-

Test 2

01/28/2023 at 05:42 • 0 comments![]()

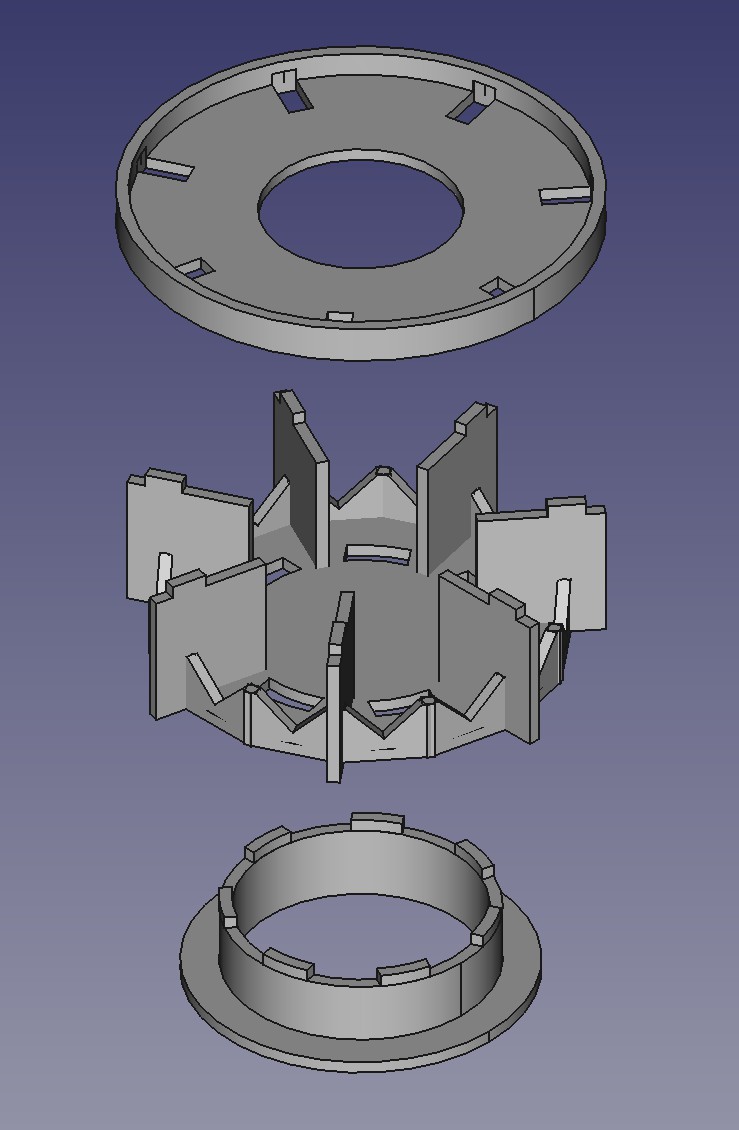

This one was 3 stacked grids to try to spread the smoke out. A cone would then try to divert it into a cylinder.

![]()

![]()

![]()

It still converged on the downwind side, even during peak efflux. 1 big improvement was a lot more smoke going down instead of up, even when the ambient air was moving. The sealed stack of cylinders gave it a lot more downdraft.

Another problem is the smoke coming out of the outside diameter gets sucked towards the center. It probably needs an outer wall below the outlets to attract it to the outside.

![]()

Autopsy showed quite a bit of melting & burning on the top grid. It's probably falling oil. Having a longer gap might cool down the oil.

The cylinder's capability as a wind break showed promise. If it could shield enough wind to spread it into an even pool, it could reduce the problem to leveling. Leveling could be solved by the magnetic receptacle of the original starship incense burner. The mane problem with that is the chance of hot oil falling on a lion paw & the cone getting moved out of position. Another idea is a 3D printer style bed with a bubble to aid the process.

-

Test 1

01/27/2023 at 18:42 • 0 comments![]()

The great task is spreading the smoke into a cylinder of engine streams. Most incense burners only create a narrow stream & pool it. To kick things off, there was a test platform to try to spread it out. It had a metal disc as a heat shield. It tried to pool it & release it around the edges. It had a 36mm diameter dictated by the heat shield.

![]()

Most of the smoke actually comes out of the top.

![]()

It has to burn partway to start going down.

![]()

As expected, it doesn't fall straight down like engine exhaust. It gets taken away by the wind & follows the lowest side. It doesn't fall evenly in a cylinder.

![]()

It peaked for only a few minutes, flowing manely downwind. It successfully created a pool but only exited on the downwind side.

![]()

Most of it outgasses from the top.

![]()

The ink marking was gone.

![]()

It left an oily residue.

![]()

The oil got on the table.

So the long term win is using a metal screen with nothing under it as a heat shield. Tests should continue using the metal disc, since a metal screen is $10. A metal screen could allow a smaller diameter since it's not acting like a heat break. The test setup could use a funnel to reduce the disc to a simulated grid diameter.

It needs to be enclosed in a glass enclosure, but it's not economical when a square foot is $2000. A foldable plastic enclosure might work. It needs air inlets on the bottom.

It should focus on just spreading out the smoke instead of pooling it. It could try passing it through several layers of grids. Then the spreaded smoke could be concentrated into a cylinder. Having a smaller diameter would help with the illusion. It should be only the diameter of a cone or 20mm.

It has to be perfectly level. The smoke spreading idea might overcome this.

The time when it flows down is so short, it might be more effective as an art piece for a nano mister & it was used for humidifying.

lion mclionhead

lion mclionhead