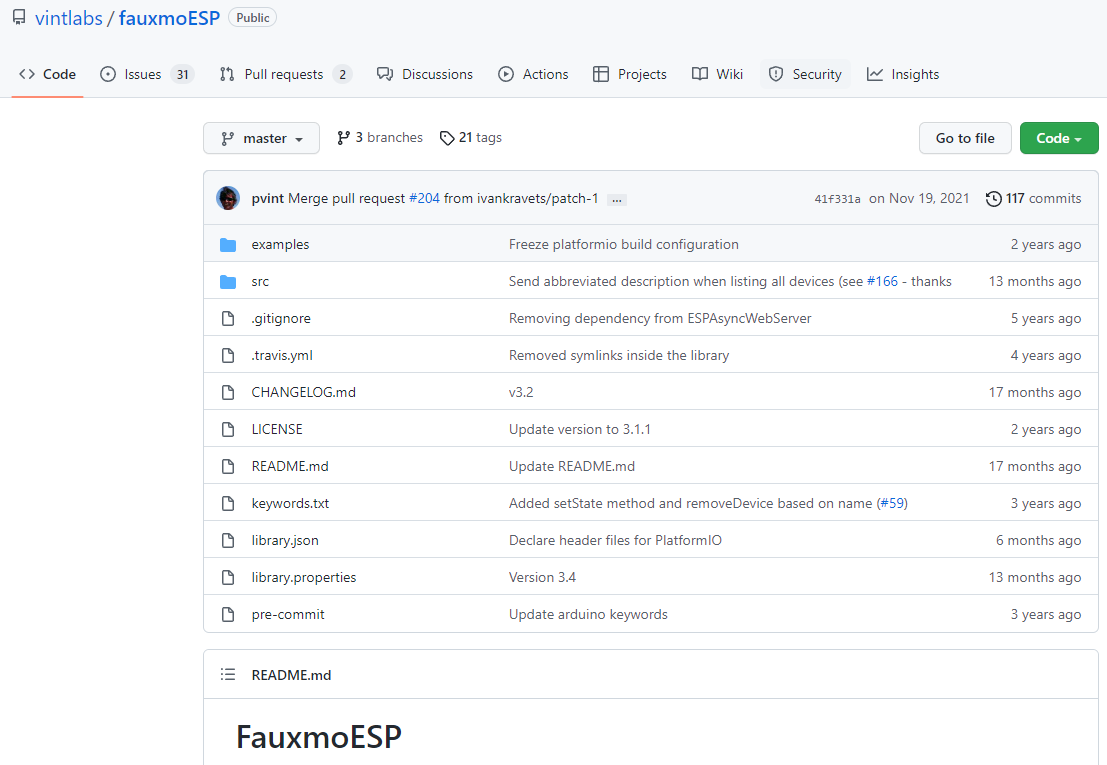

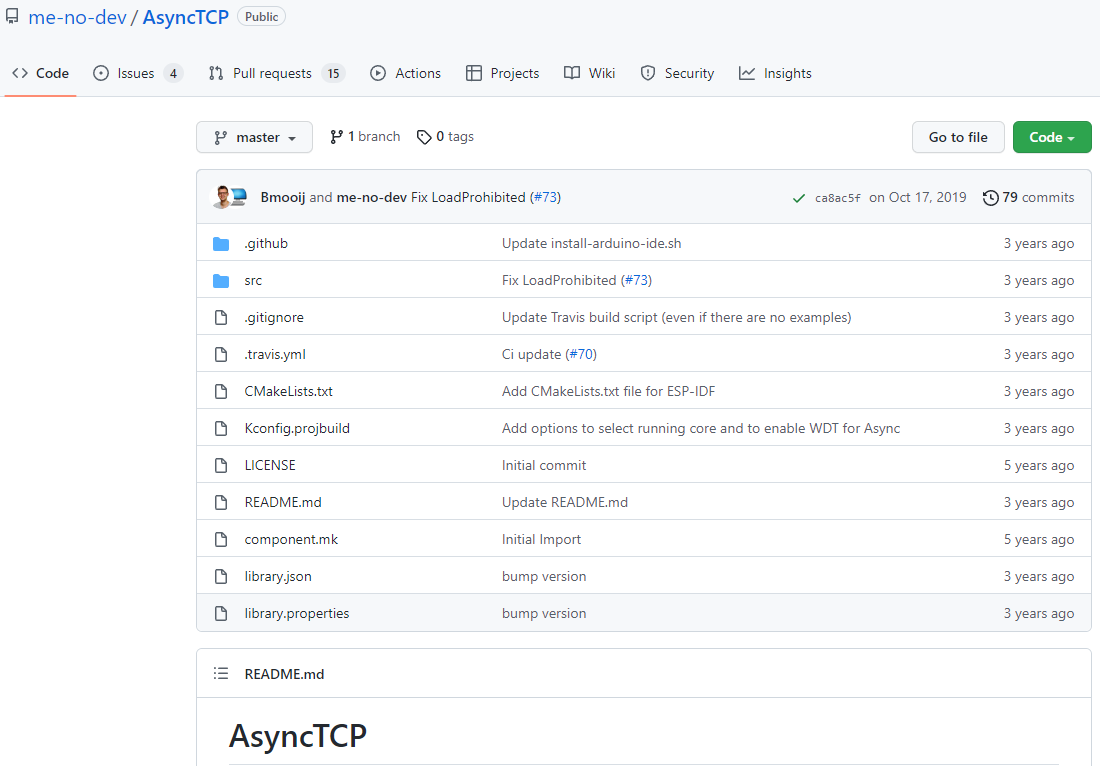

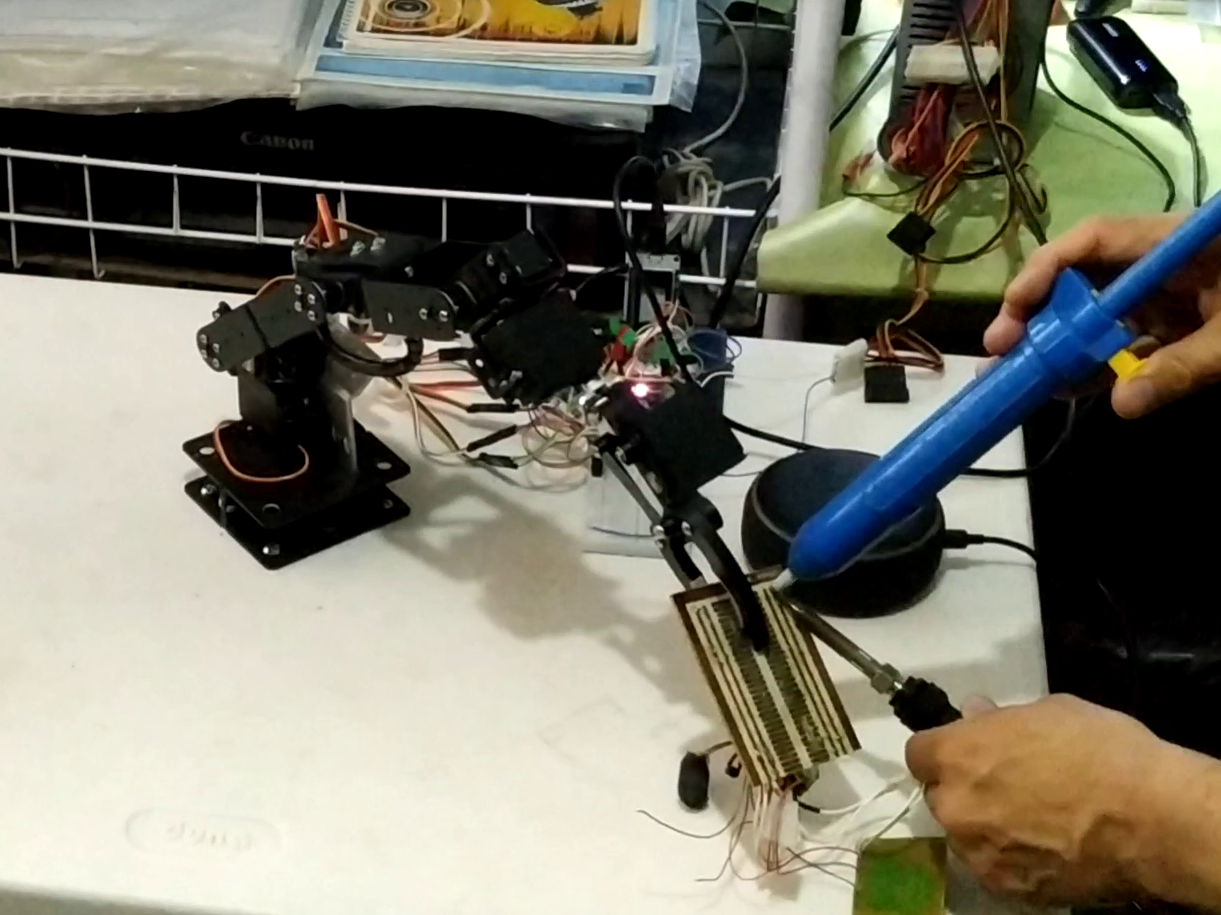

This project was a good experience as I used a free tool to control my robot arm with the Alexa Echo Dot device. Also I can increase the voice commands as far as the memory capacity of the processor allows. As you can see, the clamp has large dimensions, so it can hold much larger objects, or even hold them in the right place so that we can work comfortably, the results were interesting and you can see them in the video below

Robotic Arm for Electronic Workshop

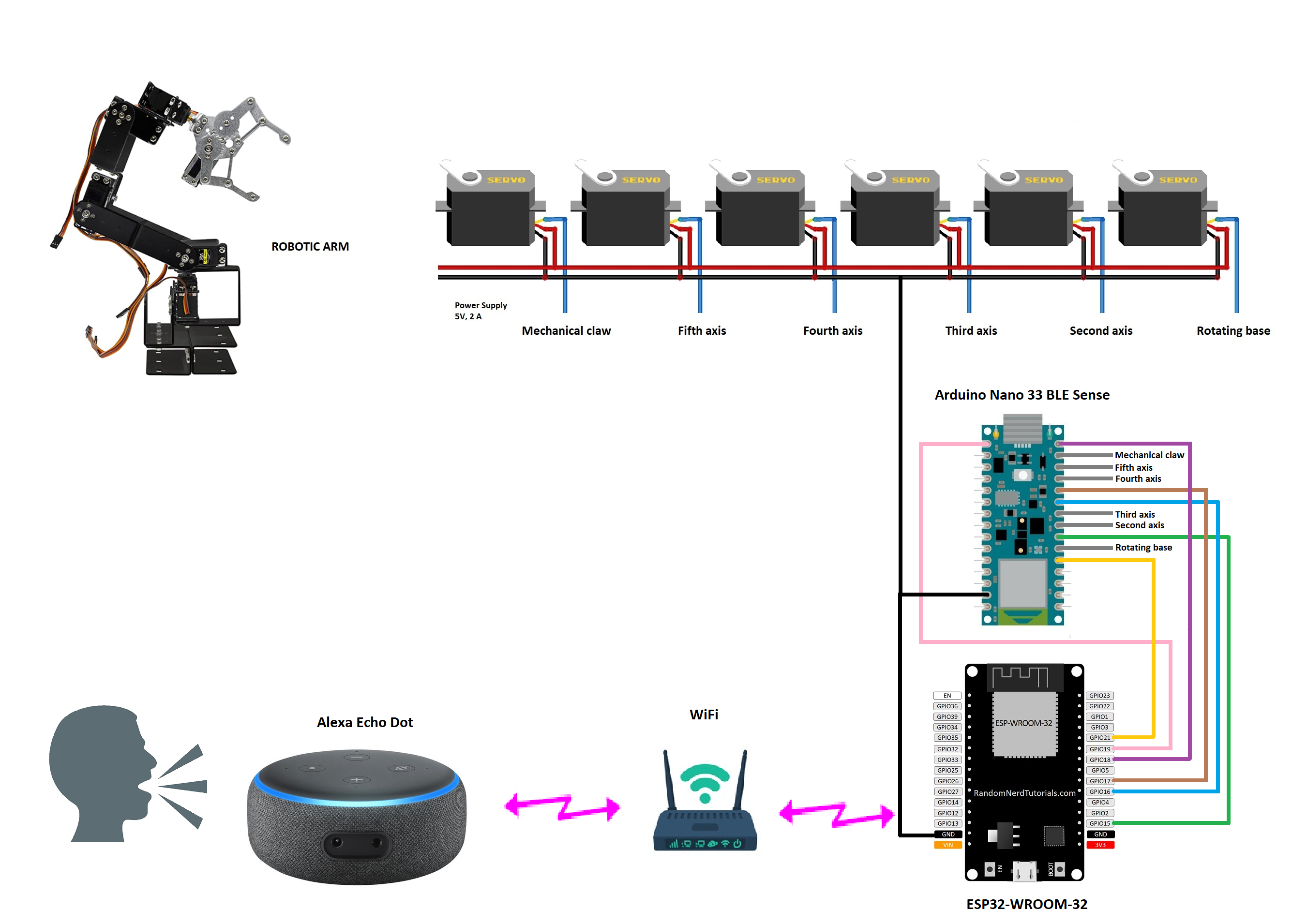

Collaborative Robotic Arm with Artificial Intelligence (AI), and Used as Assistant in an Electronic Workshop by Voice Commands

Guillermo Perez Guillen

Guillermo Perez Guillen

This project is innovative and revampes the electronic recycling market... even we can make adaptations to the gripper to collect different sizes of electronic devices, or mount support brackets to handle different types of PCB boards.