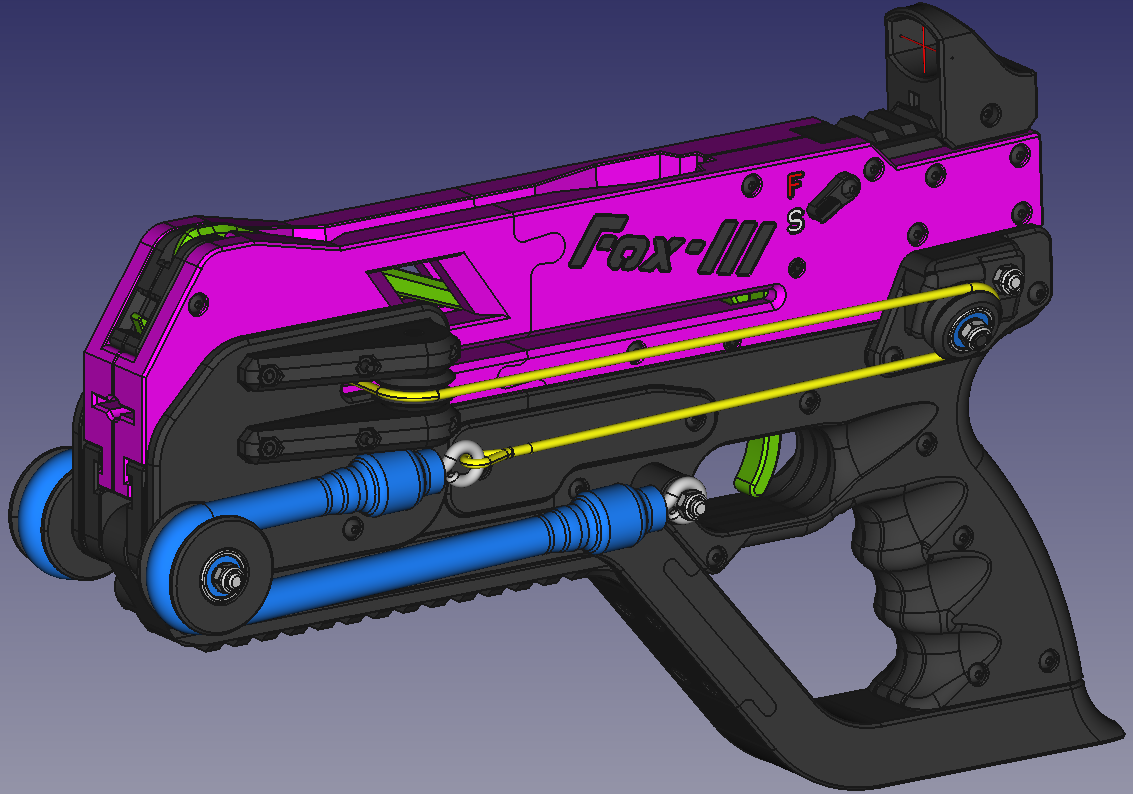

All the STL, STEP, and FreeCAD files can be found on GrabCAD.

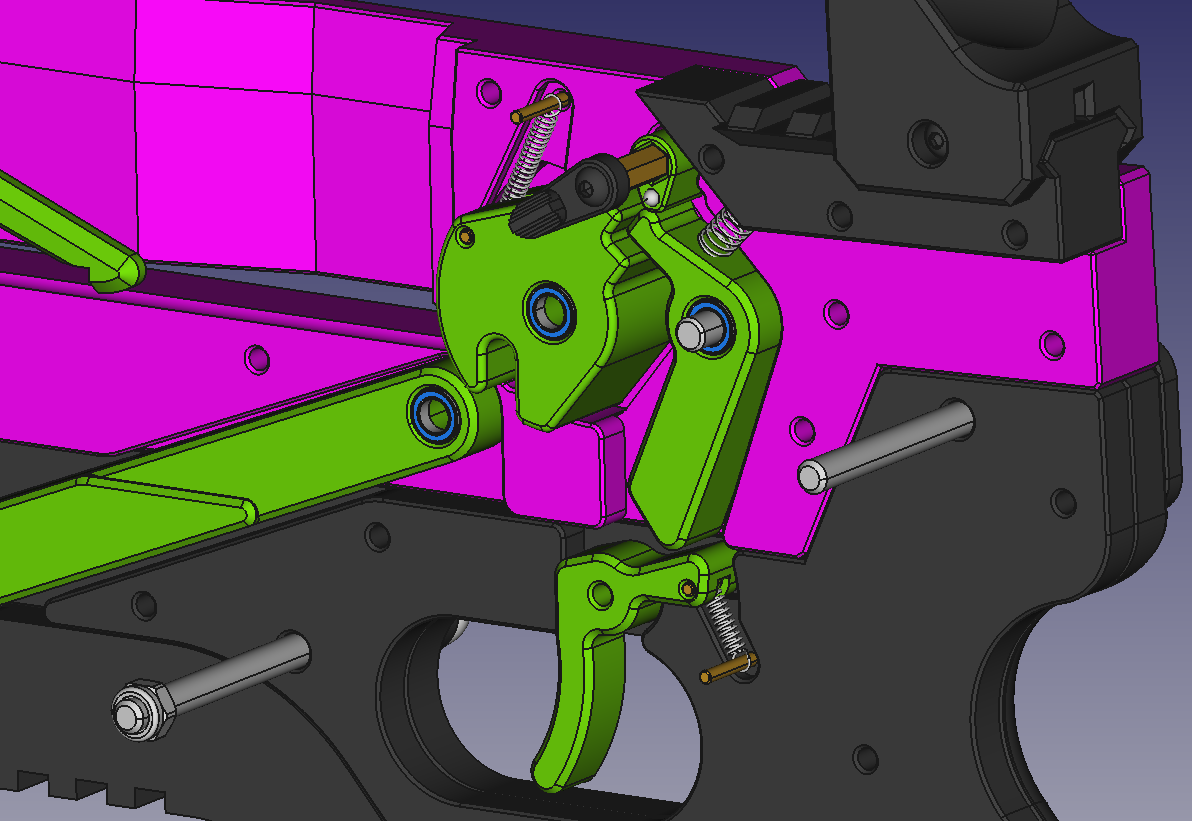

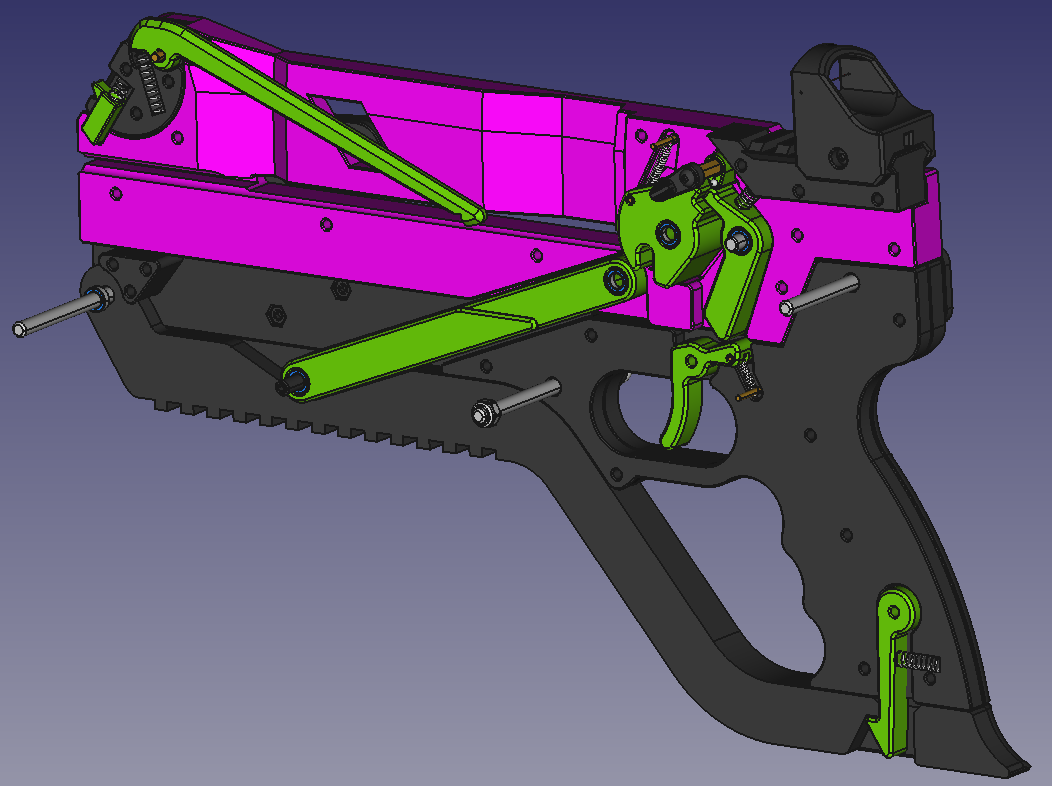

The rolling block trigger is one of the key features of this design.

The size of the rolling block makes for a very strong string catch, while the trigger design allows for the easy inclusion of a safety switch as well as allowing the slide to move independently from the trigger. The various bearings should allow for smooth operation even with high loads.

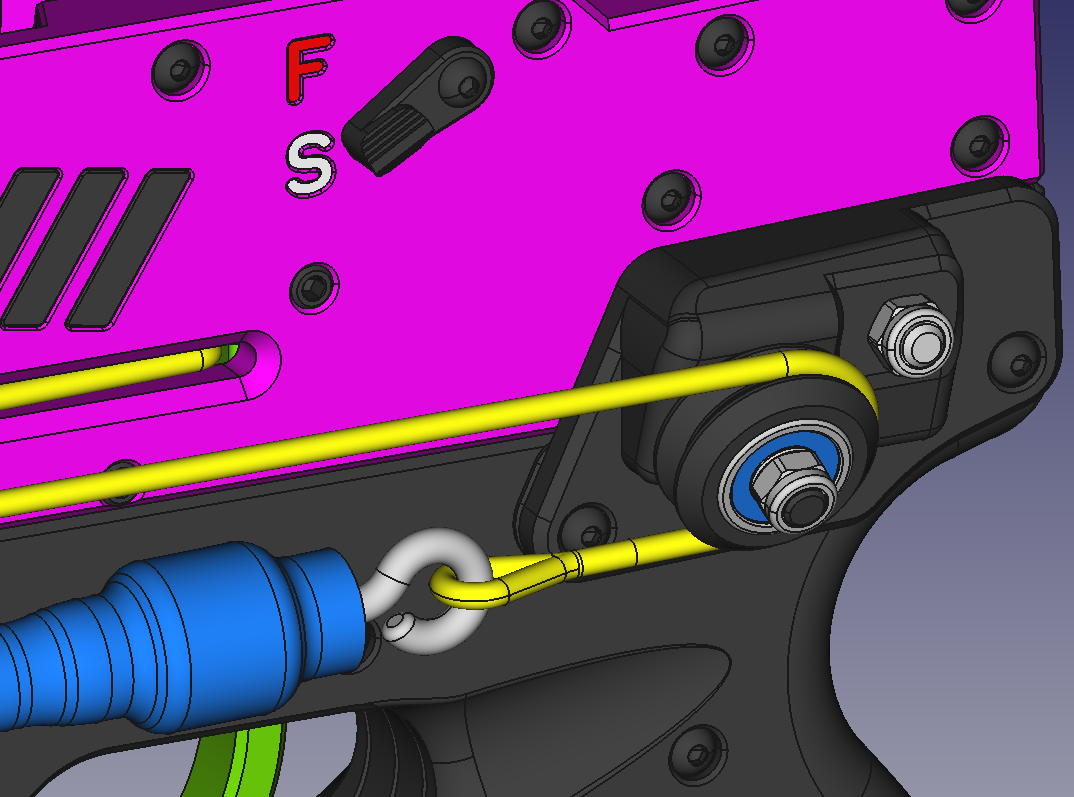

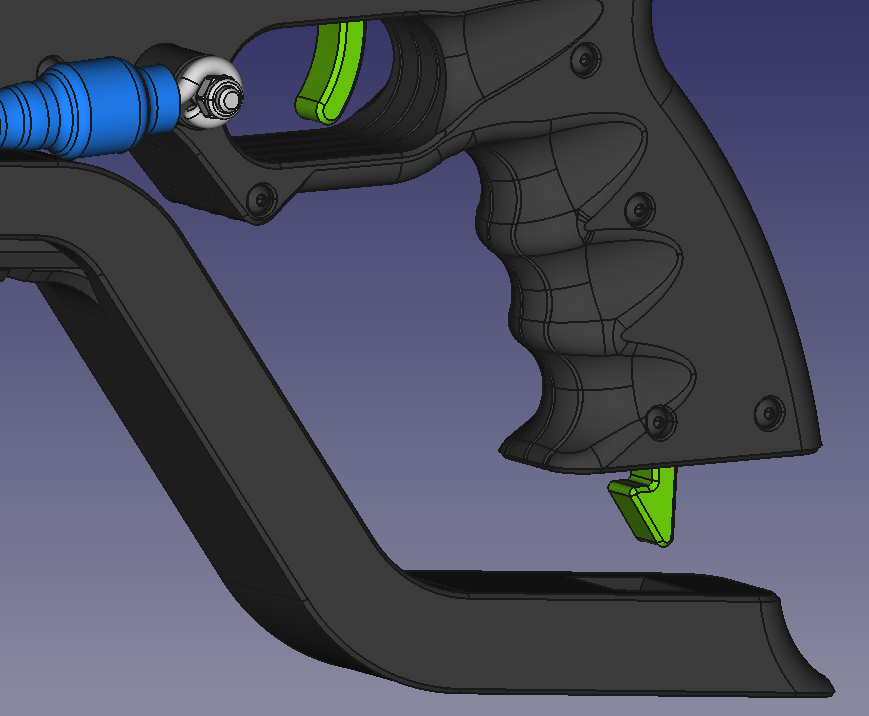

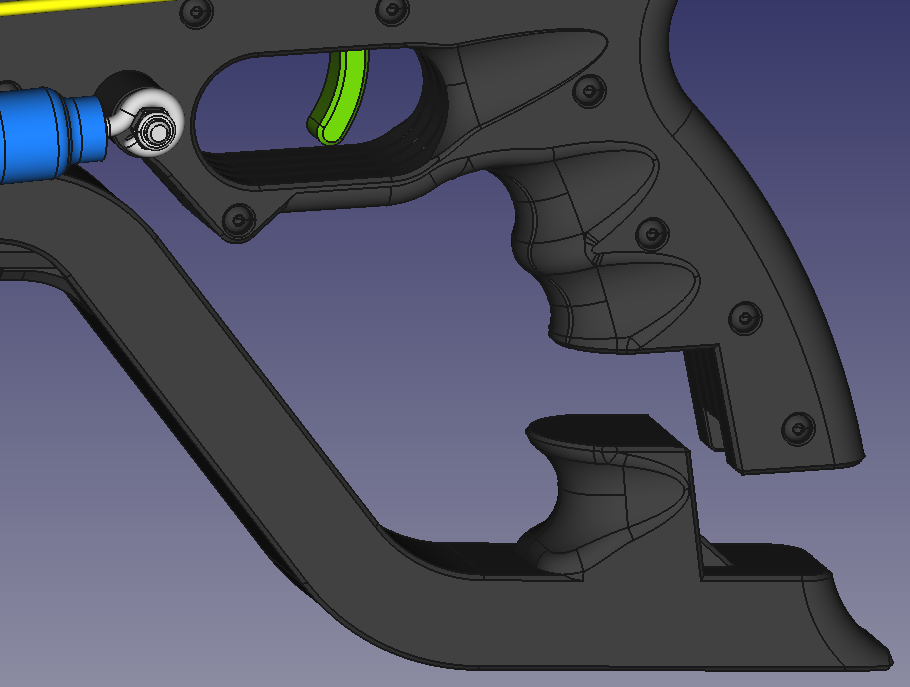

I designed two versions of the cocking arm, one that latches and one that does not. The non latching version is held in the cocked position by maintaining a grip on the handle of the pistol. The non-latching version provides an additional safety feature so that it can not be left unattended in the cocked position.

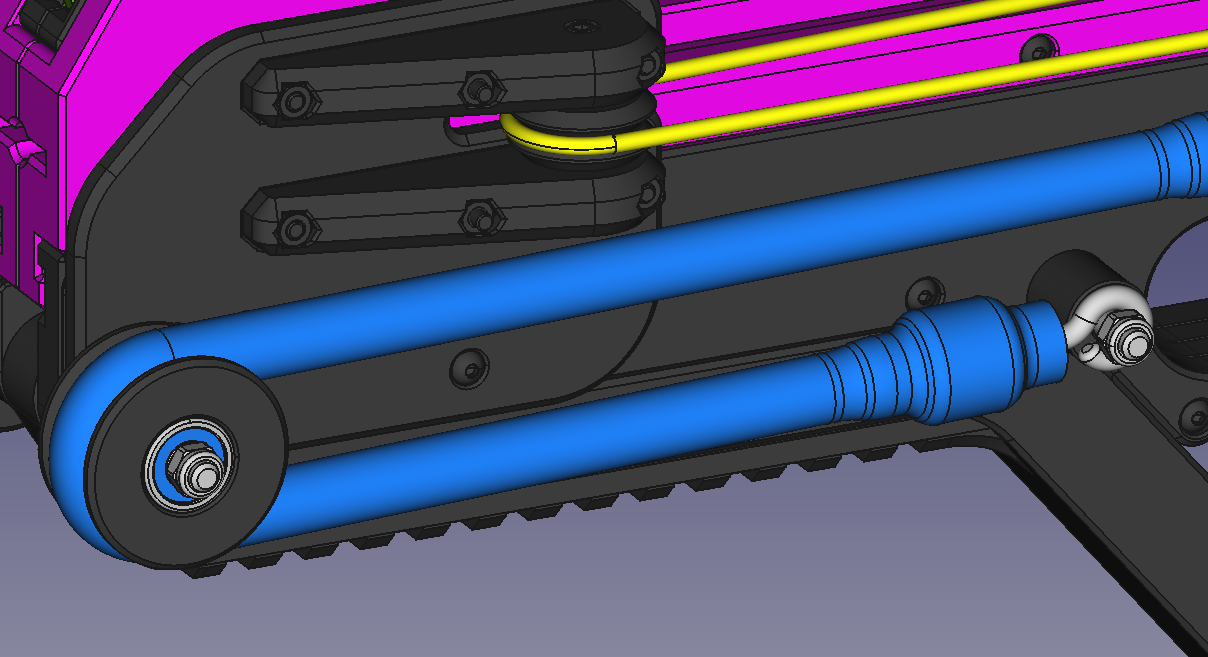

Delrin double v-groove wheels are used for the bow string pulleys as they provide a low cost readily available low friction solution to handling the bow string.

The files were designed to be printed on a 300x300mm 3D printer, but I also created a split version that can be printed on smaller printers.

When the pistol is not cocked it should be easy to pop the tubing off the front pulleys so that the tubing is not left under tension when not required.

When the pistol is not cocked it should be easy to pop the tubing off the front pulleys so that the tubing is not left under tension when not required.

John Opsahl

John Opsahl

Johannes Hassler

Johannes Hassler

Anton Khrustalev

Anton Khrustalev

Open Bionics

Open Bionics

Is there any assemble instructions?