Friday, 26/01/2024, 08:43

Well, since I bought my power source from Aliexpress, the goddang thing will take 75 days (and some times, more), so I have a plenty of time doing a whole of nothing involving this project.

You know what? I'm getting a little bit pissed off with myself.

I keep repeating myself over and over with "let's make a turbine, no, let's make a stirling engine, no, let's make a fuel cell, no, let's make a plastic piston engine, no-"

For f-ck sake, I should just shut up and just do something instead of listing 12932893282389 options that I will never use.

... Well, it would help a whole lot if I had any money to begin with...

(this is my hobby, I do it for fun, I'm having a lot of fun)

Let's talk about energy sources.

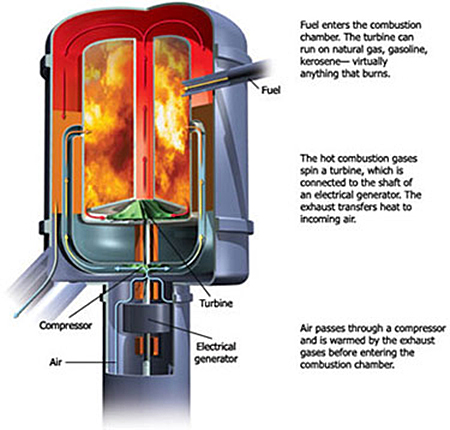

What I mean by "universal fuel engine" is that there are multifuel engines that can work with multiple types of fuel, but a lot of them have a small range of fuels.

Of course, you probably don't really need a universal fuel engine, but since I'm broke, the most probable fuel that I will find is grass and wood.

You can't put grass and wood in a turbine engine, neither a piston engine.

Asking to ChatGPT and BingGPT, steam turbine engines can convert fuel into heat, and thus steam with an incredible efficiency, around 80% or even more.

Of course, this is not a surprise if you ever saw anything about stationary energy production, like one of those giant turbine geneartors.

The bigger the blades, the more efficient they are, not to mention that the whole facility is specially built in order to make the finest control possible on fuel, fuel burn and heat exchange.

Of course, the compromise is size.

Not an issue for a energy generation facility, an issue if you want something energy dense, portable and efficient.

These madlads are building a monstertruck motorcycle, and the engine they are using (as shown in the thumbnail) has 150 horsepower, fits in a backpack and could easily power an exoskeleton.

The issues are:

- It can only use a single type of fuel.

- The generators are many times heavier and bigger than the combustion engine.

- Low efficiency, around 30% (not low for combustion piston engines).

Of course, I did find some interesting articles about ultra high speed alternators that could possibly solve the issue of generator size and weight.

(this is a conventional 10 kilowatt AC dynamo generator and it "just" weights half a ton)

The articles in question are the following:

- https://www.sciencedirect.com/science/article/pii/S1876610219313967

- https://www.researchgate.net/publication/224713273_An_Ultra-High-Speed_500000_rpm_1_kW_Electrical_Drive_System

- https://www.pes-publications.ee.ethz.ch/uploads/tx_ethpublications/zwyssig_IAS05.pdf

Of course, these are really small energy outputs, but look at the size of said generators, one of them is as small as a match head.

This means that it would be easier to use a gear box that multiplies the rpm instead of torque.

Of course, there are very low rpm geneartors, but these are not really compact. Although, they are very easy to make... At the cost of size.

Universal Fuel cells:

Basically, the first thought I had was to use a universal fuel cell, which was the idea of having a fuel cell that can directly use any kind of hydrocarbon fuel.

Of course, I'm not a company, and my Co2 footprint would be completely meaningless compared to the smallest airplane, lol.

In any manner, these supposedly "universal" fuel cells are called "direct carbon fuel cells", and apparently, the most promising ones (accordingly to the wikipedia article) are the solid oxide fuel cells and the molten carbonate fuel cells.

Both are equally complicated on their own, and both are extremely expensive on their own also. On top of that, information is limited I can barely find anything online.

Another possibility is the use of hydrides.

There are multiple types of hydrides, but the most promising ones are Ammonia-borane and Sodium Borohydride.

When the right conditions are achieved (like heating up ammonia-borane to thousands of degrees), they release hydrogen gas and are further decomposed to boron-nitride and sodium borate respectively.

Like always, information on this fascinating type of technology is scarce and I doubt I would find a way of replicating the results in a DIY way.

Here are some articles that may be interesting to read:

- Effective hydrogen release from ammonia borane and sodium borohydride mixture through homopolar based dehydrocoupling driven by intermolecular interaction and restrained water supply - Journal of Materials Chemistry A (RSC Publishing)

- A comprehensive study of hydrogen production from ammonia borane via PdCoAg/AC nanoparticles and anodic current in alkaline medium: experimental design with response surface methodology | Frontiers in Energy (springer.com)

- Activation of sodium borohydride via carbonyl reduction for the synthesis of amine- and phosphine-boranes - Dalton Transactions (RSC Publishing)

Oh, by the way, "PdCoAg/AC nanoparticles" stands for "palladium-cobalt-silver alloy nanoparticles", I have absolutely no idea how to put my hands on such material.

I said in previous Project Logs, but there are "Catalytic Condensers", which are materials that imitates the actions of catalysts by passing a current through it.

Like always², information on the subject is scarce.

Probably everyone is trying to make a patent and earn a living, it would be nice if scientists didn't need to worry about earning a living with proper support, I'd suppose if I knew what I'm talking about...

Room Temperature Turbine Engines:

Yes, adding to my list of insane ideas that will probably put me in an asylum are turbine engines that are specifically designed to operate at room temperature.

The turbine on turbine engines face temperatures from the combustion chamber up to 1700ºC, in which most common metals would be in liquid state. That is why turbines are made using superalloys such as inconel.

So, in order to make a turbine engine operate at temperatures closer to a turbocharger or even at room temperature, the idea is to cool the air exitting the combustion chambers as much as possible.

One way of achieving this would probably maybe using vacuum ejectors/jet pumps/steam injectors.

The hot air coming out of the thermally insulated combustion chamber would be at 1700ºC and a pressure around 20 MPa (common pressure inside turbine engines), such insane pressure would result in a very high amount of airflow and room temperature.

The ideal gas law tells that the air pressure is proportional to its temperature, so with such gas pressure expanding at high speeds while exchanging its temperature with the surrounding air, it would create a high airflow.

Of course, this would most probably not work.

If it was that easy to make a room temperature turbine engine, it would have already been done.

Another idea was to instead use air flow generated by the combustion chamber to drive a turbine on the outside of the combustion chamber.

Basically, the idea would be to do more or less the same thing with the previous idea, but the entire vacuum ejector would be around the entire assembly and the airflow around the engine would drive a turbine.

Imagine it like a reverse turbofan.

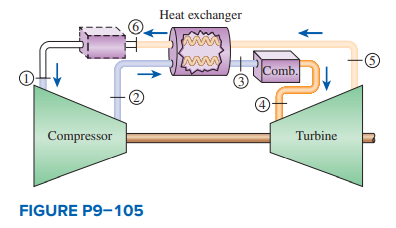

Just putting this here because I think it is interesting:

This is a 60kw microturbine engine with 40% of efficiency.

This one is a 25Kw with an bigger option for 500Kw, it is said to have 85% of efficiency.

Of course, I think it is bullcrap, but in both cases the efficiency must be higher because of the heat exchanger/recuperator.

In both cases it is a design that can fit in a backpack (I think).

I was thinking of using an electromagnetic bearing on the tip with the generator/alternator unit.

Maybe I could make a DIY titanium aluminide turbine blade, BingGPT suggested Haynes alloy HR-120 (33 wt % Fe, 37 wt % Ni and 25 wt % Cr [and maybe a little bit of tungsten]), which seems... Viable to do at a DIY setup.

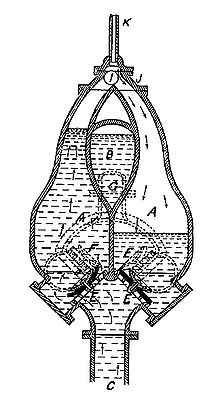

Oh yeah, I completely forgot that I could "just" make a hero turbine engine. The only problem is injecting fuel on it.

(the one in the right)

Stirling engines:

Stirling engines are the bane of my soul.

They always come up, when I'm trying to find alternative engines, but they usually suck ass.

Not in the sense of efficiency, they usually achieve efficiencies of around 40%, and have almost no moving parts. Of course, the properly made ones, like the ones made by NASA or something.

Most of the time they look like this:

This insane piece of metal can't produce a single horsepower.

In any manner, let's talk about the properly made ones:

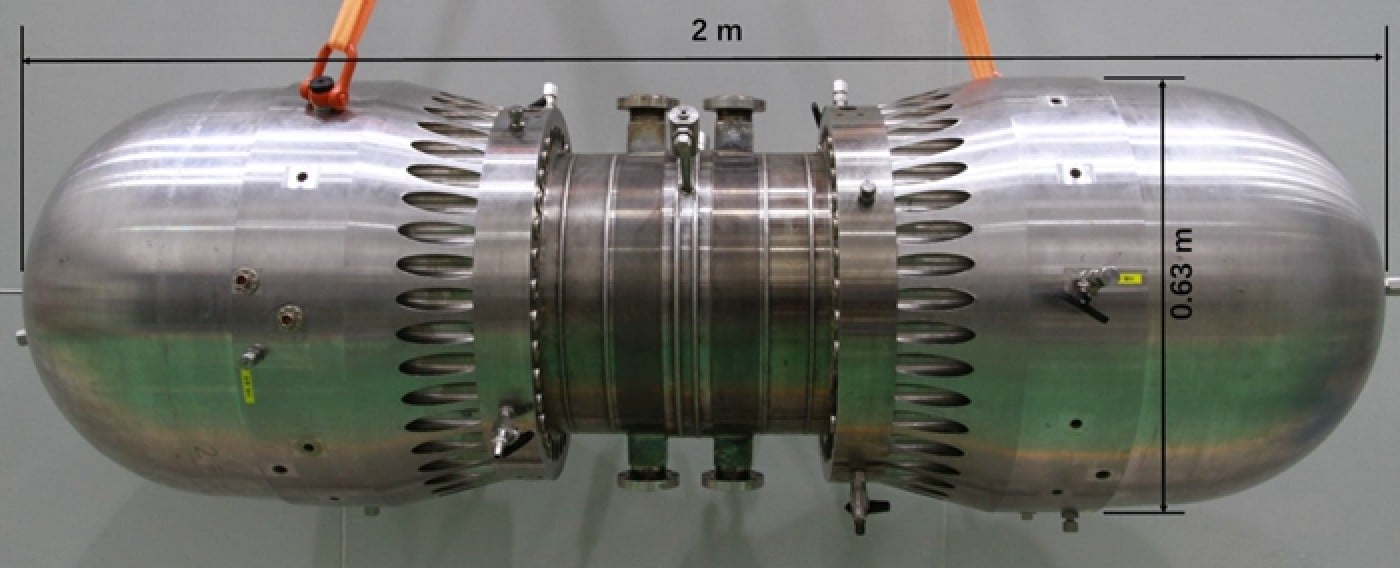

Recently, China has launched "the most powerful stirling engine yet that the world has never seen making a breakthrough that will SHOCK the industry", you know, that clickbait trash.

This chonky boy has 2 fricking meters of length and can produce 103 horsepower, it is meant for use in submarines, to turn waste heat into electricity.

And that is a common theme between stirling engine endeavors: they aren't meant to be the main power source, but a recycler of waste energy.

For the life of me, I couldn't find the diagrams, pdfs, articles or anything useful showing how this specific stirling engine works. Which I'm not very surprised, after all, it is a submarine stirling engine, who in their right mind would share this kind of top-secret machine?

However, trying to find how this ting works, I came across two types of stirling engines that I liked very much:

Free piston stirling engines

(I searched for 1 kilowatt stirling engines like the one in the pic, they are 45cm in height and 30cm in diameter, I need at least 30 of these, lol)

... And thermoacoustic stirling engines

Thermoacoustic stirling engines have absolutely no moving parts, and they can be used on a compound configuration, basically, mixing all kinds of energy generation systems.

For example, you can mix magnetohydrodynamic generators and free piston stirling engines on the same engine. Maybe even piezoelectric buzzers to convert the vibration into electricity.

Source: https://www.researchgate.net/publication/281593423_Analytical_study_of_thermoacoustic_MHD_generator

Source: https://www.sciencedirect.com/science/article/abs/pii/S0196890422002990

There is also the https://technology.nasa.gov/patent/LEW-TOPS-80 Stirling patent, but I can't find the schematics anywhere.

In any manner, I decided that I will stick to the Compound Thermoacoustic Stirling engine for the Universal Fuel Engine.

The only issue is that I don't know how compact this would be.

I remember seeing a few kilowatt thermoacoustic stirling generator that had 0.3 meters of length (30cm), it was multistaged and stackeable, but I couldn't find the gooddang picture again.

I searched for the picture for 5 hours straight and I couldn't find it, I thought I saved it on the thermoacoustic paste...

I just said this and I found it:

It is a 3 kilowatt generator, so I would need 10 of these stacked to a mere 40 horsepower generator.

It is also stated in the article itself that it only has an efficiency of 16%...

-_-

While searching for the subject I came across this two way-one way turbine, whenever direction the pulse from the burning element.

Source: https://journal.hep.com.cn/fie/EN/10.1007/s11708-020-0702-3

But I doubt I will be able to do it, my intention is exactly avoiding moving parts.

I didn't even read the articles about thermoacoustic stirling engines so I barely know those things work...

However, this did gave me an idea. I think I already talked about something like it before.

The idea would be to make a toroidal tube and add cylinders to it, they would be piston heads and this turbine would be inside the toroidal tube.

half of the cylinders/pistons would detonate and the other half would compress the other pistons, just like a liquid piston engine or a pulsometer engine.

The only problem is that I don't know how well it would work or how well

Thermoelectric Generators:

So, afterEsteban's comments in this project log, it made me realize that maybe thermoelectric generators are a more realistic option, even with its downsides.

Just like I said in Project Log 74, the thermoelectric generator could be 3D printed using Sodium Silicate, copper oxide and graphite.

You know the drill, mix this (thermoelectirc generator configuration:

And this (heat exchanger with a turbocharger):

With the air compressor feeding air like a blast furnace:

And finally, I do think it would be interesting to use the vacuum ejector idea from the "room temperature turbine" in order to use the exhaust for air flow generation, and thus, making a cooler with no moving parts. Increasing the heat difference between the cold part and the hot part.

Another point I was thinking on making:

I think that I could use a mold for making the DIY thermoelectric generator instead of building a paste 3D printer, like one of those silk screen printing plates.

Basically, 3D printing or paying someone to 3D print a mold for each layer, since these tecnically are two "E"s of each material type connected to each other in someway.

Plus, if I want to make a blast furnace-style thermoelectric generator, I would need to mix not just sodium silicate, but also refractory cement. Because blast furnaces can reach temperatures up to 1800 ºC.

The only problem is that I don't know how to make the hot air to reach all the thermoelectric cells, since the temperature lowers the further it goes away from the source.

I swear to god, I may be talking big about all these exotic energy generators, but I bet I will just switch to a simple combustion engine and shut up myself on the future.

Off-topic:

I was looking in the internet and there is a type of propulsion system called Arcjet Rocket, which has an exhaust velocity of 16 kilometers per second, accordingly to the rocket calculator, if the mass was 100kg and the final mass of 99.882kg ( 10 liters of compressed air at 10 bar weights 0.118, which would be ejected into an arcjet for extra thrust), it would accelerate the mass to 60km/h.

However, it is not that simple. Some arcjet rockets use hydrazine (super cancerous chemical) and I can't find an specific value of how many watts it consumes per thrust, but it seems to be highly dependent on the gas used.

I remember seeing one source affirming it consumed 1 kilowatt per 0.1 newtons of thrust, this would be around 100 kilowatts per kilogram of thrust. lol

Well, this paper had some graphs that would say that it more or less consumed around 90 volts and 10 amps and generated almost 180 newtons of thrust, this would be around more or less 50 watts per kilogram of thrust, which is more than electric motors.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

have you heard about Wood gas and Coal gas? They are made through the pyrolysis of either wood or coal, its a gaseous mixture of methane and carbon monoxide, not only can it make normal gasoline engines run without modification, but running an Aliexpress jet engine kit with that should be easy enough (and those turbines already run on gas, and probably diesel...).

You can find many tutorials on wood gas/coal gas chambers, and how to hook them to a traditional piston engine. "Turbo furnaces" are another similar machine that could give you some insight into how to hook one of these to a jet engine.

If you want something even more universal, maybe look into catalysts to decompose organic matter into a more combustible form... Maybe wood isn't the only thing you can gasify?

Are you sure? yes | no

Yes, I did some calculations on the subject, but I couldn't find anything on its efficiency. Combustion engines can work with syngas and methane, but it doesn't mean it is as efficient as used with its intended fuel. Besides other kinks that would need to be dealt with.

A heat engine (like the thermoacoustic stirling engine) works indepentendly of whatever fuel as long it produces heat.

Are you sure? yes | no

What about Peltier modules? Skip the kinetic step, maybe you'll get a better deal in efficiency.

Are you sure? yes | no

cars fueled with wood gas can actually get more mpg if filtered correctly

Are you sure? yes | no

You have to remember gassifers were used in ww2 and are a already proven technology used on a small scale these turbines are extremely dangerous and are meant for stationary use within an industrial scale

Are you sure? yes | no

Peltier modules have less than 10% of efficiency: https://en.wikipedia.org/wiki/Thermoelectric_generator#:~:text=heater%20or%20cooler.-,Efficiency,bimetallic%20junctions%20and%20were%20bulky.

I found an article were thermoelectric generator with efficiencies of 40% were achieved, but it was made out of gold and needed temperatures around 1200 ºC to work.

Are you sure? yes | no

What's the efficiency of your current design for a thermoacoustic generator? I don't imagine you plan to make them out of gold :^)

Are you sure? yes | no

If your planning to use methanol mofc dont require reforming as its so hot it gets done automatically

Are you sure? yes | no

Thermoacoustic generators normally have an efficiency of 30% in general... IF I had a design to begin with, maybe I could tell an specific value. :/

Well, it seems like most of the examples of thermoacoustic generators I showed can't pass the 20% efficiency mark, not doing much better than thermoelectric ones...

Are you sure? yes | no