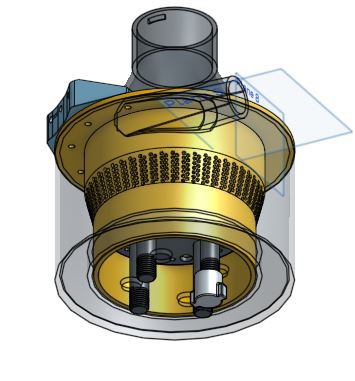

This project has gone through a number of concepts that have reached a seemingly working solution for a "shop vac". That is the extractor design is more similar to how woodworkers add a cyclone extractor to an existing vacuum system to remove the larger particles or wood chips. These large particles are collected in a bucket with the extractor bolted to the lid. An array of small cyclones are situated inside the outer chamber to collect smaller material. Its not clear how well the extractor removes small particles.

All of the modelling was done in Onshape and can be accessed in a public document, but I'll go through why the model was made the way it was and the subsequent version after.

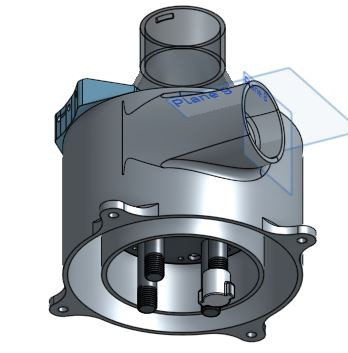

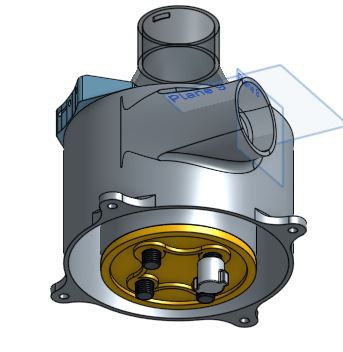

The primary driver of the extractors dimensions is the fact it is designed for printing. A benefit of bolting it to a bucket lid is that it can be printed in one piece, at least the main body. The outlet funnel is printed separately.

Those threaded legs are part of a piece sectioning off an inner chamber that is supposed to collect the small particles extracted by the second layer of cyclones.

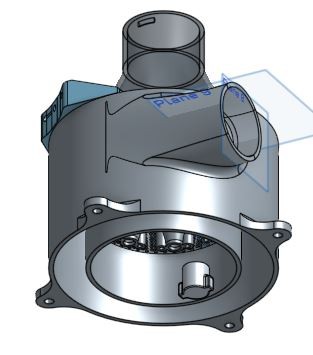

The guides for the suggest the direct of the air which is the same as the inlets direction. This is assuming there is any direction after the air passes through the mesh of holes separating the outer cyclone to the inner.

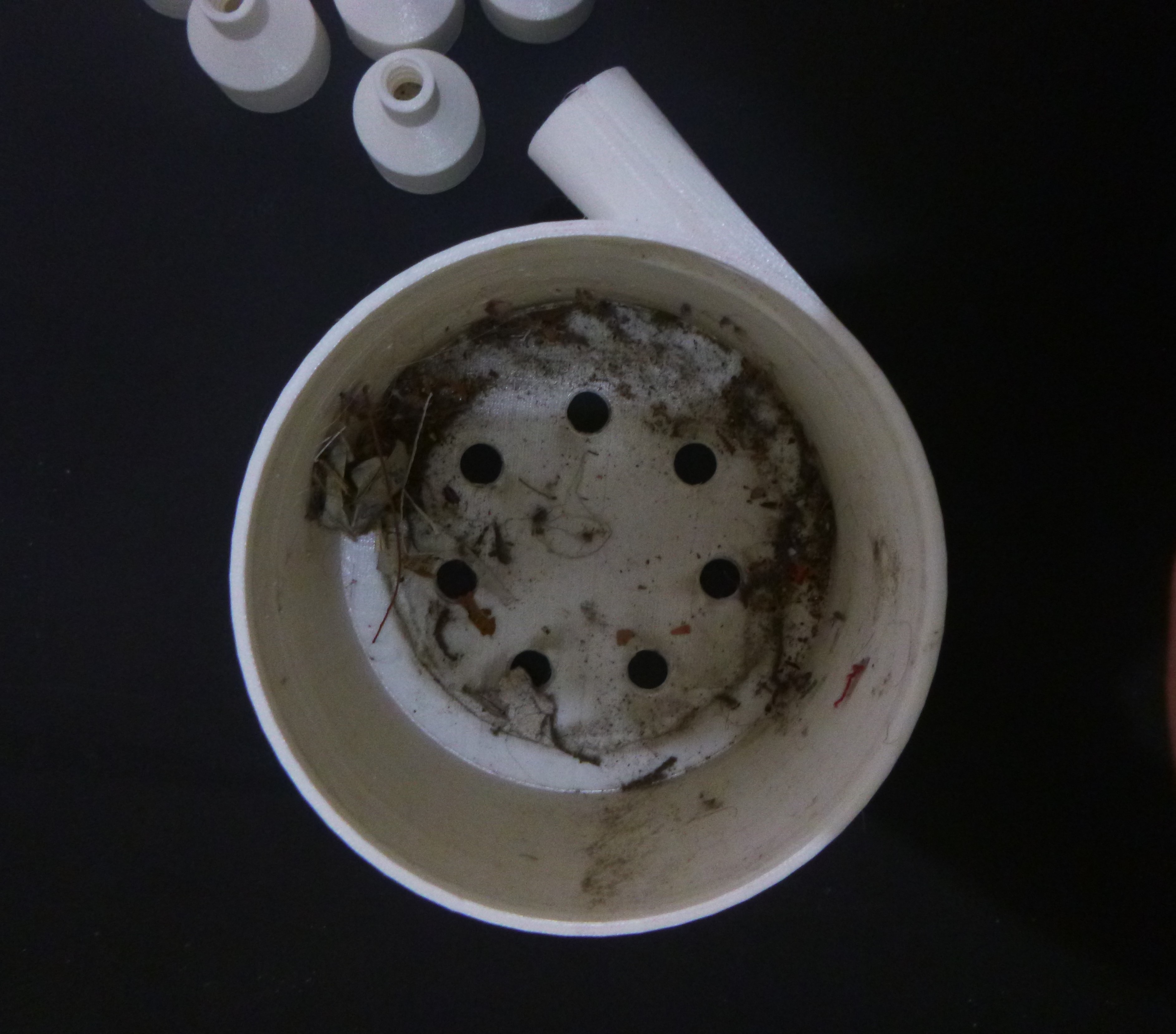

Here is probably the biggest learning from these model iterations. It is that bigger material needs to be filtered before it enters smaller cyclones because things like hair and small bit of paper clog them up. Once extractor doesn't have a cyclone, they do not function at all. This is one reason that an additional filter, like a HEPA, needs to be run is series with this type of system. Not just a cyclone system cannot filter all the smallest particle, but also if the cyclone fails. As such, it also influences futures developments of this system and why a bolt on modular extractor makes sense, as it still needs an existing high functioning fine dust filter. Adding a module like this just helps reduce the number of filters that you would consume, that's the aim at least.

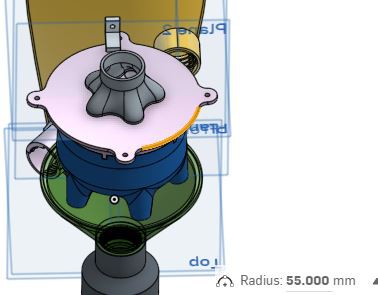

Add this extractor to and existing domestic vacuum cleaner is a bit more challenging.

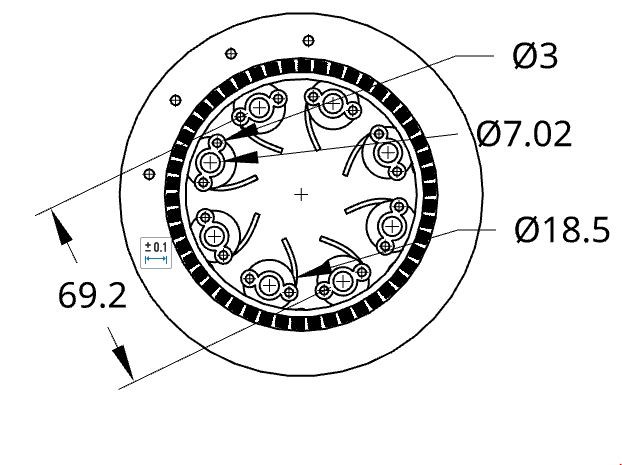

Ideally you would want this as small as possible. In the theory that these cyclonic vacuums use, the smaller the more efficient.

One of the biggest problems with these specific module is the sound from the hoses. They are irrigation hose and they aren't flexible, but they have a high pitched scream they let off when air is pulled through. Initially I thought is was the seals so I gummed them up with silicone. It wasn't until I made the one with the larger attachments mounted to the bucket did the screaming stop...

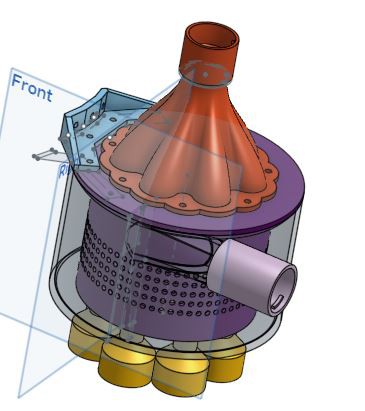

This module was based off a previous version and it mostly reflected easier to use design. The whole outer shell can be removed that has collected both chambers, the outer and smaller inner.

There are clear similarities between this and the previous version.

The issue, more than the problem, is the outer shell is attached by the small chambers collectors. This concept seemed to work with the outer chamber collecting an expected amount of detritus.

The smaller cyclone collecters also have an amount of debris in them.

Understanding where this dirt comes from is yet to be understood, but there is more that just some that fell in.

This was a step change from the previous and first concept where, I guess I was trying to be to clever. However, this was on top of all the required attachments and they got carried through the project, even the screaming hose.

This version didn't have a separate chamber collector. It initially worked, but the it didn't.

Adding a mesh to keep out the larger material that stopped the small cyclones from working as intended broke it completely. All the air ended up being pulled through the small cyclone outlets.....

Nelson Phillips

Nelson Phillips

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.