-

1Intro

Overview of the project - and how I got started. Also shows how it works.

-

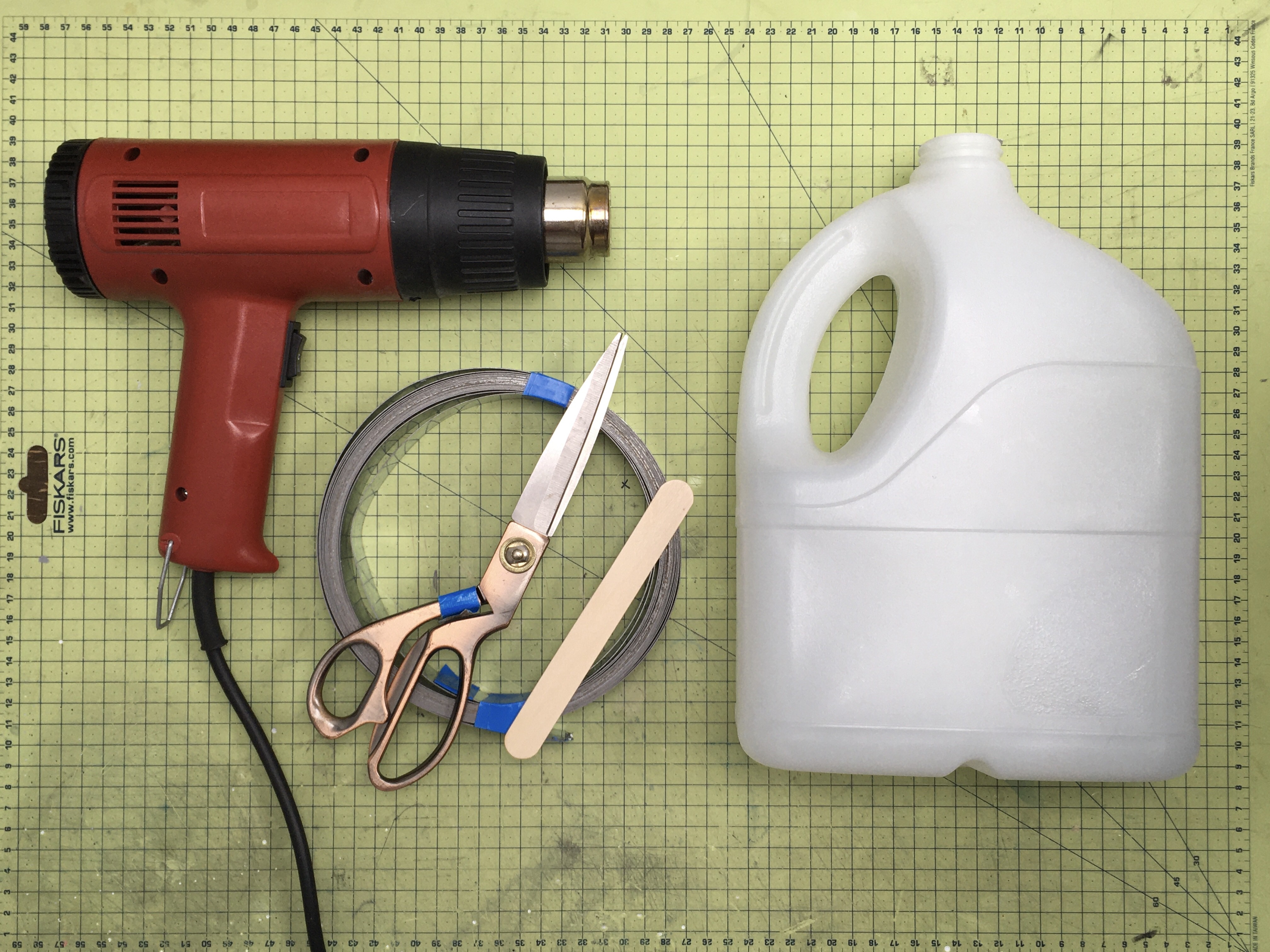

2Tools & Materials

![]()

You will need a Heat Gun (though a hairdryer will do also at a push).

Scissors, a lollypop stick, and if you have it some 1" / 25mm metal strip (You can scavenge this from a biscuit tin if you don't have this in the workshop).

-

3Cut out Section

![]()

As shown, remove a 230x230mm (approx.) section as shown. If you're unsure about what size this is, I suggest getting a bit of paper, cutting to size (perhaps a little bigger, even), and then drawing around it.

-

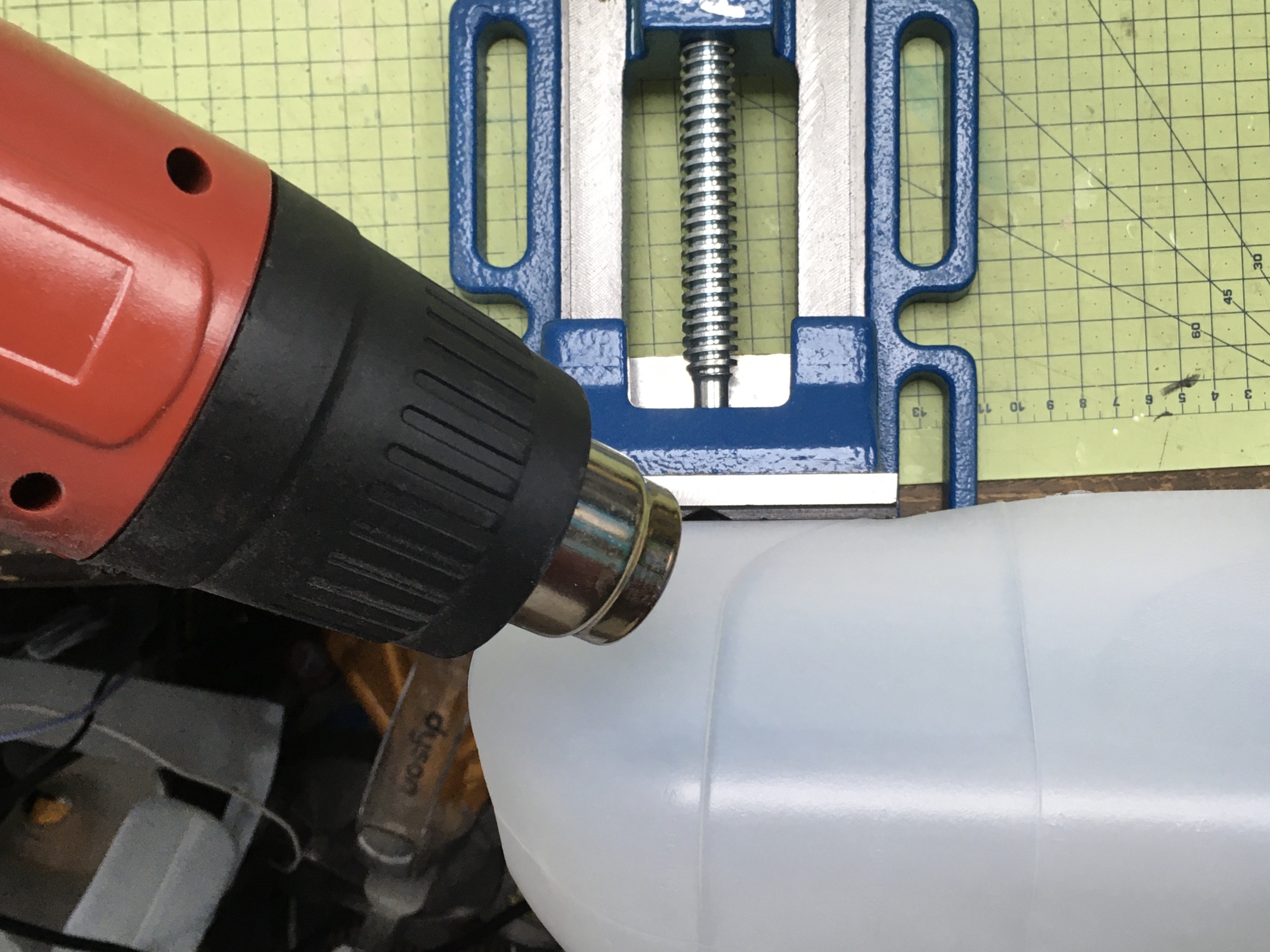

4Heat to stretch and flatten out HDPE into sheet.

![]() The Plastic can of course get pretty hot doing this, so I would suggest placing one edge in a vice, and pulling the whole thing flat, wearing some thick gloves if you like for protection.

The Plastic can of course get pretty hot doing this, so I would suggest placing one edge in a vice, and pulling the whole thing flat, wearing some thick gloves if you like for protection. -

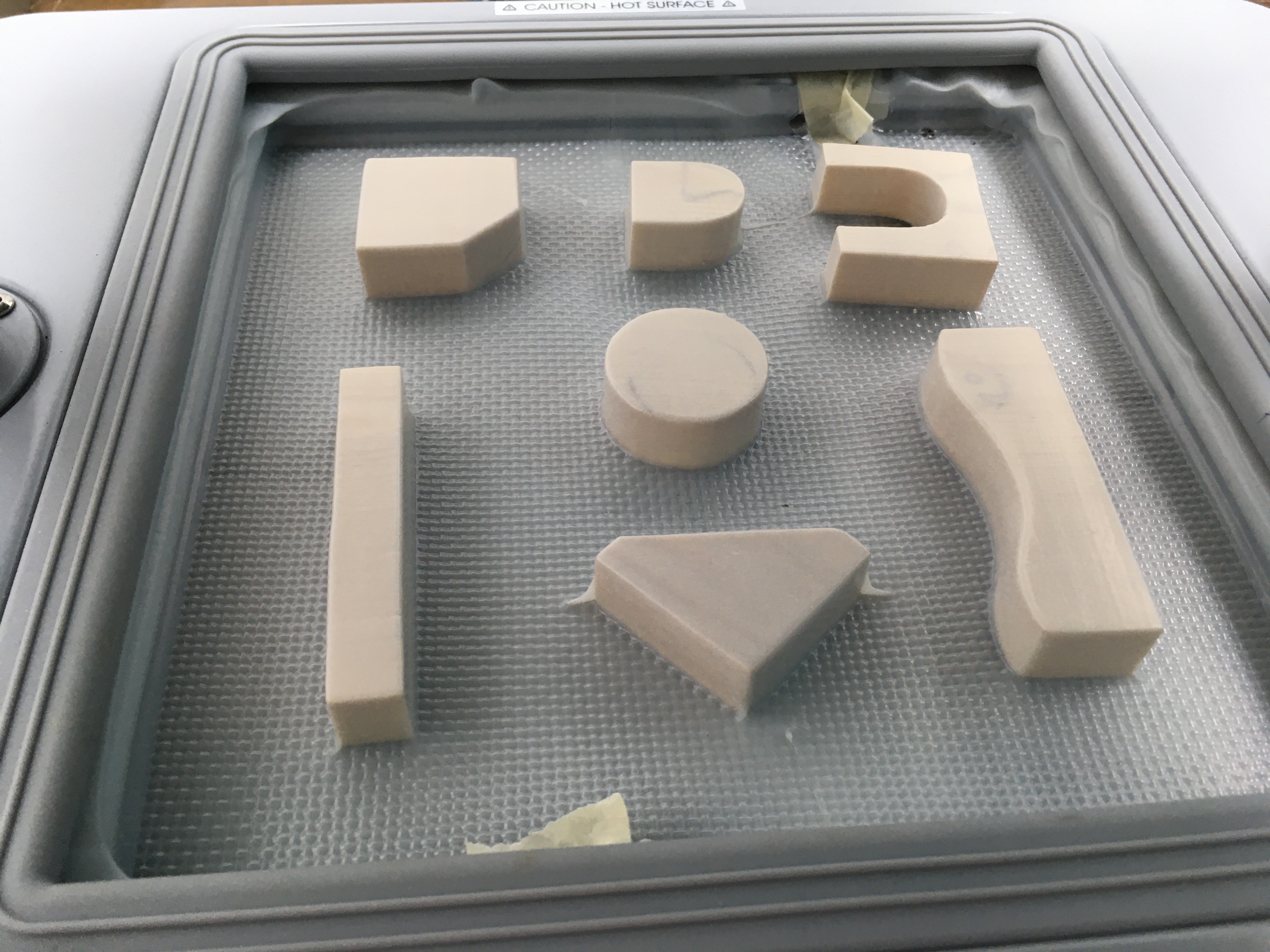

5'Raw HDPE Sheet'

![]()

Once you have wrangled it - you should have something like this. Good news is it does not need to be perfect!

-

6Warm-up

I suggest you do a 'warm-up' and do some heating without any items to vac form.

-

7Flattening Out

The HDPE will go slightly less opaque (more see though) with heating, and level out. You can actually stop the process now and let it cool like this as 'ready to use' sheet for future. Worth considering if you want the 'back-stock' for future.

-

8Vac Forming!

Now you are ready to Vac Form. Keep heating so that the HDPE sags (this is a bit of a 'trial and error', as of course results can vary from machine to machine, but once you get the basics sorted, it's easy after that!).

-

9Lower & Vaccum!

Now pull the platten down and pull the vacuum also!

-

10Tidy Up

I found that the tidy up was pretty simple, and only needed scissors.

Milk Jug (HDPE) Vacuum Forming

Milk Jugs are made from a highly recyclable plastic (HDPE), which is excellent for Vac-Forming prototypes (rather than using virgin plastic)

jude_pullen

jude_pullen

The Plastic can of course get pretty hot doing this, so I would suggest placing one edge in a vice, and pulling the whole thing flat, wearing some thick gloves if you like for protection.

The Plastic can of course get pretty hot doing this, so I would suggest placing one edge in a vice, and pulling the whole thing flat, wearing some thick gloves if you like for protection.

The HDPE will go slightly less opaque (more see though) with heating, and level out. You can actually stop the process now and let it cool like this as 'ready to use' sheet for future. Worth considering if you want the 'back-stock' for future.

The HDPE will go slightly less opaque (more see though) with heating, and level out. You can actually stop the process now and let it cool like this as 'ready to use' sheet for future. Worth considering if you want the 'back-stock' for future.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.