I was looking through the SLS4ALL discord when I found out about the Metal Base project, which aims to specifically print stainless steel 316.

Only using 316L metal powder, our extensive testing has shown that using this material in combination with the relatively low laser power does not generate any fire hazard even when used in open air with 20% oxygen content.

I wonder if this is the reason JLCPCB's only metal print material is 316L.

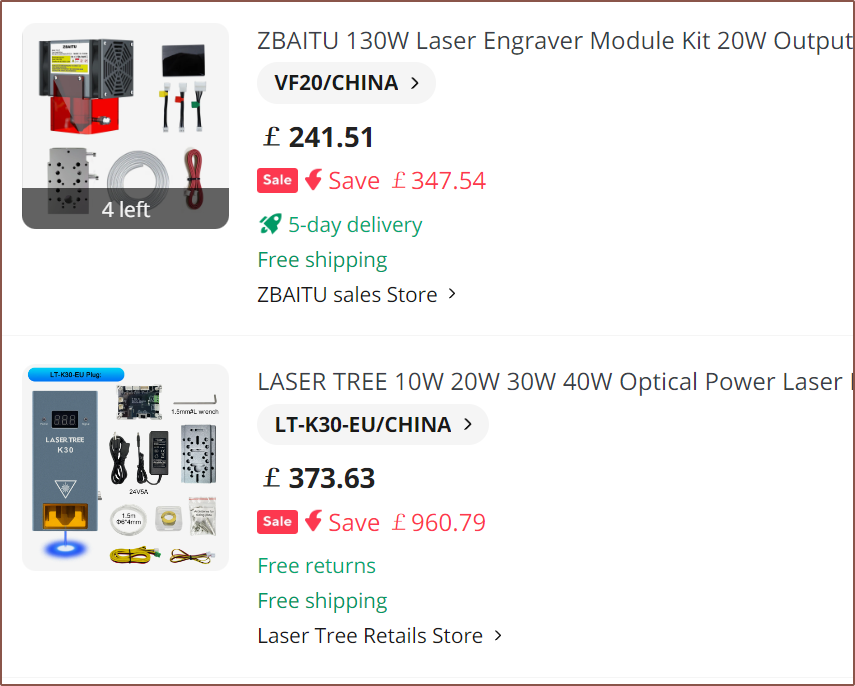

Looking through their YouTube channel, I was able to find out that a Laser Tree K30 -- a 33 - 35W output power laser -- was used. This laser has a spot size of 0.16 * 0.19mm, meaning that it comparatively has the same irradiation intensity as a 0.08 * 0.08mm 7 - 7.4W laser. The price is £375, which was where 20W lasers used to be. Today, the V20 laser, still my most ideal candidate, is only £240. All Laser Tree's modules seem to have the same spot size, which would need to be 95W to match the V20 on intensity. Their current top-end is a staggering 60W, which actually is still priced at the same £/watt as the V20 (it's around £750).

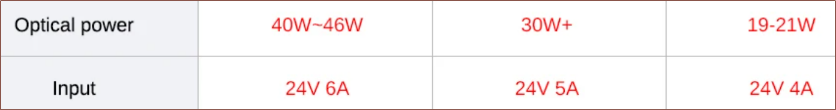

Something to note is that the K30 claims to use 10W less input power than the V20 (120W vs 130W), suggesting that its 6 diodes are more efficient. It actually seems that each 11W uses an additional 24W of input power:

Below is the result of a bottle-opener they printed:

There doesn't seem to be any video where the part is actually removed from the build plate. I theorise that it's welded onto the plate and has to be grinded off, and then ground again off the supports. Not entirely ideal for a consumer-oriented perspective and why I hope L^3 can do metal + support in a single print job.

There doesn't seem to be any video where the part is actually removed from the build plate. I theorise that it's welded onto the plate and has to be grinded off, and then ground again off the supports. Not entirely ideal for a consumer-oriented perspective and why I hope L^3 can do metal + support in a single print job.The system works by using a CMS (carbon molecular sieve) material in 2 separate air tanks that are switched between filtering and cleaning state. This is called the pressure swing absorption process.

Their price target is >$6K for the machine.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.