In simple terms, the idea behind this project is to create a machine that can re-design itself.

Let's say that you want to build this printer, but have 5 slightly different motors that are all different shapes and sizes (within reason). By using this concept, you could regenerate the machines structure to work with the hardware that you already have, and not need to find or wait for new ones.

----------------------------------------------------------------------------------------------------------------------------------------------------

This was originally submitted to the re-engineering education challenge, the information below relates to the previous submission but in principal it's the same thing, more or less, just spun differently.

----------------------------------------------------------------------------------------------------------------------------------------------------

The Gen5X project contributes to both a procedural and theoretical understanding of the concepts and methods shaping the future practices of mechanical engineers.

At the procedural level, the project aims to develop a working knowledge of generative computational design methods, additive manufacture, 5-axis machines, and their application within a conventional design and manufacturing framework.

Procedural:

- Design: Using generative design methods to create and explore the design of highly optimised functional parts and complex systems.

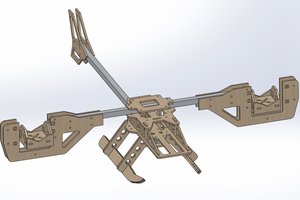

- Manufacture: Additive Manufacturing methods to slice and fabricate complex generatively designed shapes (using 3 and 5-Axis FFF 3D printing).

- Manufacturing process: The mechanics and control of the multi-axis additive manufacturing machines at the core of distributed manufacture.

On the theoretical, and much fuzzier project level, the project offers a platform to explore the emerging concept of self-designing, 'generative machines'. Machines that not only have the ability to design and manufacture products, but can also create their own updates and upgrades. Here, the following areas for research and development are identified:

Theoretical / Research:

- Self-optimisation. Could embedded sensors enable a machine to learn about itself, and further, use this data to drive the generative design optimisation of its own parts? (a very literal take on machine learning).

- Parametrically defined generative design inputs. If a system of parts is defined parametrically, could new designs be generated to incorporate any working parts that you already have, and therefore not require as many new ones! Enabling, and also promoting re-use methods. (This will be better illustrated at a later point).

Ultimately, these research findings would feed back into the procedural knowledge that the project supports, allowing for the continued development of new skills.

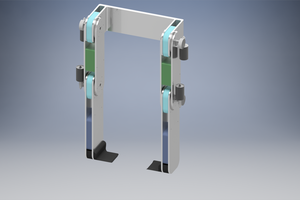

The video below shows the first working prototype of the Gen5X 5-Axis 3D Printer.

Ric Real

Ric Real

Josh Cole

Josh Cole

Josh Starnes

Josh Starnes

Javier

Javier

Dhananjay

Dhananjay