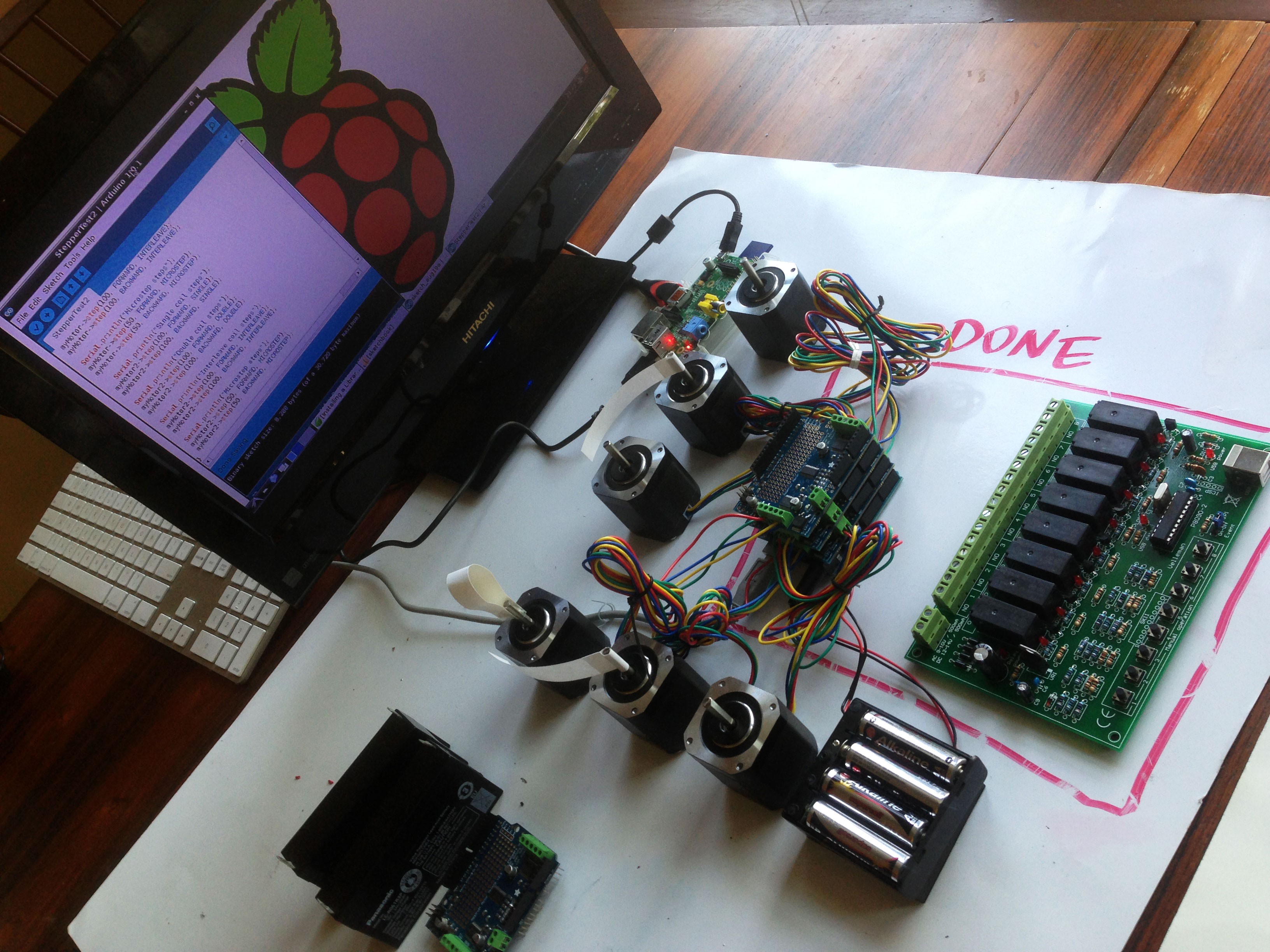

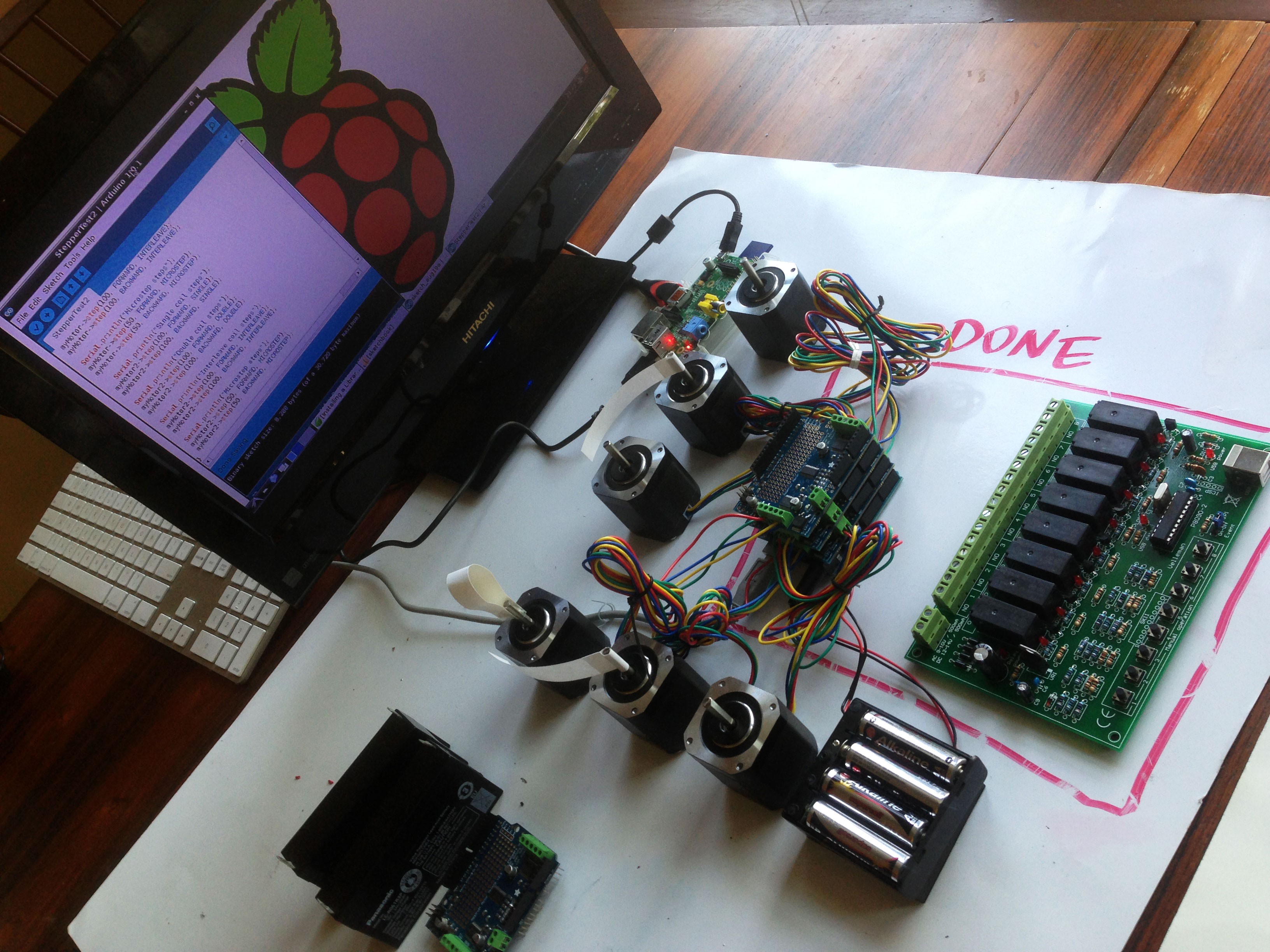

TEST BUILD: Desktop

A project log for Type 1 Civilization Builder

Futuristic dwellings & new types of efficient structures made by dynamic "Bottle Brix" : trash composites found anywhere, used everywhere!

A project log for Type 1 Civilization Builder

Futuristic dwellings & new types of efficient structures made by dynamic "Bottle Brix" : trash composites found anywhere, used everywhere!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no