-

11Fusing

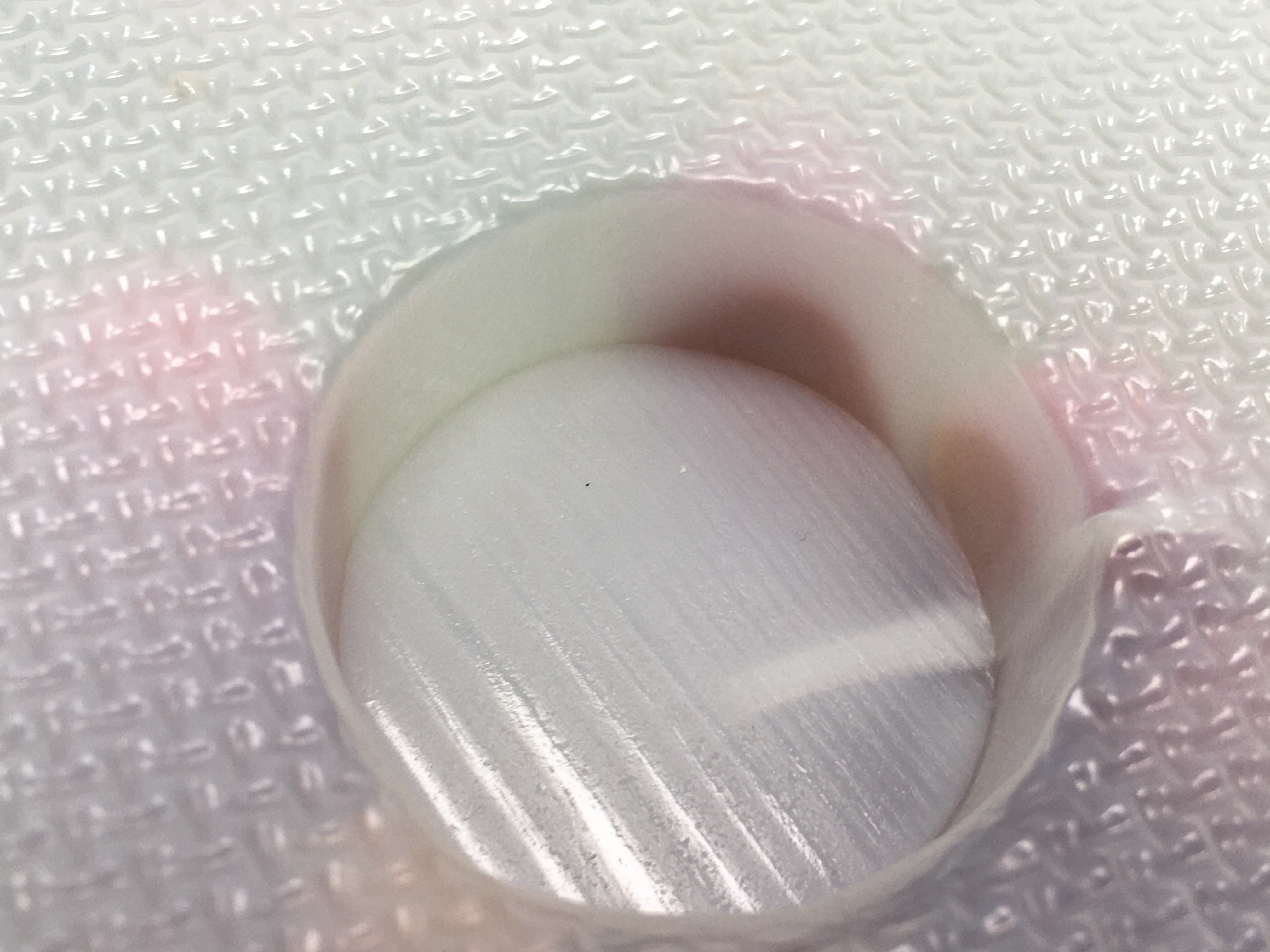

I was pleasantly surprised by how well HDPE 'fused' - by this I mean, with almost all Vac Forming, you can get 'webbing' where some material stretches and distorts. It can of course create imperfect moulds, but HDPE (perhaps because it is so soft), stays warm for a good wile, and melts back together nicely, leaving no clear trace in the mould of a weld.

Of course if I were casting a super high detail thin resin, this might be noticed, but certainly for anything like Plaster, or a resin you intend to finish-up/polish anyway, this really is not a problem.

-

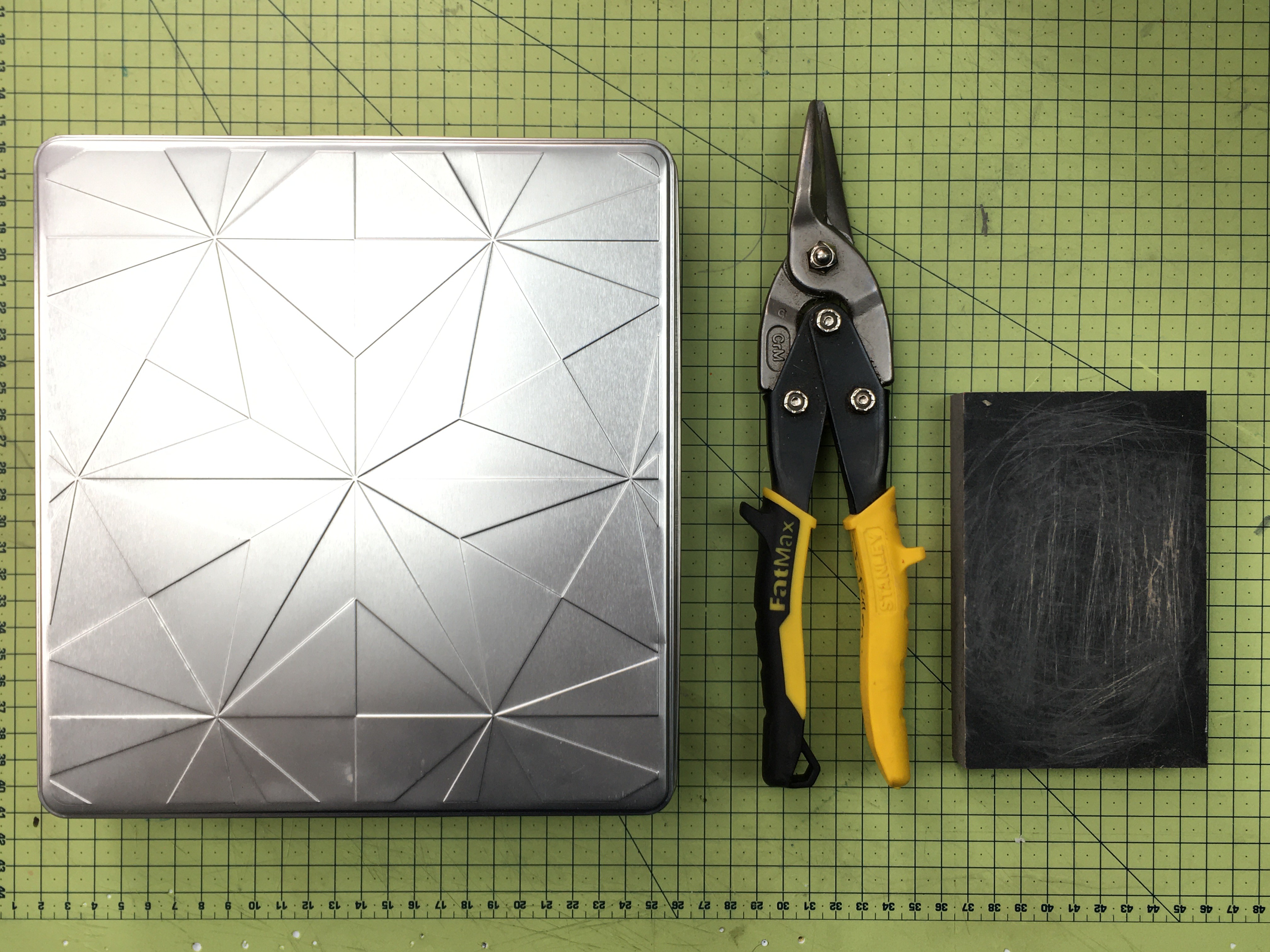

12Cheeky Biscuit Tin Hack

If you would like to heat the plastic up quicker, you can create a shroud using the 1" / 25mm metal as shown. But if you don't have this, I found a biscuit tin worked, if you have some snips and sandpaper to cut and smooth off...

-

13Ready

-

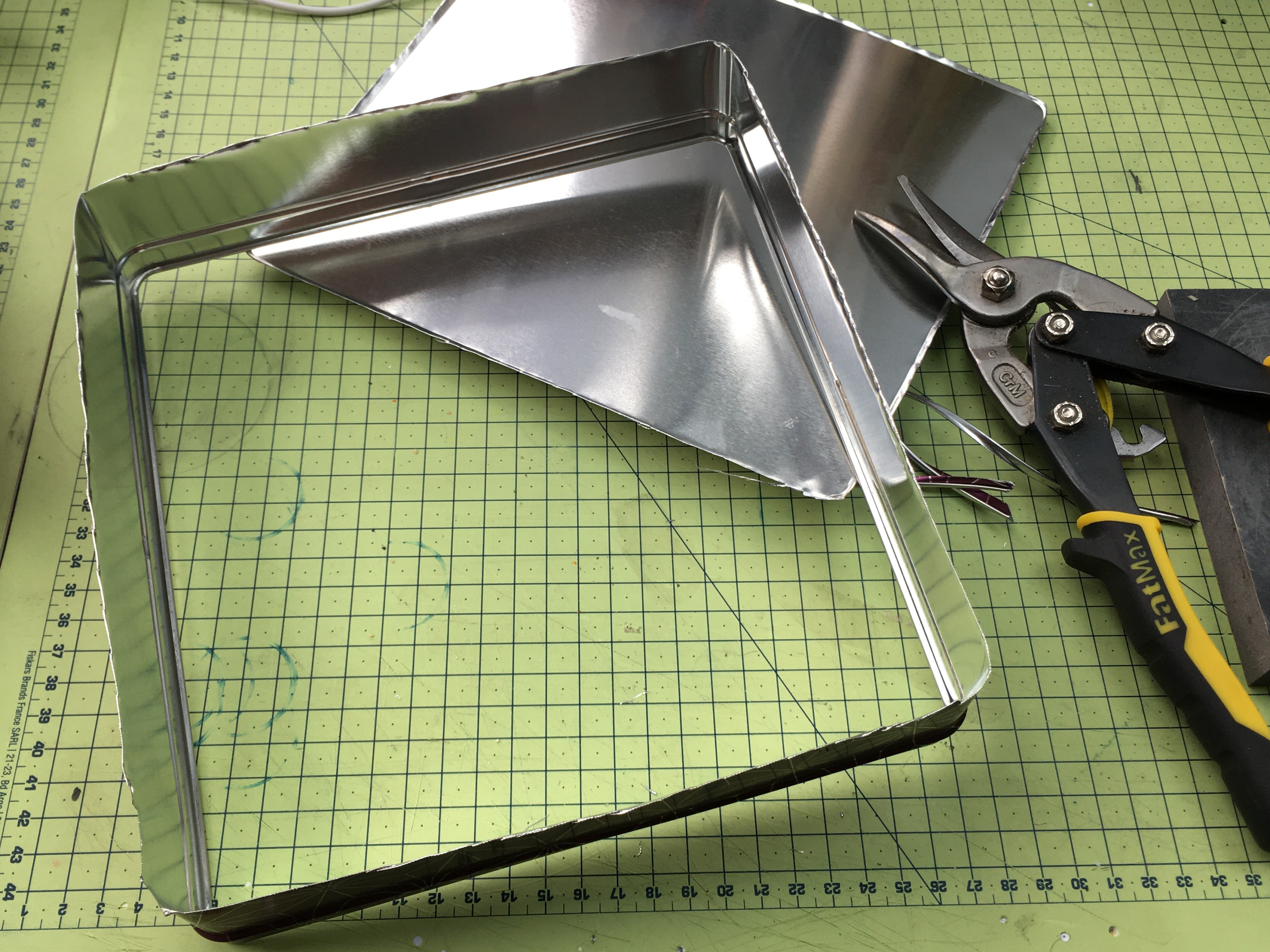

14Biscuit Tin Version

-

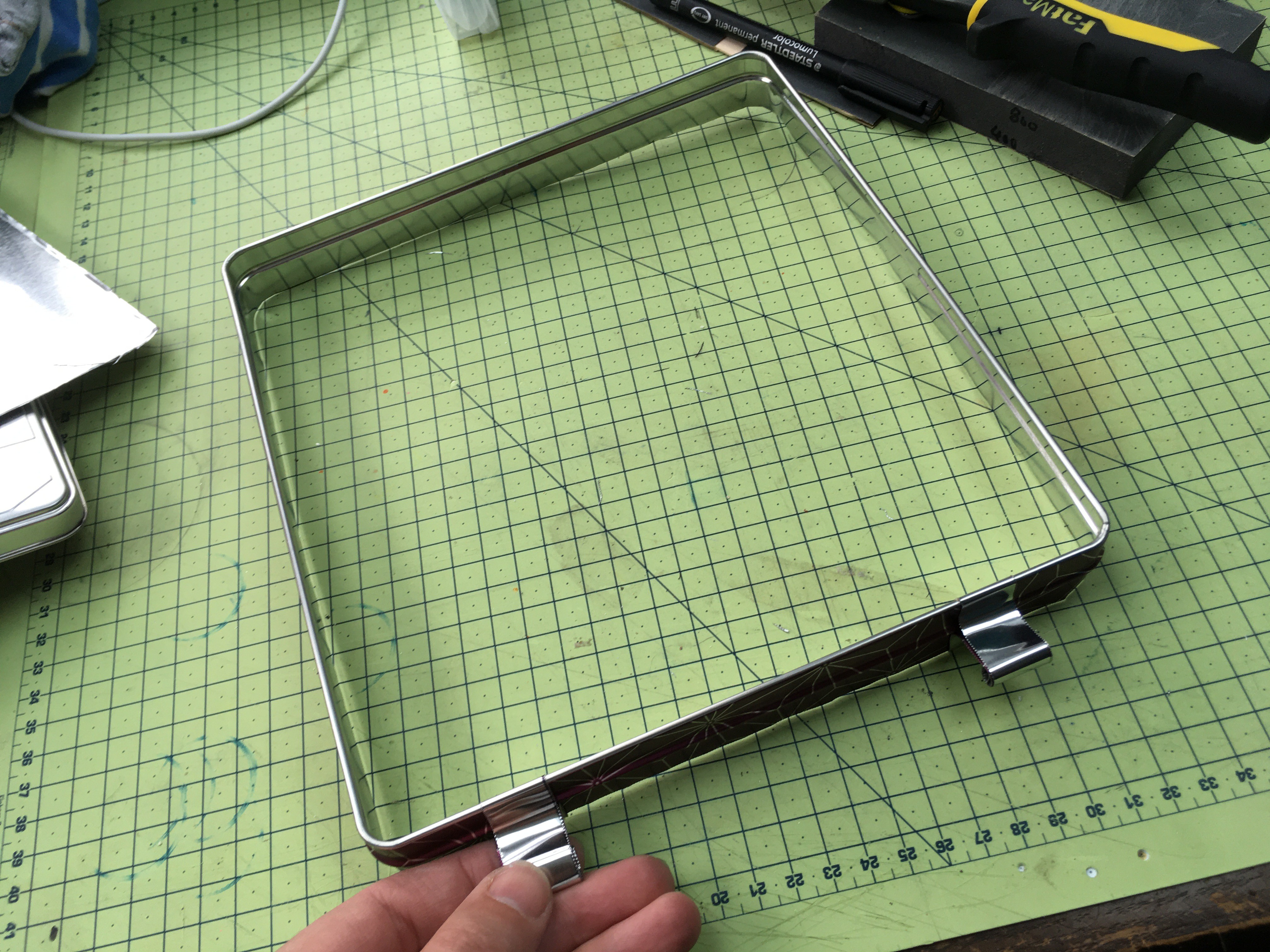

15Metal Strip Version

The slightly more rugged metal strip version.

-

16In Action

-

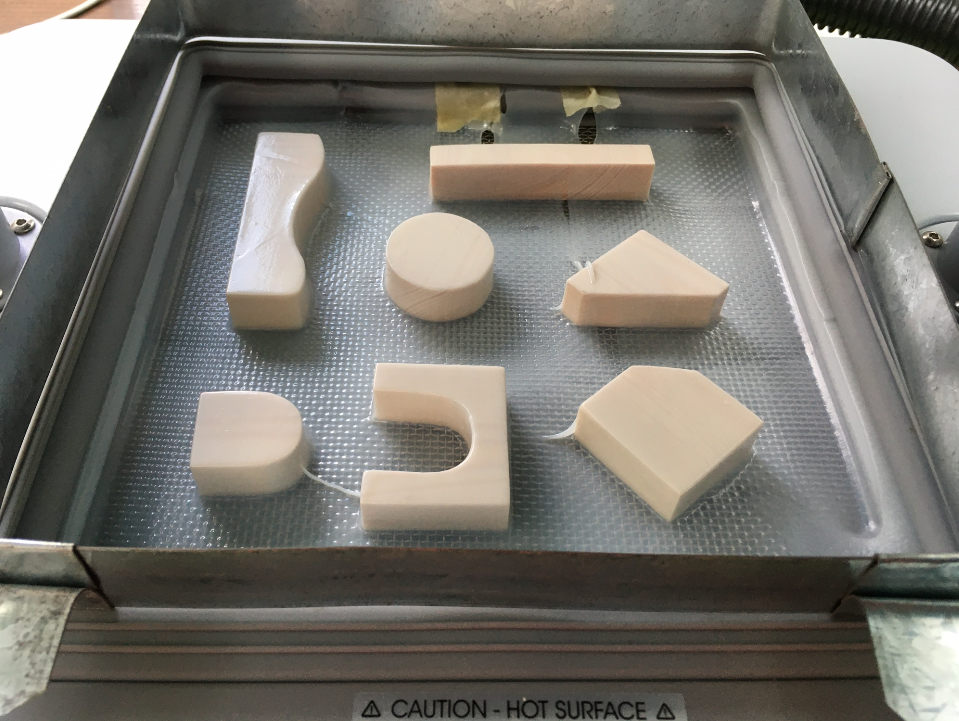

17Done!

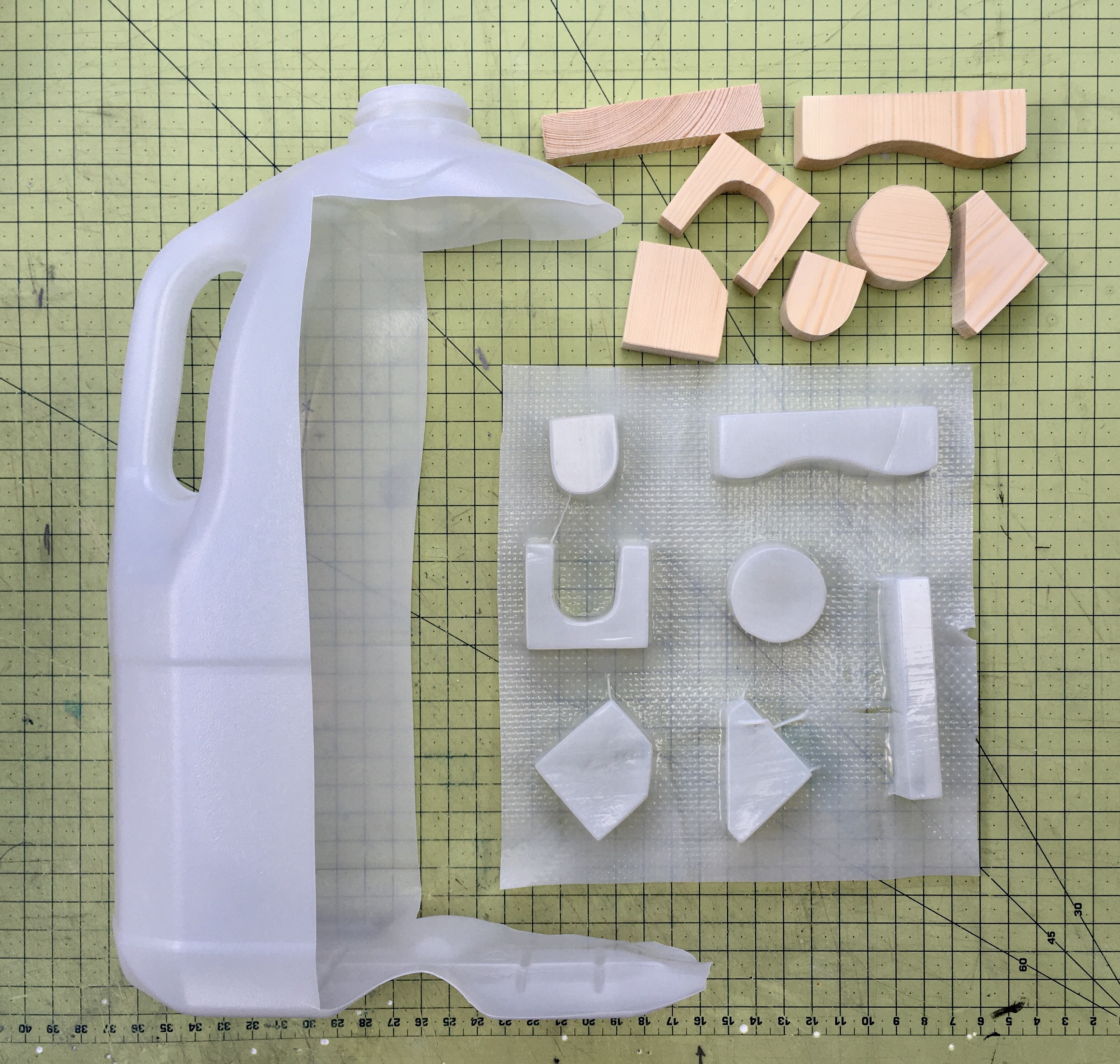

![]() So there you have it - a quick and cheap way to use Milk Jugs for prototyping Vac Forming Moulds, or as final moulds for things like Chocolate!

So there you have it - a quick and cheap way to use Milk Jugs for prototyping Vac Forming Moulds, or as final moulds for things like Chocolate!

Milk Jug (HDPE) Vacuum Forming

Milk Jugs are made from a highly recyclable plastic (HDPE), which is excellent for Vac-Forming prototypes (rather than using virgin plastic)

jude_pullen

jude_pullen

So there you have it - a quick and cheap way to use Milk Jugs for prototyping Vac Forming Moulds, or as final moulds for things like Chocolate!

So there you have it - a quick and cheap way to use Milk Jugs for prototyping Vac Forming Moulds, or as final moulds for things like Chocolate!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.