First things first:

I still need to design a machine vise and a water enclosure.

The printed vise that was used starts to bend while tightening and the plastic box used has a knob in the center. So basically the vise can be moved super easily and this creates more shorts.

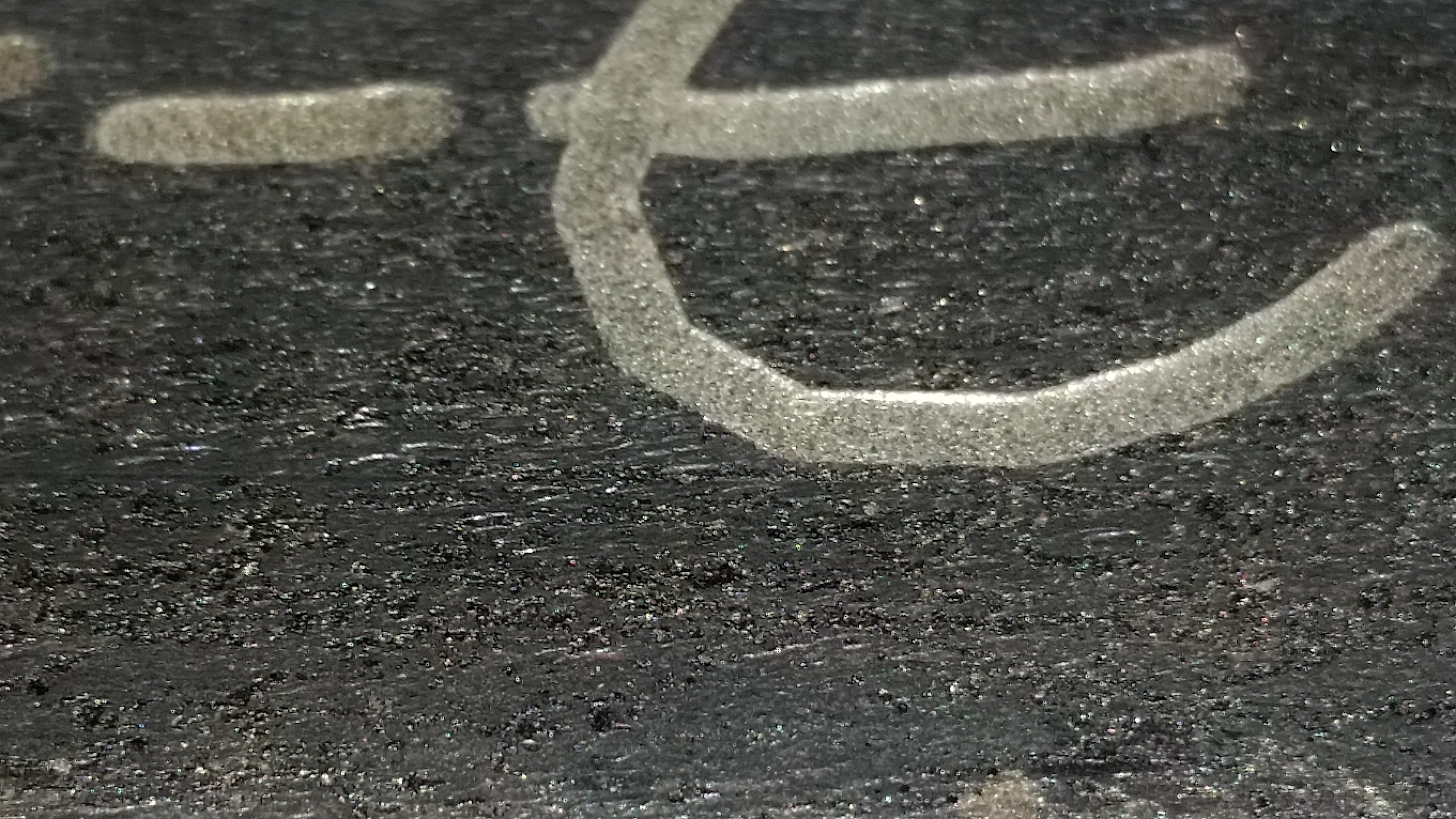

The GCode repeated three times. The process was smooth and silent at 30V 20khz 2Amps with a constant burn all along.

The GCode was generated with GRBL-Plotter and used a single line font with a 1.5mm electrode.

One problem at the start of the process is the "electrode down" movement. In the first round it hits the surface of the workpiece. This is mostly due to the bend of the vise. The metal is far from 90° to the electrode.

The down movement moves back down to the last position and starts reprobing shortly before that position. This increases the speed but needs to change so it reprobes earlier.

After the first pass the surface is mostly even and it doesn't hit the workpiece.

Another thing to change is the "electrode up" movement. The up position is 1mm above the initial probe. This will increase to 2mm.

Here's the video of the process.

gedm-dev

gedm-dev

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

[this comment has been deleted]

You can find an invite link for discord on the youtube channels about page if you want more infos.

Are you sure? yes | no