-

How does the plastic recycling process look like?

09/12/2022 at 13:02 • 0 comments![]()

As lovely as it would be, plastic recycling by 3D-printing does not work by just pushing the print button. Actually, 3D-printing is the last step in the process. Let's have a closer look on the whole process.

First of all, you need plastic. It can be collected from your local beach, your local businesses can deliver it to you for recycling or you can use your own plastic waste streams. The origin of the plastic, its age and its previous use determine the state of degradation of the material and hence its potential use cases.

Plastic degradation

Plastic degradation means the degree of broken polymer chains of the plastic. The more breakage has occurred and the shorter the polymer chains have become, the more degraded the source material is. In plastic recycling it is common to mix a small percentage of virgin plastic with the recycled one to enhance the material properties. As a rule of thumb though, you can recycle plastic up to ten times without remarkable degradation.

Degradation occurs because of different reasons:

- UV-exposure (usually Sun light)

- Oxidation

- Exposure to chemicals (incl. saline water)

- Thermal cycling (aka recycling)

Even though the ten recycles are considered the safe limit for recycling a certain plastic, there has been an interesting research on Processability and mechanical properties of extensively recycled high density polyethylene by Pavel Oblak & co. in 2015. In a nutshell the research group recycled HDPE 100 times and observed the materials behavior during this test. As a conclusion, it is possible to recycle HDPE more than ten times, but you have to put in more energy into processing due to cross-linking of the material.

Identification of the plastic type

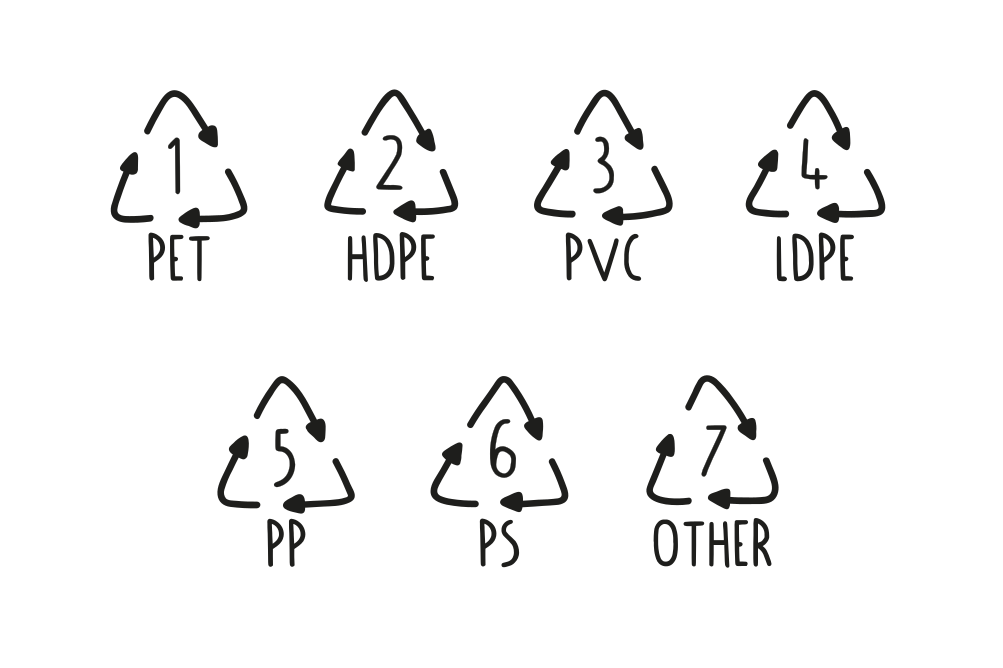

Sorting the source material is key for quality outcome of the recycling process. There are 6 main plastic types which you can identify at best by their resin identification codes.

![]()

And then there are the others, which make the whole thing a bit harder. Thermoplastics in the category 7 can include technical plastic types like ABS, PC, POM, etc. But they can include also plastic blends or inseparable multi material foils (used often in the food packaging industry).

Currently we do identification and sorting still manually, but as we get further with the development, we will switch over to automated identification by NIR spectroscopy. This process illuminates the sample with near infrared light and detects the reflection throughout the IR bandwidth. Based on the histogram fingerprint of the plastic you can identify its resin and sort it accordingly.

Shredding the plastic objects

As Bloft Mk2 makes use of plastic flakes or pellets, we need to first shred the objects into small pieces. There are already plenty of industrial shredders and open-source alternatives like the Precious Plastic shredders. These machines typically produce a flake size of ca. 3-5 mm which is close to the size of commercial virgin plastic pellets. Prior to shredding it might be necessary to pre-clean the plastic for instance to get rid of sand and other debris that could damage the shredder blades.

![]()

Washing the plastic flakes

The cleaner the plastic, the better the outcome. Most of the packaging comes with some sort of label added. Ideally this label is made from the same material as the packaging, but unfortunately there's no guarantee for that. Peeling off the label might work, but it is a tedious task, which can and should be automated. Precious Plastic has already developed a basic washing machine which uses pressurized water to blow off dirt. This might work well for dirt, but it might not work for labels. One option could be a combination of a water jet and some abrasive additives like sand as in sand blasting. But then again we would have a soup of mixed plastic which would need to be sorted again. As you see, the washing/sorting part is important and at the same time complicated to manage. This part of the process needs more research and time.

Plastic flake drying

A granulate dryer is a basic component in the plastic industry. They come in various sizes and with different working principles, with capacity ranging from a few dozen kilograms to several tons. For the current needs of the printer a dryer in the range of 20-50 kg is enough. Our dryer is fairly simple.

![]()

![]()

The basic idea of the dryer is to blow hot air through the center pipe into the bottom section of the reservoir. The hot air rises through the granulate and escapes with the moisture through the outlet.

A low moisture percentage is necessary for optimal processability and extrusion. Drying is not only needed to get rid of the moisture on the plastic surface, but also to get it out of the plastic. There are hydrophilic and hydrophobic types of plastic. Hydrophilic plastics tend to absorb moisture from the surrounding air. A good example of a hydrophilic plastic is polyamide, or Nylon.

Plastic granulation

Even though we carefully designed the printer to also accept plain plastic flakes as print material, it is recommended to granulate the plastic flakes first. Especially if you work with plastic from different sources. Granulation homogenizes the plastic and makes it uniform. This step helps to achieve a better end result. The flip side of the coin is added complexity and higher cost of the machinery. An additional extruder with a pelletizer is needed, if you want to take this step. Not mandatory, but for means of production beneficial.

3D-printing

Then finally, as the last step of process, we can start printing with plastic waste.

![]()

Where as FDM printing is fairly straight forward, you load the filament spool into your 3D-printer and start printing, is FGF printing a little different. The granulates/flakes need to be transported through a hose to the print head if you won't like to constantly fill up the print head. For overnight prints this equipment is mandatory. We've developed an automated system for regularly feeding the print head. Currently it works like intended, but we are still lacking more sensors for detecting material flow disruptions. At the end you won't want to run out of material.

-

Bad Ass Pellet Extruder v1.0

08/31/2022 at 14:31 • 0 comments![]()

The Hangprinter project by Torbjørn Ludvigsen has developed a promising and affordable concept for a large scale cable-driven 3D-printer, that has the potential to serve as the framework for an entirely new class of 3D-printers, enabling distributed local manufacturing of large end use products like furniture, vehicles, buildings etc. Up until now the Hangprinter has relied on regular FDM-extruders leaving the project far behind its true potential. Being great for desktop printers, those extruders are not suitable for printers beyond the 1 cubic meter class. Filament extrusion hits the wall in terms of speed, cost and sustainability.

We decided to circumvent this obstacle by developing an affordable pellet extruder, that enables you to print not only with industry standard plastic pellets, but also and mainly with re-granulate plastic made from your plastic waste.

Design Drivers

- Throughput 1-2 kg/hr depending on polymer

- As light as possible

- Nozzle sizes up to 10 mm, easy to swap

- Sturdy base for attachment

- Enough heating power to cover as many polymers as possible

- Tolerance for potential foreign objects (dirt, sand, etc.) within the granulate

- Automatic material transport and dispensing

- High flow cooling for the print area

The compression screw

The compression screw is the key element of a pellet extruder. It differs from a regular auger bit by having a flute depth that decreases towards the tip. The compression screw is disected into three different zones: the feed zone, the compression zone and the metering zone. The screw adds shear to the plastic granulate and accelerates the melting process. These compression screws are difficult to manufacture, so we are going to cut corners and we will use the RobotDigg 16 mm extruder screw, barrel and nozzle for now.

The RobotDigg barrel has already a flange with standard Nema 23 attachment holes and it comes with an exchangeable nozzle.

- Compression ratio 2.5

Pre-requisites

Certain set of tools is needed to start your own project. Both software and hardware tools. We are designing the pellet extruder in Autodesk Fusion 360. Although not open source, you can obtain a personal, non-commercial, license for free from Autodesk. We will provide also exchange file formats if you prefer to use other CAD software.

Among other things you should be prepared to have access to following tools:

- Drill bench

- Soldering iron

- 3D-printer

- CNC-machine

- Handtools like allen keys, wrenches, screw drivers, metal saw etc.

A word of warning

The barrel is heated by powerful mica band heaters. This leads to two serious hazards.

- The heaters are powered by grid voltage which poses a danger of a lethal electric shock! If you are not trained in connecting electric circuitry, please ask someone with experience.

- The heater bands can generate heat up to 450 degree Celcius, which can lead to serious burn injuries or a fire hazard.

Please keep this always in mind. Ask always, if in doubt.

Roadmap

- 09/2019 - 11/2019 Design, component selection

- 11/2019 - 12/2019 Manufacturing, assembly

- 01/2020 - 06/2020 Extrusion testing, iteration

- 01/2021 - 02/2021 Print testing

Project on Github

Bloft Mk2 - 3D printer for plastic waste

An open source large format 3D-printer for plastic re-/upcycling

Atte Linna

Atte Linna