-

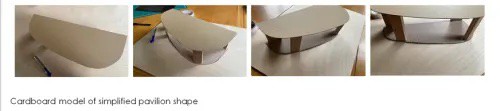

Simplified Shape

10/14/2022 at 13:18 • 0 commentsI decided to simplify the design as I thought the components for the build would be easier to make and assemble if the design was more straightforward. Not including the middle recess, meant that the shape of the pavilion was simplified and would open up more internal space. In turn, this would create a more functional and roomy space.

![]()

-

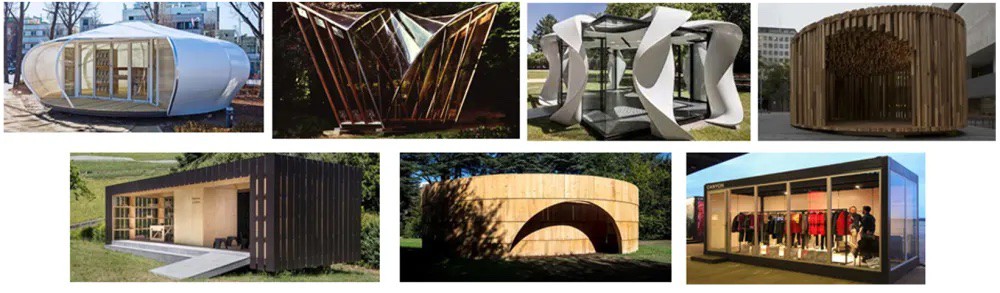

Why I Deciced To Design & Build The Air Quality Pavilion

10/14/2022 at 12:57 • 0 commentsI’ve just turned 15 and have been delivering hands-on physical computing & robotics workshops to other young people since I was 10.

Since the pandemic, social distancing along with the need for additional space and appropriate ventilation is hugely important. Therefore, I wanted to explore the concept of a POP-UP Pavilion - that could be installed in different locations to provide space & healthy indoor air quality solutions.

![]()

Air quality is something that is usually invisible to us so it is easy to ignore but it does have an impact on us from day to day, “carrying respiratory diseases which affect the probability of you getting infections". https://www.bbc.co.uk/news/science-environment-57102372

The CO2 level in a closed space is “a good indicator of air quality and can highlight the need for ventilation”. Well-ventilated rooms are crucial for reducing the spread of airborne viruses. Well-ventilated spaces should have CO2 levels below 800ppm and CO2 levels above 1500ppm would indicate poor ventilation or overcrowding. Lower CO2 levels are also “linked to improved learning outcomes and better cognitive performance”. In today’s world, this suggests that the way we design, equip & operate our shared spaces is more important than ever. Air quality & ventilation needs to be addressed in schools & restaurants. https://www.imperial.ac.uk/news/233154/curbing-covid-19-schools-imperial-scientists-support/

![]()

I wanted to develop and refine a scaled-down fully working model pavilion to test the concept, and ultimately create a workshop based on it. The workshops would enable me to deliver hands-on sessions benefiting young people by giving them the opportunity to explore how spaces can monitor & react to internal air quality to improve the experience of the users; improve their understanding of good air quality, and improve their digital & making skills. The fully realised pavilion idea would benefit schools, shared working spaces, and the hospitality sector.

![]()

-

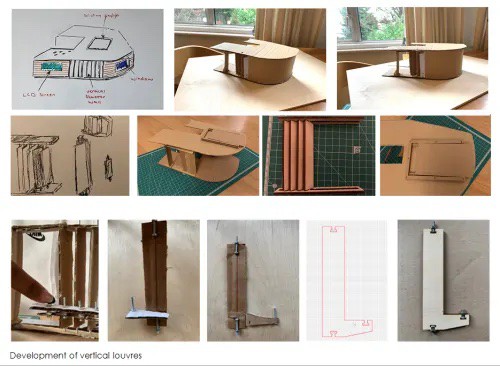

The Design Process

10/14/2022 at 12:49 • 0 commentsI made some sketches and some cardboard mock-ups to help visualise my idea and to explore using linkages to make it all move. The cardboard models were a really good way to test how different elements could fit together and also helped me to get a better idea of areas that I needed to investigate, change or drop.

Securing & concealing the big stepper motor - I chose to operate the shutter walls with stepper motors, and eventually worked out a way to attach them directly to one of the louvres within the linkage of each of the vertical shutter walls. However, this left me with the problem of how to keep the stepper motor still and secure, without spoiling the aesthetic of the pavilion.

The pavilion itself is made up of several layers of plywood and acrylic pieces which were designed in 2D design and printed out on a laser cutter.

![]()

-

How The Idea Started

10/14/2022 at 12:35 • 0 commentsI thought about what we already do to ventilate rooms & how that could be changed or improved. Opening windows stuck out the most. But what if we had the option of opening the walls & the roof as well as the windows? – What if the room could do all of this by itself? To follow up on this I looked around our home for some inspiration and eventually homed in on our wooden horizontal blinds and a set of long vertical fabric blinds that we have in our hallway. The blinds were doing exactly what I needed walls to be able to do.

After realising this I searched the internet for different types of blinds & shutters, and after several searches, I landed on an image of some ventilation shutters which had been designed by the architect Le Corbusier –

and my vertical shutter wall idea was off.

![]()

-

My Reflections & Future Plans

10/14/2022 at 12:27 • 0 commentsI produced a scaled-down pavilion that uses an internal sensor to monitor & then trigger various reactions to the CO2 levels from inside. The reactions include opening & closing motorised shutter walls, an automatic sliding skylight, a ventilation fan & colour-coded CO2 level warning lights. I have used stepper motors & servos to generate the movement and an Adafruit ESP 32-S2 as the brain stacked with a TFT screen to display the air quality data from the wall of the pavilion. The data is also visualised via IoT on Adafruit IO. In the end, the design worked as expected but I had to experiment with several different stepper motors and ways of mounting them until I found a good combination. I leaned about linkages & couplings and designed several laser-cut components & mechanisms which I will be able to use in the development of a more streamlined kit version of the pavilion that I will use to deliver workshops to other young people.

I coded the project using Circuit Python to control the stepper motors, the servos, the Neopixels, the fan, the CO2 sensor, and the TFT screen. I also used CircuitPython to code the visualisation of the date on Adafruit IO.

I worked on the project in short but regular sessions over a four-month period and was able to dedicate longer periods of time to it during school breaks.

I think I should have reached out to organisations/companies that specialise in stepper motors, this would have helped me to find appropriate motors quicker, perhaps finding smaller or more efficient motors.

Testing my finished pavilion was done by altering the internal CO2 levels (a lot of heavy breathing through the pavilion windows). The code had to be tweaked several times to achieve the correct fully open and fully closed positions for the moving shutter walls and the sliding skylight.

I am considering adding a sound alert for the workshop version of the pavilion.

I will definitely continue to develop the project into a workshop format to engage other young people. A streamlined version of the scaled-down pavilion model has the potential to go to market as an educational tool.

I designed lots of individual parts, for example the stepper motor mounts/housing, these can be used to secure similar stepper motors to other projects/products. The moving shutter walls can be scaled up or down and applied to future ideas & projects, and so can the sliding skylight mechanism.

I developed some very useful joining techniques that allowed me to create large components from several small pieces of material, making use of scrap materials whilst reducing waste.

I became more aware of good & bad CO2 levels and the importance of good ventilation.

I experimented with a lot of new functions on the CAD software, some of which I applied while designing the different components.

I used a lot of cardboard models to help visualise the different sections of the pavilion structure, so my modelling skills have definitely improved. I really enjoyed seeing my cardboard mock-ups develop into neat, precise laser-cut components, and seeing the shutter walls opening & closing on their own was satisfying.

My overall problem-solving skills were tested as there were so many different elements that needed to fit together properly and the code to work altogether.

I would like to collaborate with groups or individuals in order to build a small human-sized version of the pavilion which could be tested in a real situation.

It was very challenging to design the pavilion in a way that all of the different features & main electronic components could be easily accessed without having to do a lot of major dismantling. Making several cardboard sketch models help me to gradually figure out and quickly try out ideas, and then make modifications.

My advice to anyone considering a similar project is to ask the industry specialist to share their insights. This is something that I’ll definitely do on my next project!

Air Quality Pavilion: Rethinking Shared Spaces

The Air Quality Pavilion uses an internal sensor to collect data, monitor & then trigger various reactions to the CO2 levels

Avye

Avye