Background

Implementing a successful beginner-level computer technology program presents a variety of unique challenges for both instructors and learners. CHRP4 is the fourth major version of a design that has been continuously revised and refined over more than 10 years of classroom instruction to address many of these challenges, including:

1 - Supporting all learners

It’s no surprise to any instructor that all learners are not the same. CHRP4 is designed to engage and challenge multiple levels of learners within the same classroom by being able to be assembled in a number of different configurations. This flexibility allows individual students to choose a project of most interest to them while all students use the same, common circuit board making CHRP4-based projects simpler for the instructor to support.

2 - Making learning real/relevant

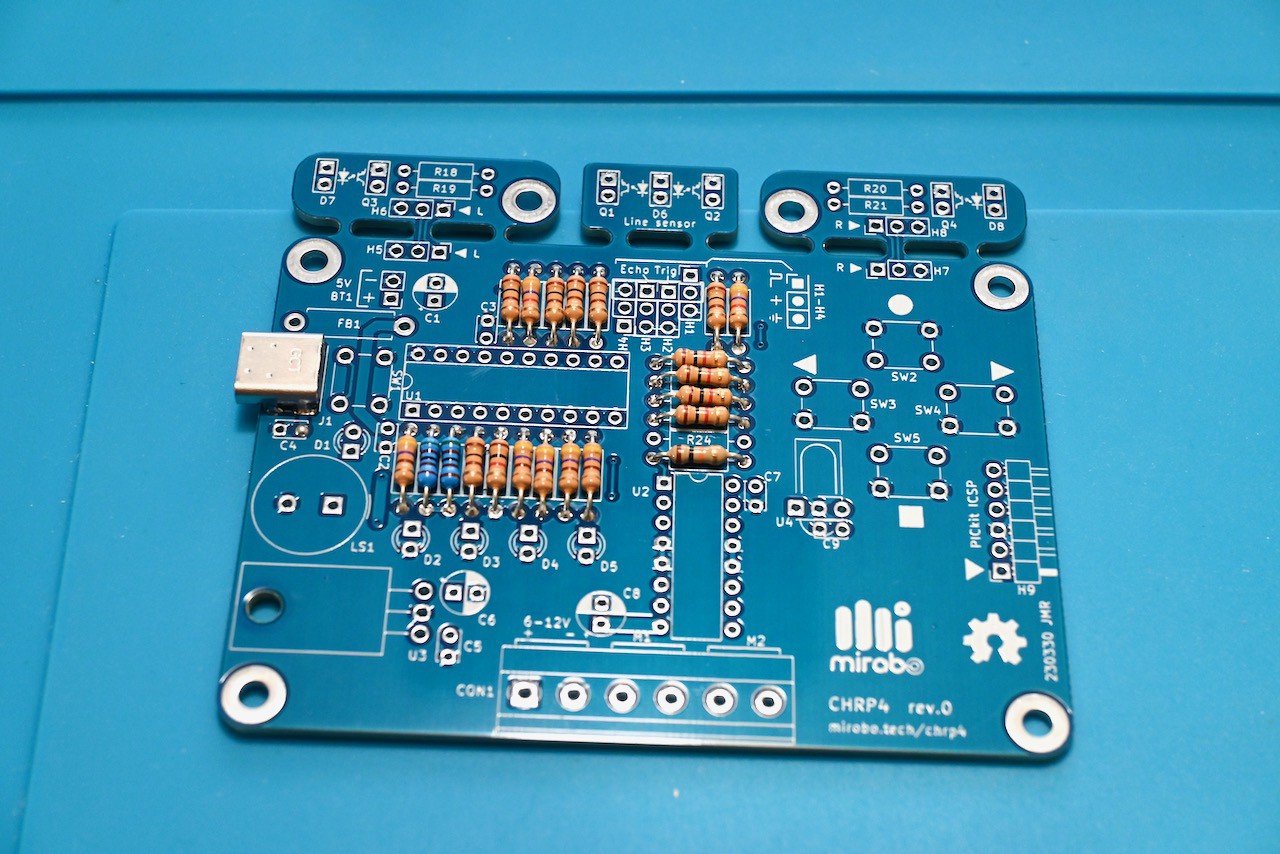

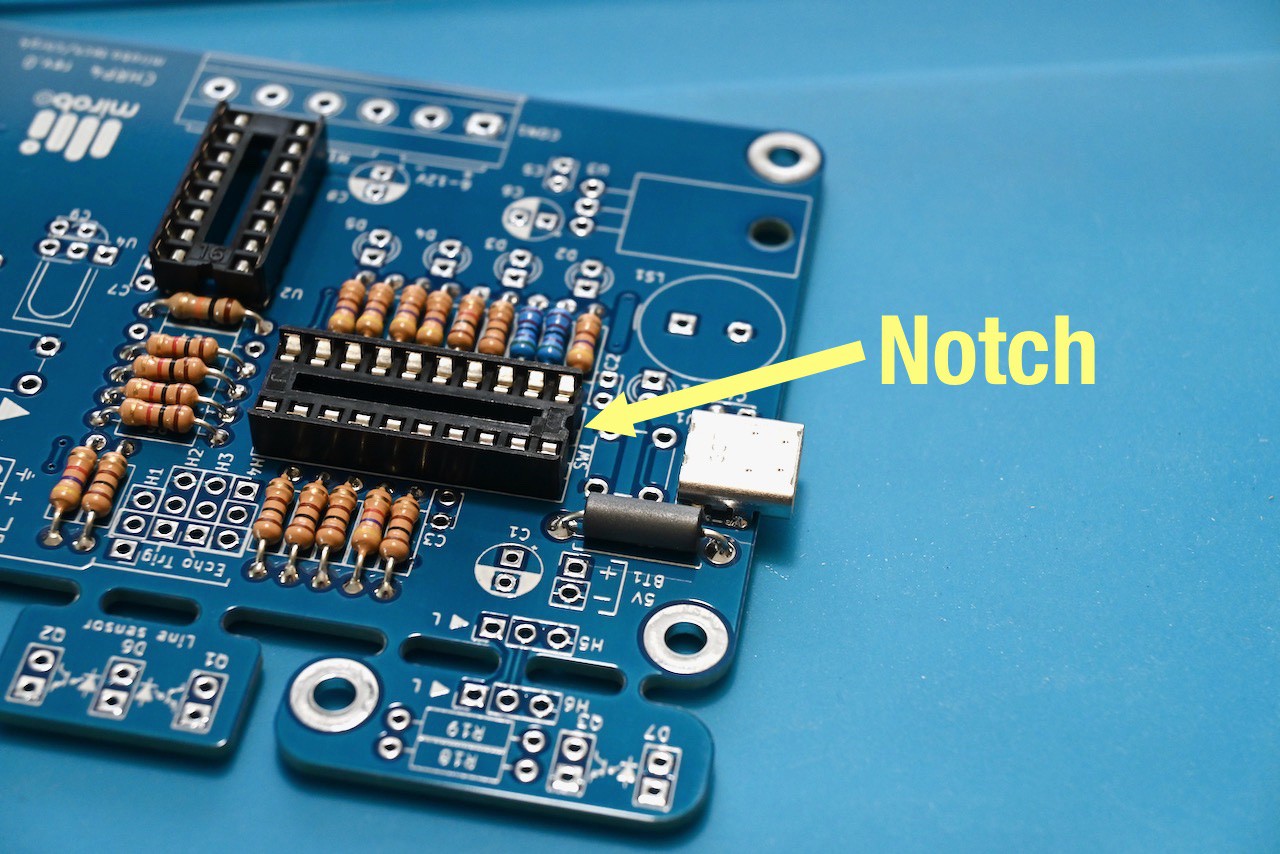

CHRP 4 is designed to be both an introductory training board as well as a student’s final project. It uses through-hole components for easy assembly, in order to support students learning about electronic components and basic circuits, and incorporates real-world challenges in its programming learning activities.

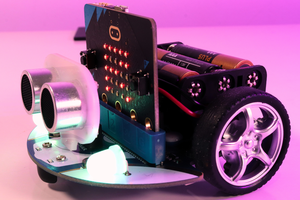

Most importantly, CHRP4 was developed specifically to fulfill the goal of having each student build their own, individual take-home project that they have ownership of, rather than building typical take-apart projects, constructed on breadboards using components that have to stay behind in the classroom at the end of the course. I’ve found that ownership of their own project promotes student buy-in and, coupled with competitive final projects (such as the fastest time for a line-following robot to complete a course, or building the best Sumo robot) provides even more incentive for students to quickly learn and apply their skills as they strive to out-perform their classmates.

3 - Minimizing project costs

The CHRP4 circuit board was designed to be built in stages and in multiple configurations. This capability allows CHRP4 to either be fully completed as a single-semester project, or to be constructed over two semesters, spreading the component costs over two individual courses or years instead of one. Either way, students build CHRP4 using only the components necessary for their particular project build.

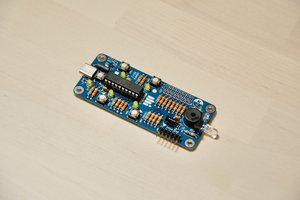

To build CHRP4 over multiple courses or years, an introductory or first year course would build CHRP4 as a (non-robotic) introductory microcontroller trainer to focus on developing students’ programming skills. Without adding the motor driver and the other components necessary to build a robot, students can make CHRP4 into a variety of other projects including: a simple music player, a reaction timer game, a Simon-style memory game, a remote control transmitter, a room alarm, a servo driver, a NeoPixel driver, and more. In a second semester, year, or advanced course, students can add the motor driver, regulator, terminal block, sensors, and motors to their existing circuit, enabling them to make line-following, obstacle sensing, remote-controlled, or Sumo robots using their same circuit board from their first course.

In addition to spreading costs over multiple courses/years, another benefit of this approach is the ease with which instructors can integrate new or beginner students into the second year/advanced course, because both courses use different forms of the same circuit board – and both share the same components and curriculum.

Another factor minimizing classroom costs is the reduced overhead required to support CHRP4 in comparison with other microcontroller circuits. Classrooms don’t need to invest in as many breadboards, jumper wires, microcontroller circuit modules, peripheral circuits, and all of the individual electronic components that will inevitably suffer breadboard damage, since all the circuitry necessary for learning using CHRP4 is a part of each student’s circuit board.

4 - Enabling deeper learning

Students learn to program CHRP4 using...

Read more » John Rampelt

John Rampelt

Jithin Sanal

Jithin Sanal

Lithium ION

Lithium ION

RoboKoding LTD

RoboKoding LTD

Good question. It really depends on where and how they can source the parts. I'm assuming you're asking about the platform that the circuit is built on. As a teacher, I was often able to get better deals through bulk purchases, or even donations of materials. A local surplus store would sell us 6V DC motors at $1.00 each for example. A local company would donate scrap UHMW plastic end-cuts that could be used instead of MDF for the robot platforms.

The platform parts have been specifically chosen for the scale of a typical classroom or maker space project – eg. buy a sheet of MDF and cut it up for the platforms, buy a 4' dowel and cut it into wheels, and buy 3' lengths of music wire and cut them to size for axles – not for a one-off build. A typical build that involves buying all of the parts should come in at under $10 per robot platform.

Of course, the PCB and electronics are on top of that, and I hope that other teachers or makerspaces will be able to build their own circuits using the files in this project.