Thursday, 13/07/2023, 11:58.

I do NOT advise you to follow my ideas and you should NOT try this at home.

Before you seriously think on doing such thing at home, just remember the carbon fiber submarine.

You may not fear death, but are you ready to die like a joke?

You should buy properly built hydrogen tanks from proper suppliers.

I ultimately decided to not proceed with this idea of hydrogen fuel cell with hydrogen tank.

I prefer to work with car batteries and/or battery packs that you can buy online and so on.

Unfortunately, I would be forced to keep the suit plugged in on the place/house and/or to generators.

__________________________________________________________________________________________________________________________________________

So...

I know I said on Project log 59 that "i'm not in the mood to make DIY high pressure hydrogen tanks and risk my life for a fancy toy", but...

--------------------------------------------------------------------

Anyway, being serious now:

I thought on making high pressure (300 bar/4500 PSI) hydrogen cartridges.

A simple CO2 cartridge can do this amount of damage:

The author of the photo said they forgot the cartridge inside their car in a sunny day, the temperature of a gas is proportional to its pressure.

Now imagine a 300 bar cartridge.

I was thinking on these DIY cartridges with inner diameter would be more or less the size of a marble and the thickness of the walls would be around 15cm.

However, that would be super over kill and it would be almost impossible to fit all hydrogen cartridges on the mech/exosuit in a safe way free of leakages.

So, I gave up on the idea.

--------------------------------------------------------------------

Actual properly made carbon fiber high pressure hydrogen tanks need a liner made either out of polyethylene or a certain grade of steel:

However, this kind of manufacturing is both for price and weight saving, you could make a way thicker one with polyethylene itself as the matrix and steel mesh/fiber/cloth as the composite.

Plus, it could be useful to use a relief valve/safety valve for, well, safety.

You can calculate the amount of force it will be applied to each part of the insides of the pressure vessel, after all, pressure is literally measured in PSI = Pounds per Square Inch, or Kgf/cm² = Kilogram Force per Square Centimeter.

So, if you want to make a safety valve for 300 bar, you could make a DIY one (or multiple) by calculating how much force these valves should be able to withstand before it gets too much pressure.

--------------------------------------------------------------------

Also, while I was researching for 3D printed gas tanks.

https://www.reddit.com/r/3Dprinting/comments/mwzcrh/ever_3d_printed_air_tanks/

https://cvra.ch/blog/2016/airtank

These links shows a post about 3D printed compressed air tanks, and the comments are really useful advice.

The first advice is: *Do NOT make this at home. It is dangerous.*

Plus, I do not intend on making it 3D printed, but I can use the 3D printed stuff for a mold.

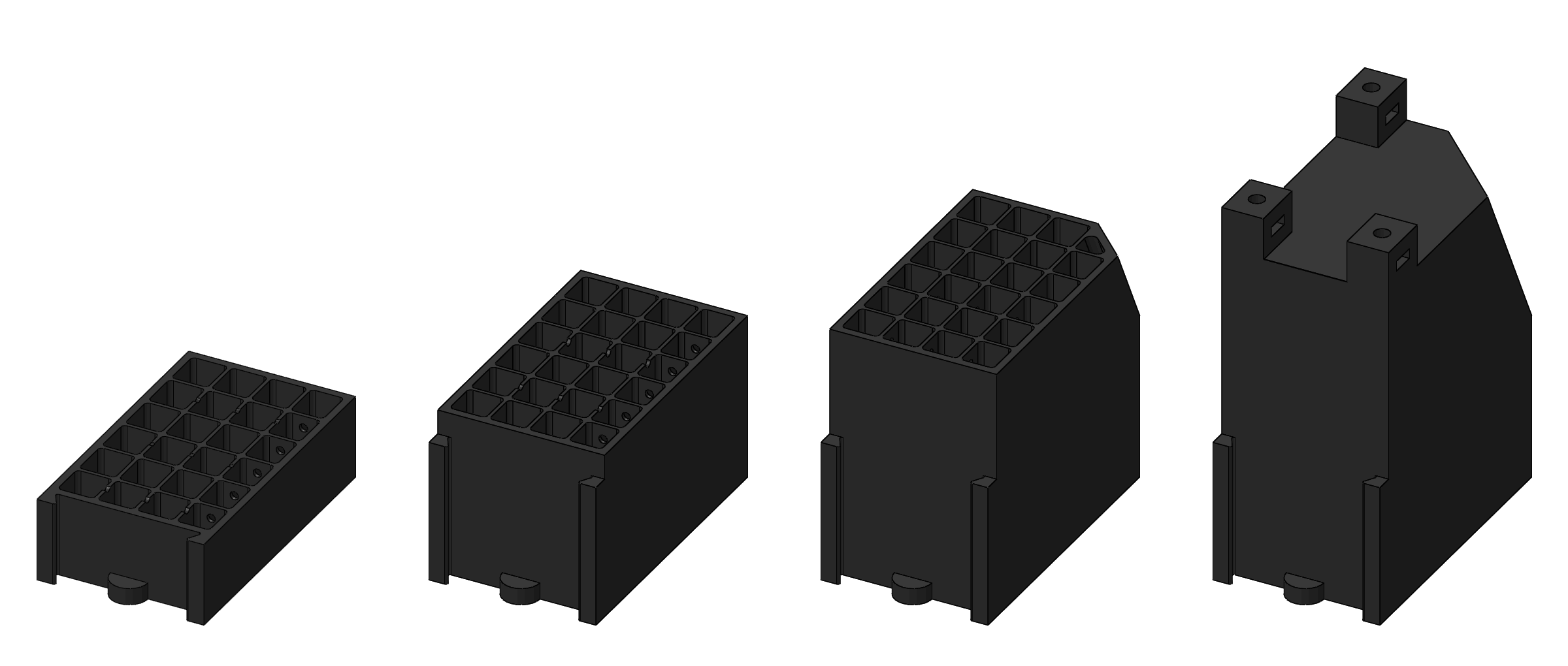

In the second link it shows a 3d printed compressed air tanks meant for a contest for maximum 4 bar of pressure, the guy used a somewhat honey comb structure to increase the material withstand the loads, which was an idea I had before.

I could use steel meshes, Aramid (kevlar) fibers, Carbon Fiber or Glass fiber ropes to reinforce the Hydrogen Cartridge.

I was looking here and a couple of meters of carbon fiber yarns are kinda cheap, actually, around 50 reais (10 dollars).

It is more or less the same thing that companies use to wind around the liner of carbon fiber tanks.

However, again, I wouldn't trust these commercially available carbon fibers for high pressure air tanks.

I'm not saying the sellers on ebay or whatever website you bought them are trying to scam you, but there is a good reason you always choose to buy from the suppliers: the suppliers know very well the characteristics of each carbon fiber they're selling.

While online sellers are just re-selling materials that they don't know very well its properties and origins, they are just selling cheap carbon fiber for DIY projects, not for high pressure hydrogen tanks.

I also thought on using actual high pressure hoses for either pneumatics or hydraulics as the tanks itself.

But it would be way more expensive than the properly made tank.

--------------------------------------------------------------------

I was thinking on using a manual or hydrualic pump for testing the resistance, fatigue, tensile strength and all that stuff before I actually insert any kind of gas on the thing.

However, you would need a properly made lab for testing all kinds of relevant characteristics for a material, which would increase the cost, work and chances of something going wrong.

--------------------------------------------------------------------

I do not have the money, neither the skills, and I would strongly suggest to you not try this at home.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.