Cheap SMD soldering tweezers from Ebay

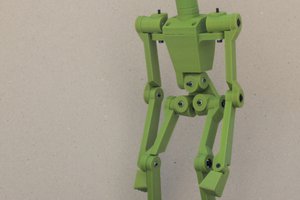

I'm making a 3d-printed support to combine two cheap soldering irons to make a pair of tweezers for SMD components.

I'm making a 3d-printed support to combine two cheap soldering irons to make a pair of tweezers for SMD components.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

preview_v4.slvsSolvespace model of the preview with the irons installed in placex-solvespace - 990.87 kB - 12/02/2016 at 22:46 |

|

|

preview.stlThis is a preview 3d model including a model of the irons in place.Standard Tesselated Geometry - 33.48 kB - 12/02/2016 at 22:46 |

|

|

muntatge_v4.slvsSolvespace model of the whole partx-solvespace - 739.67 kB - 12/02/2016 at 22:46 |

|

|

frontissa1_v4.slvsSolvespace model of the piece that holds the iron in placex-solvespace - 339.93 kB - 12/02/2016 at 22:46 |

|

|

iron.slvsSolvespace model of the ironx-solvespace - 133.66 kB - 12/02/2016 at 22:46 |

|

Create an account to leave a comment. Already have an account? Log In.

Ahoy! Love this idea, and after reading the HaD article, I picked up a couple irons and a dual-outlet USB power supply off Amazon.

I designed a similar part that doesn't require any support material and seems to work pretty well (at least with the irons I got). STL file is up here: https://www.youmagine.com/designs/desoldering-tweezers-from-two-usb-soldering-irons

Great stuff! I think i'll print your design or make a variation myself. It looks simple and effective.

Just bought a couple of irons on eBay and uploaded your .stl to Shapeways and ordered a print (don't have my own 3D printer).

sorry, I first thought you said you ordered a pint. It takes 45 minutes to print so perhaps that would be a sensible idea if you owned the printer. How much does it cost to get this printed from Shapeways? I'll feel a bit bad if you don't like the result.

$6.67 to print in black strong and flexible plastic, $4.99 to ship, $11.66 total. Don't worry about it; I'm willing to risk it. You might want to edit your post, though, to include the material you used and whether the dimensions are mm or inches. It's a pretty safe guess it's inches, but why make people guess

I see, well, I used PLA as material and printed with a 0.4 mm nozzle in an Ultimaker with "light infill" and "fast print" settings, I'm not sure about the implications of that. As for the size, the Solvespace model is in millimeters and I'm not really familiar with how this information is encoded in the STL files, never had an issue. I don't want to start a flamewar about measurement units but I'm some kind of metric hooligan.

Works fine in "black strong and flexible" material from Shapeways; don't even need wire ties.

is Solvespace free... ?

looks awesome, looks like openscad - but I have not used either... so.?

Solvespace, in my modest opinion, is much better than OpenScad because you can define constraints (e.g. this line is perpendicular to this line) and build your model the way people do in professional solid modelling software such as SolidWorks, Inventor, etc..

ordering the soldering irons JUST for this project.

NICE.

Nice. Let me know if you have any issue printing it. I think it would be good to redesign it to print as two or three separate components and be able to print it without support material. I may give the design another go now that I see the project got some attention.

would be COOL if this were a support-less 3D Print, whenever my designs have supports, the prints never come out good.

Thanks! Solvespace is the best piece of software I've discovered this year. Great stuff.

Become a member to follow this project and never miss any updates

ap-tech

ap-tech

dombeef

dombeef

ProgressTH

ProgressTH

I've been using this for some time and I love it. Thanks!

I made a version of this which is a bit easier to print and holds the soldering irons a bit sturdier. Also, with this version the tips can touch each other.

http://www.krekr.nl/content/cheap-smt-solder-tweezers/