-

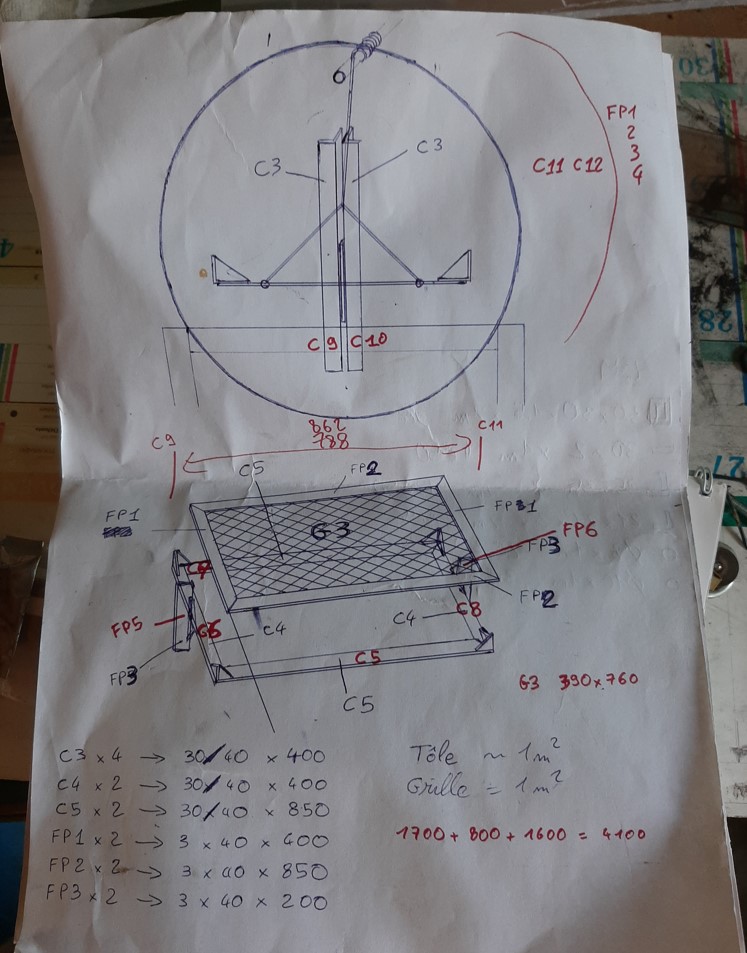

1Sketch time and CAO

Starting from a 200L drum, I designed the whole thing in Solidworks.

![]()

![]()

![]()

-

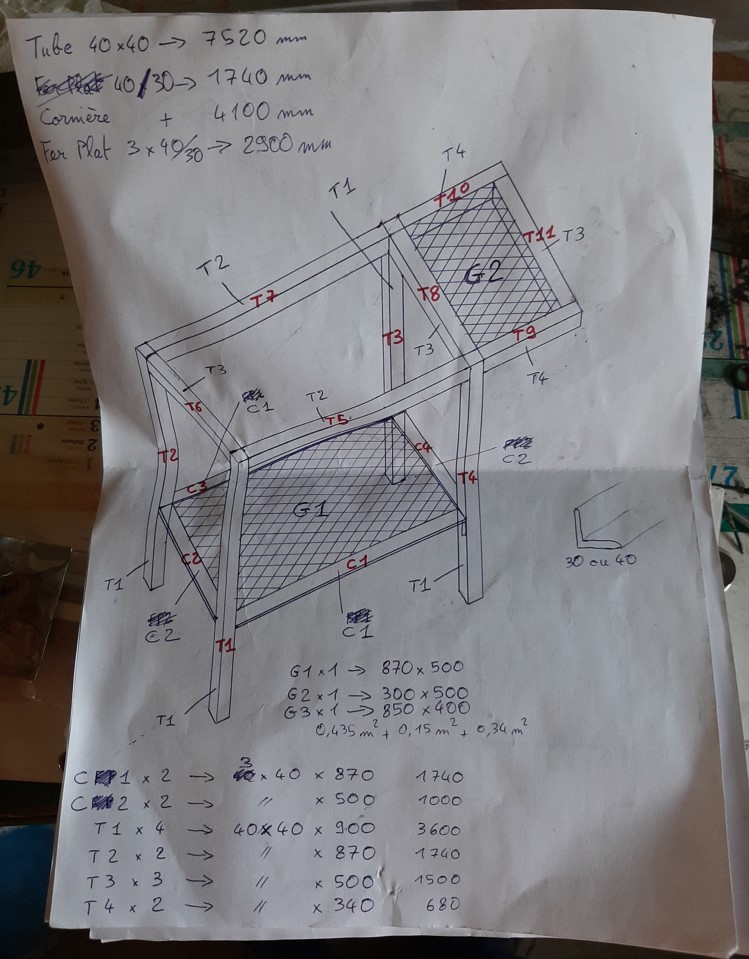

2Tool used

![]()

-

3Cutting tubes and barrel

Thanks to excel sheet, lenght has been optimized to minimize number of losses.

Tube lenght was 6 meter long.

![]()

![]()

![]()

-

4Frame welding and painting

Not the best welds I ever made but I get better at it and love welding stuff.

![]()

![]()

![]()

-

5Grid guide

I wanted something simple without complex guide. Linear guide was the solution. Screwed to the barrel on one side and riveted on the other side.

![]()

![]()

![]()

-

6Cutting refractory brick

![]()

![]()

-

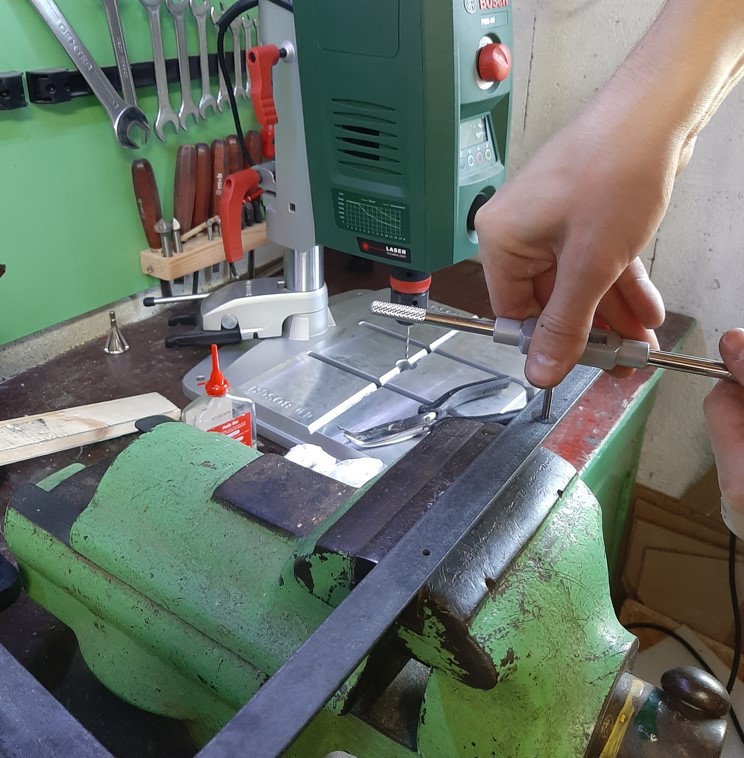

7Custom parts

Made some tube caps. It was the opportunity to test the sketch drawing under solidworks.

![]()

![]()

-

8Final assembly

A crank, bicycle brake cable for the grid.

Two hinges and bicycle inner tube all riveted to the door.

Happy cooking ;)

![]()

![]()

![]()

![]()

f4drj

f4drj

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.