I've discovered a paper that is currently the most similar to what I'm trying to do now, published just over 12 months ago:

Multi-material stereolithography using curing-on-demand printheads

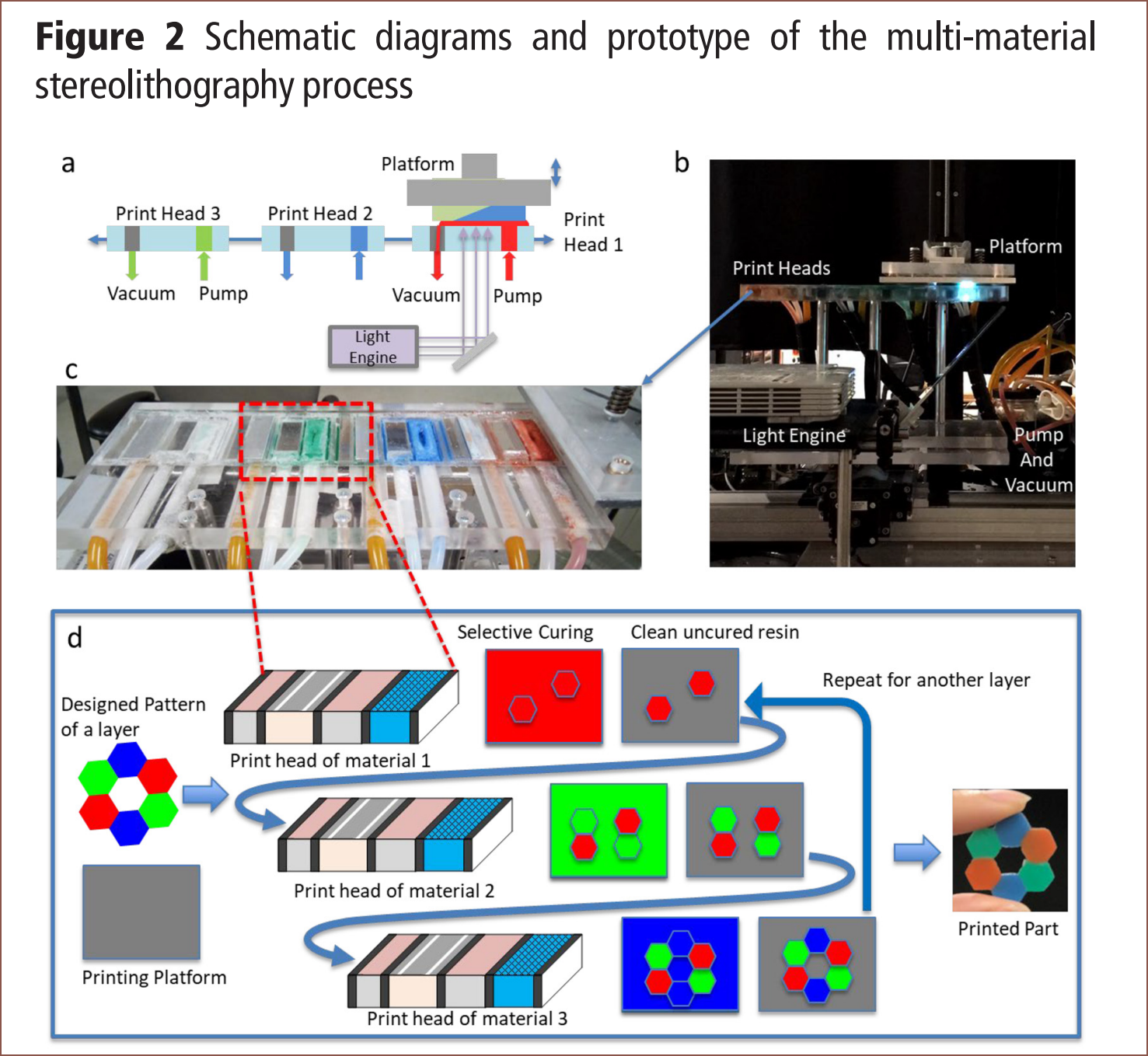

The researchers have the resin go through a mesh, cure with DLP, vacuum the excess resin and then do final cure before moving to the next print head. At least this gives some sort of confirmation that a multi material SLA can be built 1 colour at a time. The researchers call it "cure on demand" and this is their second time trying, though it does seem to have a low build volume : footprint.

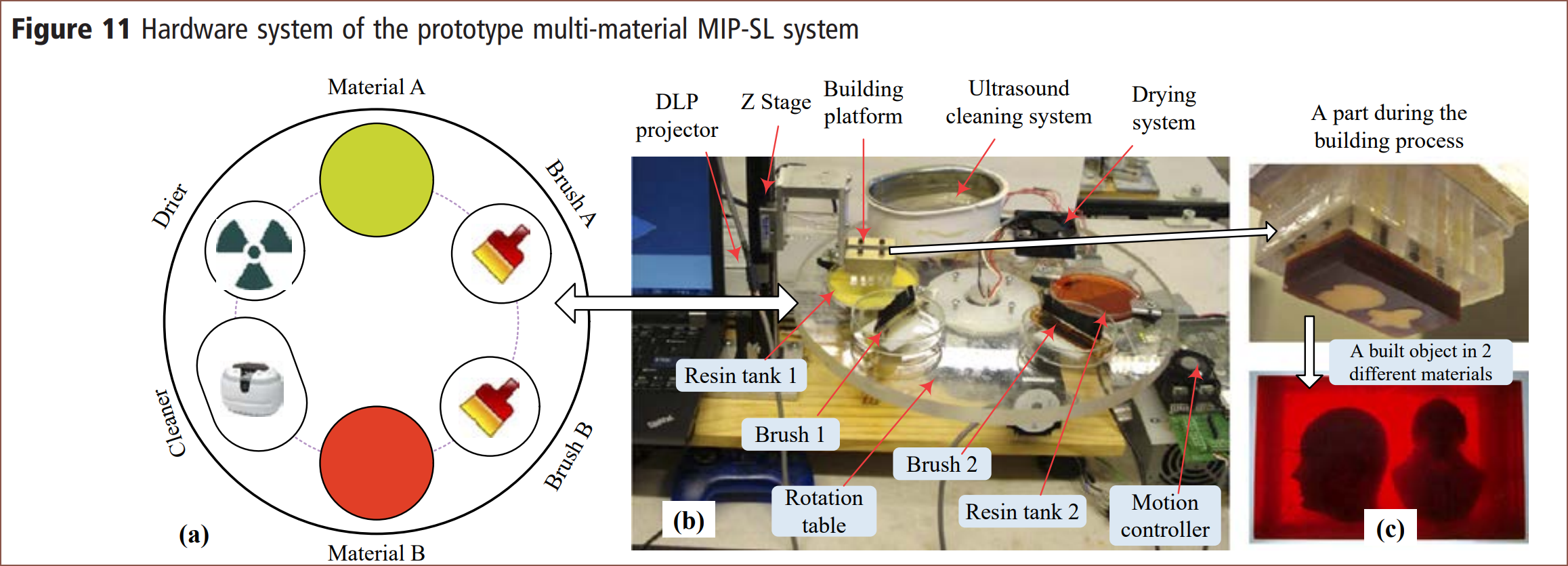

The first time is Digital material fabrication using mask‐image‐projection‐based stereolithography, where they place everything on a disk:

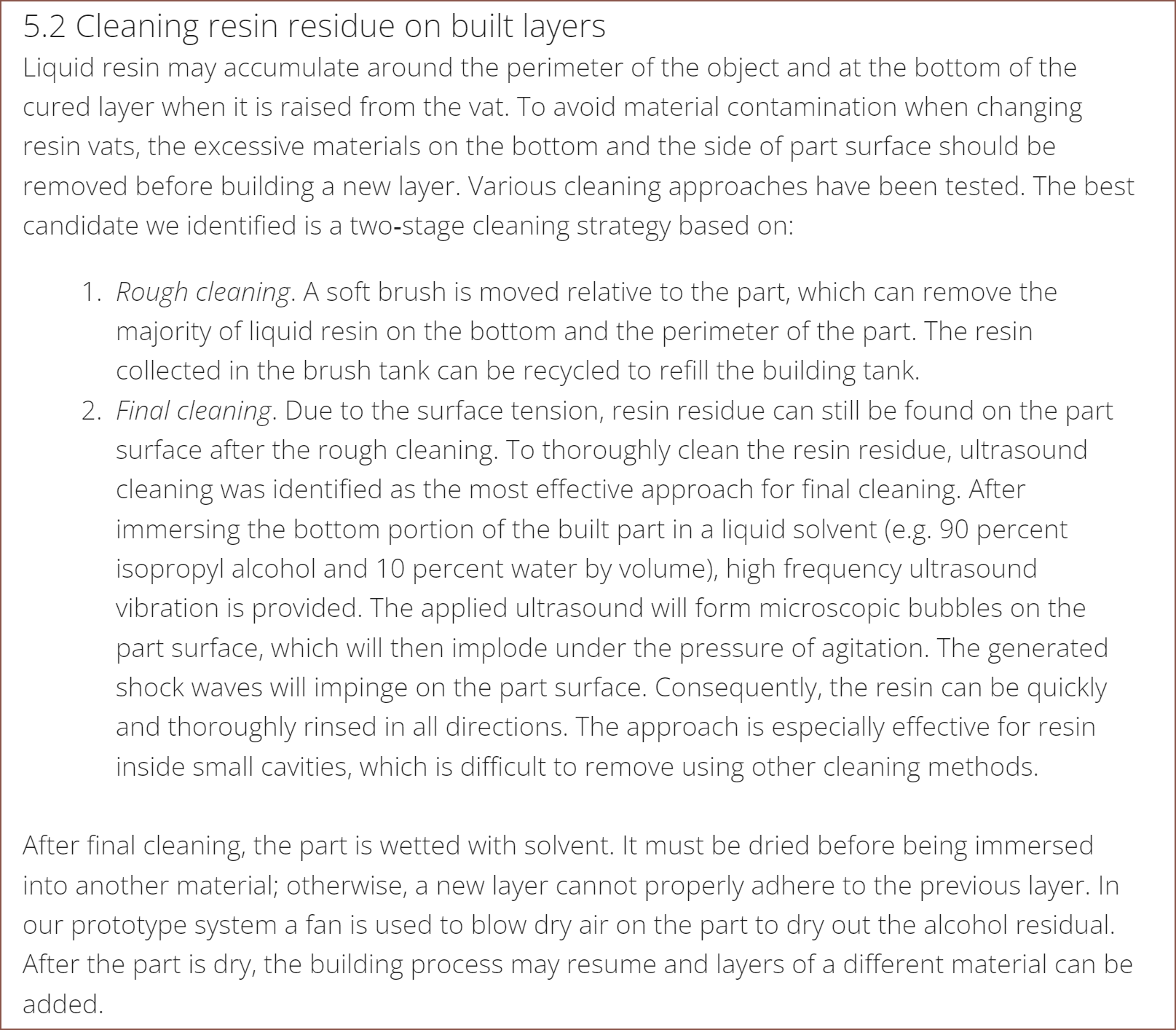

They used shallow vats that needed a minimum of 0.5mm of resin due to surface tension. I'm targetting for as low as 0.05mm. Hopefully, that would eliminate the need of the second cleaning step in their 2 step process:

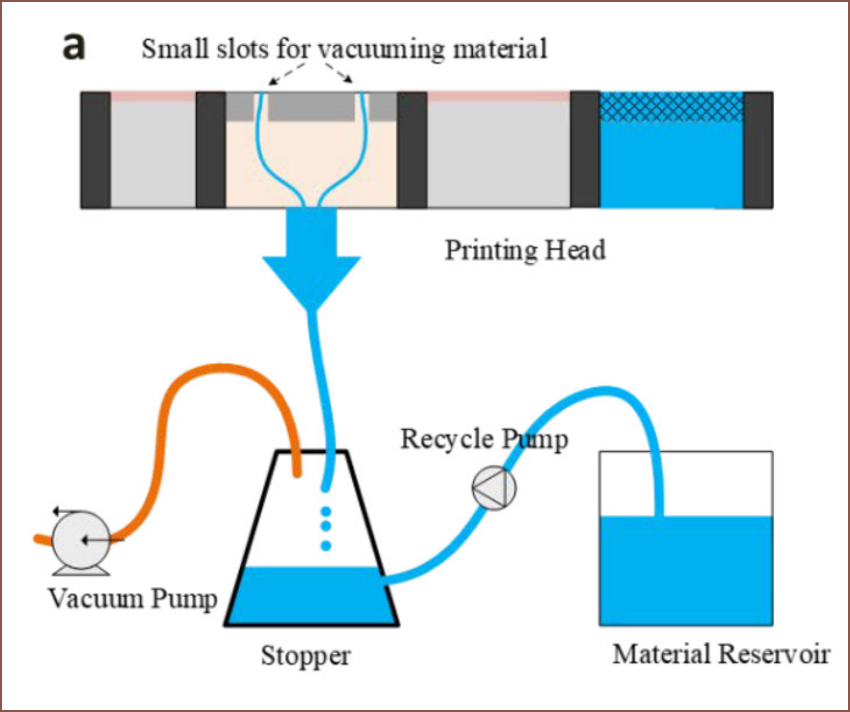

They used shallow vats that needed a minimum of 0.5mm of resin due to surface tension. I'm targetting for as low as 0.05mm. Hopefully, that would eliminate the need of the second cleaning step in their 2 step process: I'm not using a brush because I don't think that they could be cleaned over the course of an average print job. I'd like to avoid solvents due to VOCs and because of the drying requirement that they also mentioned. The vacuum from their more recent work could be an option, but they're loud and I have a 510mm span to cover. An option could be to move across the X axis, reducing the span to 168mm, but then there's the uncured resin cleaning job inside the vacuum gear to contest with, which I'd imagine would be more complex than curing a saturated thread. Speaking of the thread, I have thought about wiping the part with it directly, but I worry about consumable consumption and the thread getting caught on the print.

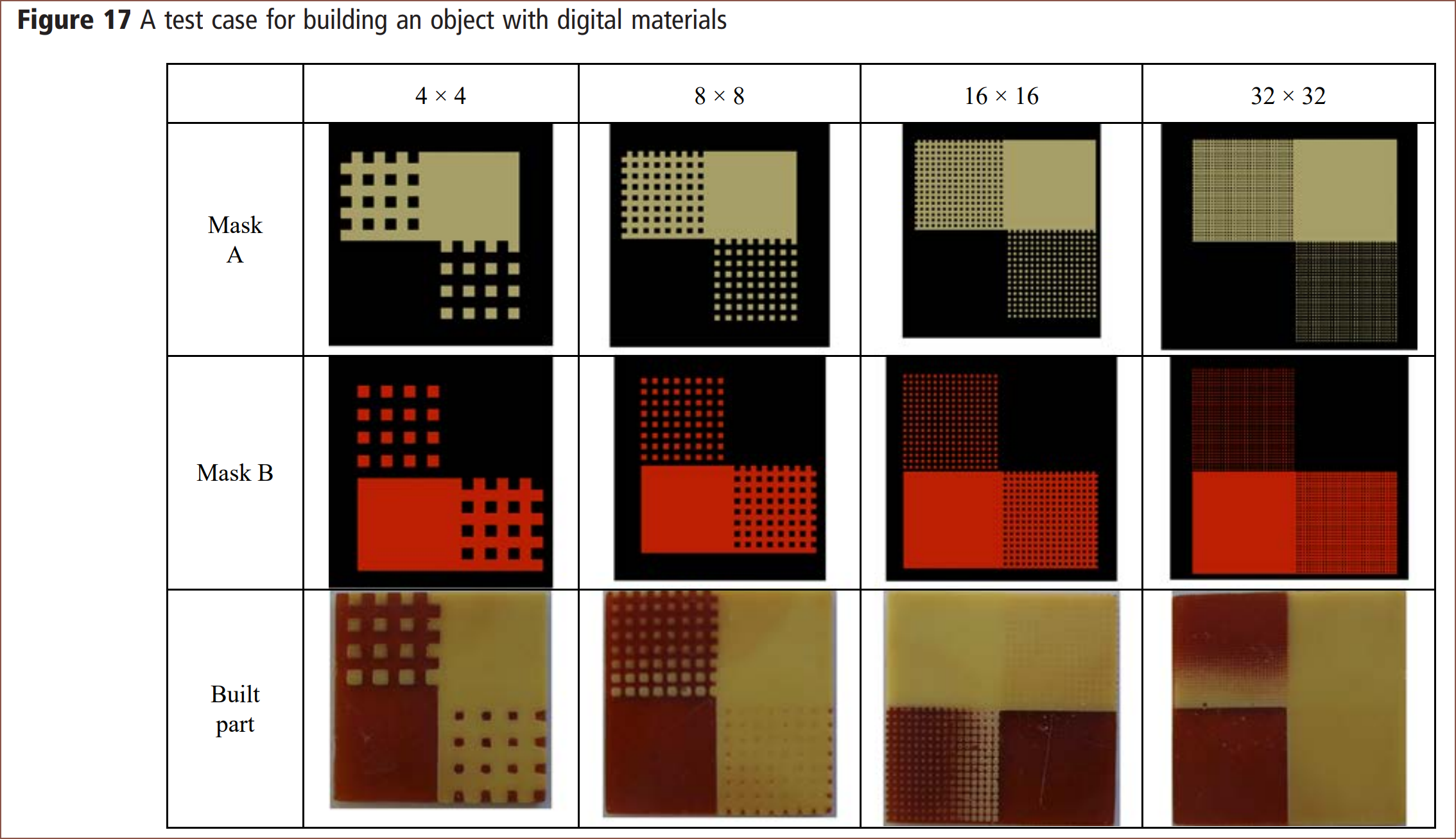

I'm not using a brush because I don't think that they could be cleaned over the course of an average print job. I'd like to avoid solvents due to VOCs and because of the drying requirement that they also mentioned. The vacuum from their more recent work could be an option, but they're loud and I have a 510mm span to cover. An option could be to move across the X axis, reducing the span to 168mm, but then there's the uncured resin cleaning job inside the vacuum gear to contest with, which I'd imagine would be more complex than curing a saturated thread. Speaking of the thread, I have thought about wiping the part with it directly, but I worry about consumable consumption and the thread getting caught on the print.They've even tried out dithering. For their attempt in 2013, the results seem somewhat all over the place.

Perhaps the reason is due to this note they made in their conclusion:

Perhaps the reason is due to this note they made in their conclusion: The potential for air cavities is the reason why I hypothesise that the smallest "colour island" would be 80um+ instead of 40um.

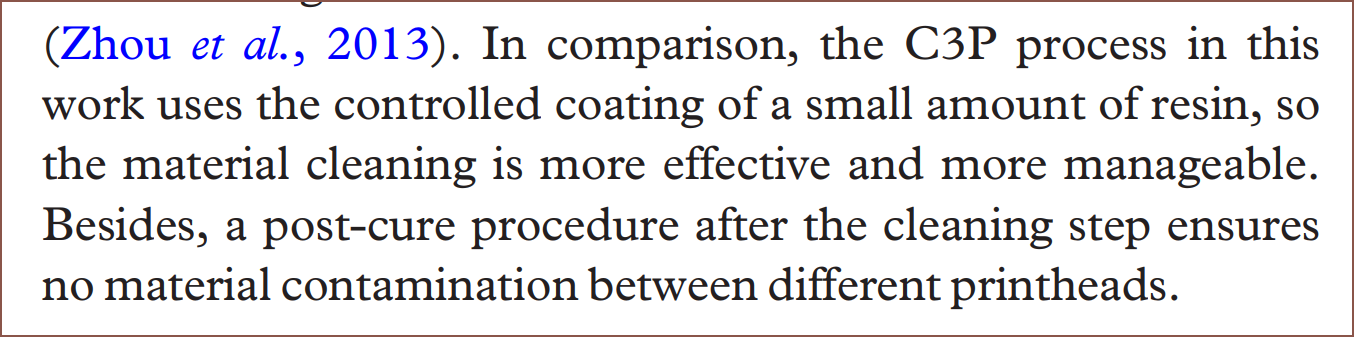

The potential for air cavities is the reason why I hypothesise that the smallest "colour island" would be 80um+ instead of 40um.Moving back to the paper I found that spurred writing this log, it seems that the thinner resin application indeed reduces the cleaning difficulty. They also mention that curing eliminates cross contamination. I was under the assumption that It'll be better to cure after the last colour so that any resin clinging on could be displaced by the next colour of resin.

For their vacuum system, they surely get closer to BCN3D's "every single drop will make it to the print" (pharaphrased) ideal.

For their vacuum system, they surely get closer to BCN3D's "every single drop will make it to the print" (pharaphrased) ideal. I have my concerns that a relatively high viscosity resin would be sucked into the vacuum, and the researchers used a speed of 3mm/s which is not going to work.

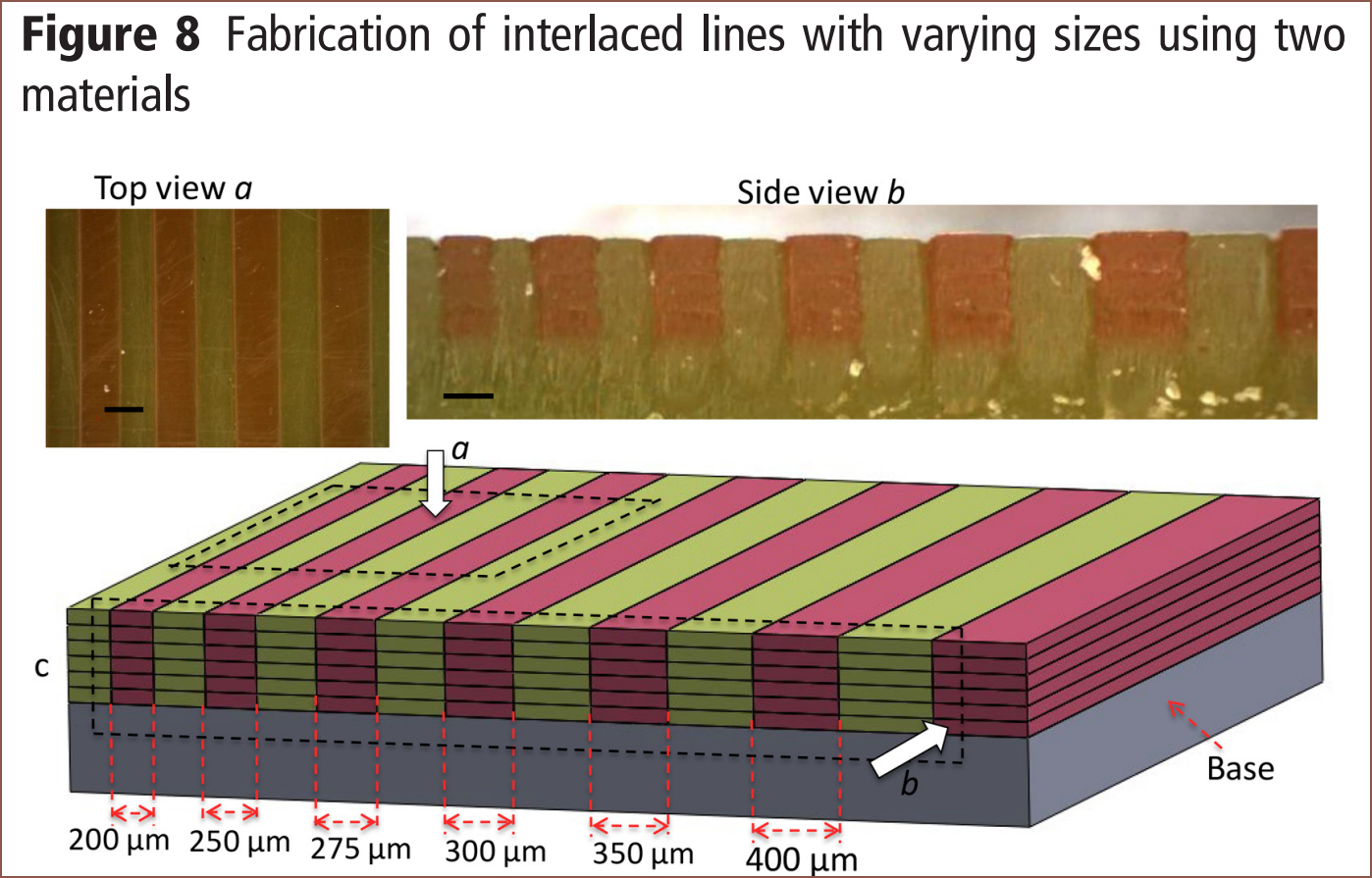

I have my concerns that a relatively high viscosity resin would be sucked into the vacuum, and the researchers used a speed of 3mm/s which is not going to work.Lastly, it does seem that their dithering attempts were mroe successful.

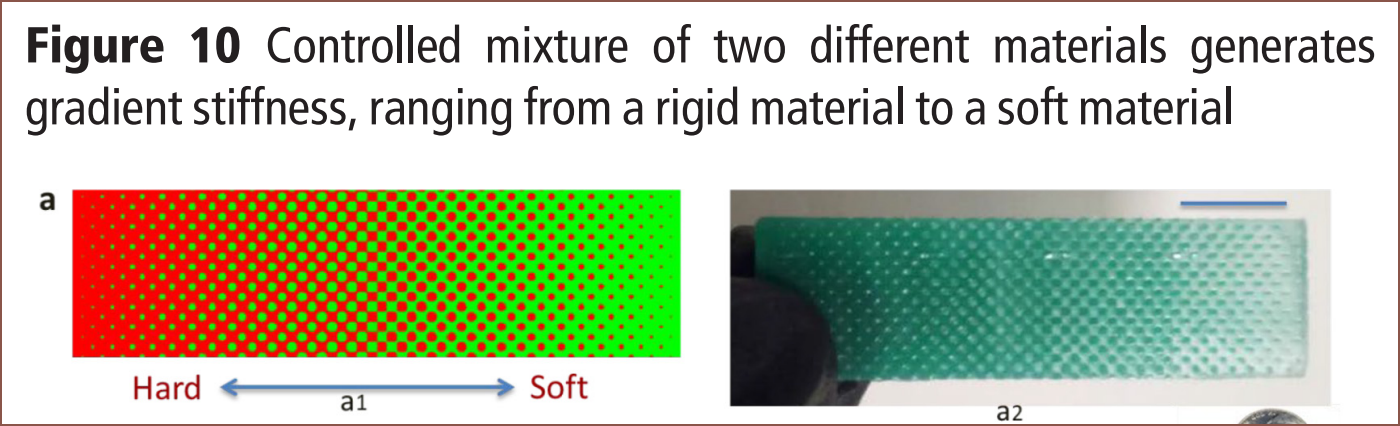

Figure 10 looks especially promising.

Figure 10 looks especially promising. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.