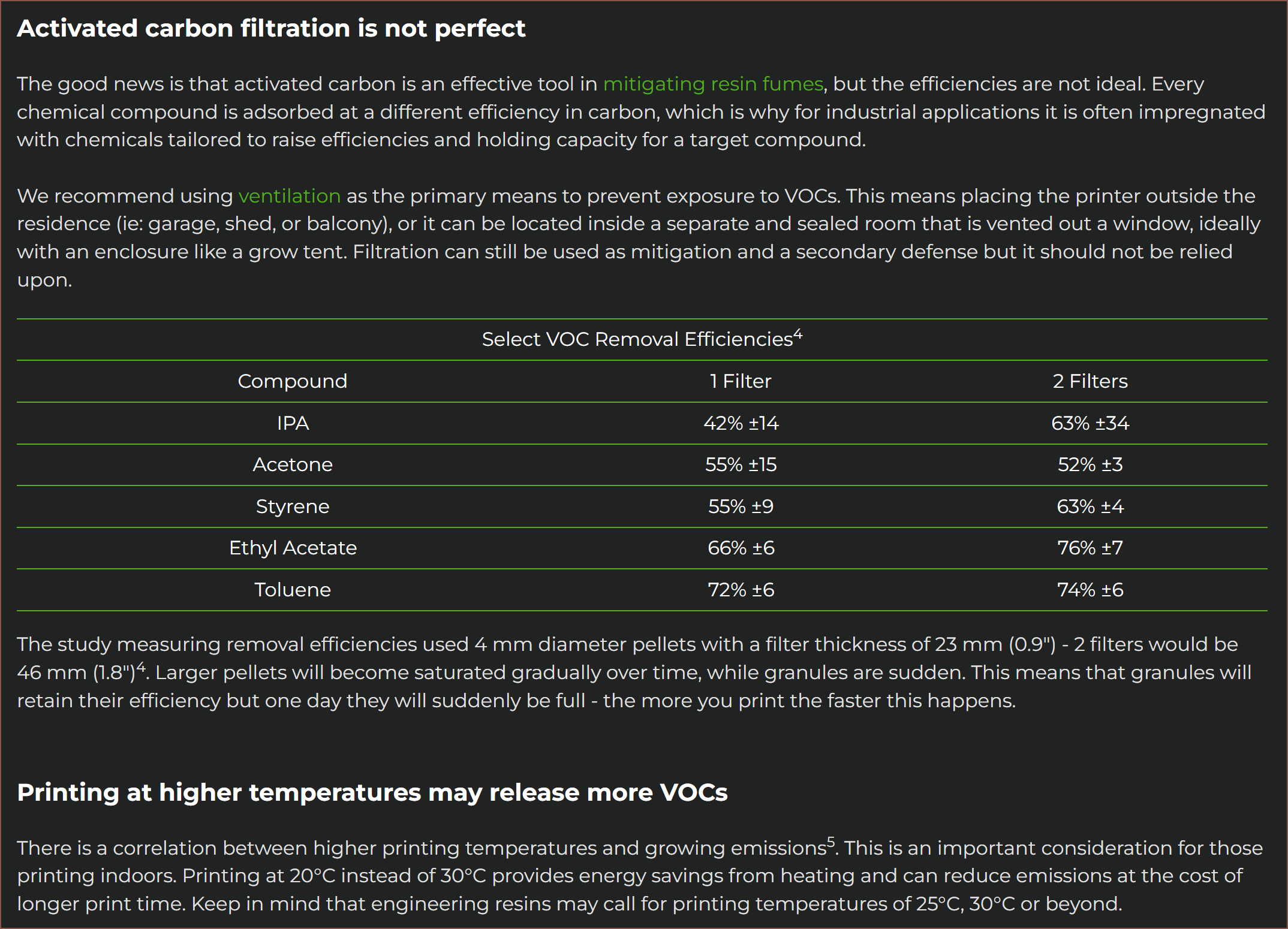

Activated carbon filter efficiency

While I'm on the subject of price, it doesn't seem that my hopes of filtration are going to pan out all that well:

Even with some thick filters, it doesn't seem that the efficiencies are ideal. Thus the log 2 logs back is likely the better solution. I don't think people in their appartment (like me) would object to venting a tube outside for 10 minutes; it's having to keep a ventilation tube for the hour or day long prints that I have an issue with. The data from the video below suggests that the seal doesn't need to be airtight to keep polutants in the print chamber.

Additionally, cooling down the print chamber may both reduce VOCs and increase viscocity. I can't imagine it'll be power efficient though. Cooling down the resin from within the cartridges sounds more efficient while reducing the chance of condensation.

Expected pricing target

Since the current BOM is down £110 and the filter system is no longer happening in the forseable future, I think I can target £1099 for the first prototype, which includes the arm attachment and extra screen. Oh and I haven't mentioned this yet, but after some thought, I'm using the same Nema 17 motor for everything. This also saved a bit on the BOM.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.