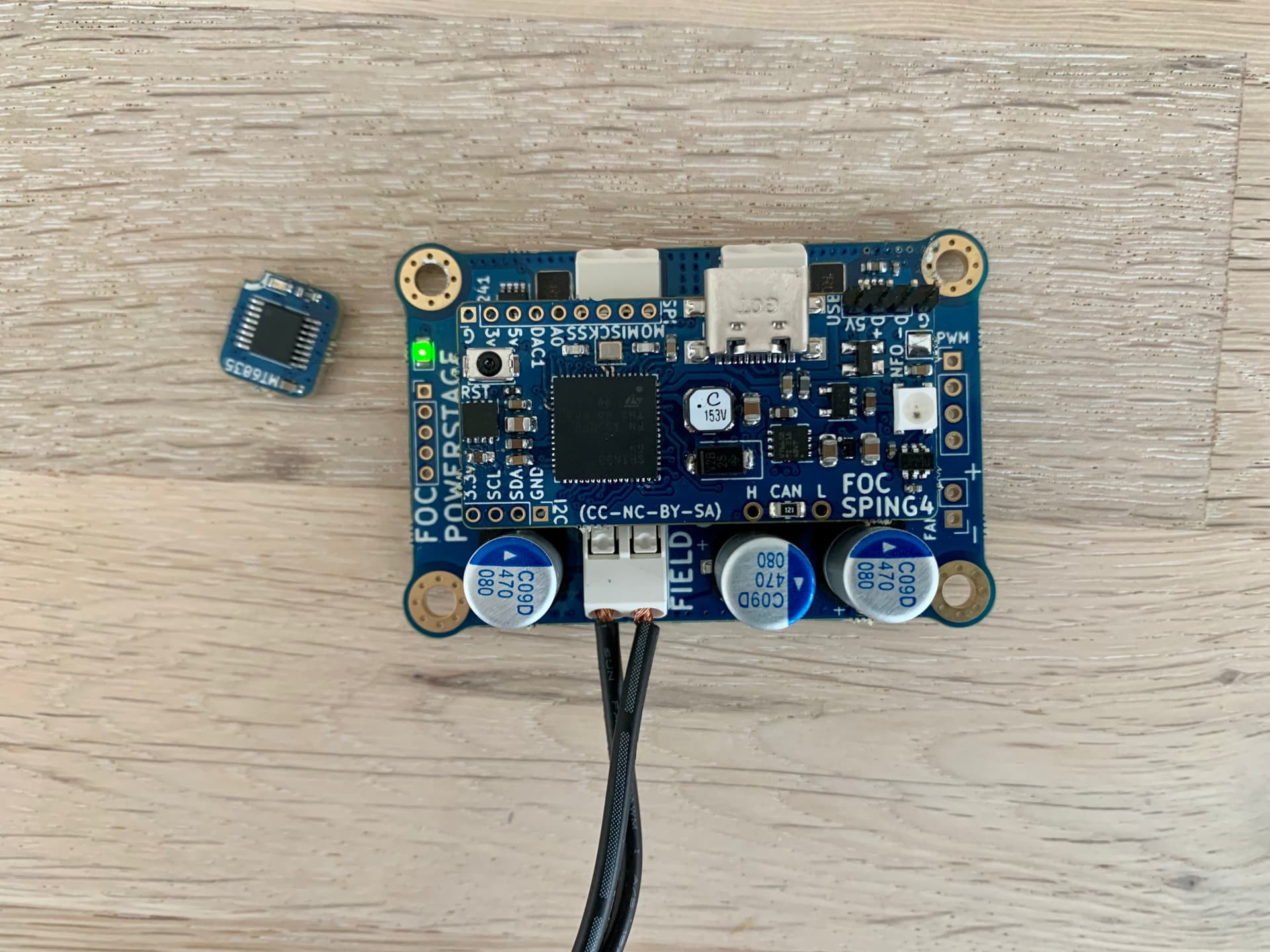

Running SimpleFOC with trapezoidal-planner. Max velocity set to 50rad/s, acceleration and de-acceleration set to 25rad/s/s

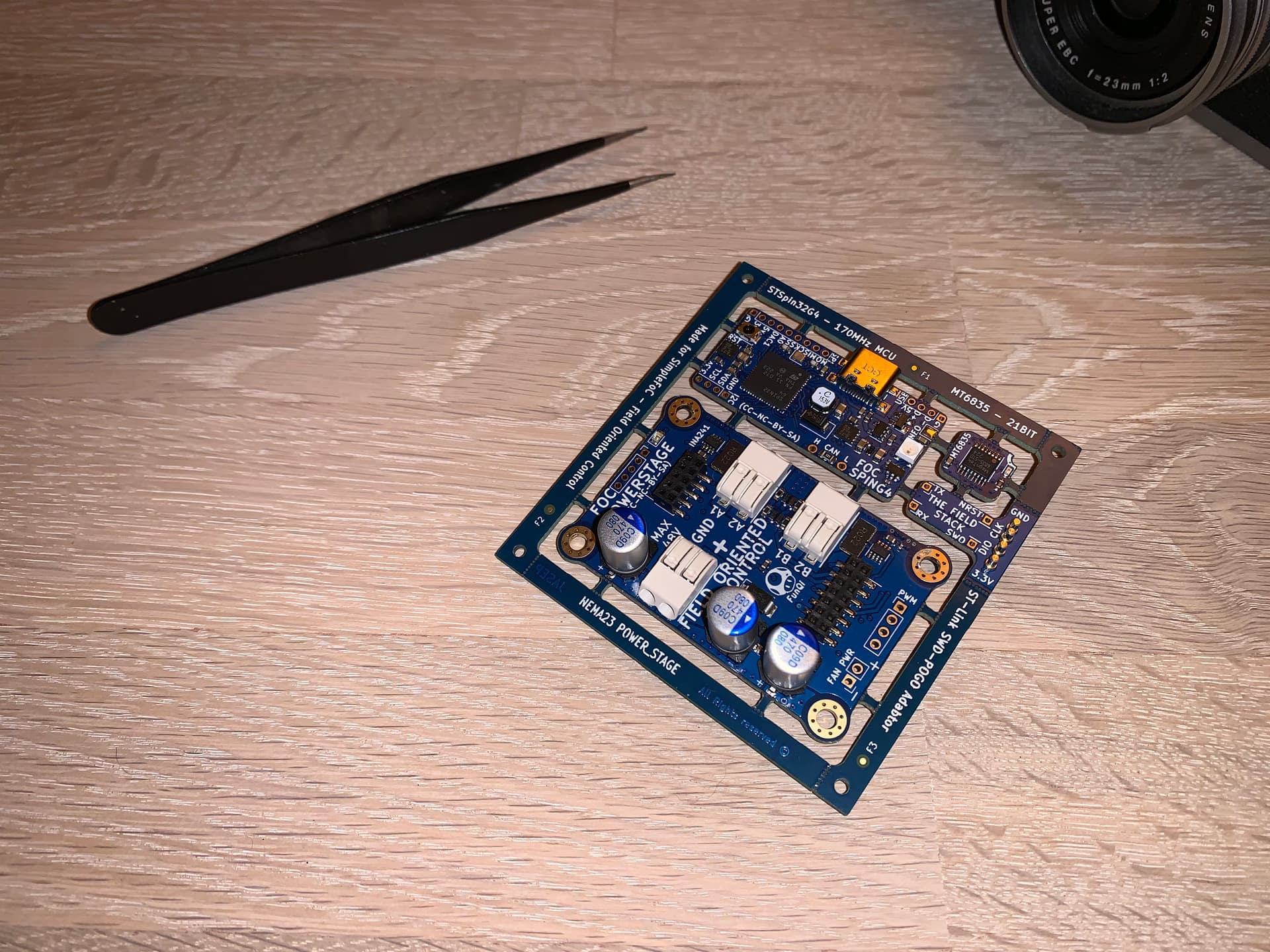

The Field Stack - NEMA23/34 FOC

If we win the Hackaday price, we will make BETA give aways. FOC field-oriented control for NEMA23/34

Juan-Antonio Søren E.P.

Juan-Antonio Søren E.P.

Love the form factor for this! Ive been wanting a stepper motor driver with an esp32 so the servo system can recieve commands via a "normal" web interface, does this wifi / bluetooth?