Hello Friend! Today we are talking about the reinforcement of printed parts. I plan to reinforce the part during printing with a fiberglass paint mesh.

Initially, I planned to experiment with PET tape, but the PLA coil caught my eye. I will print with this material.

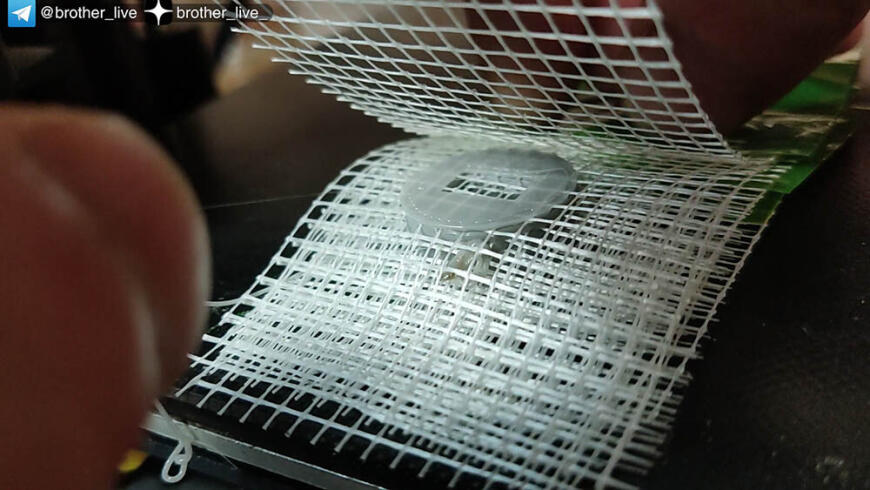

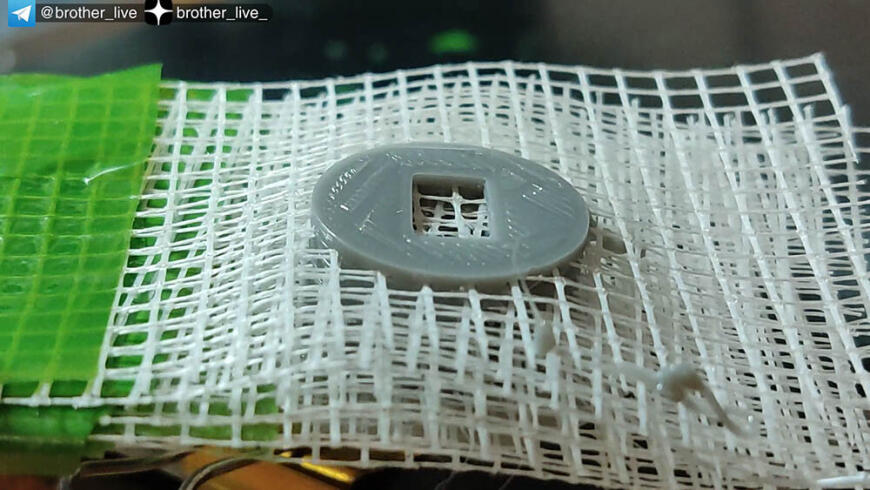

The size of the test disc is 10x20mm, the filling is 80%, the missing 20%, I think, can be easily replaced by a fiberglass mesh. I will put the reinforcement through a millimeter through a pause in the printer.

Happened! I didn't even expect it to work. Trimming cylindrical parts was not so easy.

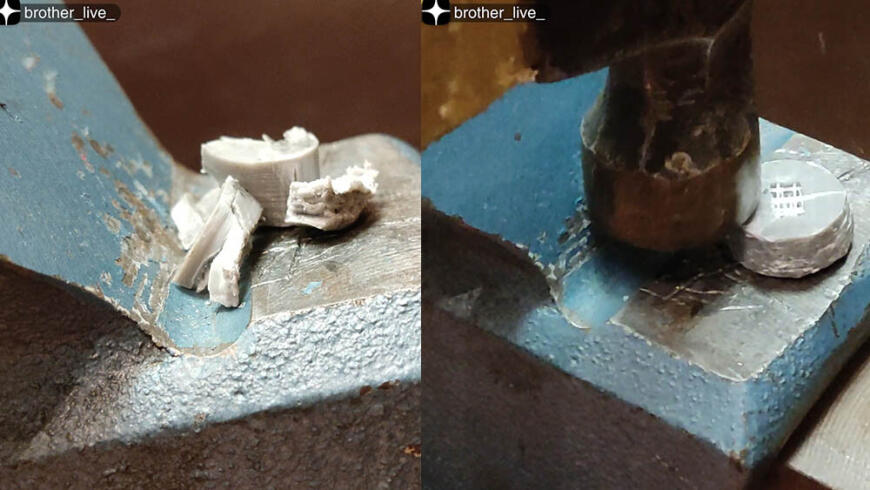

It's time to test the strength. The test disc turned out to be much stronger than the one I printed without the grid. Not bad, showed such a method of printing. Imagine, and if there would be PET with nylon to print.

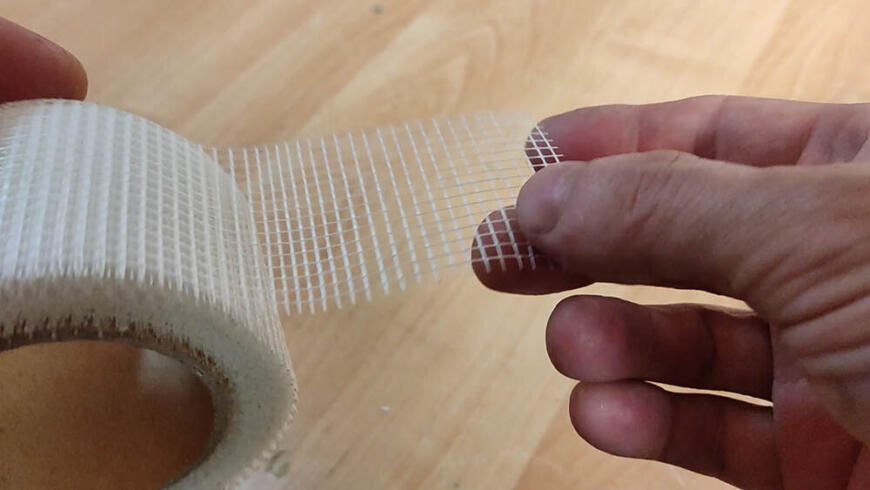

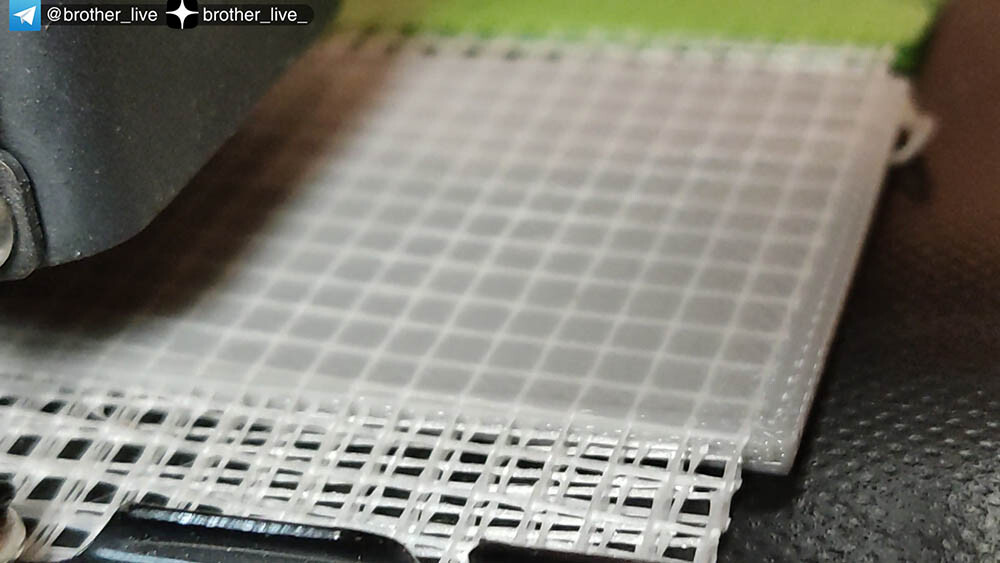

Now I will print a small plate 50x60mm. and 5mm thick. You can find such a fiberglass mesh for painting works of any size in hardware stores, starting from 5 cm. in width and ending with 100cm. This material has an adhesive surface, but I played it safe and secured the material in a more secure way.

In this test, I laid the mesh tighter every three passes of printing. Filling 80%.

The reinforced part withstood stronger impacts.

I think it's good too. We are throwing ideas where else such a reinforced type of printing can be applied?

brtv-z

brtv-z

Rotate every other fiberglass layer 45 degrees. That should give a more uniform shear strength.