lLong time no proper update, between now and the previous update I've done loads and only documented me buying enough M4 screws to sink a ship, sorry about that....

Well what have I done?

- Done some more poor design decisions

- Fixed my poor design decisions

- GOTO 1

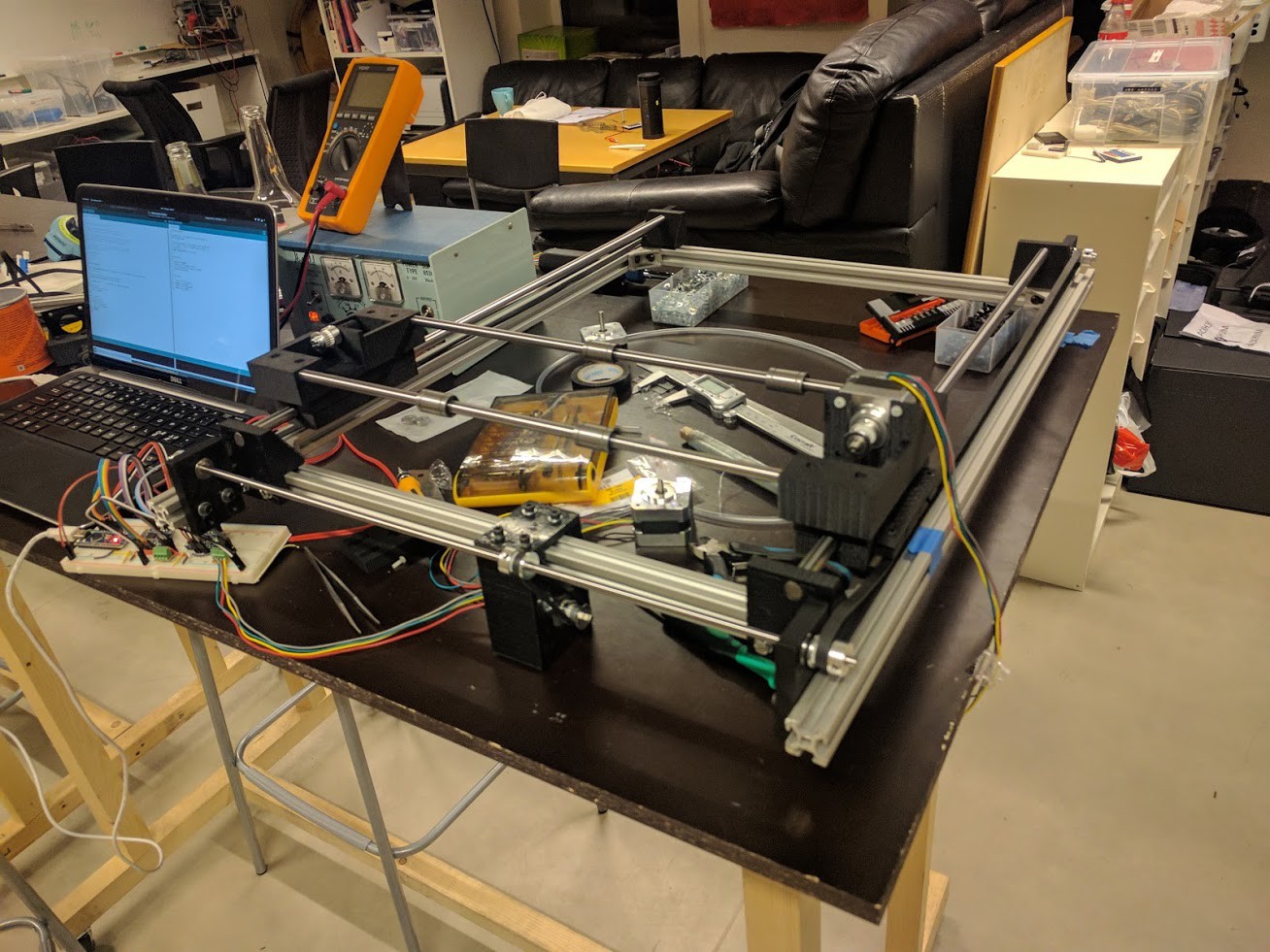

Love or hate my methodology but I've reached a stage where the machine looks like a machine and it also behaves like a machine, at least along one axis, I want to make the first axis work decently before I move on to fiddling with the next one.

Also, RS components == GREAT, i've used them a lot as they have OK prices, especially if you factor in delivery time vs ordering something from china.... oh and they use the only international courier that actually bothers about customer service around here as UPS and fedex ship all their stuff within Norway with the national postal service, and well, it is easy to see that they are ran by the state....

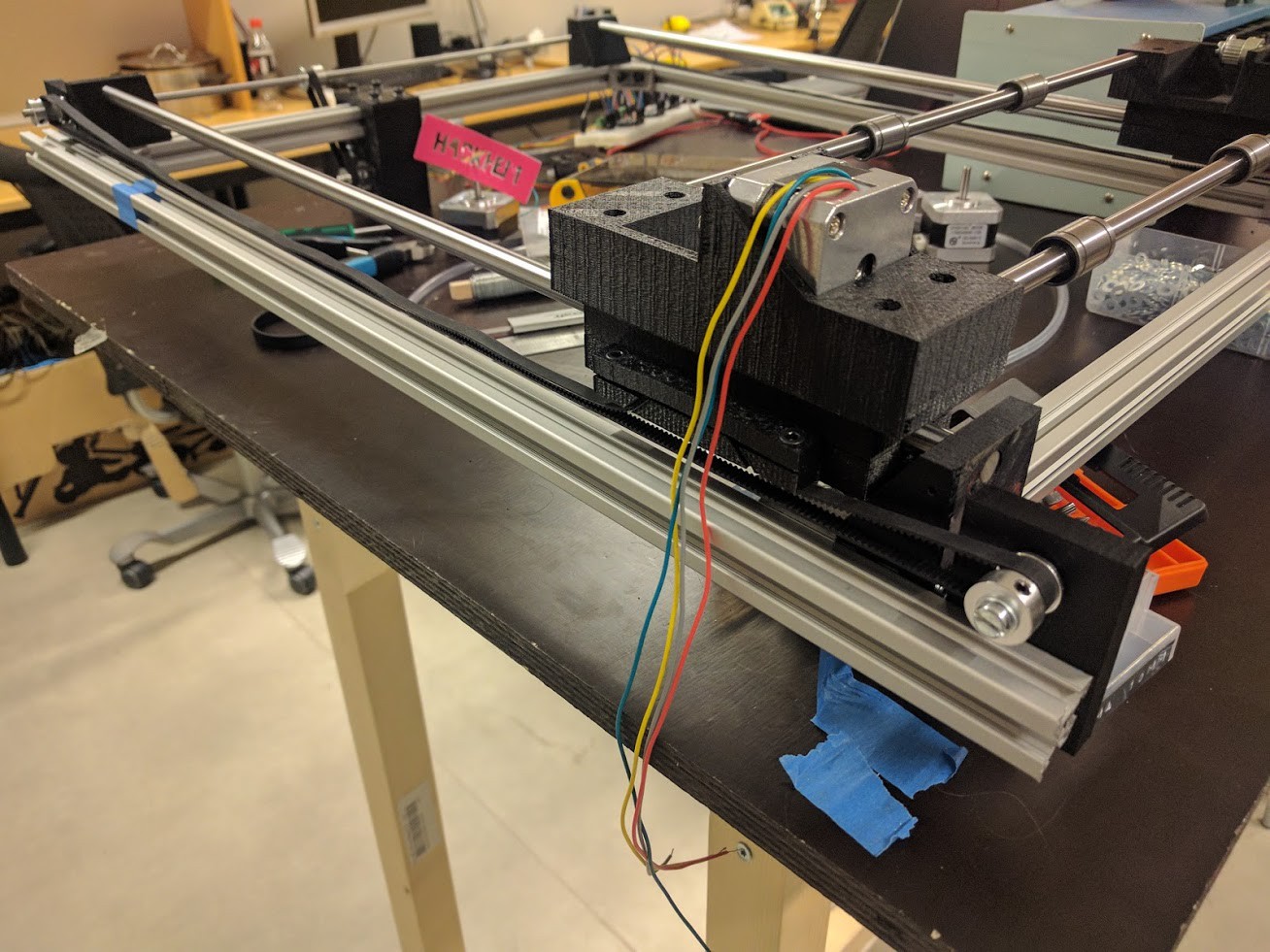

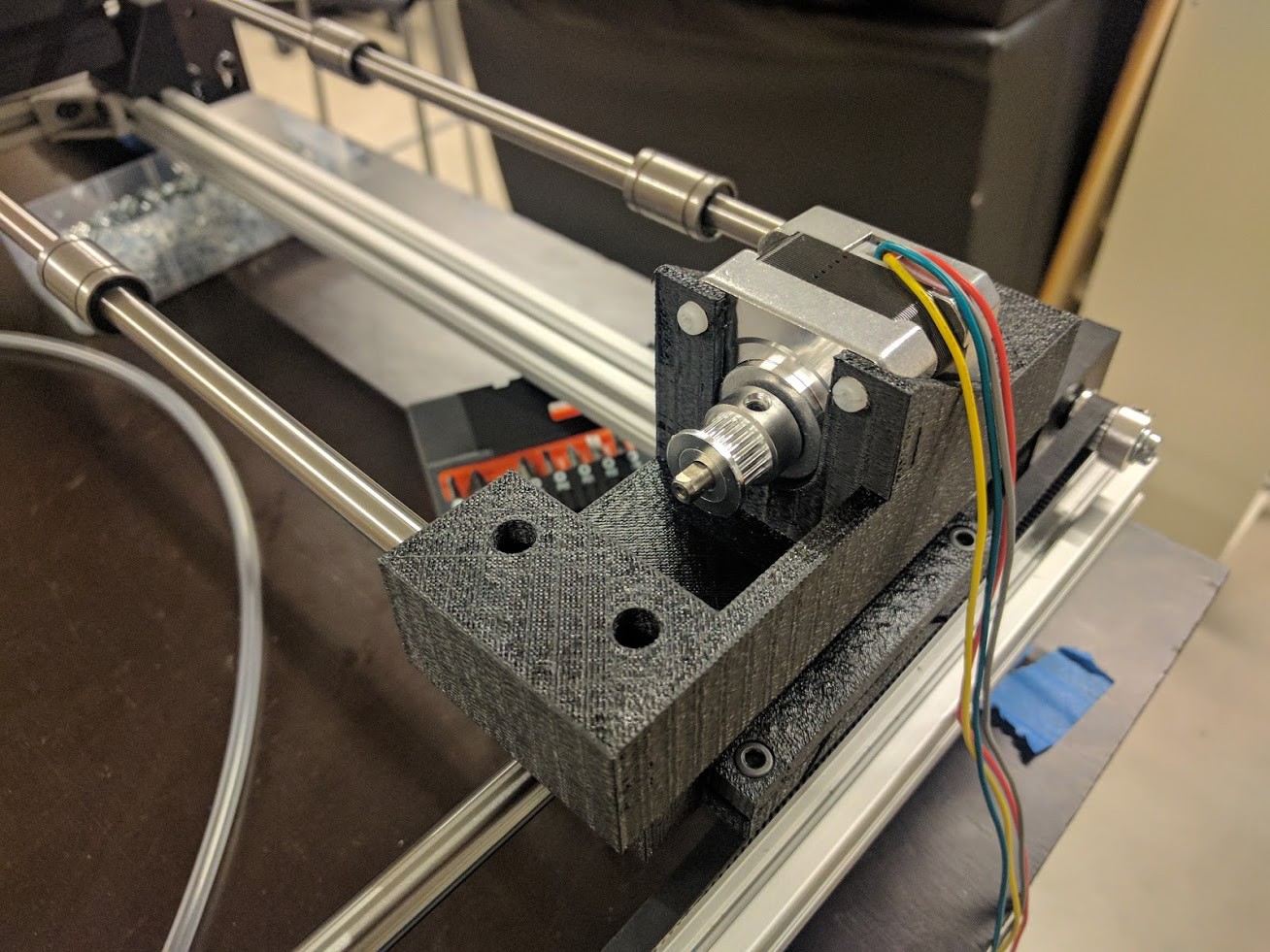

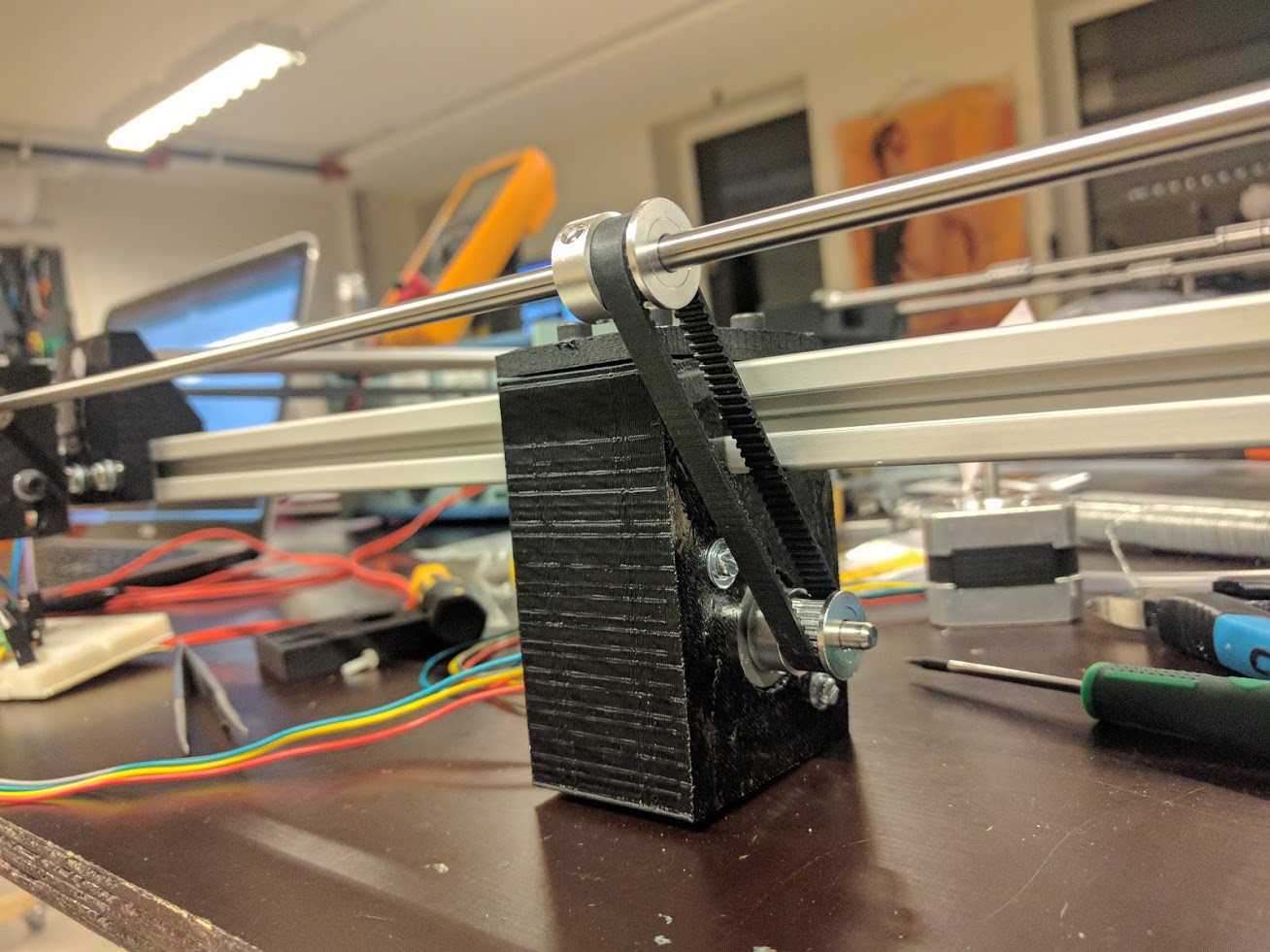

I have honestly lost track of what I did since last time but these pics should show it off fairly well:

So next steps:

- Get those long belts running along the sides properly tight and not flimsy and wobbly like they are now

- pray that the glue joining the ends of the short belt loop holds up

- Get started on the mechanics for the second axis

And if I get fed up with this I'll start looking into peristaltic pumps for the batter.

Bonus videos!

I did get the thing to move in a somewhat orderly matter so I guess I have to show that off too, I threw a pair of adafruit h-bridge stepper controllers and an arduino nano onto a breadboard and fired up one stepper, no end stops or anything here, I just tweaked the code until it ran about more or less the full length of the axis.

Nikolai Ovesen

Nikolai Ovesen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no

As someone who spends their 9-5 mired in process, I wholeheartedly support your decision to not have one for this effort.

Viva la resistance.

Are you sure? yes | no