# Origin

This is part of a console for a film/tv editing system. This is just the control panel; the actual brains of the thing, including the interfaces to the rest of the production equipment, reside in two separate rack-mounted chassis (yup, that's plural), which I don't have. Not that I even want them; those cost several times as much as the control panel itself, which is already plenty expensive -- and besides, I don't plan to use it for film production anyway, although back in the day I used to work with ones just like this.

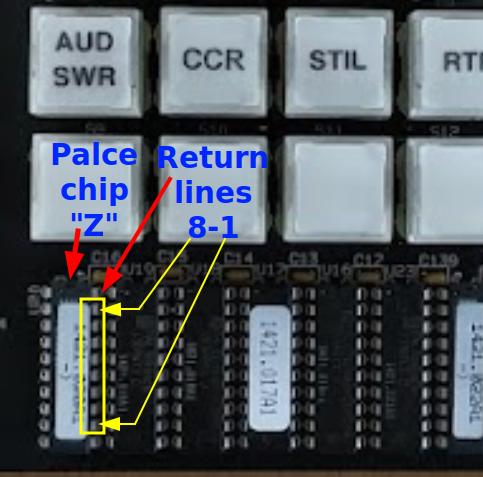

The manufacturer, Accom, folded in late 2005. Their web site is now defunct, and their documentation is not that easy to come by since the archive does not include their FTP site. I have since found that support continued under the Abekas name, which was eventually acquired by Canada-based Ross Video. I have reached out to current and former staff at these companies, contacts listed as international distributors, and repair centres around the world -- in the hope that someone, somewhere, has kept some of the old paperwork around and is willing to share. So far, no luck. This means I'll have to reverse engineer it.

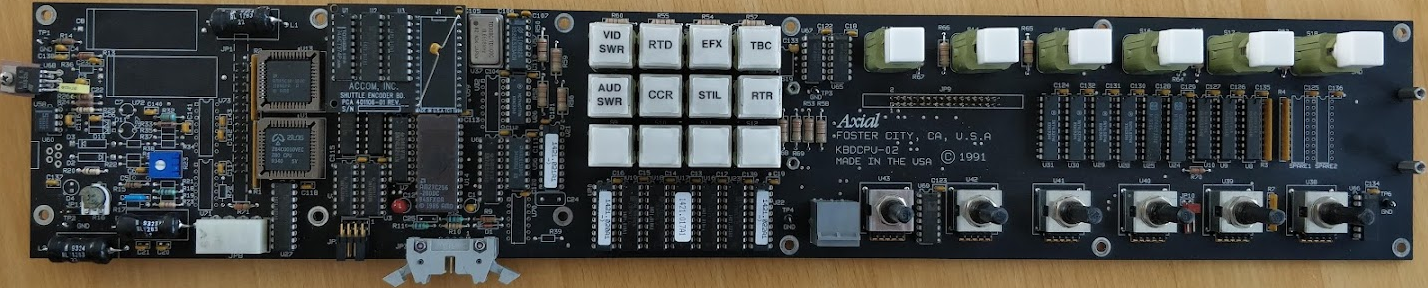

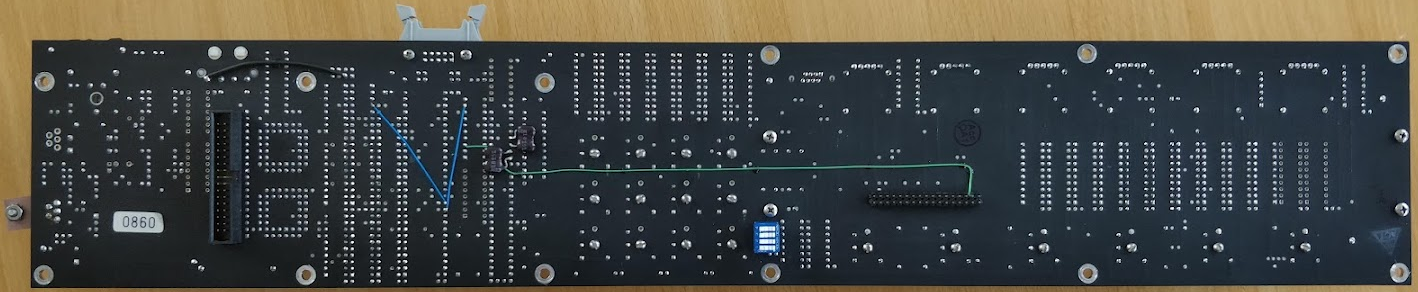

## Physical appearance

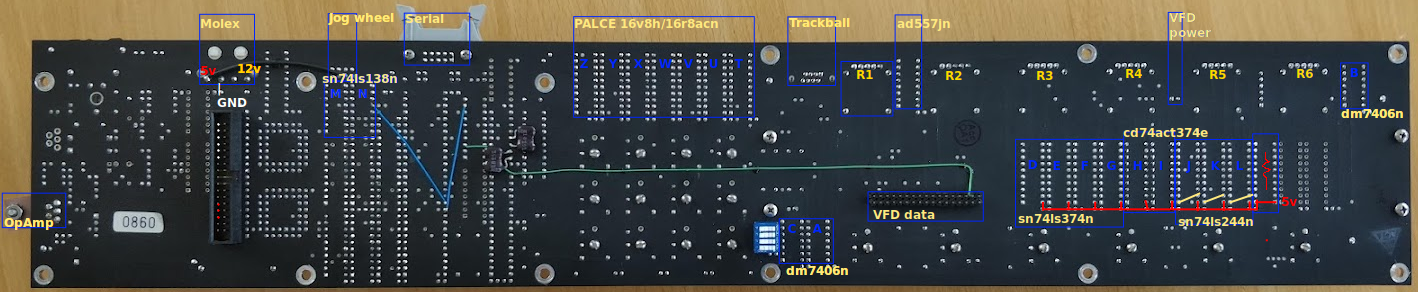

The control panel is fairly hefty: The thing weighs around 7.7kg, is 78cm wide, 16cm tall, and 32cm deep.

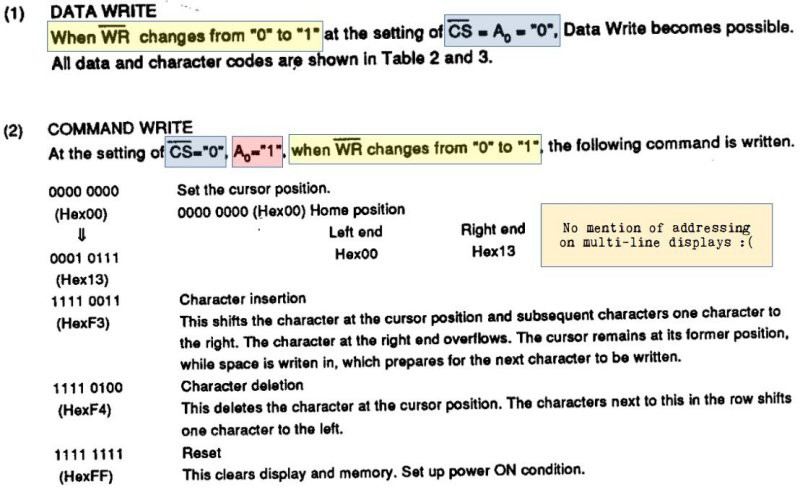

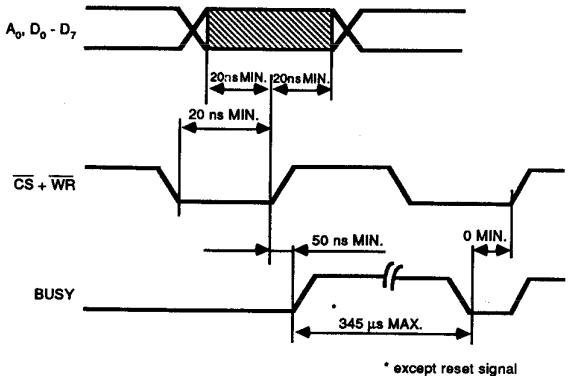

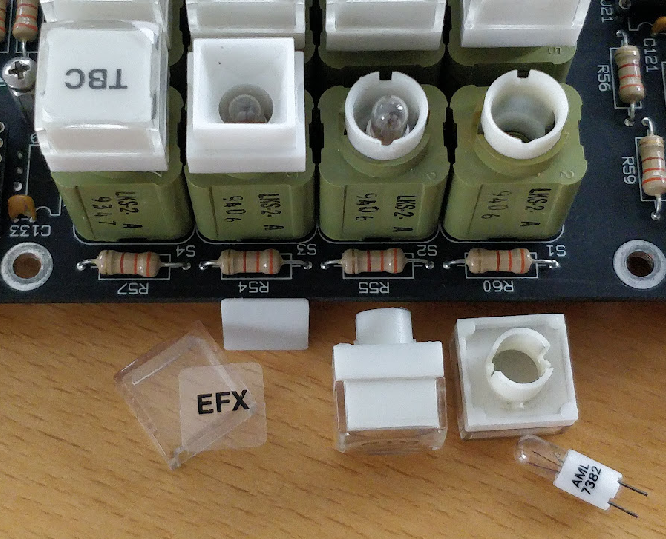

In total, there are 189 buttons, 23 of which are individually lightable, arranged into a full qwerty layout, a combined numeric/navigation block, five clusters of 12 keys each, other minor clusters, and a 2x40 character VFD display with a blue-on-black colour scheme surrounded by six sets of lighted switches, dial knobs, and keys. There's also a large trackball (although with no mouse buttons nearby), and a solid-metal jog wheel.

## What am I building?

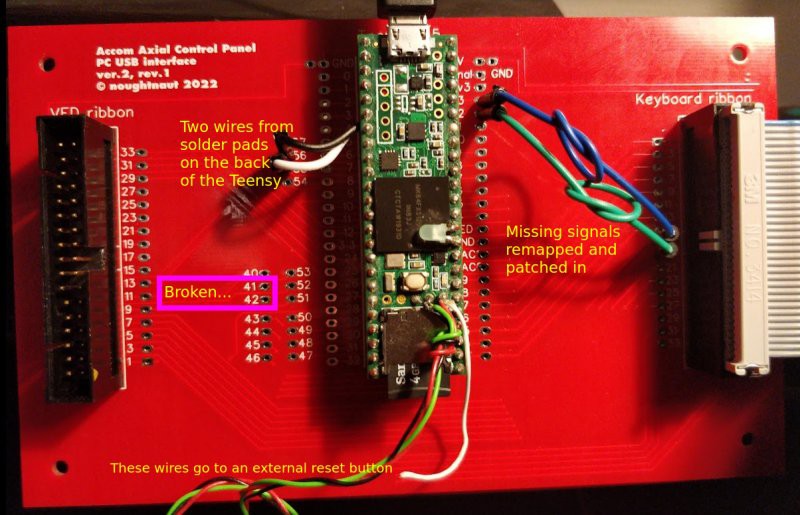

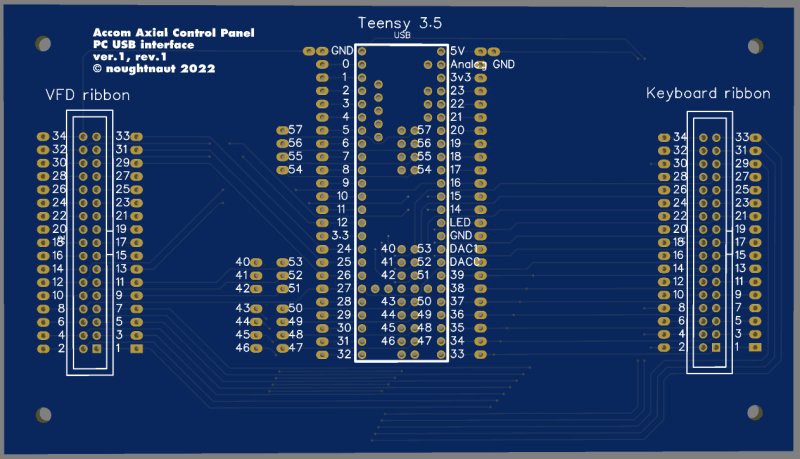

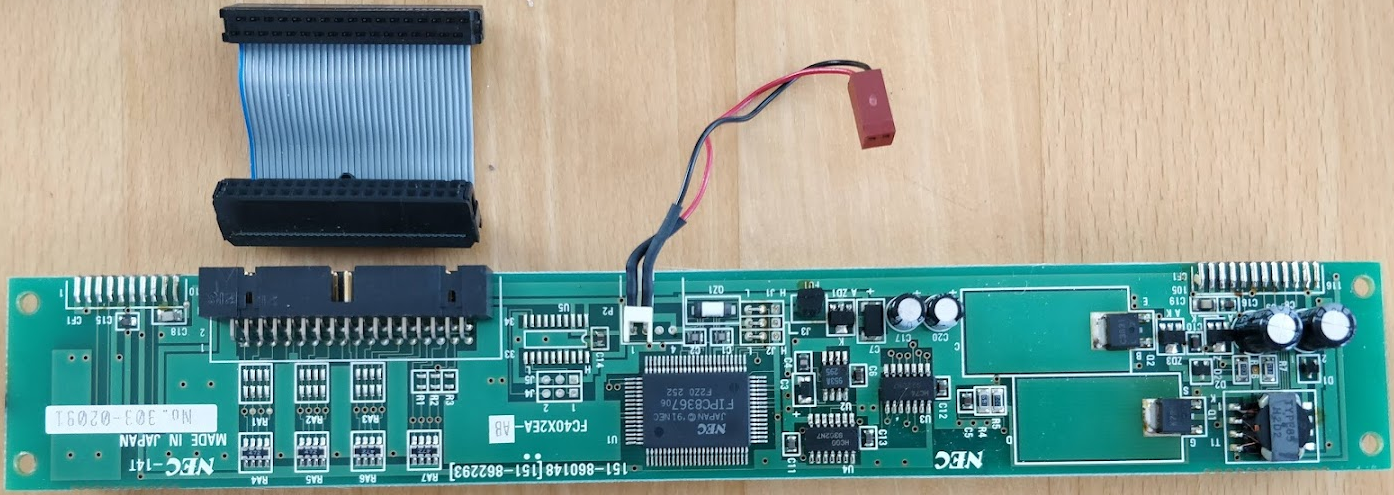

My plan is to convert this console to be useful in the context of a modern pc. How to achieve this depends on whether I can work with the original guts.

I want to make the control panel work as a USB HID input device. However, this thing has a lot of blinkenlights, and it would be a shame to not use them! Just off the top of my mind, the display and those dials could be used to select audio in/out devices and adjust volume levels; per-app tool setting adjustments; media center integration; home automation; etc.

I expect to need some form of configuration tool so that keys can be mapped to keystrokes or macros, and dials to various scalar controls. Hopefully, I'll be able to use the VFD to offer on-device management of macros and configuration, because that section just begs to be used for that purpose. Wouldn't that be something?

I also expect to need a small (desktop/cli/daemon) program running on the pc in order to provide whatever data might be useful to indicate on the VFD and lighted keys.

### Y U No Stream Deck?

I came across the term "Stream Deck", which is apparently the product name of a glorified macro keyboard that costs just over half as much as my entire console did. As with everything, it has its pro's and con's, and "of course" it has no Linux software. But hey, here's the keyword should you be searching for it.

Of course, there are free alternatives, such as deej. I haven't looked too closely at that yet; I might be able to make use it or some of its ideas.

noughtnaut

noughtnaut

Stefan Lochbrunner

Stefan Lochbrunner

Julien

Julien

Owen

Owen

I just found this project and that is a wild keyboard. Do tell us how the rocket launch goes. ;)