I'm finally starting to revamp and equalize all my details pages so that the projects can be better understood and information hidden within the depths of logs can be more easily found. The below is the old Details page.

[16 April 2022]

So I'm going about my day and I see a link in a Discord channel to this video:

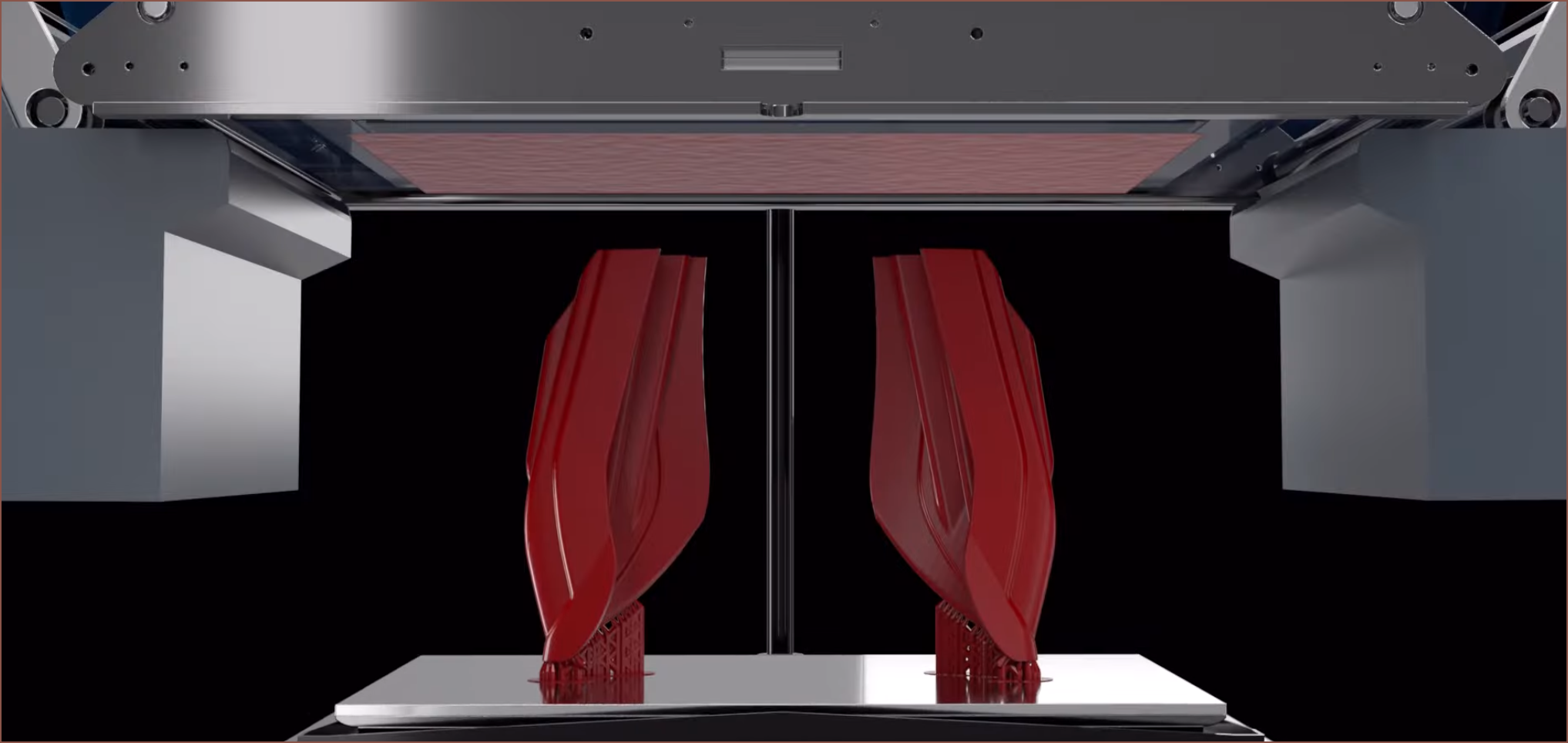

Now, looking at the logo and red material that looked like paint, my expectation was that there was some marginally new resin technology and BCN3D was trying to make a new buzzword out of it.

I'm like "BCN3D. I get it. You're now getting into the SLA business and it's all new to you from an FFF standpoint.", waving jazz hands. "But can this 3D printing industry stop over-hyping marginally new technologies like it's the next generation of 3D printing??"

However, everything changes when I get to the 30 second mark of the video and it's revealed that the camera actually isn't upside down for visually nicer footage and that the resin is seemingly suspended in air somehow.

As soon as I see that the resin is stuck to a film, I'm like "AGHHHH!!! That's so simple, so obvious now that I've seen it! How has Me In The Past (or anyone else in the hobbyist 3D printing community) not thought of this?!"

I'd love to end the thought there, but I've been thinking about what could solve the single-material and uncured resin handling issues of MSLA and what could bridge the gap between hobbyist machines and PolyJet. The reason I've never gotten an SLA printer is because, unlike FDM, the majority of my planned prints would be multi-colour, the uncured resin is toxic and the parts aren't ready fresh out of the machine.

- Me In The Past thought of a multi-vat approach where one of the vats would contain cleaning fluid. There would be 3 or 4 vats and the centre Z column would rotate around to switch to them.

- "Ahh but cleaning and moving would take so much time over the print job!"

- Ok, what about a floating resin solution where the cleaning fluid is denser than the resin? With that, the part can just move down and be washed and cured while waiting for the previous resin to be sucked back to its reservoir and the next material is pumped in. This also means that you don't need much more space or more screens to add support for more materials available in a print job.

- "Ahh but how would that deposition stay consistent. Isn't that a fair bit of plumbing work? And top-down approaches are susceptible to the machine being shaken or unlevel."

So after I saw the video, I thought:

- "That's it! That's the solution!!! Ouwgh but I don't want to wait until 2042 and beyond [to use this technology]. And it doesn't even seem like they've unlocked its full potential yet. I'm thinking like 8+ materials and washing during (or after) the print process before fully curing the part."

Thus, this project is mainly for me to do something -- anything -- to inspire someone with the ability to research / develop this kind of printer into reality, if I haven't done so myself. Other reasons are so that I'm not keeping ideas in my head (writing Future Me some documentation to work with) and so that these ideas are in the public domain, meaning that any future patents can't be too vague and over-reaching.

SecSavr Sol^2 [gd0045] is the slicing software for this machine.

SecSavr Syrum [gd0141] is the project for materials research.

This log here is where I'm posting little comments, though some of them are so large that they should've been actual logs.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.