[Published 19th Aug, 15:43 ]

Reason for starting research PnP

Watches that PnP dial video embedded in a previous log

Me: Hmm that seems kind of long... I wonder if I could at least automate the rotations of the disk.

Somewhat related hackaday article:

Me: I don't have that kind of time!

The comments:

Me: Hmm...

Looks at the link in the hackaday article

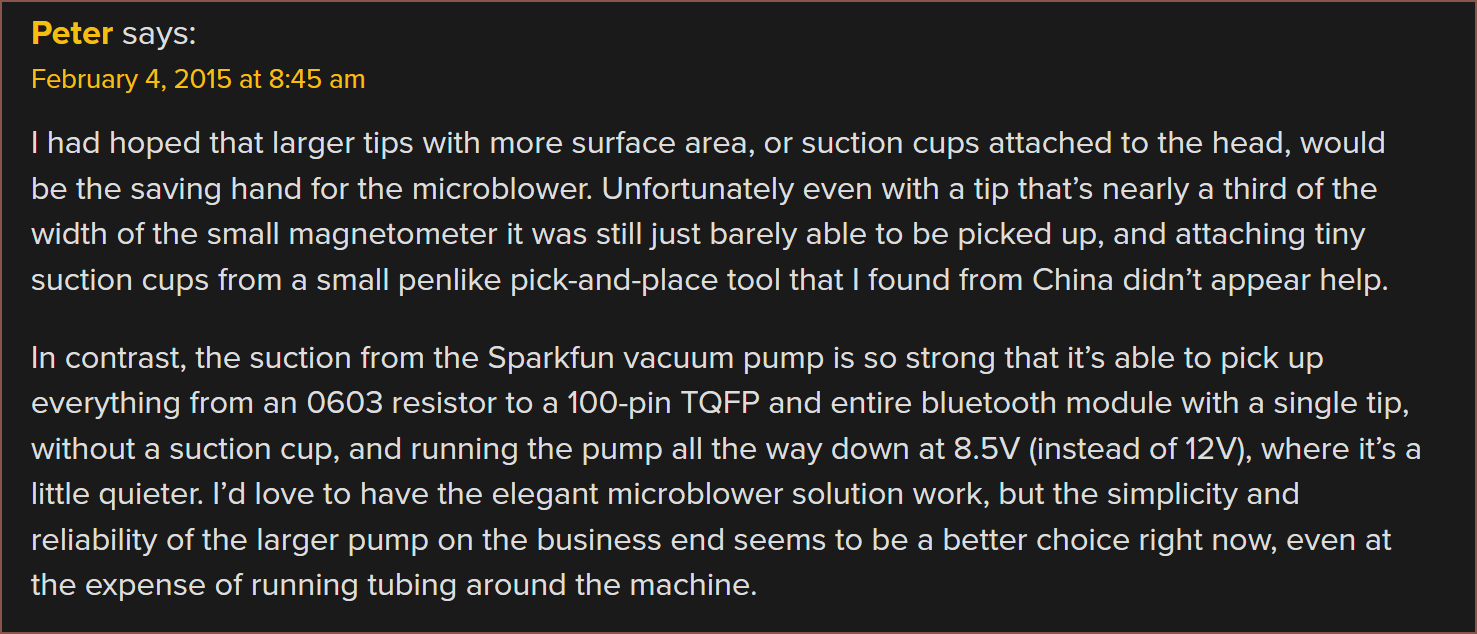

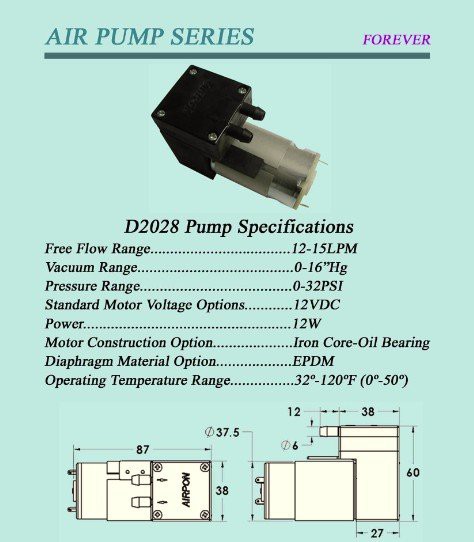

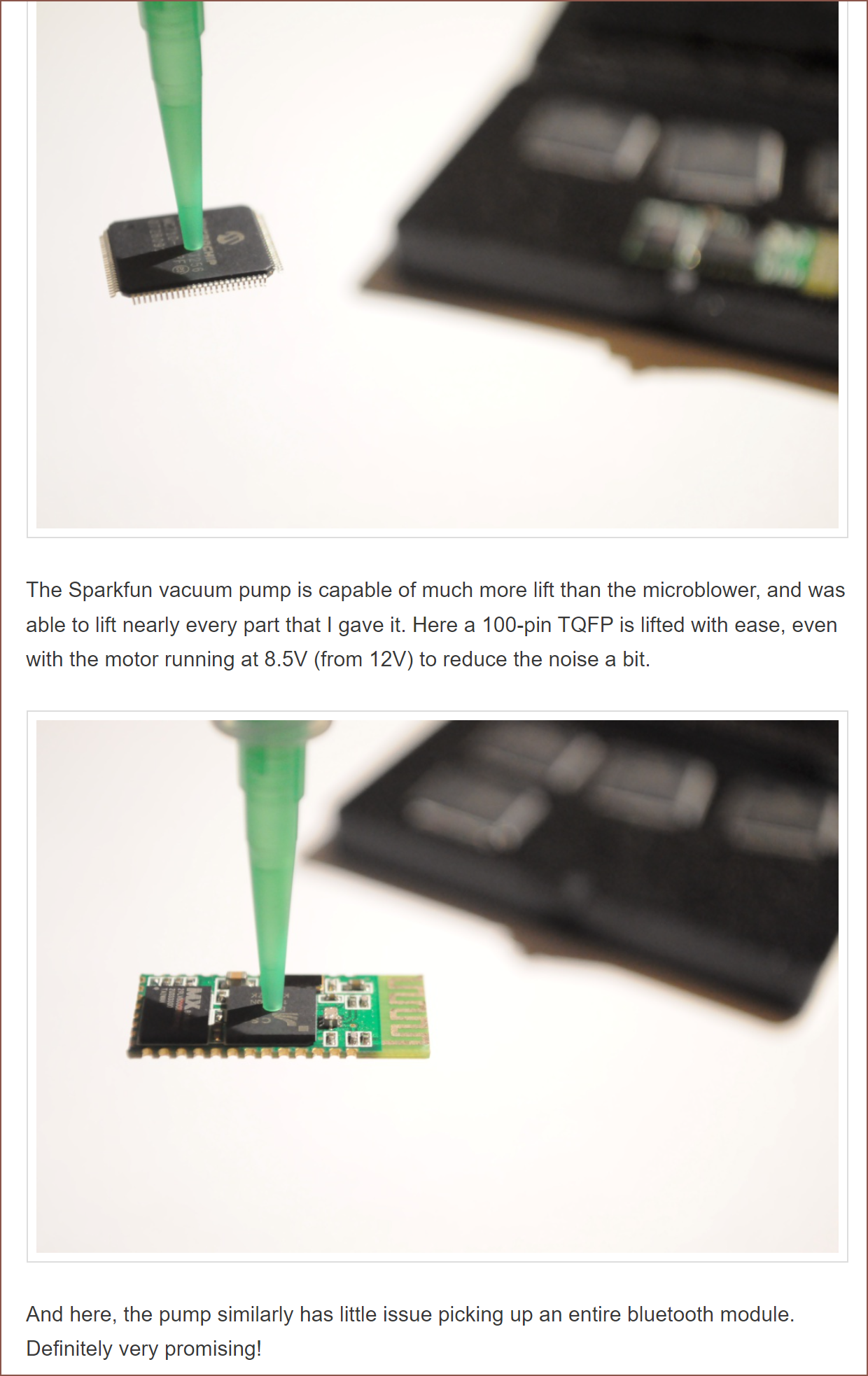

The person who made the pump:

Me, a single person designing the SuspenseSmall in a smaller volume than 125L:

Me, a single person designing the SuspenseSmall in a smaller volume than 125L:

It seems that this was written in 2015, so there's a good 7 years in which innovation could've taken place.

Wait! This is the hackaday commentor?! Well in this page's comment section, there's someone that sounds like they started FirePick.

Wait! This is the hackaday commentor?! Well in this page's comment section, there's someone that sounds like they started FirePick. Wait. It's been 7 years since the comment. How is it not even in beta?

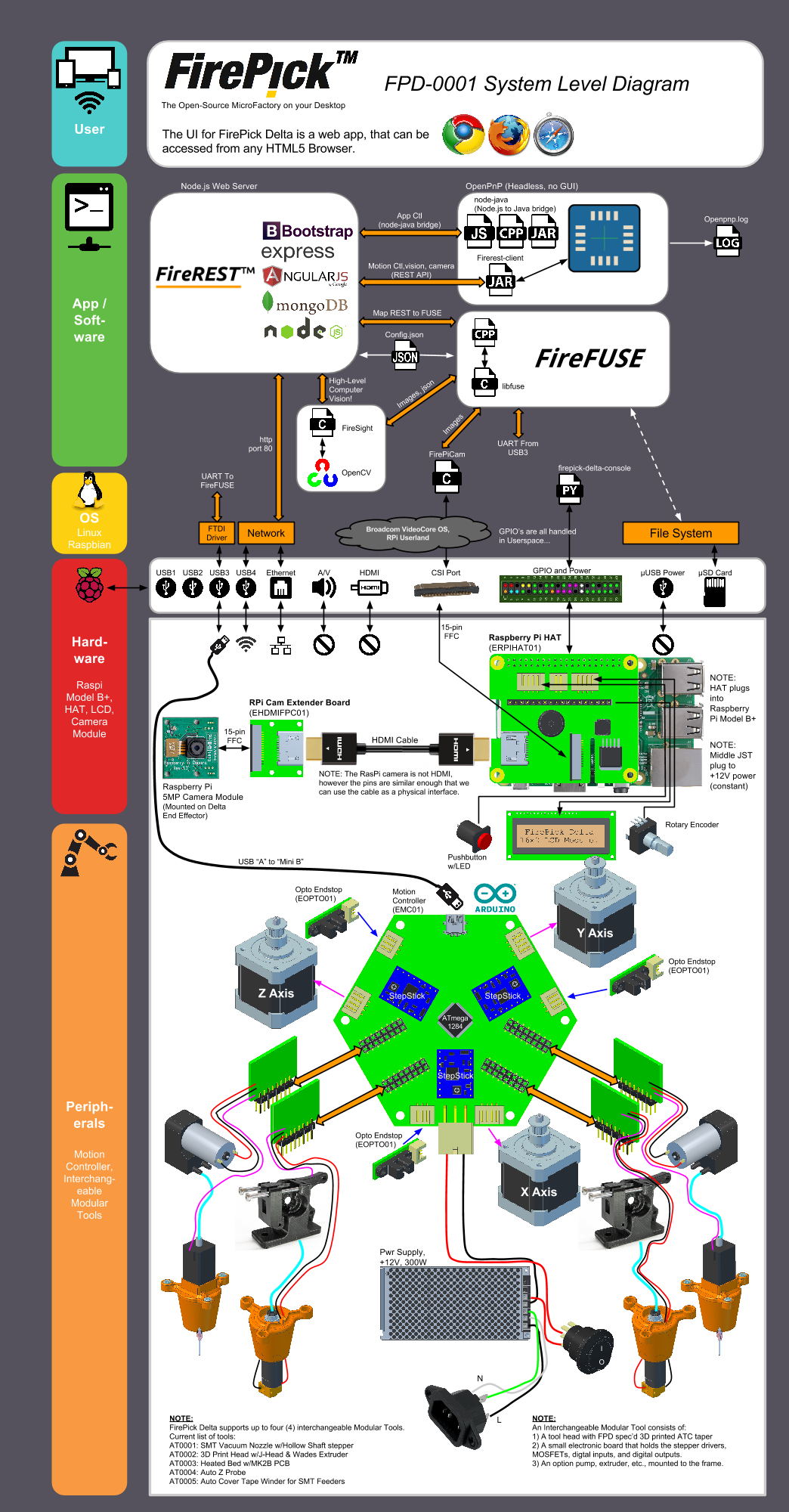

Wait. It's been 7 years since the comment. How is it not even in beta? Woah that's actually a lot of stuff.

Woah that's actually a lot of stuff. Last seen 7 years ago. Oh.

Last seen 7 years ago. Oh.Anyway, I've realised that I don't need to limit the Z height of the paste/fibre head to the same height as the roller, since as long as it's under around 65mm in Y, it can be fully moved out of the way. Thus, I'm researching PnP grabbers to see if I can fit it in the head and eliminate the arm entirely. I was worried about having to have multiple nozzle for different sized components, but as you can see from that hackaday commentor's experiment above, it's likely a non issue.

Researching silver paste

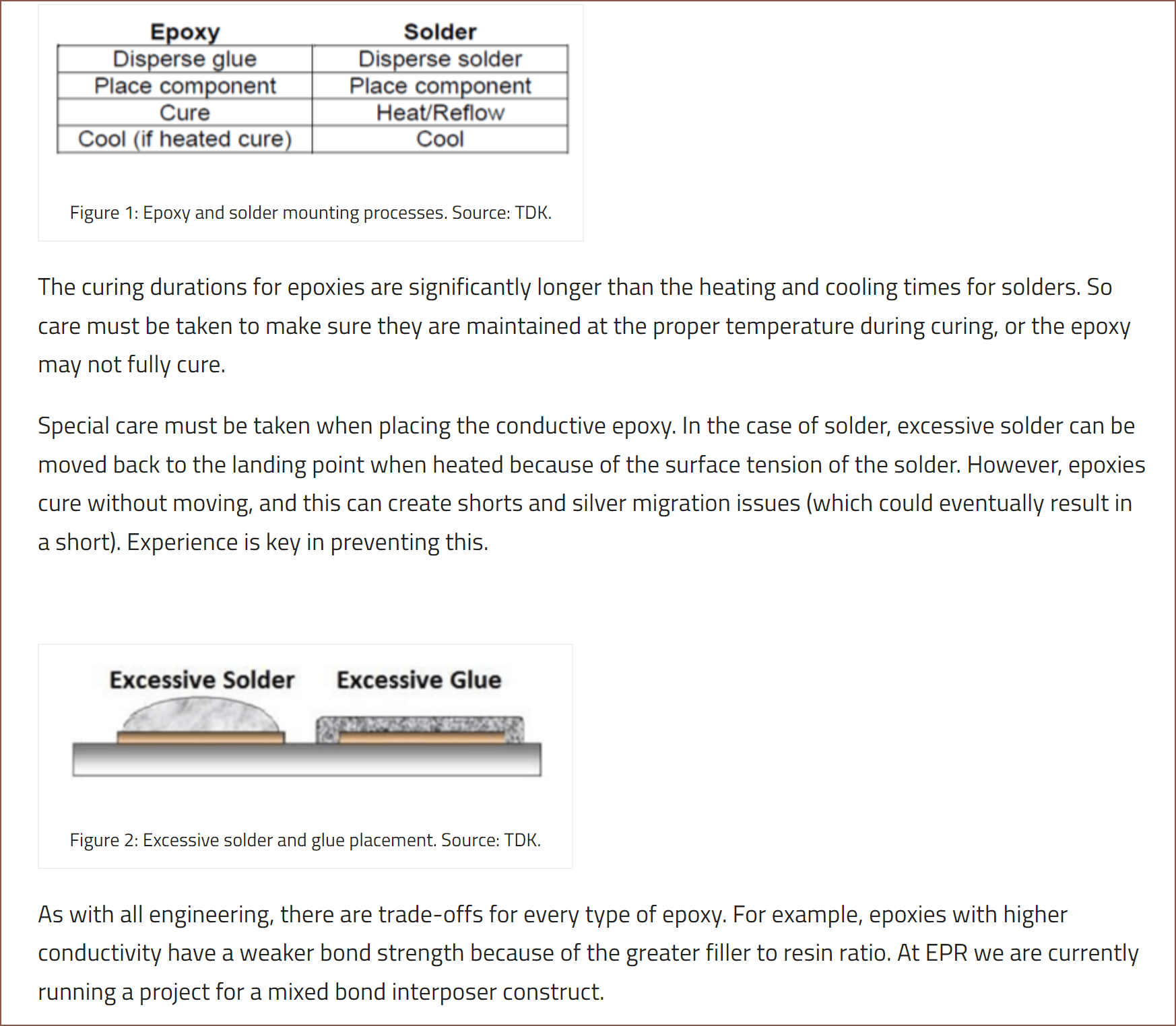

I also need to decide how heat would be applied to the components and silver paste. I might have to find a room/low temperature silver paste. Doing some light research suggests that the question of solder paste vs silver paste adhesive has been asked before.

This gives the impression that it's possible to not need the former and that the components would stay on the substrate well enough to be moved into a curing oven (in my case, probably a food dryer or a heated 3D printer bed with a bowl on it).

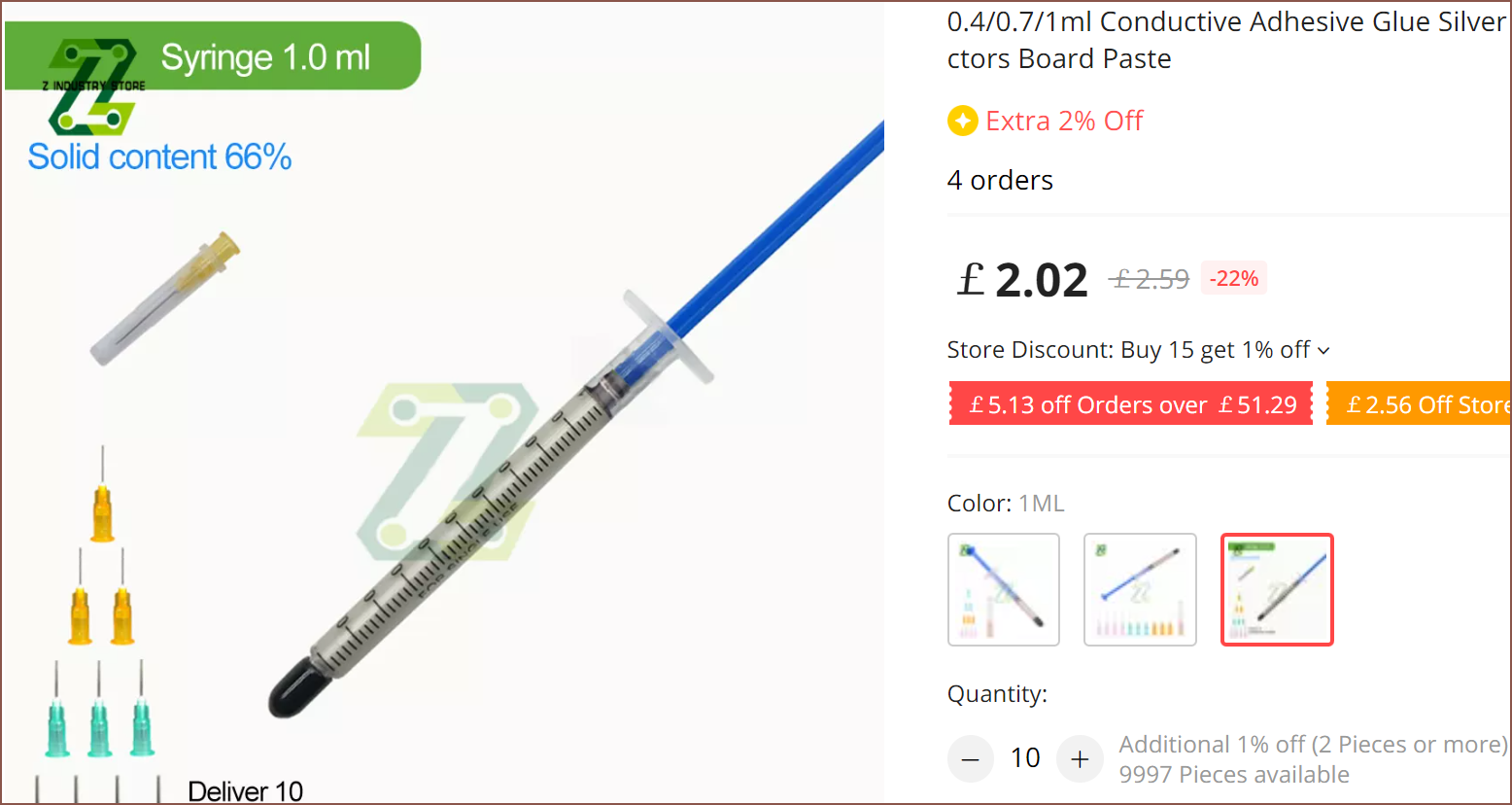

Oh. It's that easy. Wow! But doing more looking, it seems that AliExpress sellers don't just sell the same generic noname paste like I originally thought so I should look around.

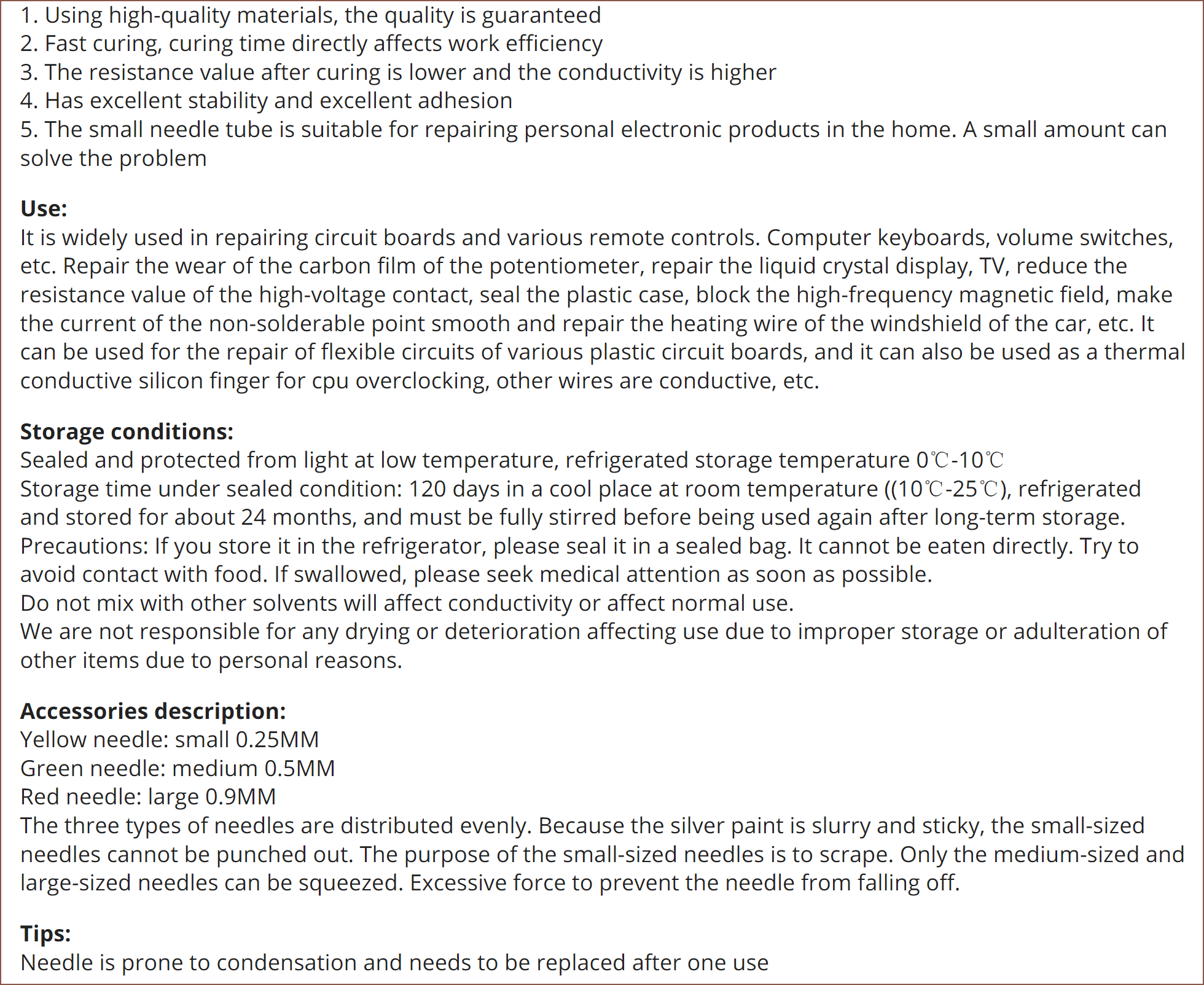

Oh. It's that easy. Wow! But doing more looking, it seems that AliExpress sellers don't just sell the same generic noname paste like I originally thought so I should look around. Hold up it's only £6 delivery for 10ml @ £2 each. That's like £3.12/ml after tax -- way under the £4.50 I estimated the PCB cost with. The description also has a wealth of information:

Hold up it's only £6 delivery for 10ml @ £2 each. That's like £3.12/ml after tax -- way under the £4.50 I estimated the PCB cost with. The description also has a wealth of information: So this one has a potlife limitation and apparently can't be extruded through a 250um nozzle. I wonder what ECA the researchers used as they were able to get track widths of 134um, so I was aiming for a 100um nozzle for 120um traces.

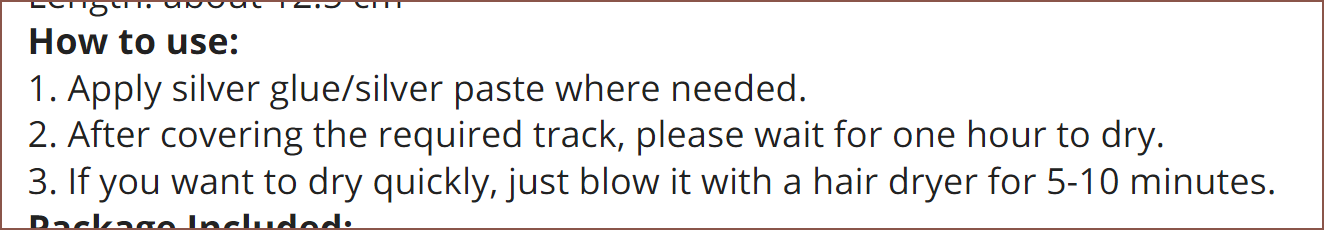

So this one has a potlife limitation and apparently can't be extruded through a 250um nozzle. I wonder what ECA the researchers used as they were able to get track widths of 134um, so I was aiming for a 100um nozzle for 120um traces. The multimeter is on the 200 ohm setting, so I believe they missed a "." in the caption. Still, 5.5 ohms for a track of that width seems kind of high. Nice to see that it'll work fine on flexible PCBs.

The multimeter is on the 200 ohm setting, so I believe they missed a "." in the caption. Still, 5.5 ohms for a track of that width seems kind of high. Nice to see that it'll work fine on flexible PCBs. This answers the question I had earlier up in the log.

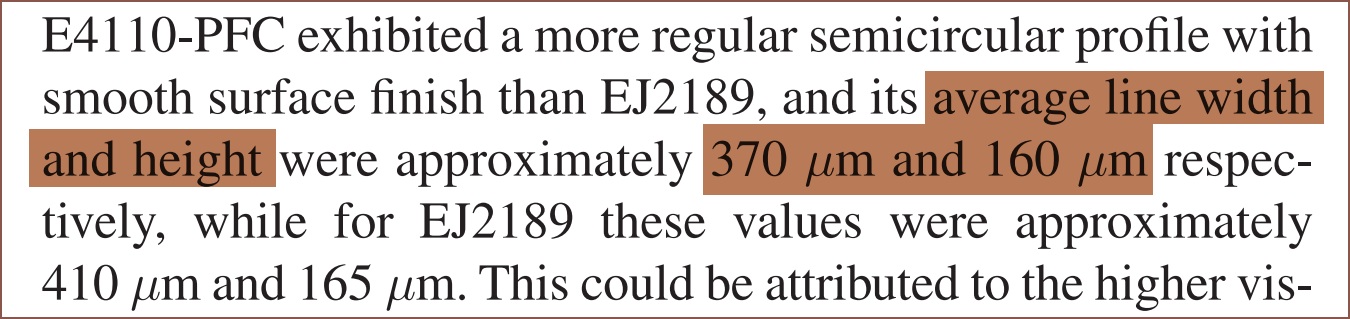

This answers the question I had earlier up in the log.Back to the research paper, they used a 250um nozzle and I didn't see the "and height" part of the below sentence:

EJ4110 has <=20um particles while EJ2189 has <=45um, so I was like "yeah that makes sense how the line width of one is slightly over 2x the other. Any line widths over 200um is a no-go-zone, so I'm thinking of going with a 150um nozzle and finding a less viscous silver paste so that I can hopefully get 160um line widths and 40um layer heights.

EJ4110 has <=20um particles while EJ2189 has <=45um, so I was like "yeah that makes sense how the line width of one is slightly over 2x the other. Any line widths over 200um is a no-go-zone, so I'm thinking of going with a 150um nozzle and finding a less viscous silver paste so that I can hopefully get 160um line widths and 40um layer heights.

https://unimtech.com/pastes-for-printed-circuit-boards/ has pastes that can go as low as 50um line width and >150mm/s print speeds with a viscosities of <350 cP and particle sizes of <8um. The issue is the high cure temperatures and no indication of price, so it's probably £££.

Concluding thoughts

It seems that implementation complexity is something that I'd have to visit at a later date, since I'd need equipment to conduct my own tests. For now, I've got a general idea of the system, so I can make a concept placeholder for the design. Due to favouring probability-of-success and wire management over saving a £ here or there, I'm going back to the M8P + Monster8V2.

Due to the fact that this printer is targetting the consumer and light prosumer, I'm expecting that most components won't be bought in enough quantities to come on a reel. The PnP would pick the components from trays similar in size to the PnP wheel.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.