To start of my research, I looked into laser toner viscosity which didn't really find anything viscosity wise, because it turns out toner is a powder and a very fine one at that. There's even magnetic versions, suggesting that it may be better to have magnetic particles in the resin instead of magnets on the printer. As I guessed, the charged and magnetic solution could be combined for dark resins, which should result in even greater cleaning performance.

Then I looked into magnetic paints. I found out about erasable crayons and dustless chalk, but then I found this:

Ok... the paint just got rip-n-torn clean off the bottom of the transparent cup. This'll work, 100% no doubt about it.

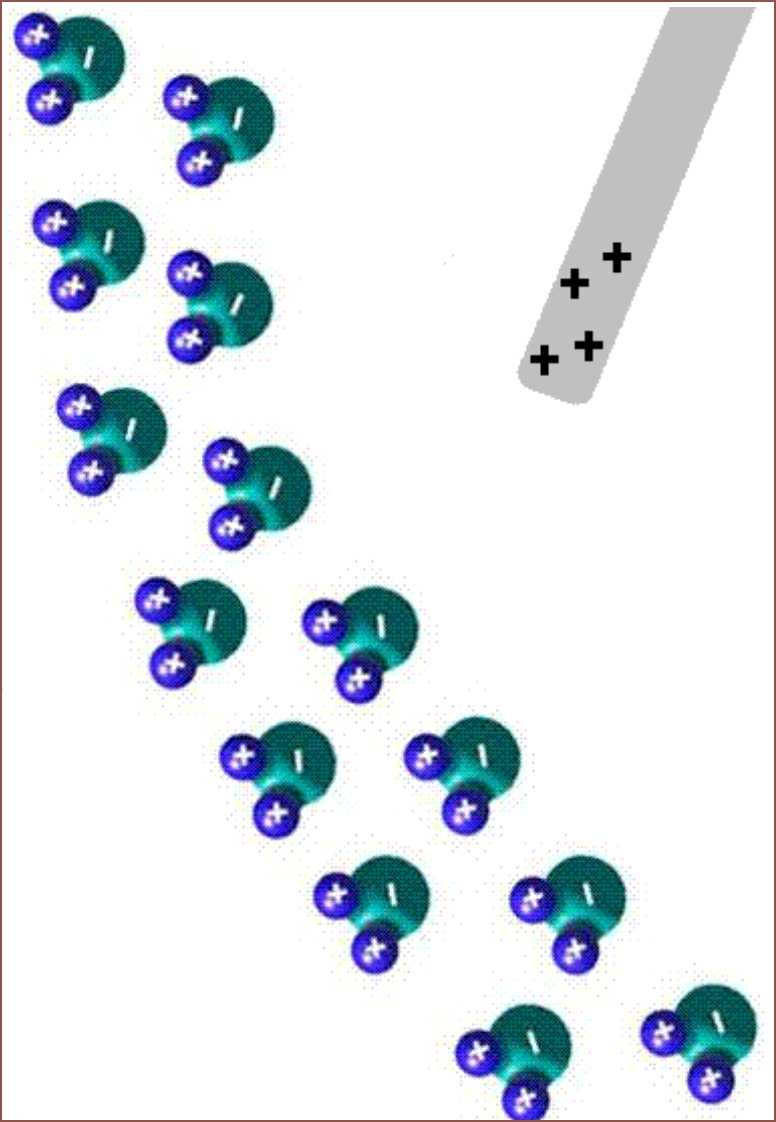

Now that the magnetic solution has been validated, I went back to researching about an electrostatic solution. I found a webpage that explained this school experiment I've long forgotten about involving a water stream and a charged rod:

The page says that polar molecules have a greater effect than regular dust. Speaking of water, it sounds like the relative humidity should be low, but that may only apply to generating static electricity by rubbing. Here's a video I found, and the force seems pretty strong even at a distance magnitudes further away than what I need:

I wouldn't imagine a vacuum being this performant at the same distance.

I also found another one that shows a cheap way to generate the charged plate needed for the printer:

This board can be powered from 3 cell batteries. From reading the comments, I was able to deduce that this one creates negative static charge. The commentor deduced this by seeing that the diode is pointing away from the output.

Conclusions

I can cut the LCD stepper motor (and slightly complex gear arrangement) solution I originally thought of and go with 2 light servo motors that only need 2 pins on the motherboard and no stepper driver controllers, since there isn't any high angle precision required (unlike the Arm Attachment). This reduces the motors needed for the Suspense + Arm Attachment to 19 and, more importantly, the SuspenseSmall to 11! Since 8 steppers are used for the Arm Attachment, they can all be mapped to the Monster8 and the main system can entirely be on the Manta M8P + EXP MOT. My eyes are now set on reducing the cartridge pumps from 2 to 1 per cartridge, and I'll write more in a future project log.

It seems that I'm going to push some of the required development to the chemical team of the project (which is just me some time in the future) and hope for a resin with embedded polar molecules. The attraction from the plate should work fine in small pockets (80um square, but ideally 40um), where mental simulations for trying the same pocket with a vacuum fails. All attracted resin goes back on the same PET film it came from, so the dream of "every single drop (minus probably 50-150ml for the minimum fill line) makes it to the print".

Also, I'm thinking that it might be possible to partially cover the side of the LCD with the charged plate, reducing UV exposure to the LCD and hopefully increasing its usable life. I need to do more research to see if this would work or if the still-exposed section of the screen would still deteriorate at the same rate. My current understanding is similar to silicon wafer yields, in that covering the screen reduces the area on the LCD that could be damaged, thus reducing the probabilty that there would be damage anywhere on the screen.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.