One thing led to another, and an allegedly "new" barrel arrived:

Barrel body and lid: 4.5 / 5 stars for suitability as an enclosure

The inside of the barrel and the lid looked fine enough:

That 3D line thing at the bottom is raised 1cm and likely remnant of the fabrication process:

You can see in the video that it looks a lot floppier when the plastic is hot and going inside the moulds.

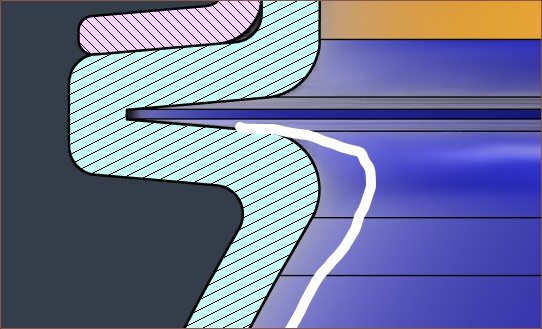

I also learned that the sealing is done with a white o-ring instead of the flanges, as implied by the CAD model:

Some of the measurements I noted down (in centimetres):

- Body

- >43 for bottom diameter

- 46 for the bump diameter before the opening (see Eccentricity below)

- >58, likely 58.5 for the widest internal diameter.

- 59.5 or thereabouts for the outer diameter.

- 36 for the vertical section

- 95 from the middle line to the rim of the barrel

- 94 if from the bumps

- 46.5 - 47.5 for the opening (see Ovality below)

- Lid

- 48.5 diameter for its tallest feature (that looks like a wall)

- 23 out from that wall-like feature as the handle clearance

- 1.8 between bottom of body flange to the taper of the lid's flange

The barrel has a slight amount of eccentricity, ovality and coning.

Eccentricity:

Ovality: It's only 1cm. I think the lid flexes when it goes ontop of the barrel.

Coning: Like a standard plastic bin or a plant pot, the "straight" section of the barrel slightly cones out. Maybe the angle is 1 degree or something so that it can release from the mold.

All these things are kinda minor, and other than the seam line at the bottom of the barrel, it looks rather easy to wipe down. Its rigidity also inspires a lot of confidence. Furthermore, the roundness means that, while large, the barrel can fit in an outer corner:

Clamp ring: 2 stars

Unfortunately, I've sent the barrel back because the clamp ring was too hard to work with. It's super easy, barely an inconvenience to open the lever and take the ring off, but the other way required levels of force I just didn't have. My brother did, but he had to take a stance like some kind of superstrength superhero when closing the lever.

One of the first issues is that all the hinges are loose-fitting and the ring isn't much taller than the thickness of the flanges. As seen in the below video (at 3m 0s), you need one hand pushed on the lever to expand the ring and then align the entire circumference so both flanges. With practice, it probably would be less of an issue.

I haven't seen a close-up image of the barrel without the metal ring on the internet, so I took a picture. Below, you can see the kind of gap between the lid and the body flange, as well as artefacts in the body flange due to the manufacturing process:

Another issue is that an additional 23cm of space from the lid ring to a wall is needed to have enough space for the lever:

This wouldn't be an issue if I didn't have to put my entire body weight on the barrel to stop it from spinning due to the high angular force applied, meaning that the lever would have to be facing away from me:

I did wonder if I had the ring upside down or something, but the ring looked symmetrical and both orientations had no effect on difficulty.

Understandably, this lever clamp ring was designed with the assumption that the user would have ample amounts of space around the barrel. Contrast to this, I'm planning as if a user just so happened to find a 60cm slot between a wall and a fridge and can only access the machine from the front.

It's also not ideal that the ring is both merely galvanised (meaning that, as seen, the underlying steel has opportunity to rust) and kind of thin (not quite thin enough to cut, but certainly worrisome).

Conclusion

Either a new way or clamping would need to be engineered (as that's how the vast majority of barrels are secured) or a barrel with a screw-on cap would have to be used for this to be a good user experience as a 3D printer enclosure. Even if this project only gets to a "university research project" level of polish, the clamp I got is far from ideal.

The barrel is ideal in most other aspects: It's blue so a diode laser can't easily poke through, it's very sturdy, it feels a bit gamified (aka getting drops out of a loot box) and it's a commercial off-the-shelf, low-cost solution.

If I could magic up a barrel, it might be a 4X larger version of this 50L one:

However, it's not like a screw-top is without its potential drawbacks, namely alignment with the threads and a loose fitting being much less obvious.

Next, there's a company called BERGER that has clamping rings as their entire business model:

Since 1950, the supplier of the packaging industry has been manufacturing 4,000 different clamping rings. The great advantage of clamping rings lies in their ease-of-use: They can be opened with just one hand.

BERGER manufactures clamping rings with a material thickness of 0.5 to 2.0 mm in [galvanised] steel and stainless steel.

Thus that at least implies that some barrel somewhere uses a stainless steel clamping ring.

Moving on, these ITP Packaging guys that made the video below are one of the handful of sellers on Amazon, with the market all within the £70 - 75 range.:

After seeing both videos, my current hypothesis is that the ring I got originally was for a slightly different barrel with slightly smaller spacing between flanges, resulting in unusually high forces required to close the lever when installed onto the barrel I received. The man puts the ring back on at 0m 39s without any particular effort but still seems to require a rather ample amount of space to thread it onto the barrel, so that's something to keep in mind. I also never found any reviewer that voiced any difficulty with the clamp ring.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.